Brother GTX600SB Instruction Manual

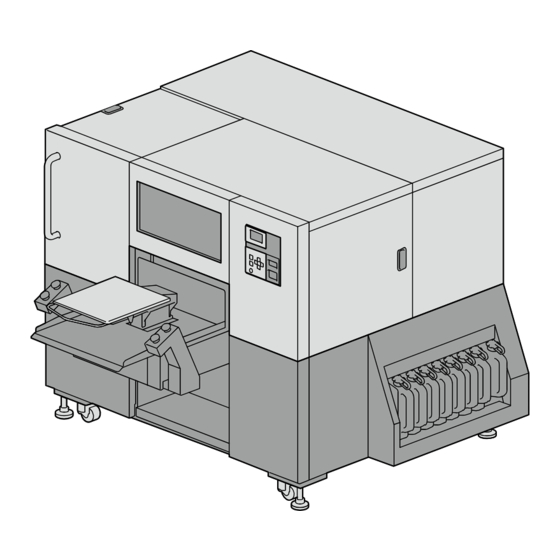

Garment printer

Hide thumbs

Also See for GTX600SB:

- Setup manual (46 pages) ,

- Instruction manual (27 pages) ,

- Installation and setup (9 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Brother GTX600SB

- Page 1 GTX600SB Professional Use GARMENT PRINTER Instruction Manual Please be sure to read this manual before using this product. Keep this manual in a safe place for future use. This printer should only be used by operators who are appropriately trained in its safe...

- Page 2 When you dispose of the machine Required Tools Phillips screwdriver: M3 to M5 Disassembling Remove the Cover of BACK SIDE bottom center. Remove the Lithium Battery (1) by pulling out the holder in the direction of the arrow. Pickup the Lithium Battery (1) to the direction of the arrow. Note based on California law (USA) on the use and handling of Perchlorate This product contains a CR Coin Lithium Battery which contains Perchlorate Material –...

- Page 3 SAFETY INSTRUCTIONS Thank you very much for buying a BROTHER printer. Before using your new printer, please read the "SAFETY INSTRUCTIONS" and handling instructions carefully. 1. Safety indications and their meanings This instruction manual and the indications and symbols that are used on the printer itself are provided in order to ensure safe operation of this printer and to prevent accidents and injury to yourself or other people.

- Page 4 The printer is not suitable for use in places where children are present. To prevent accidents and problems, do not modify the machine by yourself. Brother will not be held responsible for any accidents or problems resulting from modifications made to the machine.

- Page 5 SAFETY INSTRUCTIONS WARNING Printing If a foreign object gets inside the printer, immediately turn off the power, disconnect the power cord, and contact the place of purchase or a qualified technician. If you continue to use the printer while there is a foreign object inside, it may result in fire or electric shocks or problems with correct operation.

- Page 6 Keep the liquids out of the reach of children. When replacing parts and installing optional accessories, be sure to use only genuine Brother parts. Brother will not be held responsible for any accidents or problems resulting from the use of non-genuine parts.

- Page 7 SAFETY INSTRUCTIONS IMPORTANT Printing Do not move the platen by hand. Otherwise, the printer may be mechanically and electrically damaged. Ensure there is adequate space left in front of the printer and avoid placing any objects. The platen may be hit and damaged.

- Page 8 SAFETY INSTRUCTIONS 3. Warning labels Waste ink tank Ink bottle Waste water tank Cleaning solution bottle Pretreatment 5 kg (11 lb) Pretreatment 20 kg (44 lb) X1101...

- Page 9 SAFETY INSTRUCTIONS This printer has the following warning labels displayed on it. Follow the precautions given on each warning label for your work. When the label is peeled off or illegible, contact the place of purchase.

-

Page 10: Table Of Contents

Table of contents 1. Before Using Your Printer for the First Time 1-1. Be sure to read the following notes before using the printer ....................15 1-2. Components included with printer ............................19 1-3. Other items you must make available for use ......................... 20 1-4. - Page 11 Table of contents 4. Creating print data 4-1. Types of applications ................................77 4-2. Sending print data using Brother GTX-6 Extra Colors ORGR FileOutput (for Macintosh only)..........79 4-3. Using other applications ................................80 4-3-1. When using CorelDRAW .............................. 80 4-3-2.

- Page 12 Table of contents 5. Basic printing procedures 5-1. Basic printing process flow ..............................143 5-2. Tasks to be performed before starting print operation ......................144 5-2-1. Confirmation of Water Supply Tank ..........................144 5-3. Pretreating process for print medium ............................. 145 5-3-1.

- Page 13 Table of contents 6. Precautions to keep good printing quality/use printer over the long term 6-1. Tasks to be performed regularly ............................. 177 6-1-1. Refilling color ink ................................. 177 6-1-2. Refilling white ink ................................ 179 6-1-3. Refilling the cleaning solution ............................. 183 6-1-4.

- Page 14 Table of contents 7-11. Print Operation Settings Under Low Temperature ....................... 249 7-12. Print Operation Settings Under Low Humidity ........................250 7-13. Auto Cleaning Setting ................................251 7-14. Setting Automatic Multiple Pass Settings ..........................252 7-15. Flushing Interval Setting ............................... 253 7-16.

-

Page 15: Before Using Your Printer For The First Time

1 Before Using Your Printer for the First Time 1-1. Be sure to read the following notes before using the printer Keep in mind the following points before using the printer: Precautions for proper use PLEASE LEAVE THE PRINTER POWERED ON 24 HOURS A DAY. Even when the printer is placed in standby mode, it performs such maintenance as white ink circulation inside the main unit automatically to prevent sedimentation of the white ink. - Page 16 Before Using Your Printer for the First Time Handle the IC stick with care. Take care not to lose the IC stick. Once you have refilled ink, you cannot print until you insert the IC stick. About pretreatment Apply the pretreatment when using white ink.

- Page 17 ® marks or TM marks are not used. Brother logo is registered trademark of Brother Industries, Ltd. Apple, Macintosh, Mac OS, iOS, OS X, macOS, Safari, iPad, iPhone, iPod and iPod touch are the trademarks or registered trademarks of Apple Inc.

- Page 18 Before Using Your Printer for the First Time About software This printer uses its own software. To use this printer, you are required to agree with the End-User License Agreement for Brother Software as mentioned below. End-User License Agreement for Brother Software You can use this software if you agree to comply with the terms of the End-User License Agreement.

-

Page 19: Components Included With Printer

Before Using Your Printer for the First Time 1-2. Components included with printer The components included with the printer are shown below. However, in the event that there is any missing component(s), please contact your dealer. ① ② ③ ④ ⑤... -

Page 20: Other Items You Must Make Available For Use

Before Using Your Printer for the First Time 1-3. Other items you must make available for use What you buy from our distributors 9-L Ink bottle Cleaning solution Pretreatment AC power cord <NOTE> There is a risk of malfunction or fire if you use other cables than the specified one. Purchase the cable (optional item) from your dealer. - Page 21 Before Using Your Printer for the First Time T-shirt (printing medium) 100% cotton Polyester blended yarn fabric <TIPS> Although it is advisable to use a 100% cotton T-shirt, some textiles cannot necessarily guarantee good printing quality even if they are made of 100% cotton or blended yarn.

-

Page 22: Name And Function Of Each Component

Before Using Your Printer for the First Time 1-4. Name and function of each component 1-4-1. Front part... - Page 23 Before Using Your Printer for the First Time Name Function Top cover Open this cover when cleaning the internal area of the printer. Carriage Holds the print head. Checks the presence of any obstacles by their height (such as wrinkled T-shirt) Obstacle sensor that are within range to collide with the print head.

-

Page 24: Right Side View

Before Using Your Printer for the First Time 1-4-2. Right side view Name Function Right side cover Open this cover when cleaning the internal area of the printer. Ink tank White (W), magenta (M), cyan (C), yellow (Y), black (K), green (GR), and orange (OR) from the right side. -

Page 25: Left Side View/Rear Side View

Before Using Your Printer for the First Time 1-4-3. Left side view/Rear side view Name Function Upper left side cover Open this cover when cleaning the internal area of the printer. Lower left side cover Open the cover and replace the waste ink tank and waste water tank. Waste ink tube This tube is used to direct the flow of waste ink down into the waste ink tank. -

Page 26: Inside The Cover

Before Using Your Printer for the First Time 1-4-4. Inside the cover <IMPORTANT> If you put your hands inside the cover during regular maintenance while the power is on, follow the instructions in this manual. Name Function Print head (front: on the color side) It ejects the color ink. -

Page 27: Operation Panel

Before Using Your Printer for the First Time 1-4-5. Operation panel Name Function It indicates the job name or file name of print data, the active status of the Liquid crystal panel printer, and the menu for various settings. When it remains off: No error has occurred. Error LED When it remains on: One or more errors have been detected. - Page 28 Before Using Your Printer for the First Time Name Function With this button, such actions as printing and platen movement can be canceled. Printer will come to a stop after necessary actions for keeping the printer's good Stop button quality, such as retracting operation of print heads and capping operation, are completed.

