Omron LD-250 Assembly Instructions Manual

Mobile robot

Hide thumbs

Also See for LD-250:

- User manual (207 pages) ,

- Technical manual (28 pages) ,

- Manual (12 pages)

Summary of Contents for Omron LD-250

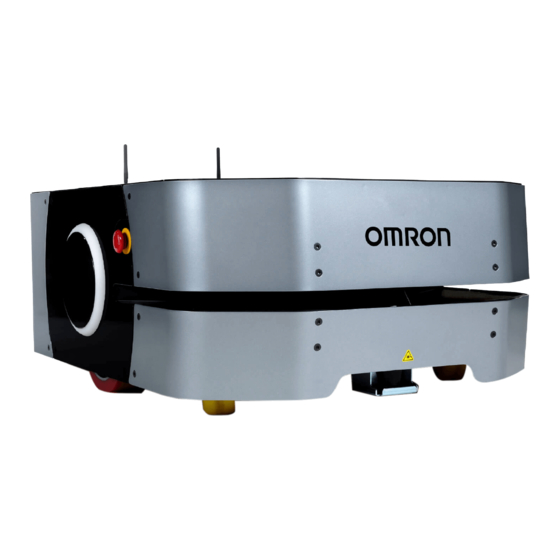

- Page 1 Mobile Robot LD-250 Assembly Instructions According to Machinery Directive 2006/42/EC (ANNEX VI)

-

Page 2: Table Of Contents

Battery Safety LD-250 Modifications Additional Safety Information Disposal 3.10 Risk Assessment 3.11 EHSRs fulfilled 3.12 PL and PFH 3.13 E-Stop Operational Considerations SENSORS Lasers Rear Sensor Other Sensors PAYLOAD STRUCTURES Mobile Robot LD-250 Assembly Instructions, Rev. A Page 2 of 77... - Page 3 Payload-Related Trade-offs Connections Between LD-250 and Payload Structure CONNECTIVITY Connections Required for Set Up Payload Bay Connections – LD-250 Core TECHNICAL SPECIFICATIONS Dimension Drawings LD-250 Specifications Docking Station Specification Mobile Robot LD-250 Assembly Instructions, Rev. A Page 3 of 77...

-

Page 4: Copyright Notice

Copyright Notice The information contained herein is the property of OMRON, and shall not be reproduced in whole or in part without a prior written approval of OMRON. The information herein is subject to change without notice and should not be construed as a commitment by OMRON. - Page 5 ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY. Further, in no event shall liability of Omron Companies exceed the individual price of the Product on which liability is asserted. 1.1.3 Suitability of Use.

- Page 6 Omron’s representative at any time to confirm actual specifications of purchased Product. 1.1.7 Errors and Omissions Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

- Page 7 Light-duty mobile robot, 250 kg max payload Performance Level as per EN ISO 13849-1 Required Performance Level as per EN ISO 13849-1 Achieved Performance Level as per EN ISO 13849-1 Mobile Robot LD-250 Assembly Instructions, Rev. A Page 7 of 77...

- Page 8 Risk assessment Overall process comprising risk analysis and risk evaluation Function of the machine whose failure can result in an Safety Function immediate increase of the risk(s) Mobile Robot LD-250 Assembly Instructions, Rev. A Page 8 of 77...

-

Page 9: Introduction

• Fleet - Two or more AMRs operating in the same workspace. • LD-250 - This is the model name of the platform. This document uses the model name LD-250 when describing the setup, configuration, and connections. • Mobile Robot - An alternate industry term for AMR. -

Page 10: Product Description

Additionally, it uses data from the following sensors: • A low front (or toe) laser to detect objects below the plane of the main laser. • A rear sensor that detects and stops the LD-250 if it senses objects close behind the AMR. - Page 11 LD-250 users typically add attachments (a payload structure) to the LD-250 base platform to customize it for use in specific applications. The LD-250 provides a payload bay that includes aluminum extruded load bars. T-slots in the load bars provide a strong and adaptable method of attaching payload structures to the Platform.

- Page 12 Figure 1: Drive Assembly in LD-250 (skins removed) 2.3.1.2 What's Included - Basic Components • One fully assembled LD-250 model platform that includes the following: o OMRON OS32C Safety and Navigation Laser (main laser). o Low Front Laser. o Rear sensor.

