Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Vittorazi Motors COSMOS 300

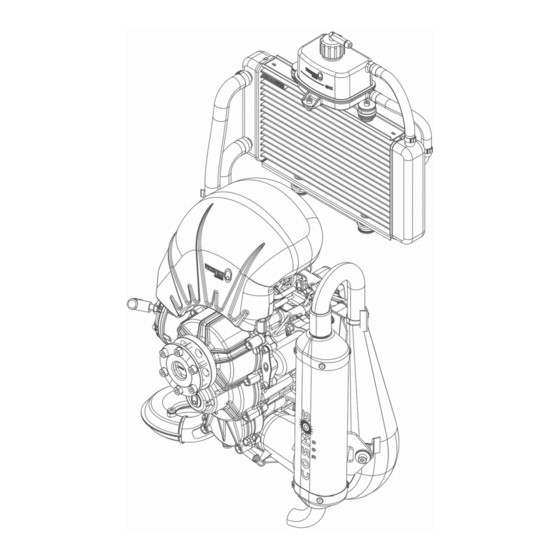

- Page 1 COSMOS 300 Maintenance manual release V2/2023 Valid for MY23 versions...

- Page 2 Cosmos 300 – Maintenance manual – V2...

-

Page 3: Table Of Contents

3.5.3 Reed valve assembly 3.6 Gaskets 3.7 Exhaust system 3.7.1 Manifold, exhaust bushing disassembly 3.7.2 Manifold, exhaust bushing maintenance 42 3.7.3 Manifold, exhaust bushing assembly 3.7.4 Silencer disassembly 3.7.5 Silencer maintenance 3.7.6 Silencer assembly Cosmos 300 – Maintenance manual – V2... - Page 4 3.12.3 Flywheel assembly 3.13 Transmission 3.13.1 Oil replacement 3.13.2 Transmission disassembly 3.13.3 Transmission disassembly – ULM model 3.13.4 Transmission maintenance 3.13.5 Transmission assembly 3.13.6 Transmission assembly – ULM model 3.14 Piston, cylinder, head Cosmos 300 – Maintenance manual – V2...

- Page 5 3.14.1 Piston, cylinder, head disassembly 3.14.2 Piston, cylinder, head maintenance 3.14.3 Piston, cylinder, head assembly 3.15 Crankcase 3.15.1 Crankcase disassembly 3.15.2 Crankcase maintenance 3.15.3 Crankcase assembly 3.16 Tightening values Cosmos 300 – Maintenance manual – V2...

-

Page 6: Introduction

The professional manual includes: technical descriptions of the maintenance phase and reference values. All the components of Vittorazi Motors are checked and tested in a process of industrial quality control before the assembling. Then by sampling the complete motors are checked to assure the functionality of all the parts through a complete test of twenty minutes on the bench. - Page 7 Reading tips: Attention, danger, risk Any situation or condition which may result in a serious danger Recommendation, warning, important advice Cosmos 300 – Maintenance manual – V2...

-

Page 8: Be Careful! Read It Completely

• Vittorazi Motors and its distributors decline any direct or indirect responsibility related to this kind of activity. By using a new engine, the owner agrees that these terms and conditions have been accepted at the time of purchase of the product. - Page 9 (Min; Max), contact the aircraft manufacturer. • 90 °C. • 65 °C. The temperature limit of EGT is 650° Celsius. Do not persist above this temperature threshold, engine overheating and irreversible damage could occur. Cosmos 300 – Maintenance manual – V2...

-

Page 10: Maintenance

Any procedure of installation, maintenance and/or repair of the products must be carried out exclusively with the original Vittorazi Motors parts and tools specified by Vittorazi, in compliance with the specifications contained in the user, installation and/or maintenance manual of the products;... -

Page 11: Maintenance Schedule

2) rope, spring, hooks or a new pull starter system 3) springs 4) each time the component is disassembled 5) head, exhaust port, decompressor hole 6) when the hoses are disassembled replace the clamps 7) or after 2 years Cosmos 300 – Maintenance manual – V2... - Page 12 Carburation from spark plug colour Spark plugs Spark plugs connectors Carburettor Carburettor membranes Airbox Snaplock Airbox Airbox sponge and sleeve Reed valve petals Pull starter system The table follows in the next page Cosmos 300 – Maintenance manual – V2...

- Page 13 Exhaust manifold with springs Soundproofing material silencer Silencer rubbers Gaskets (head, cylinder, carburettor, reed valve, exhaust, transmission, water pump) Piston Piston roller bearing Head and cylinder The table follows in the next page Cosmos 300 – Maintenance manual – V2...

- Page 14 Coolant Radiator hoses Radiator rubbers Rubber mountings (engine, exhaust) Oil seal carter case Crankshaft bearings Crankshaft Gearbox oil Transmission bearings Centrifugal clutch Clutch bell Cosmos 300 – Maintenance manual – V2...

-

Page 15: Spark Plugs

3.2 Spark plugs Time limit Spark plugs (M020) 25 h Components to replace Not required. Special tools Spark plugs: 25 Nm. Values 3.2.1 Spark plugs disassembly Disconnect the connector and unscrew the spark plugs. Cosmos 300 – Maintenance manual – V2... -

Page 16: Spark Plugs Maintenance

Check the connectors: if they are damaged or the connection to the spark plugs is not stable, replace them. Check the ignition cables: there must be no cuts or cracks, otherwise replace the ignition coils (including ignition cables). Cosmos 300 – Maintenance manual – V2... -

Page 17: Spark Plugs Assembly

The distance between the electrodes of the new spark plugs must be 0,7 mm, otherwise adjust. Screw the spark plug into the head and tighten with the torque shown in the figure. 25 Nm Cosmos 300 – Maintenance manual – V2... -

Page 18: Airbox

Sleeve with filter (AT093a) 100 h or 1 year Components Snaplock (MP093d) 50 h to replace Not required. Special tools Clamp screw: 2,5 Nm. Values 3.3.1 Airbox disassembly Unhooking the safety strap from the back support. Cosmos 300 – Maintenance manual – V2... - Page 19 Loosen the screw of the clamp securing the sleeve to the carburettor. Remove the airbox by disconnecting the 2 Snaplocks. Cosmos 300 – Maintenance manual – V2...

- Page 20 Fold the sleeve inwards and remove it from the airbox. Remove the 2 Snaplocks. Cosmos 300 – Maintenance manual – V2...

-

Page 21: Airbox Maintenance

(2) with a product suitable for cleaning rubber (the sleeve is made up of a mixture of NBR and PVC). Check the integrity of the airbox. Check the sleeve groove. Cosmos 300 – Maintenance manual – V2... - Page 22 If the above components are damaged, replace them immediately. For routine maintenance, follow the table. Use extreme caution when checking, as failure to replace damaged components can lead to detachment of the airbox and impact with the propeller. Cosmos 300 – Maintenance manual – V2...