- Page 29 Before Using Your Printer for the First Time Liquid crystal panel The picture shown below indicates a state under which the printer has received print data. On this screen, the printer's current state and necessary information for printing are displayed. Indications Function The preview display screen of received print data is shown in this window.

- Page 30 Before Using Your Printer for the First Time Indications Function This mark appears when any warning is issued. Pressing causes the Warning mark current screen to move to the warning screen where the applicable warning message is indicated. The total number of printed sheets of which printing operation is completed in Number of printed sheets response to the received print data is displayed here.

- Page 31 Before Using Your Printer for the First Time When receiving print data, press the left arrow button on the screen to switch it over to the following screen to display print information. Indications Function Time/Date Displays the current date and time. Resolution icon The printing resolution of received print data is displayed here.

- Page 32 Before Using Your Printer for the First Time Indications Function The time of the next white ink circulation is displayed. White ink circulation The time set by the maintenance tool is displayed. time The reinforced circulation of white ink will be performed if is displayed.

-

Page 33: About The Humidifier

Before Using Your Printer for the First Time 1-5. About the humidifier The humidifier works to maintain the image quality and keeps the humidity of the unit properly. Furthermore, the water accumulated inside the humidifier will be regularly discarded for hygiene control. <IMPORTANT>... - Page 34 Before Using Your Printer for the First Time Supply from a tank Tank Printer <IMPORTANT> Fill the tank with pure water. Use a clean container to supply water to the tank. Install the tank about 31.5 in. (80 cm) above the installation location of the printer. If the height is insufficient, water may not be supplied to the printer.

-

Page 35: Menu List

2 Menu list On-screen menu manipulation What to do How to operate Pressing in the wait state causes the current screen to move to the menu Start selection screen. By means of , change a menu item to another menu item to be displayed. Pressing causes the current menu to change to another menu item which is Select / Acknowledge... - Page 36 Menu list Menu list 1st layer 2nd layer Description [Position A] [Position B] [Position C] [Position D] [Position E] [Platen height This menu item is used to set the platen height. adjustment] [Position F] [Position G] [Position H] [User settings 1] [User settings 2] If no ink-jet droplets are ejected, this menu item enables you [Normal Cleaning]...

- Page 37 Menu list 1st layer 2nd layer Description [Maintenance Part Clean/Replace] [White Ink Circulation] [White Ink Tank Agitation] [Humidification] [Humidifier unit] [Waste Ink Tank Disposal] [Humidifier Drain Tank Disposal] [Tank remaining volume sensor correction] [Maintenance] Use when performing printer maintenance. [Wiper Cleaning Tank Operation] [Head Replacement] [Install Ink after Replacing Head] [Initial Ink Installation]...

- Page 38 Menu list 1st layer 2nd layer Description [Check circulation schedule] [Check humidification schedule] [Language] [Prepare Power OFF] Use when needed. [Firm Version] [Data Info] [Version] [Serial No.] [Head information]...

-

Page 39: Installation And Preparation

3 Installation and preparation Be sure to use the printer after making correct setting in accordance with the instructions described in this chapter. WARNING Do not set up the printer in a dusty environment. If dust collects inside the printer, it may cause fire or electric shocks or problems with correct operation. -

Page 40: Installation Of Printer

Installation and preparation 3-1. Installation of printer Please refer to the Setup Manual included with the printer, for details of unpacking procedures and installation procedures of accessories. For an installation site of the printer, please bear the following points in mind: ... -

Page 41: Initial Installation Of Printer

Installation and preparation 3-2. Initial installation of printer Please refer to the Setup Manual for the following initial installation procedures: Main tank unit Print switch Waste ink tank/Waste water tank Humidifier pipe Carriage belt tension adjustment ... - Page 42 Installation and preparation Tighten the upper nuts on the lefts (4 points) upwards after adjusting the level. <IMPORTANT> Check the level again with a level gage after fixing everything.

-

Page 43: Power Supply Of Printer

Installation and preparation 3-3. Power supply of printer Even when the printer is placed in standby mode, such maintenance as white ink circulation is performed automatically. PLEASE LEAVE THE PRINTER POWERED ON 24 HOURS A DAY. <IMPORTANT> Do not turn off the power because if you do so, the machine mail fail because necessary maintenance operations are not performed. -

Page 44: Turning Off The Power

Installation and preparation 3-3-2. Turning off the power When you need to turn off the power Turn off the power in the following cases. When moving the printer elsewhere. In the event that the power supply interruption is anticipated in advance, including the case where a planned power outage is scheduled. -

Page 45: When There Is No Prospect Of Electric Power Recovery For A While Due To Power Outage

Installation and preparation 3-3-3. When there is no prospect of electric power recovery for a while due to power outage Print head capping will be performed to prevent the print heads from drying out if there is a power failure while the printer is operating and no prospect of recovery for a while. - Page 46 Installation and preparation Place the cap fixing plate stored on the lower right side of the maintenance unit on the frame, and move the carriage toward you until the carriage comes in contact with the cap fixing plate. Cap fixing plate Cap fixing plate Frame <IMPORTANT>...

- Page 47 Installation and preparation Push the carriage in the maintenance direction after the carriage comes in contact with the lever. <IMPORTANT> Make sure that the protrusion on the cap touches the side of the print heads when pressing the carriage in the maintenance direction.

-

Page 48: Connection Between Printer And Pc (For Windows)

Installation and preparation 3-4. Connection between Printer and PC (for Windows) This chapter provides information about installing the GTX-6 Extra Colors ORGR printer driver and connecting the printer to a PC. Proceed with the next step while checking each procedural step. Installing the printer driver "3-4-1. -

Page 49: Installing Printer Driver Onto Your Pc

Installation and preparation 3-4-1. Installing printer driver onto your PC To begin with, on your PC, install the printer driver for file output, "Brother GTX-6 Extra Colors ORGR FileOutput". At this stage, do not connect the printer to the PC yet. -

Page 50: Connecting The Printer To Your Pc Via A Lan Cable: Adding A Printer To Pc

Chapter4 Installation and preparation 3-4-2. Connecting the printer to your PC via a LAN cable: Adding a printer to PC Before connecting via LAN, refer to ☞"7-19. Static IP address setting >>P.255" and set the IP address for the printer. Then, add the printer to your PC according to the procedure specified below. - Page 51 Installation and preparation Select [Add a local printer or network printer with manual settings], then click [Next]. Select the [Create a new port], then select [Standard TCP/IP Port] for [Type of port], and finally click [Next].

- Page 52 Installation and preparation In the [Hostname or IP address] field, enter the already-setup static IP address of the printer, make sure that [Query the printer and automatically select the driver to use] is checked, and click [Next]. (One instance of each value is cited as shown in the window below.) <TIPS>...

- Page 53 In the [Protocol], select the [LPR], enter "BINARY_P1" in [Queue Name] of the [LPR Settings], and click [OK]. When the current screen goes back to the previous screen, click [Next]. (11) When the window below is displayed, select [Brother] for [Manufacturer] and [Brother GTX-6 Extra Colors ORGR] for [Printer] and click [Next].

- Page 54 Installation and preparation (12) After the window shown below appears, select the [Replace the current driver], and click [Next]. (13) Enter [Printer name], and click [Next].

- Page 55 Installation and preparation (14) Then, the specified printer will be added to the system, following which the window shown below appears, select the [Do not share this printer], and click [Next]. (15) Click [Finish]. This exits the setting for the PC. <TIPS>...

-

Page 56: Connection Between Printer And Pc (For Macintosh)

PC. 3-5-1. Installing printer driver onto your PC To begin with, on your PC, install the printer driver for file output, "Brother GTX-6 Extra Colors ORGR FileOutput". At this stage, do not connect the printer to your PC yet. -

Page 57: Connecting The Printer To Your Pc Via A Lan Cable

Installation and preparation 3-5-2. Connecting the printer to your PC via a LAN cable Before connecting via LAN, refer to ☞"7-19. Static IP address setting >>P.255" and set the IP address for the printer. Then, add the printer to your PC according to the procedure specified below. Connect your PC with the printer by means of the LAN cable to make a network connection, and power on the printer. - Page 58 Enter the IP address of the printer for [Address]. Select [Line Printer Daemon - LPD] from [Protocol]. Enter "BINARY_P1" for [Queue]. Enter the printer name for [Name]. Select and click [Select Software…] under [Use]. Select [Brother GTX-6 Extra Colors ORGR] and click [OK]. Click [Add].