- Page 13 • A USB flash drive containing software and documentation. • In addition to the items included with every LD-250, you need at least one pendant per robot fleet. Use this pendant to manually drive the LD-250 and to create a digitized map of the work environment.

-

Page 14: Related Manuals

These assembly instructions cover safety-related aspects of the LD mobile robot, as a partly completed machinery. There are additional manuals that cover related topics. The following manuals provide information on general safety, related products, advanced configurations and system specifications. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 14 of 77... -

Page 15: Safety

• Floor—Clean and dry floors that you sweep regularly and routinely keep free of debris, dust, and liquids. • Typical Inclines—The LD-250 is intended to operate in a workspace that has a mostly flat floor. If the workspace includes inclined areas, OMRON recommends a gentle incline typical of wheelchair ramps. -

Page 16: Non-Intended Use

The battery has exceeded its temperature limits and the LD-250 will shut down immediately. • The LD-250 has an ingress protection rating of IP20 and is not liquid-proof. Keep floors dry because liquids might get into the AMR. Damp, dusty, or greasy floors might also cause its drive wheels to slip or skid. -

Page 17: User's Responsibilities

• Do not exceed the maximum recommended speed, acceleration, deceleration, or rotation limits. See Center of Gravity (CG) on page 86 (LD-250 Platform User’s Guide, Mobile Robot LD-250 Assembly Instructions, Rev. A Page 17 of 77... - Page 18 • Do not use unauthorized parts to repair the AMR. • Do not power on the AMR without its wireless antennas in place. • Although the lasers used are Class 1 (eye-safe), OMRON recommends that you not look into the laser light.

- Page 19 AMR's interior. 3.4.1.3 Magnetic Field Hazards The docking funnel creates a strong magnetic field. This component is located on the underside of the LD-250. Persons with medical implants should not approach the docking funnel. Mobile Robot LD-250 Assembly Instructions, Rev. A...

- Page 20 3.4.1.6 Configurable Warning Buzzer The LD-250 has a configurable warning buzzer. Configure this buzzer as appropriate for the facility in which the AMR operates. By default, the buzzer sounds when the AMR is moving in any direction other than forward motion.

- Page 21 • Dynamic X, Y, position and heading (velocity and direction of travel) of the AMR. • AMR size (including payload structure). • Path planning information (the individual AMR's intended route). Mobile Robot LD-250 Assembly Instructions, Rev. A Page 21 of 77...

-

Page 22: Environment

3.5.1.2 Public Access The LD-250 is designed to operate in indoor industrial environments. You must deploy it only in applications where you anticipate and mitigate potential risks to personnel and equipment. - Page 23 OMRON does not intend the LD-250 for use in uncontrolled areas without risk analysis. For example, in areas open to general public access. Use of the LD-250 in such areas requires that you deploy additional safety measures not described in this guide. For assistance, contact your local OMRON Support.

-

Page 24: Battery Safety

• The LD-250 provides active warning features such as a warning buzzer, speech synthesis, and warning indicator lights. • The LD-250 Core provides user ports that enable you to add warning indicators to your payload structure. Refer to: Indications Provided by Light Discs Light Outputs on page 127 (LD-250 Platform User’s Guide, Rev-B). -

Page 25: Ld-250 Modifications

Contact your local OMRON Support for other sources of safety information. 3.8.1.1 Mobile Robot LD Safety Guide The Mobile Robot LD Safety Guide is included with your LD-250 and provides detailed information about safe operation of your LD-250. It also provides resources for information about relevant standards. -

Page 26: Disposal

Safeguards must comply with all applicable local and national standards for the location where the AMR is installed. We have performed a Risk Assessment for OMRON AMRs, based on the intended applications of the AMR. The conclusions are summarized in this section. -

Page 27: Ehsrs Fulfilled

The AMR has a dual-channel, safety-rated laser to avoid obstacles. IMPORTANT: The AMR observes safety navigation laser protection fields only at speeds greater than 225 mm/s for LD-250. Below this speed, the AMR still uses scanner data to detect and avoid obstacles. -

Page 28: And Pfh

Machinery maintenance 3.12 PL and PFH The Performance Level (PL) calculation for safety functions of the OMRON mobile robot products are based on the ISO 13849 standard. PL evaluation has been performed for the LD models, including the supplied pendant. -

Page 29: E-Stop Operational Considerations

E-Stop. Motor re-engagement occurs because the LD-250 Core is designed to receive a consistent E-Stop signal for at least 250 ms. Signals that engage and disengage in under 250 ms cause the LD-250 Core to interpret the signal as a bumper press, which automatically re-engages the motors. - Page 30 Figure 2: Estop Circuit Mobile Robot LD-250 Assembly Instructions, Rev. A Page 30 of 77...