-

Page 23: Airbox Assembly

3.3.3 Airbox assembly Insert the sleeve into the airbox. Insert the Snaplocks. Connect the airbox sleeve to the carburettor inlet flange and 2 Snaplocks to the pins fixed on the engine. Cosmos 300 – Maintenance manual – V2... - Page 24 The airbox sleeve (1) must be completely inserted into the airbox connector (2), the fixing clamp (3) correctly inserted on the seat and aligned as in the figure. Tighten the fixing clamp by applying the torque shown in the figure. 2,5 Nm Cosmos 300 – Maintenance manual – V2...

- Page 25 Attach the safety strap to the support bracket behind the airbox, ensuring that the strap is tightened firmly. After installation, check that there is no relative movement between the rubber sleeve and the airbox connector. Cosmos 300 – Maintenance manual – V2...

-

Page 26: Carburettor

*Always replace it when disassembled. 3.4.1 Carburettor disassembly Before disassembling the carburettor, remove the fuel line and the airbox (3.3 Airbox). Remove the double wire hose clamp from the pulse line hose and disconnect the hose. Cosmos 300 – Maintenance manual – V2... - Page 27 Remove the carburettor flange (2). Remove the 2 self-locking nuts M8 (3) at the base of the carburettor. Remove the carburettor (4) and the gasket (5). Disassemble the carburettor by removing the components. Cosmos 300 – Maintenance manual – V2...

-

Page 28: Carburettor Maintenance

Check the condition of the diaphragms: they must be soft and free of cuts, otherwise they must be replaced. For routine maintenance, follow the table. Check the pulse line hose: there must be no cracks or damaged areas, otherwise replace it. Cosmos 300 – Maintenance manual – V2... -

Page 29: Carburettor Assembly

3.4.3 Carburettor assembly Check metering lever: 2,4 mm Replace the diaphragms and gaskets. Cosmos 300 – Maintenance manual – V2... - Page 30 - part 1 fuel pump gasket - part 1 fuel pump body - part 2 fuel pump diaphragm - part 2 fuel pump gasket - part 2 diaphragm cover assembly diaphragm gasket diaphragm Cosmos 300 – Maintenance manual – V2...

- Page 31 In the event of a fault, measure the height of the metering lever again and replace the spring if necessary. Replace the gasket (5) and the 2 self-locking nuts M8 (3) each time they are disassembled. Cosmos 300 – Maintenance manual – V2...

- Page 32 16 Nm Insert the 4 Allen screws M6x30 (1) into the carburettor flange (2), tighten progressively, then tighten with the torque shown in the figure. 10 Nm Cosmos 300 – Maintenance manual – V2...

- Page 33 Connect the pulse line hose to the carburettor and secure it with the double wire hose clamp. Cosmos 300 – Maintenance manual – V2...

-

Page 34: Reed Valve

*Always replace it when disassembled. 3.5.1 Reed valve disassembly Before disassembling the reed valve, remove the airbox (3.3 Airbox). Remove the double wire hose clamp from the pulse line hose and disconnect the hose. Cosmos 300 – Maintenance manual – V2... - Page 35 Remove the 3 Phillips screws M3x6 (9) from one side of the reed valve. Remove the stoppers (10) and petals (11). Carry out the same operations on the other side of the reed valve. Cosmos 300 – Maintenance manual – V2...

-

Page 36: Reed Valve Maintenance

In the right side of the photo, you can see deformed petals that remain slightly raised. If the previous checks are not passed or if routine maintenance is required, replace the petals. Cosmos 300 – Maintenance manual – V2... -

Page 37: Reed Valve Assembly

Please note: the two chamfers on the stopper and on the petals (blue circles) may not match. Carry out the same operations on the other side of the reed valve. Replace the gaskets (3, 7) each time they are disassembled. Cosmos 300 – Maintenance manual – V2... - Page 38 Insert the 4 Allen screws M6x30 (1) into the carburettor flange (2), tighten progressively, then tighten with the torque shown in the figure. 10 Nm Connect the pulse line hose to the carburettor and secure it with the double wire hose clamp. Cosmos 300 – Maintenance manual – V2...

-

Page 39: Gaskets

Also, if the engine is not used for a long period of time, check the condition of the gaskets. For gasket replacement see the following chapters: 3.4 Carburettor, 3.5 Reed valve, 3.7 Exhaust system, 3.13 Transmission, 3.14 Piston, cylinder, head. Cosmos 300 – Maintenance manual – V2... -

Page 40: Exhaust System

Screws M8: 13 Nm. Values *Always replace it when disassembled. 3.7.1 Manifold, exhaust bushing disassembly Remove the safety cables around the springs. Remove the 4 bushing springs and the 2 exhaust manifold springs. Cosmos 300 – Maintenance manual – V2... - Page 41 Remove the exhaust manifold (1), the 2 self-locking nuts M8 (2) with washers (3), the exhaust flange with bushing (4) and the gasket (5). Remove the bronze ring (6) from the flange (4). Cosmos 300 – Maintenance manual – V2...

-

Page 42: Manifold, Exhaust Bushing Maintenance

For routine maintenance, follow the table. Check that the exhaust joints are regular. Small defects on the surface (sticking marks, cracks, steps) must not prevent a regular motion of the joint. Cosmos 300 – Maintenance manual – V2... -

Page 43: Manifold, Exhaust Bushing Assembly

Clean the end of the exhaust manifold (7), sand it with sandpaper and apply Molykote grease. Clean the second joint (8) with an abrasive sponge (e.g. Scotch-Brite), degrease it with solvent and apply Molykote grease. Cosmos 300 – Maintenance manual – V2... - Page 44 Add copper paste to the nuts. Insert the 2 self-locking nuts M8 (2) with the washers (3) and tighten with the torque shown in the figure. Position the exhaust manifold (1). 32 Nm Cosmos 300 – Maintenance manual – V2...

- Page 45 Run 2 cables around the springs of the joint (one cable for each spring), insert a clamp on the ends and tighten with pliers. Hook in the 4 springs of the bushing. Run one cable around the 4 bush springs, insert a clamp at each end and tighten with pliers. Cosmos 300 – Maintenance manual – V2...

-

Page 46: Silencer Disassembly

Remove the 2 Allen screws M8 with washers, the 2 rubbers and the 2 bushings from the silencer. Disconnect the silencer from the exhaust pipe (In order to facilitate the release of the silicone heat with a heat gun, the connection between the exhaust and the silencer before disassembly). Cosmos 300 – Maintenance manual – V2... - Page 47 REFERENCE MARK Use a heat gun to heat the muffler end caps (1, 4). Remove the following components from the silencer housing (3): the end caps (1, 4) and the sound-absorbing material (2). Cosmos 300 – Maintenance manual – V2...

