Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Fluke VIBXPERT II

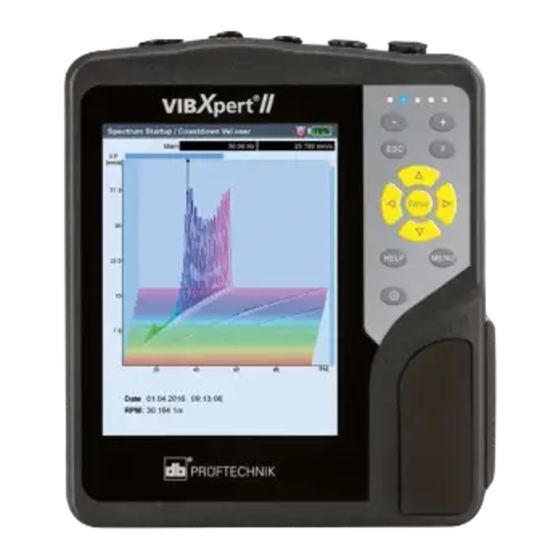

- Page 1 Data Collector & Vibration Analyzer VIBXPERT II Users Manual...

- Page 2 VIBXPERT ® Dual channel FFT data collector and signal analyzer Operating instructions Series: VIB 5.310 Firmware version: 3.2x PN5178694 12.2019, Rev. 2 06.2022...

- Page 3 The trademarks mentioned in this manual are generally noted as such and are the property of their owners. Lack of such designation does not imply, however, that names are not protected by trademark laws. © Copyright 2010-2022 by Fluke Corporation...

- Page 4 Foreword Foreword Congratulations! And thank you for selecting the VIBXPERT II * Also referred to as 'VIBXPERT' and FFT data collector and signal analyzer*. This newly developed 'device' in these operating instructions. measurement device is not just the ideal companion for your routine measurement round, but also a reliable on-site aid for recording and analyzing complex machine signals.

- Page 5 Foreword Structural analysis: - Coast down / Run up analysis (natural frequencies, machine) - Impact test (natural frequencies, machine components) • Advanced measurements - 1+1 dual measurement (simultaneous 2-channel measurement) - Multitask (measure multiple measurement tasks in a sequence) - On-site balancing in one or two planes - TrendingSpectrum (a measurement provides a time signal, a spectrum and several characteristic overall values, in route and template mode).

-

Page 6: Table Of Contents

Contents Contents Chapter 1: Prior to starting ..........1-9 Safety and operating notes............1-10 Chapter 2: Getting started ..........2-1 Overview ....................2-1 Keyboard ......................2-2 Status display per LED ..................2-2 Notes on operation ................2-3 Interfaces ...................2-5 Power supply ..................2-7 Charging the battery in the device ..............2-7 Carrying pouch - VIB 5.356 ............2-9 Belt .........................2-9 Hand strap ......................2-9... - Page 7 Contents Typical workflow of a route ................3-7 Start Route ......................3-7 Icons ........................3-9 MENU functions in the tree / list view ............3-10 MENU functions in the measurement task selection screen ......3-12 Measuring with a machine template ........... 3-13 Preliminary remarks ..................3-14 Start measurement ....................

- Page 8 Contents Chapter 5: Measurement tasks ...........5-1 Characteristic overall vibration values...............5-1 Shock pulse measurement ..................5-2 RPM measurements ....................5-4 Temperature measurement .................5-5 Runup / Coastdown .....................5-6 Shaft centerline plot ..................5-12 Phase measurement ..................5-14 Orbit ........................5-16 Envelope analysis ..................... 5-18 Cepstrum analysis .....................

- Page 9 Empty page...

-

Page 10: Chapter 1: Prior To Starting

Service addresses Feel free to contact us in case of questions: Hotline: +49 89 99616-0 Service address: Fluke Deutschland GmbH Freisinger Str. 34, 85737 Ismaning, Germany About this manual This manual describes the basic functions and operation of the measurement device in the 'Multimode', Templates' and 'Route' operating modes. -

Page 11: Safety And Operating Notes

1-10 Safety and operating notes Safety and operating notes Read this section carefully, paying especially close attention to the safety notes, before working with the device. Symbols used This symbol warns of operating errors that can lead to data loss or equipment damage. Attention! ... - Page 12 1-11 Safety and operating notes General safety The following notes must be carefully read and completely understood before the device is put into service. Risk of injury when measuring on a running machine! Observe the safety regulations. Install the measurement equip- ment properly.