- Page 59 Installation and preparation The screen returns to the [Printers and Scanners] screen, and the GTX-6 Extra Colors ORGR printer (LAN) is added. Select GTX-6 Extra Colors ORGR printer under [Default Printer] if necessary. This exits the LAN settings.

-

Page 60: Adjustment

Installation and preparation 3-6. Adjustment Adjust the printer using "GTX-6 Extra Colors ORGR Maintenance". Refer to the operating Menu name Description Things to prepare procedure with GTX-6 Extra Colors ORGR Maintenance [Initial settings after Make settings after print head "3-6-1. Initial settings after ―... -

Page 61: Initial Settings After Head Replacement

Set V-rating after replacing the print head or completing the setup procedure. Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". -

Page 62: Color Adjustments Between Color/Orgr Heads

Make several sheets of A4-size or letter-size white paper available for use. Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". -

Page 63: Firing Adjustment

Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". -

Page 64: Same Color Heads Position Adjustment

Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". -

Page 65: Platen-Rolling Adjustment

Make several sheets of A4-size or letter-size white paper available for use. Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". -

Page 66: White And Color/Orgr Alignment

Prepare a sheet of black paper or a pretreated black or dark color T-shirt. Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". -

Page 67: Setting Of The Time Displayed On The Nozzle Check Pattern

Set the time displayed on the nozzle check pattern. Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". - Page 68 Installation and preparation Perform the required operation by following the on-screen instructions in the dialog box. <CAUTION> Confirm that the date and time of your PC are set correctly, and continue. After the setting is completed, the currently displayed screen will go back to the Main screen.

-

Page 69: Set The Scheduled Time For White Ink Circulation

Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". After the window shown below appears, select [Set the scheduled time for white ink circulation] and click [Next]. - Page 70 Installation and preparation After the next window appears, select [Set the scheduled time for white ink circulation.]. Then, click [Next].

- Page 71 Installation and preparation Set the scheduled time for white ink circulation and click [Next]. <CAUTION> Confirm that the date and time of your PC are set correctly, and continue. Enter at least six start-time settings. Set the white ink circulation interval to be between one hour and six hours. ...

-

Page 72: Humidification Schedule Settings

Make settings when reserving the operation schedule of the humidifier. Make sure that the printer and PC are connected via a LAN cable. On the PC, from [All Programs] in the Start menu, select "GTX-6 Extra Colors ORGR Maintenance" from "Brother GTX-6 Extra Colors ORGR Tools". - Page 73 Installation and preparation After the window shown below appears, click the [Set the scheduled time for humidification]. Then, click [Next].

- Page 74 Installation and preparation Set the start time and end time for humidification and click [Next]. <CAUTION> Confirm that the date and time of your PC are set correctly, and continue. You can enter the start time and end time if you check the day of the week. Humidification will not start or end in time on days that are not checked.

- Page 75 Installation and preparation Select the elapsed time to finish humidification and click [Next].

-

Page 76: Moving The Printer

Installation and preparation 3-7. Moving the printer When moving the printer elsewhere, please contact your dealer. -

Page 77: Creating Print Data

You are recommended to use Brother product applications as far as possible. If you want to use other applications, however, you are recommended to use one of the three recommended applications to achieve high-quality print results. - Page 78 When performing file output, use the printer driver, "Brother GTX-6 Extra Colors ORGR FileOutput". If the file output is performed using the [Print to file] command that is supplied with each application, there may be some cases where the file extension cannot be saved as .arx6/.arx6e or the file destination cannot be specified.

-

Page 79: Sending Print Data Using Brother Gtx-6 Extra Colors Orgr Fileoutput (For Macintosh Only)

The procedure for outputting a file from "Brother GTX-6 Extra Colors ORGR FileOutput" is the same as for a Windows PC. Sending print data Follow the procedure below to send print data to the printer if the print data has been saved using the "Brother GTX-6 Extra Colors ORGR FileOutput" printer. -

Page 80: Using Other Applications

Creating print data 4-3. Using other applications 4-3-1. When using CorelDRAW First of all, perform the following procedures: Color setting Print size As required, perform the following procedures: Create print data (ARX6E/ARX6 file). Use the color palette in Useful Tools. ... - Page 81 If [Printer] is set to "Brother GTX-6 Extra Colors ORGR", the print data will be sent to the printer at the time of printing. If [Printer] is set to "Brother GTX-6 Extra Colors ORGR FileOutput", the print data at the time of printing will be saved as an ARX6E/ARX6 file.

- Page 82 Creating print data Make the following settings in the [Page Size] window: [Size]: [Custom] [Width]: 14.6 in. (370 mm) [Height]: 16.5 in. (420 mm) Page orientation: Portrait <TIPS> Set the width and height to the size of platen to be used. The above size is the standard 14X16 platen size. ・In the case of print data using white ink ☞"4-4-2.

- Page 83 The print data will be sent to the printer if the specified [Printer] is set to "Brother GTX-6 Extra Colors ORGR". If the specified [Printer] is set to "Brother GTX-6 Extra Colors ORGR FileOutput", the print data will be saved as an ARX6E/ARX6 file.

- Page 84 Creating print data When you press [OK] in the [Print] dialog box, the dialog box shown below will be displayed. After that, click [Save]. <TIPS> There may be cases where this saving process takes several minutes. Specify the [Save In] and [File name] first, and then click [Save] to save the ARX6E/ARX6 file to your PC. Use the color palette in Useful Tools.

- Page 85 Creating print data Convert data to bitmap image data In the menu bar, select [Bitmaps] > [Convert To Bitmap]. Set the [Color mode] to [RGB Color]. <TIPS> When the white ink is used for performing the printing, unmark the [Anti-aliasing] checkbox. <TIPS>...

- Page 86 Creating print data Replace RGB=255 in bitmap image data with RGB=254 RGB=255 is identified as a transparent color. To a portion where RGB=255 is contained, no ink will be ejected. In order for the white ink to be printed, select an area for RGB=255, and replace it with RGB=254. To make such replacement, use the method mentioned below.

-

Page 87: When Using Adobe Photoshop

Creating print data 4-3-2. When using Adobe Photoshop In Photoshop, configure the settings mentioned below: Color setting As required, perform the following procedures: Create print data (ARX6E/ARX6 file). Use the color palette in Useful Tools. Replace RGB=255 with RGB=254 <TIPS>... - Page 88 For details of directly sending data to the printer from an application, ☞"5-6-2. Sending print data from applications >>P.164" In the menu bar, select [File] > [Print]. If the PC's default printer is either "Brother GTX-6 Extra Colors ORGR" or "Brother GTX-6 Extra Colors ORGR FileOutput", the layout is set to the platen size.

- Page 89 Creating print data When you press [Print], the dialog box shown below will be displayed on the screen. After that, click [Save]. <TIPS> There may be cases where this saving process takes several minutes. Specify the [Save In] and [File name] first, and then click [Save] to save the ARX6E/ARX6 file to your PC.

- Page 90 Creating print data Use the color palette in Useful Tools. Save the color pallet file for Photoshop, "GT_Colors_T.ase", on your PC, following the instructions on screen. In the menu bar, select [Window] > [Swatches]. Click on to open the submenu. From [Read Swatches], select [Swatch Exchange (*.ASE)] for the type of file and then select the file name [GT_Colors_T.ase].

- Page 91 Creating print data What to do when replacing RGB=255 with RGB=254 RGB=255 is identified as a transparent color. To a portion where RGB=255 is contained, no ink will be ejected. In order for the white ink to be printed, select an area for RGB=255, and replace it with RGB=254. To make such replacement, use the method mentioned below.

-

Page 92: When Using Adobe Illustrator

・Before start-up, specify the PC's default printer as the "Brother GTX-6 Extra Colors ORGR" or the "Brother GTX-6 Extra Colors ORGR FileOutput". ・Use the "Brother GTX-6 Extra Colors ORGR FileOutput" printer driver to output a file, then display and check the print preview. ... - Page 93 Creating print data Color setting In the menu bar, select [Edit] > [Color Settings]. Click on the [More Options]. Ensure selection of the settings as mentioned below, and click [OK]. [Settings]: [Custom] [Working Spaces] [RGB]: [sRGB IEC61966-2.1] [Color Management Policies] ...