-

Page 48: Silencer Maintenance

Thoroughly clean and degrease the end caps and body of the silencer with a cloth. Check the integrity of the silencer body both internally and externally: there must be no cracks or damaged areas, otherwise replace it. For routine maintenance, follow the table. Cosmos 300 – Maintenance manual – V2... -

Page 49: Silencer Assembly

Fix the end caps on the body with 8 rivets respecting the references taken during disassembly. Make sure that the end caps are fully inserted before fixing. Wet the rivets with high-temperature silicone (HT Sil-N) before fastening and fix the end caps (1, 4) on the body. Cosmos 300 – Maintenance manual – V2... - Page 50 Put silicone on the upper end of the silencer and connect it to the exhaust pipe. Replace the 2 rubbers on the silencer. Insert the 2 bushings, 2 rubbers, 2 Allen screws M8 with washers and tighten with the torque shown in the figure. 13 Nm Cosmos 300 – Maintenance manual – V2...

-

Page 51: Cooling System

Coolant (ACC085) 150 h or 1 year Not required. Special tools Screws M5x20: 8 Nm. Values *Always replace it when disassembled. 3.8.1 Cooling system emptying Remove upper cap from the coolant reservoir. Cosmos 300 – Maintenance manual – V2... - Page 52 Remove the lower screw M5x10 with copper seal from the water pump cover. Wait a few minutes for all the coolant to escape. For optimal cleaning, remove the clamp and disconnect the lower hose. Wait a few minutes for all the coolant to escape. Cosmos 300 – Maintenance manual – V2...

- Page 53 Replace the clamp each time it is disassembled. Connect the lower pipe, tighten the clamp with suitable pliers and ensure that the connection is secure. Replace the copper seal each time it is disassembled. Cosmos 300 – Maintenance manual – V2...

- Page 54 Insert the lower screw M5x10 with copper seal into the water pump cover and tighten with the torque shown in the figure. 3 Nm Cosmos 300 – Maintenance manual – V2...

-

Page 55: Cooling System Filling

-20 °C and 110 °C) into the coolant reservoir up to the maximum level. Remove vent screw M5x10 with copper seal from the cylinder to allow any air to escape. Cosmos 300 – Maintenance manual – V2... - Page 56 When a few drops of coolant escape, close with the vent screw M5x10, copper seal and tighten with the torque shown in the figure. 3 Nm Fill the coolant reservoir again with coolant up to the maximum level. Cosmos 300 – Maintenance manual – V2...

- Page 57 Turn off the engine. If the coolant level has dropped add more coolant up to the maximum level. Screw upper cap on the coolant reservoir. Never start the engine without propeller. Cosmos 300 – Maintenance manual – V2...

-

Page 58: Radiator Rubbers Disassembly

Remove the 2 clamps from the coolant tray hoses. Remove the 2 hoses. Remove the 2 Allen screws M5x20 (1) with the 2 washers 5x28x2,5 (2). Remove the 2 rubbers (3), the upper bracket (4) and the 2 washers 10x28x2,5 (5). Cosmos 300 – Maintenance manual – V2... - Page 59 Remove the 2 Allen screws M5x16 (6) with the 2 washers 5x28x2,5 (7). Remove the 2 rubbers (8), the lower bracket (9) and the 2 washers 10x28x2,5 (10). Cosmos 300 – Maintenance manual – V2...

-

Page 60: Radiator Rubbers Assembly

Insert the 2 washers 10x28x2,5 (5) between the rubbers and the radiator. Insert the 2 Allen screws M5x20 (1) with the 2 washers 5x28x2,5 (2) and tighten with the torque shown in the figure. 6 Nm Cosmos 300 – Maintenance manual – V2... - Page 61 Replace the clamps each time they are disassembled. Connect the 2 hoses to the radiator, tighten the clamps with suitable pliers and ensure that the connection is secure. Cosmos 300 – Maintenance manual – V2...

-

Page 62: Cooling System Maintenance

Check the integrity of the coolant reservoir. If there is any damage replace it Clean that interior of the coolant reservoir, from any deposit or dirt. Do not clean the radiator with pressure washer. Cosmos 300 – Maintenance manual – V2... -

Page 63: Rubber Mountings

*Always replace it when disassembled. 3.9.1 Rubber mountings disassembly When locking the rubber mountings during maintenance take care not to damage them. Remove the safety cable around the springs. Remove the 4 bushing springs. Cosmos 300 – Maintenance manual – V2... - Page 64 Remove the 3 self-locking nuts M8 with washers. Remove the exhaust system. Cosmos 300 – Maintenance manual – V2...

- Page 65 Remove the 4 self-locking nuts M8 with washers and the 4 rubber mountings from the motor mount. Cosmos 300 – Maintenance manual – V2...

- Page 66 Remove the 3 self-locking nuts M8 with washers and the 3 rubber mountings of the exhaust system. Cosmos 300 – Maintenance manual – V2...

-

Page 67: Rubber Mountings Maintenance

3.9.2 Rubber mountings maintenance Check the integrity of the rubber mountings: there must be no cracks or detachment of material, otherwise they must be replaced. For routine maintenance, follow the table. Cosmos 300 – Maintenance manual – V2... -

Page 68: Rubber Mountings Assembly

Replace the safety belts, the 4 rubber mountings of the engine mount. Replace the 4 self-locking nuts M8 each time they are disassembled. Insert the 4 engine rubber mountings and the 4 self-locking nuts M8 with washers. Cosmos 300 – Maintenance manual – V2... - Page 69 Replace the 3 self-locking nuts M8 each time they are disassembled. Insert the 3 rubber mountings of the exhaust system, the 3 self-locking nuts M8 with washers and tighten with the torque shown in the figure. 18 Nm Cosmos 300 – Maintenance manual – V2...

- Page 70 Insert the exhaust system. Replace the 3 self-locking nuts M8 each time they are disassembled. Insert the 3 self-locking nuts M8 with washers and tighten with the torque shown in the figure. 18 Nm Cosmos 300 – Maintenance manual – V2...

- Page 71 Hook in the 4 bushing springs. Run a cable around the four bushing springs, insert a clamp on the ends and tighten with pliers. Apply heat shrinkable hoses Cosmos 300 – Maintenance manual – V2...

-

Page 72: Pull Starter System

Screws M6x25: 10 Nm. Aluminium bushing (C042c): 12 Nm Values *Always replace it when disassembled. 3.10.1 Pull starter system disassembly Untie the knot securing the starter handle and pull the rope out of the guide eyelet. Cosmos 300 – Maintenance manual – V2... - Page 73 Allow the winding pulley to rotate so that the tension given by the recovery spring is lost. Remove the 3 flange head screws M6x25 (1) from the manual starter bracket (2). After removing the manual starter, the cup (3) mounted on the flywheel is visible. Cosmos 300 – Maintenance manual – V2...

