Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Vittorazi Motors MOSTER 185 EFI

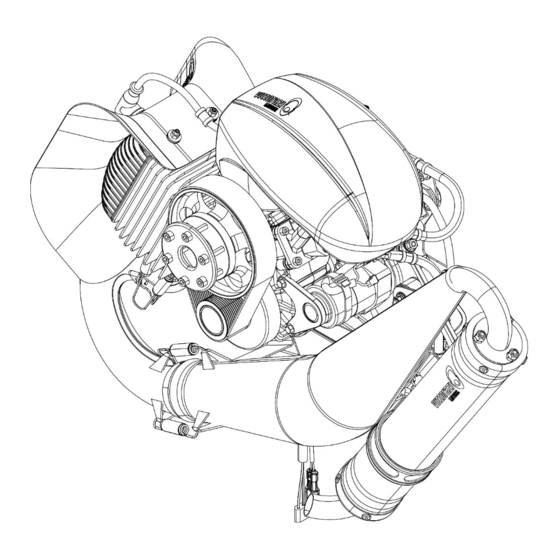

- Page 1 MOSTER 185 EFI Installation manual Release V1/2024. Valid for MY24 version.

- Page 2 Moster 185 EFI - Installation manual – V1/2024...

-

Page 3: Table Of Contents

Be careful! Read it completely Installation 3.1 Preparing for installation 3.2 Supports to the frame 3.3 Electrical system 3.4 Battery 3.5 Display 3.6 Fuel system 3.7 Throttle bowden cable 3.8 Propeller assembling 3.9 Final checks Moster 185 EFI - Installation manual – V1/2024... -

Page 4: Introduction

The professional manual includes: technical descriptions of the installation phase and reference values. All the components of Vittorazi Motors are checked and tested in a process of industrial quality control before the assembling. Then by sampling the complete motors are checked to assure the functionality of all the parts through a complete test of twenty minutes on the bench. - Page 5 Reading tips: Attention, warning, danger, risk Any situation or condition which may result in a serious danger Recommendation, caution, important advice Moster 185 EFI - Installation manual – V1/2024...

-

Page 6: Be Careful! Read It Completely

• Vittorazi Motors and its distributors decline any direct or indirect responsibility related to this kind of activity. By using a new engine, the owner agrees that these terms and conditions have been accepted at the time of purchase of the product. - Page 7 Proceed at reduced power and once on the ground contact your dealer. LiPo batteries are high-tech products but potentially dangerous to property, animals or people, especially if used improperly or without experience. Moster 185 EFI - Installation manual – V1/2024...

-

Page 8: Installation

Frame design must give strong consideration to the following sections: 3.2 Supports to the frame, 3.3 Electrical system, 3.4 Battery, 3.6 Fuel system. It is also recommended to carry out the checks described in the relevant paragraph (3.9 Final checks) before starting the engine. Moster 185 EFI - Installation manual – V1/2024... -

Page 9: Preparing For Installation

Check that there is no damage of any kind related to the transport of the engine. Engine openings are closed by special plugs to prevent the entry of foreign substances and moisture. These should only be removed when necessary for installation. Moster 185 EFI - Installation manual – V1/2024... - Page 10 Moster 185 EFI - Installation manual – V1/2024...

- Page 11 Moster 185 EFI - Installation manual – V1/2024...

-

Page 12: Supports To The Frame

The components to be installed, in particular the fuel tank, fuel hoses and the battery, must have a certain distance from the exhaust system as high temperatures are reached during engine operation. Moster 185 EFI - Installation manual – V1/2024... - Page 13 When reinstalling it, check that the airbox has been fitted correctly, and in particular that the fixing clamp (1) on the sleeve and the safety strap (2) have been securely fastened. Moster 185 EFI - Installation manual – V1/2024...

-

Page 14: Electrical System

(4) and the coil signal cable (5), an M4x12 screw (9) that fix the ground cable (3) and an M5 F6 rubberized cable clamp (10) that fix the spark coil signal cable (5). Signal wiring scheme: Air rotary valve Injector Spark coil Ground Stick Moster 185 EFI - Installation manual – V1/2024... - Page 15 Position the fastening point at least 20 cm away from the throttle bowden fixing support. Frame Throttle bowden cable Moster 185 EFI - Installation manual – V1/2024...