- Page 94 Creating print data Open a new file Set up a new document as follows: [Width]: 14.6 in. (370 mm) [Height]: 16.5 in. (420 mm) [Orientation]: Portrait [Color Mode]: [RGB] <TIPS> Set the width and height to the size of platen to be used. The above size is the standard 14×16 platen size. ・In the case of print data using white ink ☞"4-4-2.

- Page 95 For file output, there are some cases where neither file output destination nor extension cannot be specified by the [Print to file] command. Use the printer driver "Brother GTX-6 Extra Colors ORGR FileOutput". For details of directly sending data to the printer from an application, ☞"5-6-2. Sending print data from applications >>P.164"...

- Page 96 If [Printer] is set to "Brother GTX-6 Extra Colors ORGR", the print data will be sent to the printer. If [Printer] is set to "Brother GTX-6 Extra Colors ORGR FileOutput", the print data will be saved as an ARX6E/ARX6 file.

- Page 97 Creating print data Use the color palette in Useful Tools. Save the color pallet file for Illustrator, "GT_Colors_T.ase", on your PC, following the instructions on screen. In the menu bar, select [Window] > [Swatches]. Click on , and select [Open Swatch Library] from the submenu. Select [Other Library].

-

Page 98: Driver Settings For Print Data Using White Ink

Creating print data 4-4. Driver settings for print data using white ink 4-4-1. Setting up the printer driver <TIPS> The GTX-6 Extra Colors ORGR printer driver treats RGB=255 as a "Transparent color" and does not eject the ink. For such an image that you wish to print out in pure white color with white ink, make such a setting as RGB=254. - Page 99 Creating print data In the dialog box for setting the printer driver, configure required settings. If you click on the [Advanced], [White Ink Settings], [Color Processing], [Color Balance] and [Uni-Directional Printing] can be configured. <TIPS> Depending on the settings you have made in the [Select Ink:] option or the like, setup items that appear on the screen vary. ...

-

Page 100: Select The Platen Size

Creating print data 4-4-2. Select the platen size From the pull-down menu of [Platen Size:], select a platen size for print area. <TIPS> The platen size is equivalent to the paper size. Setup item Platen to be used Size [24×24] 24×24 platen 24.0 in. -

Page 101: Selecting Platen Height

Creating print data 4-4-3. Selecting platen height From the pull-down menu of [Platen Height:], select the platen height. When the printer receives print data, the platen automatically changes to the specified platen height. You can select the height from [No designation], [A], [B], [C], [D], [E], [F], [G], and [H]. <TIPS>... -

Page 102: Select The Ink Type

Creating print data 4-4-4. Select the ink type From the [Select Ink:] option, select a combination of inks to be used. Setup item Description [Color+White Ink] This option enables a color image to be printed out on the mask layer of white ink. [White Ink Only] This option enables the white ink only to be used for printing out a monochrome image. -

Page 103: Select The Mode

Creating print data 4-4-5. Select the mode If you set [Mode:] > [White:] to [Eco-Mode], the white ink volume serving as the background is automatically adjusted to reduce the overall ink consumption. For colors, you can set [Vibrant] and [Natural] in [Color:] only when you select [Extra Colors ORGR] in [Ink Selection:]. Setup item Description [Vibrant]... -

Page 104: Select The Resolution

Creating print data 4-4-6. Select the resolution The range that can be set for highlighting will change, and the printing time will also differ, depending on the resolution selected in [Resolution:]. Resolution Resolution Description 1200dpi × 1200dpi Prints at 1200 dpi × 1200 dpi. 1200dpi ×... -

Page 105: Set Up The White Ink

Creating print data 4-4-7. Set up the white ink If you have selected [Color+White Ink] or [White Ink Only] in the [Select Ink:], the setup items for [White Ink Settings:] will appear. Adjust the white ink volume separately in the [Highlight:] (visible white ink volume) and in the [Mask:] (white ink volume to cover the background color). - Page 106 Creating print data Highlight This enables you to select whiteness (thickness) of RGB=254 in such nine levels as [1] to [13]. When you increase this value, the White ink volume will increase. You can specify [10] to [13] only if [2 Layer White] is enabled. Highlight setpoints Ink volume White ink volume 200%...

- Page 107 Creating print data 2 Layer White You can make highlight settings at a level of [1] to [13] when 2 Layer White is enabled. Set 0-60 seconds for the time from the start of printing the first white ink layer to the start of printing the second white ink layer.

-

Page 108: Specify Whether Or Not To Use The Background Black Color

Creating print data 4-4-8. Specify whether or not to use the background black color If you have selected [Color+White Ink] in the [Select Ink:], the setup items of [Use background black color (for black T-shirts only)] will appear. In the event that you wish to print a black T-shirt making use of the T-shirt's background black color, mark the [Use background black color (for black T-shirts only)] checkbox. -

Page 109: Specify Whether Or Not To Perform Multiple Pass Printing

Creating print data 4-4-9. Specify whether or not to perform Multiple Pass Printing The setup items for [Color Multiple Pass Printing] will appear if you have selected the [Color+White Ink], [Color Ink Only], or [Black Ink Only] in the [Select Ink:]. In cases where small and horizontal stripes are noticeable in the print result, mark the [Color Multiple Pass Printing] checkbox. -

Page 110: Set Up The White Ink

Creating print data 4-4-10. Set up the white ink If you have selected [Color+White Ink] or [White Ink Only] in the [Select Ink:], this setting menu will be enabled. When you click on the [Advanced] in the [Printing Preferences] dialog box, the setup items of [White Ink Settings] appear. - Page 111 Creating print data Transparent color With this option, specify a color which is treated as a transparent color without using any color during the printing process. If you want to specify other colors excluding the RGB=255 as "Transparent color", perform the following procedures to make your setting.

- Page 112 Creating print data Minimum white ink volume When printing with [Color+White Ink], the volume of background white color ink for dark or black color ink can be controlled. When printing with [Color+White Ink], you can increase the amount of the white ink volume used as the base in a dark area by specifying a larger value.

-

Page 113: Set Up The Image Quality

Chapter6 Creating print data 4-4-11. Set up the image quality When you click on the [Advanced] in the [Printing Preferences] dialog box, the setup items of [Color Processing] appear. In the [Color Processing] option, you can make settings for [Saturation:], [Brightness:] and [Contrast:]. Make adjustments to increase vividness, brightness and clarity of an image without using any functions of application software. -

Page 114: Set Up The Color Balance

Creating print data 4-4-12. Set up the color balance When you click on the [Advanced] in the [Printing Preferences] dialog box, the setup items of [Color Balance] appear. In the [Color Balance], you can make settings for [Cyan:], [Magenta:], [Yellow:], [Black:], [Green:], and [Orange:]. You can adjust the color in 11 gradations, -5 to +5. - Page 115 Creating print data...

-

Page 116: Specify The Print Direction

Creating print data 4-4-13. Specify the print direction When you click on the [Advanced] in the [Printing Preferences] dialog box, you can make the settings for [Uni-Directional Printing]. <TIPS> What you have specified on the printer's operation panel are prioritized, and this option becomes active only when the print direction specified on the printer side is set to [Auto]. -

Page 117: Driver Settings For Print Data Using Color Ink And Black Ink Only

Creating print data 4-5. Driver settings for print data using color ink and black ink only 4-5-1. Setting up the printer driver <TIPS> The GTX-6 Extra Colors ORGR printer driver treats RGB=255 as a "Transparent color" and does not eject the ink. For such an image that you wish to print out in pure white color with white ink, make such a setting as RGB=254. - Page 118 Creating print data In the dialog box for setting the printer driver, configure required settings. If you click on the [Advanced], [White Ink Settings], [Color Processing], [Color Balance] and [Uni-Directional Printing] can be configured. <TIPS> Depending on the settings you have made in the [Select Ink:] option or the like, setup items that appear on the screen vary. ...