- Page 74 Remove the spring of the hooks (4), the 2 hooks (5), the washers (6) and the pulley (7) taking care to leave the recovery spring (8) in its place. Remove the rope by untying the knot and pulling it off the pulley. Cosmos 300 – Maintenance manual – V2...

- Page 75 Unscrew the aluminium bushing (11) from the manual starter bracket (2). Cosmos 300 – Maintenance manual – V2...

-

Page 76: Pull Starter System Maintenance

Check the hooks, in particular the tips must not be damaged, otherwise they must be replaced. For routine maintenance, follow the table. Check the washers: if they show signs of wear as in the picture, replace them with new washers of the same thickness. Cosmos 300 – Maintenance manual – V2... - Page 77 Check the aluminium bushing: replace it if it shows signs of wear. Failure to replace a worn pin can block the movement of the pulley and thus prevent the manual starter rope from being rewound correctly. Cosmos 300 – Maintenance manual – V2...

-

Page 78: Pull Starter System Assembly

3.10.3 Pull starter system assembly If the washers are different, place the thinner ones first and then the thicker ones. Insert the washers (6), the 2 hooks (5) and the spring of the hooks (4). Cosmos 300 – Maintenance manual – V2... - Page 79 Insert the aluminium bushing (11) on the manual starter bracket (2) with threadlocker (Loxeal 55-03/Loctite 243 recommended) and tighten with the torque shown in the figure. 12 Nm Cosmos 300 – Maintenance manual – V2...

- Page 80 Turn the pulley 3 turns counterclockwise to get the correct preload for the recovery spring. Insert the rope into the rope guide. Secure the rope with a cable tie and make a mark on the rope. Cosmos 300 – Maintenance manual – V2...

- Page 81 10 Nm Insert the rope into the guide eyelet of the handle and tie a knot to prevent it from slipping out. Pull the handle and check that the pulley rotates smoothly without blocking. Cosmos 300 – Maintenance manual – V2...

-

Page 82: Electric Starter

Remove the 2 Allen screws M6x20 (1) from the electric starter plate (2). Remove the 2 flange head screws M6x35 (3) from the electric starter. Remove the electric starter (4) from the crankcase housing (5). Remove the O-ring (6) from the electric starter. Cosmos 300 – Maintenance manual – V2... -

Page 83: Electric Starter Maintenance

3.11.2 Electric starter maintenance Check the teeth of the electric starter and Bendix: if they show signs of wear, replace the components. Cosmos 300 – Maintenance manual – V2... -

Page 84: Electric Starter Assembly

Insert the O-ring (6) on the rear of the electric starter (4). Position the reinforcement plate (2). Insert the 2 Allen screws M6x20 (1) in the plate (2) and tighten with the torque shown in the figure. M6x35: 10 Nm M6x20: 10 Nm Cosmos 300 – Maintenance manual – V2... -

Page 85: Flywheel (And Bendix)

Remove the Exhaust System before disassembling. 3.12.1 Flywheel disassembly Remove the 5 flange-head screws M8x55 (1) with washers (2) from the support plate (3). Remove Bendix (5) from its housing and the Bendix washer (4). Cosmos 300 – Maintenance manual – V2... - Page 86 Screw the flywheel extractor (ACC105) into the starter cup. Turn the central pin of the extractor until the flywheel is removed from the crankshaft. Check that the key (9) remains in the shaft. Cosmos 300 – Maintenance manual – V2...

- Page 87 Remove the 2 Allen screws M6x25 (11) and the stator (10). Remove the 2 Allen screws M5x14 (12) and the pick-up (13). Remove the 3 countersunk screws M6x20 (16) to disassemble the pull starter cup (18) from the flywheel (17) Cosmos 300 – Maintenance manual – V2...

-

Page 88: Flywheel Maintenance

Check the integrity of the flywheel: there must be no cracks or damaged areas, otherwise replace it. Check the ring gear teeth: If they show excessive signs of wear, replace the flywheel. Check that the Bendix teeth are not broken or excessively worn. Cosmos 300 – Maintenance manual – V2... - Page 89 Check that the Bendix bushings are not worn Check that the stator wires are still flexible and not broken. Cosmos 300 – Maintenance manual – V2...

-

Page 90: Flywheel Assembly

Insert the 2 cable ties, the 2 screws M5x14 (12) and tighten with the torque shown in figure. Position the stator and the wiring according to the image below. M5x14: M6x25: 8 Nm 10 Nm Respect the orientation of the cable ties (15). Cosmos 300 – Maintenance manual – V2... - Page 91 Position the 2 pins of the flywheel locking tool [ACC110] in the 2 holes of the flywheel (8). Hold the end of the flywheel locking tool and tighten the nut (6) with the torque shown in the figure. 90 Nm Cosmos 300 – Maintenance manual – V2...

- Page 92 Position the support plate (3) on the engine casing. Insert the 5 flange-head screws M8x55 (1) with washers (2) into the support plate and tighten with the torque shown in figure. 20 Nm Cosmos 300 – Maintenance manual – V2...

-

Page 93: Transmission

Screws M6x30: 10 Nm. Values Upper cap: 10 Nm. Lower cap: 10 Nm. Oil bottle: 250 ml. *Always replace it when disassembled. Before proceeding with the next operations on the transmission, remove the airbox (3.3 Airbox). Cosmos 300 – Maintenance manual – V2... -

Page 94: Oil Replacement

3.13.1 Oil replacement Place a container under the transmission to collect the oil. Remove upper cap with copper seal. Cosmos 300 – Maintenance manual – V2... - Page 95 Wait a few minutes for all the oil to drain. Replace the copper seal each time it is disassembled. Clean the lower cap, insert it with copper seal and tighten with the torque shown in the figure. 10 Nm Cosmos 300 – Maintenance manual – V2...

- Page 96 Fill the transmission with the specific oil (Motul Transoil 10W-40). Vittorazi supplies 250 ml bottle (C120) that is required to fill completely the transmission box. Fill the oil until is leaking from the front hole. Wait a few minutes for the oil to settle. Cosmos 300 – Maintenance manual – V2...

- Page 97 Replace the copper seal each time it is disassembled. Insert front screw M5x10 with copper seal and tighten with the torque shown in the figure. 3 Nm Cosmos 300 – Maintenance manual – V2...

- Page 98 Replace the copper seal each time it is disassembled. Insert upper cap with copper seal and tighten with the torque shown in the figure. 10 Nm Cosmos 300 – Maintenance manual – V2...