- Page 31 Mobile Robot LD-250 Assembly Instructions, Rev. A Page 31 of 77...

-

Page 32: Sensors

Sensors Lasers The LD-250 uses an on-board laser for navigation and safety. A second low front laser detects obstacles that are too close to the ground for the main laser to detect. An optional rear-facing laser is also available. Figure 3:LD-250 lasers 4.1.1 Safety Scanning Laser... -

Page 33: Rear Sensor

LD-250 can plan paths to avoid these objects. 4.1.3 Low Front Laser The low front laser [Figure3(B)] detects obstacles below the scanning plane of the safety laser, such as an empty pallet or a human foot. This laser also detects obstacles that might be significantly wider at the base, such as a column base, where the main safety laser might detect only the upper portion of the column. - Page 34 4.2.1 Rear Sensor Operational Considerations The figure below is a top-down view of the LD-250 showing the approximate locations of the sensor fields (not to scale). As the figure below shows, there are sensor blind spots to the left and right of the AMR.

- Page 35 AMR wait X seconds for the obstacle to move. If the obstacle is no longer detected within the elapsed time, the AMR either proceeds or fails depending on the value of other GoToStraight attributes. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 35 of 77...

-

Page 36: Other Sensors

AMR operating parameters to stay within safe operation limits. (See: Payload Dimensions and Design on page 80 (LD-250 Platform User’s Guide, Rev-B).) In particular, see: Overhanging Payloads and the AMR Swing Radius on page 194 (LD-250 Platform User’s Guide, Rev-B). - Page 37 4.3.2 Rear Sensor An infrared time-of-flight (ToF) sensor array is mounted at the rear of the LD-250 for remote sensing obstacles when traveling in reverse or when obstacles move close behind the LD- 250. A User Bumper connector enables you to add your own payload structure bumpers. The LD- 250 Core's rear upper panel (in the payload bay) provides connections for front left, center, and right sensors, and rear right, center, and left sensors.

-

Page 38: Payload Structures

LD-250. Safety 5.1.1 Warning Label A No Riding label ships, unattached, with each LD-250. You must place this in a prominent location on the payload, so operators will see it. Other warning labels are applied at the factory. 5.1.2 Warning Lights Your AMR should include warning lights appropriate for its application. -

Page 39: Considerations

• Power requirements for any electrical devices on the payload. • Serviceability and maintenance requirements. Adding weight to the LD-250 tends to have less effect on battery run time than does increasing electrical power consumption. Operating your AMR over soft surfaces (such as carpet) significantly shortens battery runtime than compared to hard surfaces. - Page 40 • If you operate the LD-250 on the recommended hard, flat surface, additional payload mass has a minimal effect on battery duration and operating time between recharges. • If the payload is tall and also has substantial weight, consider its effect on the AMR's center of gravity.

- Page 41 5.2.5 Payload Bay Access The area between the LD-250 and your payload structure is the payload bay. This is where you access the LD-250 Core's power and I/O connectors, in addition to any mechanical fasteners that secure your payload to the LD-250.

- Page 42 5.2.7 Mounting Locations in the Payload Bay The payload bay is located under the LD-250's top skin. It provides access to the LD-250 Core for power and data connections, and attachment points for your payload structure.

- Page 43 Figure 6: Payload Mount Locations The extrusion's cross section is a 40 mm x 40 mm square T-slot profile with three open T- slots, one on each 40 mm face. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 43 of 77...

- Page 44 These extrusions bear the main structural load of any payload, transferring stresses directly to the LD-250's formed steel chassis. You can easily adjust and move your payload in relationship to the LD-250's center of gravity (see: Center of Gravity (CG) on page 86 (LD-250 Platform User’s Guide, Rev-B)).

- Page 45 Use T-nuts appropriate for the mass of your payload. To maintain access to the payload bay, consider incorporating hinged attachment points on one side of your payload structure so that you can tilt it away from the bay. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 45 of 77...