-

Page 119: Select The Platen Size

Creating print data 4-5-2. Select the platen size From the pull-down menu of [Platen Size:], select a platen size for print area. <TIPS> The platen size is equivalent to the paper size. Setup item Platen to be used Size [24×24] 24×24 platen 24.0 in. -

Page 120: Selecting Platen Height

Creating print data 4-5-3. Selecting platen height From the pull-down menu of [Platen Height:], select the platen height. When the printer receives print data, the platen automatically changes to the specified platen height. You can select the height from [No designation], [A], [B], [C], [D], [E], [F], [G], and [H]. <TIPS>... -

Page 121: Select The Ink Type

Creating print data 4-5-4. Select the ink type From the [Select Ink:] option, select a combination of inks to be used. Setup item Description [Color+White Ink] This option enables a color image to be printed out on the mask layer of white ink. [White Ink Only] This option enables the white ink only to be used for printing out a monochrome image. -

Page 122: Specify Whether Or Not To Perform Multiple Pass Printing

Creating print data 4-5-5. Specify whether or not to perform Multiple Pass Printing The setup items for [Color Multiple Pass Printing] will appear if you have selected the [Color+White Ink], [Color Ink Only], or [Black Ink Only] in the [Select Ink:]. In cases where small and horizontal stripes are noticeable in the print result, mark the [Color Multiple Pass Printing] checkbox. -

Page 123: Set Up The Color Ink

Creating print data 4-5-6. Set up the color ink If you have selected [Color Ink Only] or [Black Ink Only] in the [Select Ink:], the setup items of [Color Ink Settings:] will appear. You can make your setting from the [Ink Volume:] or [Double Printing:] option in the [Color Ink Settings:] window. - Page 124 Creating print data Ink volume This enables you to select the ink volume in such ten levels as [1] to [10]. Setup value Description [10] This is the default value. This value corresponds to 100%-cotton fabrics as well as for blended yarn fabrics (hemp 50%/polyester 50% or cotton 50%/polyester 50%).

-

Page 125: Set Up The Image Quality

Creating print data 4-5-7. Set up the image quality When you click on the [Advanced] in the [Printing Preferences] dialog box, the setup items of [Color Processing] appear. In the [Color Processing] option, you can make settings for [Saturation:], [Brightness:] and [Contrast:]. Make adjustments to increase vividness, brightness and clarity of an image without using any functions of application software. -

Page 126: Set Up The Color Balance

Creating print data 4-5-8. Set up the color balance When you click on the [Advanced] in the [Printing Preferences] dialog box, the setup items of [Color Balance] appear. In the [Color Balance], you can make settings for [Cyan:], [Magenta:], [Yellow:], [Black:], [Green:], and [Orange:]. You can adjust the color in 11 gradations, -5 to +5. - Page 127 Creating print data...

-

Page 128: Specify The Print Direction

Creating print data 4-5-9. Specify the print direction When you click on the [Advanced] in the [Printing Preferences] dialog box, you can make the settings for [Uni-Directional Printing]. <TIPS> What you have specified on the printer's operation panel are prioritized, and this option becomes active only when the print direction specified on the printer side is set to [Auto]. -

Page 129: Using Useful Tools

4-6. Using Useful Tools Useful tools and print data are provided for adjusting colors or searching for an appropriate print setting. The "Useful Tools" will be installed onto the subdirectory under the "Brother GTX-6 Extra Colors ORGR Tools" subdirectory on your PC. -

Page 130: Check The Color Sample

Creating print data 4-6-3. Check the color sample Use when checking the color sample. Please use this color chart as a color sample like the one that is commonly provided by an ink maker, for the print data (ARX6 file) you created using your desired printer driver setting. <TIPS>... -

Page 131: Print A Grid Pattern On The Platen Sheet

Creating print data 4-6-4. Print a grid pattern on the platen sheet You can print a grid pattern onto a new platen sheet. Platen sheet Grid Platen X0163 From the "Useful Tools", open such an ARX6 file (for example, Grid14×16.arx6) that has a grid size suitable to the platen size. -

Page 132: Adjust The Ink Volume

Creating print data 4-6-5. Adjust the ink volume Set an optimum setting for [Ink Volume:] of the printer driver. Download the data from "Useful Tools" and perform printing (☞"5. Basic printing procedures >>P.141") to check the blurring beforehand. <TIPS> Appropriate ink volume setting value depends on color or material of the T-shirt. -

Page 133: Print Out Of Highlight Check Pattern/Mask Check Pattern

Creating print data 4-6-6. Print out of highlight check pattern/mask check pattern Set an optimum setting for [Highlight:] of the printer driver. Download the data from "Useful Tools" and print the highlight check pattern for checking whiteness, background hiding level, and blurring beforehand. <TIPS>... -

Page 134: Color Adjustments Between Color/Orgr Heads

Creating print data 4-6-7. Color adjustments between color/ORGR heads Check the color adjustment of the color side and OR/GR side heads. Color adjustment for color side heads From the "Useful Tools", click "COLOR ADJUSTMENT_COLOR.arx6 " to download data. Send the data to the printer and perform printing. Check the print result to make sure the color adjustment has been set correctly. - Page 135 Creating print data Color adjustments to OR/GR side heads From the "Useful Tools", click "COLOR ADJUSTMENT_ORGR.arx6e" to download data. Send the data to the printer and perform printing. Check the print result to make sure the color adjustment has been set correctly. If the adjustment is not good, readjust the print head according to "...

-

Page 136: Check The Ejection Timing

Creating print data 4-6-8. Check the ejection timing Check whether or not the ejection timing is correct. From "Useful Tools", click "FIRING CHK COLOR A.arx6", "FIRING CHK COLOR B.arx6", "FIRING CHK WHITE A.arx6", "FIRING CHK WHITE B.arx6", "FIRING CHK ORGR_A.arx6e" or "FIRING CHK ORGR_B.arx6e" to download data. -

Page 137: Position Adjustment For The 2 Heads Of The Same Color

Creating print data 4-6-9. Position adjustment for the 2 heads of the same color Check the position of the print head. From the "Useful Tools", click "HEAD POSITION ADJUSTMENT_COLOR.arx6", "HEAD POSITION ADJUSTMENT_WHITE.arx6", or "HEAD POSITION ADJUSTMENT_ORGR.arx6e" to download data. Send the data to the printer and perform printing. Check the print result to make sure the position adjustment has been set correctly. -

Page 138: Platen Feed Adjustment

Creating print data 4-6-10. Platen feed adjustment Check whether or not the platen feed adjustment is appropriate. From the "Useful Tools", click "FEEDING PATTERN(1).arx6" to download data. Send the data to the printer and perform printing. Check the print result to make sure the platen feed adjustment has been set correctly. If the adjustment is not good, readjust the print head according to "... -

Page 139: Check The Print Position

Creating print data 4-6-11. Check the print position Alignment of the print position on the white side and color side heads Check the alignment of the print position on the white side and color side heads. From the "Useful Tools", click "ALIGN CHK_COLOR.arx6" to download data. Send the data to the printer and perform printing. - Page 140 Creating print data Alignment of the print position on the white side and OR/GR side heads Check the alignment of the print position on the white side and OR/GR side heads. From the "Useful Tools", click "ALIGN CHK_ORGR.arx6e" to download data. Send the data to the printer and perform printing.

-

Page 141: Basic Printing Procedures

5 Basic printing procedures WARNING If a foreign object gets inside the printer, immediately turn off the power, disconnect the power cord, and contact the place of purchase or a qualified technician. If you continue to use the printer while there is a foreign object inside, it may result in fire or electric shocks or problems with correct operation. - Page 142 Basic printing procedures IMPORTANT Do not move the platen by hand. Otherwise the printer may be mechanically and electrically damaged. Ensure there is adequate space left in front of the printer and avoid placing any objects. The platen may be hit and damaged.

-

Page 143: Basic Printing Process Flow

Basic printing procedures 5-1. Basic printing process flow What are described below are the basic work flows before the start and after the completion of print process. Before starting printing, perform check and preparation tasks on the printer. Tasks to be ☞"5-2. -

Page 144: Tasks To Be Performed Before Starting Print Operation

Basic printing procedures 5-2. Tasks to be performed before starting print operation 5-2-1. Confirmation of Water Supply Tank Before starting the work, check that the water supply tank has water in it. -

Page 145: Pretreating Process For Print Medium

Be sure to wear a pair of plastic gloves, a mask and protective glasses during the work operation. For information on handling of the pretreatment, see the Material Safety Data Sheet issued by us. http://sds.brother.co.jp/sdsapp/index.html Pretreatment It refers to distilled water, purified water, etc. which is used to dilute the pretreatment with it. - Page 146 For information on handling of the pretreatment, see the Material Safety Data Sheet issued by us. http://sds.brother.co.jp/sdsapp/index.html <IMPORTANT> If you are using an electric spray to apply the pretreatment, perform the work at a place as far as possible from the printer.