-

Page 99: Transmission Disassembly

Remove the 9 Allen screws M6x30 (1) from the transmission cover (2). Place the 2 set screws M4x30 (3) [ACC111] into the position A and screw in alternately until the cover (2) is removed. Remove the gasket (4). Cosmos 300 – Maintenance manual – V2... - Page 100 Turn the countershaft gear to position it as shown in the figure. Insert the part A of the transmission locking tool into the holes of the 2 gearwheels. Cosmos 300 – Maintenance manual – V2...

- Page 101 Secure the locking tool with the 2 Allen screws M6x20 (5). Remove the nut M14x1,5 (6) with the washer (7) from the crankshaft (10). Remove the clutch bell (8). Remove the 2 roller bearings (9). Remove the bushing (11). Cosmos 300 – Maintenance manual – V2...

- Page 102 Do not remove the spring from the clutch. Remove the 3 Torx screws M5x14 (12) from the clutch (13). Remove the clutch plate (14). Cosmos 300 – Maintenance manual – V2...

- Page 103 Position the extractor (15) [ACC113] on the clutch (13) and tighten the 3 screws M5x70 (16). Turn the central pin (17) until the clutch (13) is removed from the crankshaft. Remove the nut M12x1,25 (18) with the washer (19) from the countershaft (20). Cosmos 300 – Maintenance manual – V2...

- Page 104 Remove the 2 Allen screws M6x20 (5). Remove the part B. Remove the part A. Remove the driven gear (21) from the countershaft (20). Cosmos 300 – Maintenance manual – V2...

- Page 105 Remove the drive gear (22) from the crankshaft (10). Check the condition of the key (23): remove it from the crankshaft (10) if damaged. Cosmos 300 – Maintenance manual – V2...

- Page 106 Unbend the anti-unscrewing washer (28). Fix the propeller hub locking tool (25) [ACC110] on the hub (29) with 2 screws M8x25 (26). Hold the end of the locking tool (25) and remove the left-handed screw M8 (27). Cosmos 300 – Maintenance manual – V2...

- Page 107 Remove the locking tool (25). Remove the anti-unscrewing washer (28) and the propeller hub (29) from the propeller shaft (30). Remove the 2 flange head screws M4x8 (31). Cosmos 300 – Maintenance manual – V2...

- Page 108 Heat the cover to 120 °C. Remove the propeller shaft (30) with the bearing (32) and the bushing (33). Remove the pinion bearing (34). Remove the oil seal (35) from the transmission cover (2). Cosmos 300 – Maintenance manual – V2...

- Page 109 Remove the bearing (32) from the propeller shaft (30) using a bearing extractor. To remove the compensating ring (37) from the clutch (13) insert a pair of long nose pliers into the clutch groove. Cosmos 300 – Maintenance manual – V2...

- Page 110 Cosmos 300 – Maintenance manual – V2...

-

Page 111: Transmission Disassembly - Ulm Model

Remove the 9 Allen screws M6x30 (1) from the transmission cover (2). Place the 2 set screws M4x30 (3) [ACC111] into the position A and screw in alternately until the cover (2) is removed. Remove the gasket (4). Cosmos 300 – Maintenance manual – V2... - Page 112 Turn the countershaft gear to position it as shown in the figure. Insert the part A of the transmission locking tool into the holes of the 2 gearwheels. Cosmos 300 – Maintenance manual – V2...

- Page 113 Secure the locking tool with the 2 Allen screws M6x20 (5). Remove the nut M14x1,5 (6) with the washer (7) from the crankshaft (10). Remove the clutch bell (8). Remove the 2 roller bearings (9). Remove the bushing (11). Cosmos 300 – Maintenance manual – V2...

- Page 114 Do not remove the spring from the clutch. Remove the 3 Torx screws M5x14 (12) from the clutch (13). Remove the clutch plate (14). Cosmos 300 – Maintenance manual – V2...

- Page 115 Position the extractor (15) [ACC113] on the clutch (13) and tighten the 3 screws M5x70 (16). Turn the central pin (17) until the clutch (13) is removed from the crankshaft. Remove the nut M12x1,25 (18) with the washer (19) from the countershaft (20). Cosmos 300 – Maintenance manual – V2...

- Page 116 Remove the 2 Allen screws M6x20 (5). Remove the part B. Remove the part A. Remove the driven gear (21) from the countershaft (20). Cosmos 300 – Maintenance manual – V2...

- Page 117 Remove the drive gear (22) from the crankshaft (10). Check the condition of the key (23): remove it from the crankshaft (10) if damaged. Cosmos 300 – Maintenance manual – V2...

- Page 118 Fix the propeller hub locking tool (25) [ACC110] on the hub (29) with 2 screws M8x25 (26). Hold the end of the hub locking tool (25) and remove the left-handed screw M8 (27) and the anti- unscrewing washer (28). Cosmos 300 – Maintenance manual – V2...

- Page 119 Heat the propeller hub (29) to 200 °C. Position the extractor on the propeller hub (29) and tighten the 2 screws M5. Turn the central pin until the propeller hub (29) is removed from the propeller shaft (30). Cosmos 300 – Maintenance manual – V2...

- Page 120 Remove the 2 flange head screws M4x8 (31). Cosmos 300 – Maintenance manual – V2...

- Page 121 Heat the cover to 120 °C. Remove the propeller shaft (30) with the bearing (32) and the bushing (33). Remove the pinion bearing (34). Remove the oil seal (35) from the transmission cover (2). Cosmos 300 – Maintenance manual – V2...

- Page 122 Remove the bearing (32) from the propeller shaft (30) using a bearing extractor. To remove the compensating ring (37) from the clutch (13) insert a pair of long nose pliers into the clutch groove. Cosmos 300 – Maintenance manual – V2...

- Page 123 Cosmos 300 – Maintenance manual – V2...

-

Page 124: Transmission Maintenance

Check the clutch bell, in particular the inner surface in contact with the friction material must not show any scratches or different colouring due to overheating, otherwise (as in photo) it must be replaced. For routine maintenance, follow the table. Cosmos 300 – Maintenance manual – V2... - Page 125 Check the clutch: the friction material on the pads must be intact. If the previous check is not passed, replace the clutch. For routine maintenance, follow the table. New clutch Worn clutch groove depth: 0,5 mm groove depth: 1,5 mm Cosmos 300 – Maintenance manual – V2...

- Page 126 Check the 3 bearing seats: there must be no polished areas. Also measure the diameter of the 3 seats, the table shows the factory settings. Dimension Factory settings at 20° C (mm) 51,965-51,985 36,980-36,996 51,976-51,995 Cosmos 300 – Maintenance manual – V2...

- Page 127 Measure the diameter of the 2 bearing seats, the table shows the factory settings. Dimension Factory settings at 20° C (mm) 24,980-24,993 25,002-25,015 Cosmos 300 – Maintenance manual – V2...