- Page 46 The figure below shows the approximate positions of the clip nuts relative to the edge of the top plate and its center lines. You can obtain the CAD and engineering drawing sources from the OMRON web site if you need to determine the precise locations. Mobile Robot LD-250 Assembly Instructions, Rev. A...

- Page 47 Figure 9: Position of the Clip Nuts around the payload bay 5.2.8 AMR Coordinate System OMRON AMRs use the X, Y, Z and Theta (θ) coordinate system. This information is relevant for some of the procedures used in this manual, such as identifying which are the left or Mobile Robot LD-250 Assembly Instructions, Rev.

- Page 48 Keep your payload structure's center of gravity (CG) centered over the LD-250's own center of gravity and as low (close to the LD-250's top) as possible. This provides optimum stability, particularly when the LD-250 crosses raised thresholds or irregularities in the floor.

- Page 49 If the AMR tilts more than 60 degrees in any direction, an E-Stop event occurs. This is not intended to prevent the AMR from tipping over. However, it can notify you if the AMR runs off a ramp or tilts over for any reason. See: Releasing an E-Stop on page 31 (LD-250 Platform User’s Guide, Rev-B).

- Page 50 Figure 11: Side view (X) of recommended payload CG (mm) Mobile Robot LD-250 Assembly Instructions, Rev. A Page 50 of 77...

- Page 51 Figure 12: Top view (Z) of recommended payload CG (mm) Mobile Robot LD-250 Assembly Instructions, Rev. A Page 51 of 77...

-

Page 52: Payload-Related Trade-Offs

MobilePlanner software to compensate for changes in its driving characteristics. This is necessary so that the AMR remains consistent and safe in operation. Contact your local OMRON Support If your parameters differ from those described in this section. In general, you must reduce the maximum acceleration, deceleration, and rotational velocities. - Page 53 An additional touchscreen panel, is available as an option to display MR status, The touchscreen does not include the switch an button controls integrated into the Operator panel (HMI). See Touchscreen on page 188 (LD-250 Platform User’s Guide, Rev-B). Many other LD-250 Core connections are available. For details and specifications of available connections, refer to Connectivity on page 93 (LD-250 Platform User’s Guide, Rev-B).

- Page 54 1. Keep the Operator Panel’s cable in place, connected to the LD-250 core. 2. Securely attach a jumper (Part Number 13387-000) to terminate the end of the cable (in place of the Operator Panel). 3. Loop the cable and secure it with zip ties within the payload bay so that it does not interfere with the payload or any other moving parts.

-

Page 55: Connectivity

The two connections outside of the payload bay are the pendant port and the Maintenance Ethernet port, which are located under an access door on the rear of the LD-250. Both external ports are connected to the LD-250 Core inside the payload bay. -

Page 56: Payload Bay Connections - Ld-250 Core

The connections described in this section are available for use with standard options and user supplied accessories. The LD-250 ships with dual antennas that you can relocate if necessary. If you relocate the antenna, make sure that they are not in a position that might attenuate the WiFi signal, depending on the AMR's orientation. - Page 57 6.2.1 LD-250 Core Front, Upper Figure 15: Front Upper LD-250 Core 6.2.1.1 Digital I/O The LD-250 Core's Digital I/O HDB44F connector provides the user with digital inputs and outputs for payload customization. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 57 of 77...

- Page 58 Mobile Robot LD-250 Assembly Instructions, Rev. A Page 58 of 77...

- Page 59 6.2.1.2 Digital Input and Output Specifications The following tables describe specifications for the LD-250 Core's digital inputs. NOTE: The input current specifications are provided for reference. Voltage sources are typically used to drive the inputs. Mobile Robot LD-250 Assembly Instructions, Rev. A...

- Page 60 Figure 16: Typical digital input wiring example NOTE: You can use all input signals for either sinking or sourcing configurations. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 60 of 77...

- Page 61 Figure 17: Typical digital output wiring example 6.2.1.3 Analog I/O The LD-250 Core's Analog I/O HDB15M connector is reserved for internal use only. Contact your local OMRON Support before attempting to use these circuits. 6.2.1.4 Aux Sensors The LD-250 Core's Aux Sensors HDB15M connector provides circuits used by the Low Front Mobile Robot LD-250 Assembly Instructions, Rev.