- Page 16 CHT probes cable (2) and two plastic cable clamps (6, 7) that fix the starter relay power cable (3). Power supply wiring scheme: Starter relay EGT sensor CHT sensor ECU supply Moster 185 EFI - Installation manual – V1/2024...

- Page 17 3.3.3 Electric starter wiring The Electric starter wires are clamped with three M6 F8 rubberized cable clamps (1, 2, 3) and a 26- 92 mm plastic cable tie (4). Electric starter wiring scheme: Moster 185 EFI - Installation manual – V1/2024...

- Page 18 When the battery XT60 connector is connected, the starter wiring is powered, take care not to cut the cables or create a short circuit. A 60A fuse (BF1 type) is housed inside the upper battery compartment. Electric starter: Moster 185 EFI - Installation manual – V1/2024...

- Page 19 Place the fixing point at about 10 cms from the connectors. Supply cables Frame Connectors Moster 185 EFI - Installation manual – V1/2024...

- Page 20 Do not fix the connectors to the frame, this could damage the connectors due to vibration, creating the risk of short-circuiting and/or engine shutdown during flight. Moster 185 EFI - Installation manual – V1/2024...

- Page 21 3.3.4 EGT and CHT Sensor housing The cables and connector of EGT and CHT probes are arranged inside the sensors support as shown in the figure. Moster 185 EFI - Installation manual – V1/2024...

- Page 22 (cod. MI031a). Screw the spark plug into the head and tighten to 25 Nm. Fully insert the spark plug cap into the spark plug and check that the connection is secure. Moster 185 EFI - Installation manual – V1/2024...

- Page 23 Once the spark plug cap is inserted check that the rubber cap is in contact with the cooling shroud. Moster 185 EFI - Installation manual – V1/2024...

-

Page 24: Battery

For safety reasons, the battery must be placed in a position that can be reached safely by the pilot during flight, as far as possible from any source of heat and possible impacts and on the opposite side from the fuel inlet. Moster 185 EFI - Installation manual – V1/2024... - Page 25 It is important that the battery support does not completely cover the base of the battery to allow air to pass through and liquids to escape in the event of leaks Moster 185 EFI - Installation manual – V1/2024...

- Page 26 Remove the protective tape from the dual on the back of the battery (1) and attach it to the battery support (2) Place the back part of the Velcro holder (3) on the back of the battery support (2). Moster 185 EFI - Installation manual – V1/2024...

- Page 27 Attach the front part of the Velcro holder (4). Secure the battery (3) with the Velcro holder (6). Moster 185 EFI - Installation manual – V1/2024...

- Page 28 Connect the ECU supply cable (SQUBA 3.6 connector). Connect the starter supply cable (XT60 connector). Moster 185 EFI - Installation manual – V1/2024...

- Page 29 When the battery is not used for a long period of time, it is recommended to bring the battery charge to storage voltage (50 ÷ 75 % charge level or two steady and two flashing leds on the battery charger). Moster 185 EFI - Installation manual – V1/2024...

- Page 30 By purchasing these products, the buyer assumes all responsibility for the risks listed below, agreeing not to hold manufacturers, distributors, or retailers in any way responsible for any accidents to property, animals or persons. Moster 185 EFI - Installation manual – V1/2024...

-

Page 31: Display

Before installing the RJ-45 cable on the PPG frame, check for the two openable Ferrite Rings placed at its end. Ferrite rings Insert the RJ45 waterproof plug into the ECU socket, screw on the ferrule. Moster 185 EFI - Installation manual – V1/2024... - Page 32 Take care to leave a wide bend on the RJ-45 cable between the two fixing points to allow the ECU box to swing around its rubber mounts without pulling the RJ-45 cable. RJ-45 Frame cable Moster 185 EFI - Installation manual – V1/2024...

- Page 33 Make sure the display holder is securely fixed to the PPG frame arm. Attach the display on the Velcro display support. Pass the 90° plug of the RJ-45 cable through the elastic band provided on the display support. Elastic 90° RJ-45 band plug Moster 185 EFI - Installation manual – V1/2024...

- Page 34 Insert the ferrite ring of the RJ45 cable inside the elastic band provided on the display support. Ferrite ring inside the elastic band Connect the 90° plug of the RJ-45 cable on the display. Moster 185 EFI - Installation manual – V1/2024...