-

Page 128: Transmission Assembly

Check the position of the Seeger ring: the lubrication hole (38) must be between the 2 ends of the ring (39). Heat the inner bearing ring (32) to 120 °C and fit it to the shaft (30) on the propeller side. Cosmos 300 – Maintenance manual – V2... - Page 129 Insert the pinion bearing (34) and the 2 flange head screws M4x8 (31) and tighten with the torque shown in the figure. 4,5 Nm Insert the propeller shaft (30) with the bearing (32) into the cover. Wait a few minutes for the transmission cover to cool before continuing assembly. Cosmos 300 – Maintenance manual – V2...

- Page 130 Replace the propeller side oil seal (35) each time it is disassembled. Grease the propeller side oil seal (35) with FP Silicompound 225 and place it on the transmission cover (2) using the specific tool (40) [ACC114] to insert it. Cosmos 300 – Maintenance manual – V2...

- Page 131 Place the O-ring (36) in the bushing (33), grease it with FP Silicompound 225 and place it on the propeller shaft (30). Clean and degrease the threads of the screw (27) and the propeller shaft (30) threaded hole. Cosmos 300 – Maintenance manual – V2...

- Page 132 Replace the anti-unscrewing washer (28) each time it is disassembled. Insert the propeller hub (29), the anti-unscrewing washer (28) and the left-handed screw M8 (27). Cosmos 300 – Maintenance manual – V2...

- Page 133 Use the propeller hub locking tool (25) [ACC110] and tighten with the torque shown in the figure. 28 Nm Remove the hub locking tool (25) Bend the anti-unscrewing washer (28) as shown in the figure to make it adhere perfectly to one face of the hexagon of the screw. Cosmos 300 – Maintenance manual – V2...

- Page 134 Heat the upper bearing seat to 120 °C and insert the propeller shaft bearing (24). Insert the key (23) on the crankshaft (10). Cosmos 300 – Maintenance manual – V2...

- Page 135 Turn the crankshaft to have the reference point (indicated by a dot near the toothing) at the bottom. Turn the countershaft to obtain the alignment shown in the figure. Check that the pin is on the countershaft before continuing with the assembly. Cosmos 300 – Maintenance manual – V2...

- Page 136 Insert the driven gear (21) on the countershaft (20) aligning the 2 points on the gears. Cosmos 300 – Maintenance manual – V2...

- Page 137 The positioning of the transmission locking tool as shown in the figure confirms that the 2 gears have been mounted with the correct phase. Insert the part B of the transmission locking tool as shown in the figure. Secure the locking tool with the 2 Allen screws M6x20 (5). Cosmos 300 – Maintenance manual – V2...

- Page 138 72 Nm Insert the clutch plate (14), the 3 Torx screws M5x14 (12) on the clutch (13) and tighten with the torque shown in the figure. 8 Nm Cosmos 300 – Maintenance manual – V2...

- Page 139 Provisionally position the old clutch, without the compensating ring, on the crankshaft until it is in contact with the gearwheel. Measure the distance between the clutch plane (A) and the transmission cover separation plane (B) as shown in the figure. Cosmos 300 – Maintenance manual – V2...

- Page 140 Insert the compensating ring (37) into the clutch (13) by positioning the ring opening 180° from the clutch groove (highlighted in the figure). Lubricate the surface of the crankshaft. Insert the clutch (13) on the crankshaft (10) without looking for a phase. Cosmos 300 – Maintenance manual – V2...

- Page 141 Turn the part B with a 32 mm spanner and apply the torque shown in the figure. 110 Nm To remove the clutch assembly tool, unscrew both parts of the tool (A, B) at the same time. Cosmos 300 – Maintenance manual – V2...

- Page 142 Insert the clutch bell (8). Insert the nut M14x1,5 (6) with the washer (7) and tighten with the torque shown in the figure. Use a torque wrench, do not use a pneumatic impact screwdriver. 100 Nm Cosmos 300 – Maintenance manual – V2...

- Page 143 Remove the part B. Remove the part A. Replace the gasket (4) each time it is disassembled. Place the gasket (4) on the 2 pins (38). Insert the previously assembled transmission cover (2). Cosmos 300 – Maintenance manual – V2...

- Page 144 Insert and pre-tighten alternately the 2 highlighted Allen screws M6x30. Insert the remaining 7 Allen screws M6x30 (1) into the cover (2). Cosmos 300 – Maintenance manual – V2...

- Page 145 Pre-tighten progressively, then tighten in the order and with the torque shown in the figure. 10 Nm Check that all screws are tightened correctly in clockwise order. After assembly, fill the transmission with oil. Cosmos 300 – Maintenance manual – V2...

-

Page 146: Transmission Assembly - Ulm Model

Check the position of the Seeger ring: the lubrication hole (38) must be between the 2 ends of the ring (39). Heat the inner bearing ring (32) to 120 °C and fit it to the shaft (30) on the propeller side. Cosmos 300 – Maintenance manual – V2... - Page 147 Insert the pinion bearing (34) and the 2 flange head screws M4x8 (31) and tighten with the torque shown in the figure. 4,5 Nm Insert the propeller shaft (30) with the bearing (32) into the cover. Wait a few minutes for the transmission cover to cool before continuing assembly. Cosmos 300 – Maintenance manual – V2...

- Page 148 Replace the propeller side oil seal (35) each time it is disassembled. Grease the propeller side oil seal (35) with FP Silicompound 225 and place it on the transmission cover (2) using the specific tool (40) [ACC114] to insert it. Cosmos 300 – Maintenance manual – V2...

- Page 149 Place the O-ring (36) in the bushing (33), grease it with FP Silicompound 225 and place it on the propeller shaft (30). Clean and degrease the threads of the screw (27) and the propeller shaft (30) threaded hole. Cosmos 300 – Maintenance manual – V2...

- Page 150 Place the shaft on a stable support and carefully align the axis of the shaft and the piston of the press. Cosmos 300 – Maintenance manual – V2...

- Page 151 Replace the propeller hub (29) each time it is disassembled. Heat the propeller hub (29) to 200 °C and place it on the propeller shaft (30) making sure to match the gearings. Handle using thermal gloves to protect hands from thermal risks. Cosmos 300 – Maintenance manual – V2...

- Page 152 Push the hub (29) with a press on the surface highlighted in the figure to bring the hub (29) into contact with the bushing (33). Do not apply a load exceeding 1000 kg to prevent damage to the propeller hub. Cosmos 300 – Maintenance manual – V2...

- Page 153 Add threadlocker (recommended Loxeal 55-03/Loctite 243): insert it into the propeller shaft (29) threaded hole. Hardening time of the threadlocker: 3 hours. Replace the anti-unscrewing washer (28) each time it is disassembled. Insert the anti-unscrewing washer (28) and left-handed screw M8 (27) Cosmos 300 – Maintenance manual – V2...