- Page 62 Laser and optional Side Lasers (tilted lasers). 6.2.1.5 RS232 1 and 2 The LD-250 Core's RS232 1 and 2 DB9M connector provides two ports for use with peripheral devices such as the HAPS sensors (See: High-Accuracy Positioning System (HAPS) on page 190 (LD-250 Platform User’s Guide, Rev-B).) If not used for other devices, you can also use the ports for port forwarding information from other RS232 devices.

- Page 63 6.2.2 LD-250 Core Rear Upper Connectors Figure shows the connectors on the LD-250 Core's upper rear interface panel. Some if these connectors are available for customer use. Figure 18: LD-250 core rear upper interface panel Mobile Robot LD-250 Assembly Instructions, Rev. A...

- Page 64 Use the pendant for manual driving and mapping. 6.2.2.2 Power Connections The LD-250's battery provides conditioned 5, 12, and 20 VDC, and raw (battery) 22 - 30 VDC power to the LD-250’s accessory electronics, including the LD-250 Core and laser LIDAR (Light Detection And Ranging).

- Page 65 Safe 22 - 30 VDC. 6.2.2.3 LIGHTS (Light Pole) The LD-250 Core's light pole Mini-Fit® 2 x 3 connector enables you to connect a light pole or other payload warning lights. Mobile Robot LD-250 Assembly Instructions, Rev. A...

- Page 66 6.2.2.4 User Interface (Brake and E-Stop) The LD-250 Core's User Interface Mini-Fit® 2 x 7 connector provides circuits for the Brake release, ON, OFF, and E-Stop buttons. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 66 of 77...

- Page 67 6.2.2.5 User Bumper The LD-250 Core's User Bumper Mini-Fit® 2 x 4 connector provides 6 circuits for optional user-supplied payload bumpers. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 67 of 77...

- Page 68 6.2.2.7 User Power The LD-250 Core's User Power Mini-Fit® 2 x 6 connector provides battery power for payload devices. Refer also to Power Consumption on page 79 (LD-250 Platform User’s Guide, Rev-B) which specifies limits on power draw.

- Page 69 • It is not possible to use the RS-422 data connections. 6.2.2.9 Sonar 1 The LD-250 Core's Sonar 1 DB9M connector is connected to the rear sensor in the LD-250. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 69 of 77...

-

Page 70: Technical Specifications

Technical Specifications Dimension Drawings Figure 19: Length Dimensions from side of AMR Mobile Robot LD-250 Assembly Instructions, Rev. A Page 70 of 77... - Page 71 7.1.1 Width Measurements Figure 20: Width dimensions from rear of AMR Mobile Robot LD-250 Assembly Instructions, Rev. A Page 71 of 77...

-

Page 72: Ld-250 Specifications

7.1.2 Component Weight 7.1.3 Capabilities NOTE: Refer also to Payload Structures (Section 5) for information about the payload mount location and dimensions. LD-250 Specifications 7.2.1 Physical Dimensions Mobile Robot LD-250 Assembly Instructions, Rev. A Page 72 of 77... - Page 73 7.2.2 Performance Mobile Robot LD-250 Assembly Instructions, Rev. A Page 73 of 77...

- Page 74 7.2.3 Overhanging Payloads and the AMR Swing Radius If your payload overhangs the default LD-250 footprint, it alters the AMR's swing radius and exponentially affects its maximum safe rotational speed. Should the AMR size increase significantly, you might need to adjust the AMR's maximum rotation speed to stay within 300 mm/sec or slower.

- Page 75 The LD-250 provides a path for ESD grounding through the casters. While adequate to protect the LD-250 and any other equipment it touches, this method is not IEC compliant. Keep both the floor and casters clean so that there is adequate conductivity. See: Mobile Robot LD-250 Assembly Instructions, Rev.

-

Page 76: Docking Station Specification

Environment and Floor on page 115 (LD-250 Platform User’s Guide, Rev-B). ⚫ Docking Station Specification NOTE: The LD-250 can also use older model docking stations that use a 10 A time-lag fuse. Mobile Robot LD-250 Assembly Instructions, Rev. A Page 76 of 77...

Need help?

Do you have a question about the LD-250 and is the answer not in the manual?

Questions and answers