-

Page 147: Dilution Of Pretreatment

Be sure to wear a pair of plastic gloves and protective glasses during the work operation. For information on handling of the pretreatment, see the Material Safety Data Sheet issued by us. http://sds.brother.co.jp/sdsapp/index.html Dilution ratio Use within the ratio range of x3 (Pretreatment:Pure water=1:2) (Volume ratio). - Page 148 Basic printing procedures Orient the pour spout of faucet in the position as shown in the figure below. Faucet Pretreatment X0081 Pour the pretreatment with the carton into the container for dilution and dilute the pretreatment with pure water. <IMPORTANT> ...

-

Page 149: Application Of Pretreatment

For information on handling of the pretreatment, see the Material Safety Data Sheet issued by us. http://sds.brother.co.jp/sdsapp/index.html <IMPORTANT> Some T-shirts may leave distinct imprints of the pretreatment after it is fixated. Wash away any imprint of the pretreatment with water, if any. - Page 150 Basic printing procedures For coating with a pretreatment applicator (commercial product: preferably of an electrically-operated type) Fill the pretreatment applicator with the diluted pretreatment. <TIPS> Please use a pretreatment applicator (preferably of an electrically-operated type) that can emit fine spray. Set the T-shirt on the pretreatment applicator, and apply the pretreatment evenly onto the print surface.

- Page 151 For information on handling of the pretreatment, see the Material Safety Data Sheet issued by us. http://sds.brother.co.jp/sdsapp/index.html <IMPORTANT> If you are using an electric spray to apply the pretreatment, perform the work at a place as far as possible from the printer.

-

Page 152: Fixation Of Pretreatment

For information on handling of the pretreatment, see the Material Safety Data Sheet issued by us. http://sds.brother.co.jp/sdsapp/index.html <TIPS> Because the pretreatment will not work best if it is dried through oven-based drying or air drying, be sure to use the heat press. - Page 153 Basic printing procedures Place the silicone foam, T-shirt and peel-off sheet in position under the heat press first, and fixate the pretreatment properly. <TIPS> Water droplets are generated around the heat press to evaporate water content of the pretreatment by the heat of heat press.

-

Page 154: Platen Adjustment

Basic printing procedures 5-4. Platen adjustment Replace the currently used platen with another one that suits the medium to be printed. <CAUTION> Hold the platen with both hands and be careful not to drop the platen at the time of platen replacement. <TIPS>... - Page 155 Basic printing procedures Remove the platen moving it straight upwards by holding both ends of it. Platen Put another platen to be used in position directly from above. Platen Tighten the platen fixing handle. <TIPS> Place the platen fixing handle sideways so that the platen fixing handle will not come in contact when setting the platen or T-shirt.

-

Page 156: Platen Height Adjustment

Basic printing procedures 5-4-2. Platen height adjustment Select a proper position of the platen corresponding to the print medium. Select [Platen Height Adjustment] from the menu, and select an appropriate position from [Position A] to [Position <IMPORTANT> Do not handle the platen while printing. Injury may result if your hand gets caught between the platen or T-shirt tray and a door or cover. -

Page 157: Placing Print Medium In Position

Basic printing procedures 5-5. Placing print medium in position In order to provide an optimum printing image quality when a print medium is placed in position, you need to adjust the platen's height in accordance with the thickness of the T-shirt or other print medium. <CAUTION>... - Page 158 For the position alignment of white or pale-colored T-shirts, a grid to be printed out on the platen sheet is available from [All Programs] in the Start menu by selecting "Brother GTX-6 Extra Colors ORGR Tools" > "Useful Tools". ☞"4-6-4. Print a grid pattern on the platen sheet >>P.131"...

- Page 159 Basic printing procedures The T-shirt should be placed on the T-shirt tray, trying not to draw the excessive parts like sleeves and hems into the printer. T-shirt T-shirt tray X1042 On the operation panel, press , and move the platen toward the rear of the printer. Try moving the platen, and check on the gap between the T-shirt surface and the obstacle sensor over the entire print area.

-

Page 160: Sending/Loading Print Data

Double click on the ARX6E/ARX6 file, or select [All Programs] in the Start menu > "Brother GTX-6 Extra Colors ORGR Tools" > "GTX-6 Extra Colors ORGR File Viewer", to select and open the ARX6E/ARX6 file. You can also load ARXP and ARX4 files. - Page 161 Basic printing procedures • When [Color Ink Only] is selected • [Details]...

- Page 162 Basic printing procedures If you have selected [Color+White Ink] or [White Ink Only] in the Select Ink operation, you can change the background color of the preview window and preview the print image. Select [Change...] > [Define Custom Colors], and enter RGB value. <TIPS>...

- Page 163 Basic printing procedures For the print data that requires multiple cycles of platen reciprocate movement, print data of each layer can be verified separately by selecting the desired layer to be displayed. From the [Present Layer], select a layer that you want to bring into the view.

-

Page 164: Sending Print Data From Applications

The print data will be sent to the printer if the specified [Printer] is set to "Brother GTX-6 Extra Colors ORGR". If the specified [Printer] is set to "Brother GTX-6 Extra Colors ORGR FileOutput", the print data will be saved as an ARX6E/ARX6 file. - Page 165 Basic printing procedures Adobe Photoshop In the menu bar, select [File] > [Print]. If the PC's default printer is either "Brother GTX-6 Extra Colors ORGR" or "Brother GTX-6 Extra Colors ORGR FileOutput", the layout is set to the platen size.

- Page 166 If [Printer] is set to "Brother GTX-6 Extra Colors ORGR", the print data will be sent to the printer. If [Printer] is set to "Brother GTX-6 Extra Colors ORGR FileOutput", the print data will be saved as an ARX6E/ARX6 file.

-

Page 167: Loading Print Data (Arx6E/Arx6 File) From Usb Flash Memory

Basic printing procedures 5-6-3. Loading print data (ARX6E/ARX6 file) from USB flash memory Insert a USB flash memory into the insertion slot in front of the operation panel of the printer. <IMPORTANT> Do not apply undue force to the USB flash memory when you insert it into the slot. Otherwise, it could be damaged. <TIPS>... - Page 168 Basic printing procedures Check the print image displayed in the preview window, and press <IMPORTANT> Never touch the USB flash memory when the print button is blinking. Otherwise, any already-saved data may be corrupted. <TIPS> Depending on data size, it may take several minutes before the loading process is completed. ...

-

Page 169: Executing A Printing Job

Basic printing procedures 5-7. Executing a printing job 5-7-1. Executing a print job once for a single print medium Receiving a print data file. The print button blinks during reception of data. When the data reception is completed, an audible alarm is activated and the print button illuminates. -

Page 170: Executing A Print Job Several Times For Multiple Print Media

Basic printing procedures 5-7-2. Executing a print job several times for multiple print media You can keep the identical print data and execute a print job several times for multiple print media. <TIPS> When the power is turned off, the retained print data is erased. Make sure that the print data you want to print out is displayed on the liquid crystal panel, and press and hold the two print buttons at the same time to start printing. -

Page 171: Performing The Printing From Receiving History

Basic printing procedures 5-7-3. Performing the printing from receiving history You can print out such print data that you have received before. <TIPS> The print data that can be retained are max. 100 pieces of them and 800 MB in total capacity, wherein each print data will be erased in the order from the oldest to the latest. -

Page 172: Scheduling A Print

Basic printing procedures 5-8. Scheduling a print Even if the printer is not in the standby state, this function allows you to schedule printing by pressing the Print button in advance so that the printer will start printing as soon as it becomes available. 5-8-1. -

Page 173: Removing Printed Matter From Platen

Basic printing procedures 5-9. Removing printed matter from platen Hold the shoulder portions of print medium with your hand, and pull it out slowly in the forward direction indicated. <IMPORTANT> Because the printed surface is still wet with ink, avoid touching it. ... -

Page 174: Fixation Of Ink

Basic printing procedures 5-10. Fixation of ink For fixation of ink, use the heat press or oven. Heat press It is useful because you can control its temperature and operating time with ease. Oven If the number of articles to be printed is high, it will improve the operational efficiency. <CAUTION>... - Page 175 Basic printing procedures Ink fixation by means of heat press Place the silicone foam, T-shirt and peel-off sheet in position under the heat press first, and fixate the ink properly. <TIPS> For the guidelines on fixation conditions of ink, ☞"5-10. Fixation of ink >>P.174" ...