- Page 154 Use the propeller hub locking tool (25) [ACC110] and tighten with the torque shown in the figure. 28 Nm Bend the anti-unscrewing washer (28) as shown in the figure to make it adhere perfectly to one face of the hexagon of the screw. Cosmos 300 – Maintenance manual – V2...

- Page 155 Heat the upper bearing seat to 120 °C and insert the propeller shaft bearing (24). Insert the key (23) on the crankshaft (10). Cosmos 300 – Maintenance manual – V2...

- Page 156 Turn the crankshaft to have the reference point (indicated by a dot near the toothing) at the bottom. Turn the countershaft to obtain the alignment shown in the figure. Check that the pin is on the countershaft before continuing with the assembly. Cosmos 300 – Maintenance manual – V2...

- Page 157 Insert the driven gear (21) on the countershaft (20) aligning the 2 points on the gears. Cosmos 300 – Maintenance manual – V2...

- Page 158 The positioning of the transmission locking tool as shown in the figure confirms that the 2 gears have been mounted with the correct phase. Insert the part B of the transmission locking tool as shown in the figure. Secure the locking tool with the 2 Allen screws M6x20 (5). Cosmos 300 – Maintenance manual – V2...

- Page 159 72 Nm Insert the clutch plate (14), the 3 Torx screws M5x14 (12) on the clutch (13) and tighten with the torque shown in the figure. 8 Nm Cosmos 300 – Maintenance manual – V2...

- Page 160 Provisionally position the old clutch, without the compensating ring, on the crankshaft until it is in contact with the gearwheel. Measure the distance between the clutch plane (A) and the transmission cover separation plane (B) as shown in the figure. Cosmos 300 – Maintenance manual – V2...

- Page 161 Insert the compensating ring (37) into the clutch (13) by positioning the ring opening 180° from the clutch groove (highlighted in the figure). Lubricate the surface of the crankshaft. Insert the clutch (13) on the crankshaft (10) without looking for a phase. Cosmos 300 – Maintenance manual – V2...

- Page 162 Turn the part B with a 32 mm spanner and apply the torque shown in the figure. 110 Nm To remove the clutch assembly tool, unscrew both parts of the tool (A, B) at the same time. Cosmos 300 – Maintenance manual – V2...

- Page 163 Insert the clutch bell (8). Insert the nut M14x1,5 (6) with the washer (7) and tighten with the torque shown in the figure. Use a torque wrench, do not use a pneumatic impact screwdriver. 100 Nm Cosmos 300 – Maintenance manual – V2...

- Page 164 Remove the part B. Remove the part A. Replace the gasket (4) each time it is disassembled. Place the gasket (4) on the 2 pins (38). Insert the previously assembled transmission cover (2). Cosmos 300 – Maintenance manual – V2...

- Page 165 Insert and pre-tighten alternately the 2 highlighted Allen screws M6x30. Insert the remaining 7 Allen screws M6x30 (1) into the cover (2). Cosmos 300 – Maintenance manual – V2...

- Page 166 Pre-tighten progressively, then tighten in the order and with the torque shown in the figure. 10 Nm Check that all screws are tightened correctly in clockwise order. After assembly, fill the transmission with oil. Cosmos 300 – Maintenance manual – V2...

-

Page 167: Piston, Cylinder, Head

Before disassembling the cylinder unit, remove the spark plugs (3.2 Spark plugs), the exhaust system (3.7 Exhaust system) and the coolant (3.8 Cooling system). In order to disassemble cylinder/head/piston it is not necessary to disassemble the thermostat and the connector to the cooling system Cosmos 300 – Maintenance manual – V2... - Page 168 Remove the clamp on the pipe exiting the head. Remove the pipe from the head. Remove the 2 Allen screws M5x10 (1) with washers (2). Remove the connector (3), the O-ring (4) and the thermostat (5). Cosmos 300 – Maintenance manual – V2...

- Page 169 Remove the head (8) and the head gasket (9). Remove the 4 self-locking nuts M8 (10) with washers (11) from the engine studs (14). Remove the cylinder (12) and the cylinder base gasket (13). Cosmos 300 – Maintenance manual – V2...

- Page 170 Remove the circle clip (15), the pin (16), the piston (17) and the roller bearing (18). Remove the 2 piston rings (19) and the circle clip (15) from the piston (17). Cosmos 300 – Maintenance manual – V2...

-

Page 171: Piston, Cylinder, Head Maintenance

Check the selection class engraved on the piston. Measure the diameter of the piston 10 mm from the base of the shell. Measure the diameter of the cylinder 10 mm from the top. Cosmos 300 – Maintenance manual – V2... - Page 172 Determine the maximum clearance, if equal to or greater than the indicated value replace the piston and/or cylinder. Check the piston and cylinder for signs of seizure, otherwise replace them. For routine maintenance, follow the table. Cosmos 300 – Maintenance manual – V2...

-

Page 173: Piston, Cylinder, Head Assembly

Insert the gasket (13) [C014] with the water passage holes at the bottom and on the side shown below. Position the gasket as in the photo: the silicone profile on the gasket is on the cylinder side. Cosmos 300 – Maintenance manual – V2... - Page 174 2 piston ring retainers. Insert a circle clip (15) on the piston (17) respecting the position shown in the photo. The triangle on the top of the piston indicates the exhaust side. Cosmos 300 – Maintenance manual – V2...

- Page 175 Insert the cylinder and the 4 self-locking nuts M8 (10) with washers (11) on the engine studs (14). Tighten the nuts progressively then cross-tighten with the torque shown in the figure. 17 Nm Cosmos 300 – Maintenance manual – V2...

- Page 176 Replace the gasket (9) [C016] each time it is disassembled. Position the gasket (9) [C016] as in the photo on the left: the white mark (highlighted in the photo) is on the side of the head. Cosmos 300 – Maintenance manual – V2...

- Page 177 Move the head (8) closer to the cylinder, paying attention to the position of the gasket (9). Cosmos 300 – Maintenance manual – V2...

- Page 178 Insert the 6 Allen screws M6x30 (6) with washers (7) on the head (8) and pre-tighten. Remove the pin (20). Cosmos 300 – Maintenance manual – V2...

- Page 179 Grease the O-ring (4) with FP Silicompound 225 and place it on the connector (3). Insert the thermostat (5), the connector (3), the 2 Allen screws M5x10 (1) with washers (2) and tighten with the torque shown in the figure. 3 Nm Cosmos 300 – Maintenance manual – V2...

- Page 180 Connect the radiator hose to the head and tighten the clamp with a specific pliers. Check the squish measurement on 2 sides of the piston on the pin axis: acceptable values range from 1,25 mm to 1,45 mm. Cosmos 300 – Maintenance manual – V2...