-

Page 35: Fuel System

In case of occlusion of a component inside the FBU, it will be necessary to replace the Full Integrated Unit (FIU) and ship the defective one to the Vittorazi headquarters (See maintenance manual chapter 3.5 Full integrated unit (FIU)). Moster 185 EFI - Installation manual – V1/2024... - Page 36 Secure all joints with the tube clips supplied by Vittorazi to prevent leakage and unwanted movement. Moster 185 EFI - Installation manual – V1/2024...

- Page 37 (14) is a static pressurized line. The electrovalve (16) is only opened during the fuel line filling in order to allow the fuel to circulate and remove any air bubbles and in case of overpressure due to fast throttle release. Moster 185 EFI - Installation manual – V1/2024...

- Page 38 Insert a Vittorazi pass-through (4) on the other extremity of the catch tube (3) and insert the O- ring (5). Moster 185 EFI - Installation manual – V1/2024...

- Page 39 Insert the second Vittorazi pass-through (18) with Oring (19) on the second M10 hole and fix it with the M10 nut (20) and the 10x16x1 washer (21) for the return line. Insert the fuel supply pipe (8) and the fuel return pipe (17). Moster 185 EFI - Installation manual – V1/2024...

- Page 40 When the main switch is turned on, to see fuel entering in the FBU. • With the engine running, to notice possible bubbles due to the air aspiration in the fuel line. In this case, carefully check the pipe connections. Moster 185 EFI - Installation manual – V1/2024...

- Page 41 Insert the brass porex filter (23) supplied by Vittorazi at the end of the vent pipe (22) to prevent the entry of impurities inside the fuel tank. Tygon Saint Gobain LP- 1200 tube Tank Tube vent clip Vittorazi pass-through fitting Moster 185 EFI - Installation manual – V1/2024...

- Page 42 40 ± 15 cms. A different distance may generate a variation in fuel flow rate, compromising the performance of the EFI system and creating a risk of engine overheating. In case this value cannot be respected due to particular aircraft geometries, contact Vittorazi directly. Moster 185 EFI - Installation manual – V1/2024...

-

Page 43: Throttle Bowden Cable

The Start/Stop button of the V-throttle is connected to the bipolar connector through the two wires coming out of the bipolar connector, it does not require a ground connection. Screw the throttle bowden cable inside the fixing support (1). Moster 185 EFI - Installation manual – V1/2024... - Page 44 Bowden cable is secured in the screw nipple; • the full opening of the shutter; • the sliding of the system; • the return to the stop position each time the throttle is released. Connect the start/stop button cable. Moster 185 EFI - Installation manual – V1/2024...

- Page 45 The V-Thottle is setted by default in the left-hand configuration, to switch it to the right-hand configuration remove the 2 screws M3x16, the flange and the adjustable strap and reinsert it on the other side Moster 185 EFI - Installation manual – V1/2024...

-

Page 46: Propeller Assembling

1/2,87 140 cms (prop. H30F 1,40m L-NMM-05-2) The operation of the Moster 185 EFI engine is determined by the coupling with the correct propeller. All the EFI parameters have been calibrated and optimized with the correct coupling between the engine and the approved propeller. - Page 47 Fast acceleration propeller approved from Vittorazi, does not require a spacer between the hub and the propeller. Moster 185 EFI - Installation manual – V1/2024...

- Page 48 Be sure that the screws are suitable to the propeller in use: the thread of the screws is inserted in the hub for at least 12 mms for carbon propellers. Moster 185 EFI - Installation manual – V1/2024...

- Page 49 Engine safety and reliability are given by the long endurance tests (200 hours) performed in extreme conditions with the approved propellers, to check if there are any critical issues before the production. Moster 185 EFI - Installation manual – V1/2024...

- Page 50 Airbox system (airbox, sleeve, safety devices). • More. In case of damage of the propeller, replace it immediately with a propeller guaranteed by Vittorazi Motors. Replace in any case all screws of the propeller. Moster 185 EFI - Installation manual – V1/2024...

-

Page 51: Final Checks

For each new model aircraft, a series of test must be performed and documented in appropriate reports after the initial engine installation. The company Vittorazi strongly recommends sending those reports that contain operating data (RPM, temperatures, consumption, etc) for validation. Moster 185 EFI - Installation manual – V1/2024... - Page 52 Moster 185 EFI - Installation manual – V1/2024...

- Page 53 Moster 185 EFI - Installation manual – V1/2024...

Need help?

Do you have a question about the MOSTER 185 EFI and is the answer not in the manual?

Questions and answers