-

Page 176: Precautions To Keep Good Printing Quality/Use Printer Over The Long Term

Keep the liquids out of the reach of children. When replacing parts and installing optional accessories, be sure to use only genuine Brother parts. Brother will not be held responsible for any accidents or problems resulting from the use of non-genuine parts. -

Page 177: Tasks To Be Performed Regularly

Precautions to keep good printing quality/use printer over the long term 6-1. Tasks to be performed regularly 6-1-1. Refilling color ink is displayed in the remaining ink volume indication window on the operation panel screen, refill the ink. <CAUTION> Be sure to wear a pair of plastic gloves and protective glasses during the work operation. - Page 178 Precautions to keep good printing quality/use printer over the long term Open the ink bottle and attach the supplied faucet. <IMPORTANT> Protect the ink on the faucet in use with a plastic bag to prevent the ink from drying out. ...

-

Page 179: Refilling White Ink

Precautions to keep good printing quality/use printer over the long term 6-1-2. Refilling white ink is displayed in the remaining ink volume indication window on the operation panel screen, refill the ink. Agitate the white ink sufficiently to remove sediments before refilling it. Agitate the ink beforehand because it takes time. <IMPORTANT>... - Page 180 Precautions to keep good printing quality/use printer over the long term Hold the ink bottle upside down and apply lighting to its side face to visually check sediments. A dark shadow is seen on the bottom if sediments are remaining, so repeat steps (1) and (2) until such a dark shadow disappears.

- Page 181 Precautions to keep good printing quality/use printer over the long term How to refill white ink × Error Ink refill: White From the menu, select [Ink refill] and press Select [White] and press Insert the white IC stick and press <TIPS>...

- Page 182 Precautions to keep good printing quality/use printer over the long term Open the ink bottle and attach the supplied faucet. <IMPORTANT> Protect the ink on the faucet in use with a plastic bag to prevent the ink from drying out. ...

-

Page 183: Refilling The Cleaning Solution

Precautions to keep good printing quality/use printer over the long term 6-1-3. Refilling the cleaning solution is displayed in the remaining ink volume indication window on the operation panel screen, refill the ink. <CAUTION> Be sure to wear a pair of plastic gloves and protective glasses while working. <TIPS>... - Page 184 Precautions to keep good printing quality/use printer over the long term Open the cleaning solution tank lid and fill the tank with the cleaning solution up to above graduation mark 6. <IMPORTANT> Take care not to exceed graduation mark 6. Cleaning solution tank X1107 Press...

-

Page 185: Correcting The Remaining Ink Level

Precautions to keep good printing quality/use printer over the long term 6-1-4. Correcting the remaining ink level When a warning message appears in the warning message window, correct the remaining ink level. WARNING Tank correction timing From the menu, select [Maintenance] > [Correct tank volume sensor], and press Press . -

Page 186: Replacement Of Maintenance Parts

Precautions to keep good printing quality/use printer over the long term 6-1-5. Replacement of maintenance parts When a warning message appears on the operation panel screen, replace each maintenance part. WARNING Replace wiper Replace cap foam Replace flushing foam Replace carriage foam <TIPS>... -

Page 187: Replacing The Wiper

Precautions to keep good printing quality/use printer over the long term 6-1-6. Replacing the wiper When a warning message appears on the operation panel screen, conduct replacement work. <TIPS> Once you have selected [Maintenance Part Clean/Replace], you do not need to select it repeatedly in the case of replacing the wiper, flushing foam, cap tip, cap foam, and carriage foam in sequence. - Page 188 Precautions to keep good printing quality/use printer over the long term Hold the latch of the new wiper on the left-hand side and insert the new wiper into the maintenance unit from the right-hand side. <IMPORTANT> Replace the wipers of the six locations at the same time. ...

-

Page 189: Replacing The Cap Chip And Cap Foam

Precautions to keep good printing quality/use printer over the long term 6-1-7. Replacing the cap chip and cap foam When a warning message appears on the operation panel screen, conduct replacement work. <TIPS> Once you have selected [Maintenance Part Clean/Replace], you do not need to select it repeatedly in the case of replacing the wiper, flushing foam, cap tip, cap foam, and carriage foam in sequence. - Page 190 Precautions to keep good printing quality/use printer over the long term Remove the cap chip and cap foam from the maintenance unit. <CAUTION> Do not use sharp objects, such as tweezers, and be sure to remove the cap chip and cap foam by hand. Cap foam Cap chip Wipe the gloves with a waste cloth.

- Page 191 Precautions to keep good printing quality/use printer over the long term <CAUTION> Set the cap foam by aligning the cap foam hole with the protrusion on the backside of the cap rubber. Be careful not to reverse the orientation of the cap foam. ...

-

Page 192: Replacing The Flushing Foam

Precautions to keep good printing quality/use printer over the long term 6-1-8. Replacing the flushing foam When a warning message appears on the operation panel screen or in the warning message window, replace the specified flushing foam with a new one. <TIPS>... - Page 193 Precautions to keep good printing quality/use printer over the long term Remove the flushing foam from the maintenance unit. <IMPORTANT> Ink droplets will drop off from the hole in flushing foam. After removal, apply a waste cloth to the bottom face. <NOTE>...

- Page 194 Precautions to keep good printing quality/use printer over the long term Set the flushing foam in the maintenance unit. <IMPORTANT> After this assembly process is completed, make sure that no flushing foam extends off the outboard end portions of the maintenance unit.

-

Page 195: Replacing The Carriage Foam

Precautions to keep good printing quality/use printer over the long term 6-1-9. Replacing the carriage foam When a warning message appears in the warning message window, replace the specified carriage foam with a new one. <TIPS> Once you have selected [Maintenance Part Clean/Replace], you do not need to select it repeatedly in the case of replacing the wiper, flushing foam, and carriage foam in sequence. - Page 196 Precautions to keep good printing quality/use printer over the long term Pull and remove the carriage foam toward you along the sliding surface of the foam guide after making sure that the carriage foam is in contact with the surface of the foam guide. Carriage foam Put a proper amount of cleaning solution into the cleaning cup.

- Page 197 Precautions to keep good printing quality/use printer over the long term Clean the side of the print heads. <TIPS> The use of a flashlight is recommended to make it easier to see when cleaning. It is not easy to see the rearward side of the nozzle guard. It is recommended to clean it while checking the cleaning condition with a mirror.

- Page 198 Precautions to keep good printing quality/use printer over the long term Head frontward and rearward cleaning X1049 (10) Remove ink clots, if any, protruding from the nozzle surface on the underside of the carriage. Nozzle surface...

- Page 199 Precautions to keep good printing quality/use printer over the long term Ink clot example <CAUTION> When removing ink clots, do not use hard objects like iron tweezers. The nozzle may be damaged, resulting in non-ejection if the objects touch the nozzle or other parts. Use gloves and remove ink clots by pinching them with a clean stick or your fingers.

- Page 200 Precautions to keep good printing quality/use printer over the long term <CAUTION> Be sure to use a clean waste cloth. Using a waste cloth with pretreatment may lead to non-ejection. Do not rub the parts strongly. Doing so may damage the parts. ...

- Page 201 Precautions to keep good printing quality/use printer over the long term (12) Place the tip of the new carriage foam on the sliding surface of the foam guide. (13) Move the foam along the sliding surface of the guide in the direction of the arrow, and move the carriage foam until it touches the two foam pads.

- Page 202 Precautions to keep good printing quality/use printer over the long term (14) Rotate and assemble the foam to the magnet on the carriage. Make sure that the carriage foam does not ride on the four foam pads. <IMPORTANT> Be careful not to let the carriage foam come into contact with the nozzle surface of the head. Foam pad Make sure that the nozzle surface is below the bottom surface of the foam.

-

Page 203: Replacing The Mist Fan Filter

Precautions to keep good printing quality/use printer over the long term 6-1-10. Replacing the mist fan filter When a warning message appears in the warning message window, replace the mist fan filter with a new one. The inside of the main unit may become dirty with mist, which may cause a malfunction if you continue using the mist fan filter without replacement. - Page 204 Precautions to keep good printing quality/use printer over the long term Hold the grip and remove the mist fan filter. Mist fan filter Insert a new mist fan filter and push in and close the mist fan door. <CAUTION> Insert the mist fan filter completely, on the side with the grip facing upward.

-

Page 205: Replacing The Platen Sheet

Precautions to keep good printing quality/use printer over the long term 6-1-11. Replacing the platen sheet When the platen sheet gets soiled, replace it with a new one. Remove the platen from the main unit of the printer. ☞"5-4-1. Replacing the currently used platen with another one >>P.154"... - Page 206 Precautions to keep good printing quality/use printer over the long term Position the platen sheet to match the platen surface, and onto the platen, stick the portion of the platen sheet where the release paper (small) was removed. Positioning Platen sheet Platen X1029 Peel off the rest of the release paper, and paste the whole platen sheet onto the entire platen.