-

Page 181: Crankcase

(3.8 Cooling system), the rubber mountings (3.9 Rubber mountings), the pull starter system (3.10 Pull starter system), the electric starter (3.11 Electric starter), the flywheel (3.12 Flywheel), the transmission (3.13 Transmission) and the cylinder unit (3.14 Piston, cylinder, head). Cosmos 300 – Maintenance manual – V2... - Page 182 Remove the oil seal (1) and the Seeger ring (2) from the crankshaft (3). Remove the 5 Allen screws M5x20 (4) from the water pump cover (5). Remove the cover (5) and the gasket (6). Cosmos 300 – Maintenance manual – V2...

- Page 183 Insert the countershaft locking tool (7) [ACC117] and hold it in position. Remove the nut (8) and unscrew the pump impeller (9) from the countershaft. Cosmos 300 – Maintenance manual – V2...

- Page 184 Remove the 10 Allen screws M6x50 (10) from the crankcase (11). Position the extractor (12) [ACC113] on the crankshaft (3), tighten the 2 screws M6 (13) and turn the central pin (14) until the 2 case-half are separated. Cosmos 300 – Maintenance manual – V2...

- Page 185 Remove the crankshaft bearing (15), the countershaft bearing (16), the crankshaft oil seal (17). Remove the countershaft oil seal (18) using the specific tool (19) [ACC120]. Heat the transmission side crankcase to 120 °C. Remove the countershaft (20). Cosmos 300 – Maintenance manual – V2...

- Page 186 Heat the countershaft (20) near the pin at 120°C and remove the pin (21). Heat the bearing (22) and remove it. Remove the crankshaft (3) using a press in the direction shown in the figure. Cosmos 300 – Maintenance manual – V2...

- Page 187 Remove the 3 screws M5x12 (23) and the bearing retainer (24). Heat the transmission side crankcase to 120 °C. Remove crankshaft bearing (25) on the transmission side. Cosmos 300 – Maintenance manual – V2...

-

Page 188: Crankcase Maintenance

Check the 4 bearing seats: there must be no polished areas. Also measure the diameter of the 4 seats, the table shows the factory settings. Dimension Factory settings at 20° C (mm) 61,955-61,970 39,980-39,996 61,955-61,970 39,980-39,996 Cosmos 300 – Maintenance manual – V2... - Page 189 Measure the clearance at the small end and big end of the connecting rod. Factory nominal clearance* (mm) Small end 0,011±0,005 Big end 0,03±0,005 * at 20 °C Check on the connecting rod that there are no areas of different color due to overheating. Cosmos 300 – Maintenance manual – V2...

- Page 190 If the above checks are not passed, replace the crankshaft. Measure the diameter of the 2 bearing seats on the crankshaft, the table shows the factory settings. Dimension Factory settings at 20° C (mm) 16,983-16,994 16,983-16,994 Cosmos 300 – Maintenance manual – V2...

-

Page 191: Crankcase Assembly

Heat the inner rings of the 2 bearings of the countershaft (16, 22) to 120 °C. Fit the 2 bearings (16, 22) on the countershaft (20). Insert the pin (21) with threadlocker (Loxeal 55-03/Loctite 243 recommended) on the countershaft (20). Cosmos 300 – Maintenance manual – V2... - Page 192 Heat the inner ring of the bearing (15) to 120 °C and fit it on the crankshaft (3). Heat the transmission side crankcase to 120 °C. Insert the countershaft (20) with the 2 bearings. Cosmos 300 – Maintenance manual – V2...

- Page 193 Insert the crankshaft bearing (25) with the bearing retainer (24) and the 3 screws M5x12 (23) and tighten with the torque shown in the figure. 5 Nm Heat the inner ring of the bearing (25) to 120 °C. Insert the crankshaft (3) with the bearing. Cosmos 300 – Maintenance manual – V2...

- Page 194 Carry out subsequent operations within a maximum of 5 minutes (application of silicone and closing of the crankcase). Carefully add silicone paste (Three Bond 1215) to the crankcase profile as shown in the figure. Height, width silicone profile: 2 mm x 2,5 mm. Cosmos 300 – Maintenance manual – V2...

- Page 195 Close with the manual starter side crankcase still warm at 120 °C. Insert the 10 Allen screws M6x50 (10) on the crankcase (11) and tighten with the torque shown in the figure. 10 Nm Cosmos 300 – Maintenance manual – V2...

- Page 196 Grease the oil seal (17) with FP Silicompound 225 and place it on the crankshaft (2) using the specific tool (17) [ACC118] to insert it. Insert the part A of the specific tool [ACC119] on the countershaft. Cosmos 300 – Maintenance manual – V2...

- Page 197 Abundantly grease the oil seal (18) with FP Silicompound 225 and place it on the part B. Insert the part B with the oil seal on the countershaft. Fully insert the part C on the part B. Cosmos 300 – Maintenance manual – V2...

- Page 198 Insert the countershaft locking tool (7) [ACC117] and hold it in position. Screw the pump impeller (9) onto the countershaft. Insert the nut (8) and tighten with the torque shown in the figure. 8 Nm Cosmos 300 – Maintenance manual – V2...

- Page 199 Insert the water pump cover (5), paying attention to the position of the gasket. Insert the 5 Allen screws M5x20 (4) into the cover (5) and cross-tighten with the torque shown in the figure. 8 Nm Cosmos 300 – Maintenance manual – V2...

- Page 200 Insert the part A of the specific tool [ACC121] on the crankshaft. Grease the oil seal (1) with FP Silicompound 225 and place it on the crankshaft using the part B to insert it. Remove the part B and A. Cosmos 300 – Maintenance manual – V2...

- Page 201 Check the tightening of screws. Insert oil into the 2 lubrication holes (highlighted in the figure). Check the sliding of shafts on the bearings. Cosmos 300 – Maintenance manual – V2...

-

Page 202: Tightening Values

Snaplock airbox 10 Nm pivots Loctite 243 Airbox fixing 50-70 mm 2,5 Nm clamp (clamp size) Flywheel nut 90 Nm M12x1,25 Stator screws 10 Nm M6x25 The table follows in the next page Cosmos 300 – Maintenance manual – V2... - Page 203 Loctite 270 Pinion bearing 4,5 Nm M4x8 screws Oil level screw 3 Nm M5x10 Cylinder vent 3 Nm M5x10 screw Water pump 3 Nm M5x10 lower screw The table follows in the next page Cosmos 300 – Maintenance manual – V2...

- Page 204 Thermostat 3 Nm M5x10 screws Bearing retainer 5 Nm M5x12 screws Carbon 12-14 Nm propeller screws Cosmos 300 – Maintenance manual – V2...

- Page 205 Cosmos 300 – Maintenance manual – V2...

- Page 206 Cosmos 300 – Maintenance manual – V2...

Need help?

Do you have a question about the COSMOS 300 and is the answer not in the manual?

Questions and answers