-

Page 207: Replacement Of Print Head

Precautions to keep good printing quality/use printer over the long term 6-1-12. Replacement of print head If a problem of non-ejection of ink-jet droplets is not cleared even after cleaning the head nozzle, replace a The print head with a new one. Check the head position of the corresponding print head with the non-ejection of ink-jet droplets in the nozzle check pattern, and replace the print head by following the procedure. - Page 208 Precautions to keep good printing quality/use printer over the long term Remove the upper case of a new print head. Remove the caps from the new print head. <TIPS> Remove all the four caps when replacing a color or white side print head. When replacing an OR/GR side print head, remove the two caps 1·5 and 2·6 on top of the head cover.

- Page 209 Precautions to keep good printing quality/use printer over the long term Remove the head board of the corresponding print head. <CAUTION> Be sure not to touch other boards. Head board Head board Head board Remove the hook and clamp and disconnect the flat cable. Flat cable Clamp Hook...

- Page 210 Precautions to keep good printing quality/use printer over the long term (12) Mount the new print head onto the carriage and push in the lock bar of the print head to lock the print head. <IMPORTANT> Be careful not to pinch the flat cable between the metal plate of the print head and the carriage. ...

- Page 211 Precautions to keep good printing quality/use printer over the long term (15) Close the carriage board cover. <IMPORTANT> Make sure that the latch is securely closed. Ensure that the flat cables do not extend past the edge of the cover. <CAUTION>...

- Page 212 Precautions to keep good printing quality/use printer over the long term (19) From the menu, select the corresponding head under [Maintenance] > [Install Ink after Replacing Head] and press Perform the work operation by following the on-screen instructions. <TIPS> After the procedures are completed, the current screen will go back to the standby mode screen.

-

Page 213: Cover Adjustments

Precautions to keep good printing quality/use printer over the long term 6-1-13. Cover adjustments Adjust each cover if they do not close smoothly. Upper left side cover Lower left side cover Upper right side cover Tilt adjustments Turn the adjustment screw on the front side clockwise or counterclockwise to make adjustments if a cover is tilted. Turn the adjustment screw clockwise to lower the cover and counterclockwise to raise the cover. - Page 214 Precautions to keep good printing quality/use printer over the long term Left/right adjustments Turn the adjustment screw on the front side clockwise or counterclockwise to make adjustments if the cover interferes with the adjacent cover. Turn the adjustment screw clockwise to reduce the clearance and counterclockwise to increase the clearance.

- Page 215 Precautions to keep good printing quality/use printer over the long term Back/Forth adjustments Turn the adjustment screw On the inside clockwise to make back and forth adjustments. Hinge Adjustment screw...

-

Page 216: Tube Air Bleed

Precautions to keep good printing quality/use printer over the long term 6-1-14. Tube air bleed If air is mixed in the print head or tube and ink non-ejection is not improved, bleed the air in the tube. While the printer is in standby mode, press on the operation panel to bring the menu screen into view. -

Page 217: Head Cleaning

Precautions to keep good printing quality/use printer over the long term 6-1-15. Head cleaning This printer has been designed to perform the Auto Cleaning every time 72 print jobs are printed after the previous Auto Cleaning, or before starting the printing using the white ink when one hour or more elapses after the previous printing that used the white ink. - Page 218 Precautions to keep good printing quality/use printer over the long term By pressing , select [All Colors], [All OR/GR], [All Whites], or [All Print Heads], and press <TIPS> Under the condition that the nozzle which has been confirmed not ejecting ink-jet droplets, determine the color for which the head cleaning should be performed.

-

Page 219: White Ink Circulation

Precautions to keep good printing quality/use printer over the long term 6-1-16. White ink circulation When whiteness is not enough, it may be solved by performing white ink circulation. While the printer is in standby mode, press on the operation panel to bring the menu screen into view. From the menu, select [Maintenance] >... -

Page 220: Print Out The Nozzle Check Pattern (Checking On The Print Heads)

Precautions to keep good printing quality/use printer over the long term 6-1-17. Print out the nozzle check pattern (checking on the print heads) By printing out a nozzle check pattern, you can check on the printing quality. It is recommended to always perform this procedure to verify the output. <TIPS>... - Page 221 Precautions to keep good printing quality/use printer over the long term From the menu, select [Test Print] > [Nozzle Check White], and press and hold the two print buttons simultaneously. Then, printing will begin. <TIPS> You will hear a sound each time you press the print buttons and after a certain period has lapsed. Keep pressing them until the second sound is heard.

- Page 222 Precautions to keep good printing quality/use printer over the long term Check to see if the printed results of all nozzles are acceptable, and if no ink-jet droplets have been ejected, perform a head cleaning for print heads. ☞"6-1-15. Head cleaning >>P.217" <IMPORTANT>...

-

Page 223: Cleaning

Precautions to keep good printing quality/use printer over the long term 6-2. Cleaning 6-2-1. Cleaning the nozzle guard and suction cap When a warning message appears in the warning message window, perform the cleaning. In the event that maintenance has been performed inadequately, a printed material may be soiled with waste ink during a print session or a printed surface quality may deteriorate. - Page 224 Precautions to keep good printing quality/use printer over the long term Unlock the upper left-hand-side cover and top cover and clean the suction cap. Unlock and open the right-hand-side cover and clean the nozzle guard. Two types of clean sticks are provided. Use either the clean stick T or R depending on what you want to clean. <TIPS>...

- Page 225 Precautions to keep good printing quality/use printer over the long term The nozzle guard and suction cap should be cleaned separately for the white side and color side. For the way to perform cleaning, refer to the respective items. Perform cleaning of the white side. Prepare a new clean stick R and the cleaning solution.

- Page 226 Precautions to keep good printing quality/use printer over the long term Cleaning the nozzle guard (Use clean stick R) Put a proper amount of cleaning solution into the cleaning cup. Moisten a new clean stick R with the cleaning solution. <IMPORTANT>...

- Page 227 Precautions to keep good printing quality/use printer over the long term Wipe the area between the print head's nozzle surface and nozzle guard. <IMPORTANT> Be sure not to touch the red-frame zone of the nozzle surface. For cleaning, be sure not to use any tool other than clean stick R. ...

- Page 228 Precautions to keep good printing quality/use printer over the long term Remove ink clots, if any, protruding from the nozzle surface on the underside of the carriage. Nozzle surface Ink clot example <CAUTION> When removing ink clots, do not use hard objects like iron tweezers. The nozzle may be damaged, resulting in non-ejection if the objects touch the nozzle or other parts.

- Page 229 Precautions to keep good printing quality/use printer over the long term Cleaning suction cap (Use clean stick T) Wipe the lip of the suction cap in parallel with the side surface of the tip of clean stick T, and then wipe the outer frame in the same way.

- Page 230 Precautions to keep good printing quality/use printer over the long term Cleaning conditions Pre-cleaning state Post-cleaning state...

- Page 231 Precautions to keep good printing quality/use printer over the long term Cleaning the backside of the carriage Clean the area shown below on the backside of the carriage. Cleaning location Use the clean stick R or waste cloth to clean the area. Wipe off the adhered mist ink with a Absorb ink droplets with the clean stick R waste cloth...

- Page 232 Precautions to keep good printing quality/use printer over the long term Cleaning ink droplets Pre-cleaning state Post-cleaning state Mist-state ink Pre-cleaning state Post-cleaning state...

-

Page 233: Cleaning And Replacing Maintenance Parts

Precautions to keep good printing quality/use printer over the long term 6-2-2. Cleaning and replacing maintenance parts Clean the maintenance area, if it is dirty, when replacing the flushing foam. Prepare a waste cloth. <IMPORTANT> Please complete the task within 25 minutes, in order to prevent the print heads from drying up. ... -

Page 234: Cleaning The Surrounding Area Of Nozzle Surface

Precautions to keep good printing quality/use printer over the long term 6-2-3. Cleaning the surrounding area of nozzle surface Make the clean stick R, cleaning cup, gloves and cleaning solution, which come standard with the printer, available for use. <IMPORTANT> ... - Page 235 Precautions to keep good printing quality/use printer over the long term Put a proper amount of cleaning solution into the cleaning cup. Moisten a clean stick R with the cleaning solution. <IMPORTANT> Be sure to use a different clean stick R separately for the color head and the white head. Use a new clean stick R when you start cleaning.

- Page 236 Precautions to keep good printing quality/use printer over the long term With a clean stick R, clean the surrounding area of nozzle surface of print head. <IMPORTANT> Be sure not to bring the clean stick R into contact with the nozzle surface. ...

-