- Page 13 1-12 Safety and operating notes Nameplates The diagram below shows the locations and the contents of the device nameplate and the battery nameplate (standard version). VIB 5.310 00100 Nameplate for the VIBXPERT device with serial number ('S.No.') Nameplate for the rechargeable battery with with serial number and 00100 safety notes...

-

Page 14: Chapter 2: Getting Started

Getting started Chapter 2: Getting started Overview The illustrations show the interfaces and operating elements: Full color display - large, backlit, high contrast. Ambient light sensor con- trols keyboard illumination. Four LEDs indicate: - Alarm condition - Measurement error - Battery charge status. Keyboard - ergonomic, backlit. -

Page 15: Keyboard

Getting started Keyboard The keys can be comfortably operated with the thumb of the right hand. In a dark environment the keyboard illumination automatically turns on. Plus (+) / Minus (-) key Additional (ENTER) key on - Zoom for X axis the rear panel (p. -

Page 16: Notes On Operation

Getting started - Operation Notes on operation To keep operation as simple and intuitive as possible, the graphical user interface guides the user step-by-step and is based on the 'Microsoft Windows' operating concept. Switch on / off Switching on VIBXPERT To switch on the device, hold the On/Off key down for two seconds. - Page 17 Getting started - Operation Menu The functions of the current program section are found in the 'Menu' which is displayed with the MENU key and hidden again with the ESC key. An arrow next to a menu entry indicates a further submenu. To open it, press the right navigation key.

-

Page 18: Interfaces

Getting started - Interfaces Interfaces The connections for the sensor and data cables are located on the front of the measurement device. The cable connectors and sockets are colored for easy identification. To unplug the connector, push the connector sleeve backwards to release the lock. - Page 19 Getting started - Interfaces Digital The yellow channel is used as the: - Input for digital signals from a trigger or a RPM sensor - Serial interface for data transmission (RS 232) - Output for the analog signal (connection for headphone/ oscilloscope) - Output for stroboscope control (TTL signal) The permissible range for trigger signals is:...

-

Page 20: Power Supply

Getting started - Power supply Power supply VIBXPERT is supplied with energy by a Lithium-Ion rechargeable battery. With the power on the the battery icon on the display indicates the residual charge of the battery: Battery is being charged Battery icon Residual charge 100% Residual charge 25% Battery almost empty... - Page 21 Getting started - Power supply During extended periods of non-use and during storage, connect VIBXPERT regularly to the mains supply. This prevents the battery from becoming completely discharged, and the date and time settings are retained.

-

Page 22: Carrying Pouch - Vib 5.356

Getting started - Carrying pouch Carrying pouch - VIB 5.356 The stable and functional carrying pouch allows safe and convenient transport of the measurement device. A belt and a hand strap can be attached to the pouch: Belt Fasten the belt to the two diagonally opposite eyelets. Adjust the belt length so that the measurement device hangs comfortably from the shoulder to allow convenient operation. -

Page 23: Memory Card

2-10 Getting started - Memory card Memory card For older devices — Serial Number 30000 – 39999 A CompactFlash (CF) card with 2 GB memory capacity is installed in the VIBXPERT as standard. Backup all data before replacing the card using the 'VIBXPERT util- ity' program (see page 6-8)! When closing the cover, it must be additionally sealed with a sili- cone adhesive (NOVASIL S 11) to ensure the dust seal (IP 65). - Page 24 2-11 Getting started - Memory card • Installation: Insert the new card in the guide rails of the card slot. Carefully press in the card up to the endstop. Make sure the card is correctly oriented! The top of the card should face the back of the device.

-

Page 25: Basic Settings - Device Setup

2-12 Getting started - Basic settings Basic settings - Device Setup Before carrying out measurements with VIBXPERT, the basic settings in the 'Device Setup' should be checked and changed if necessary. • Switch on VIBXPERT. • Click on 'Device Setup' in the start screen. The 'Device Setup' screen appears. -

Page 26: Display Settings, Switchoff And Additional Options

2-13 Getting started - Basic settings Display settings, switchoff and additional options • Click on 'Display' in the 'Device Setup' screen. Brightness: Press the navigation key right or left until the desired brightness is achieved. To accept the setting, press 'Enter'. Switch backlight off / Auto power off: The display/ the device automatically switches off if no action occurs within the turn-off time (illumination: 10s ... -

Page 27: Route

2-14 Getting started - Basic settings Route • Click on 'Route' in the 'Device Setup'. The settings in the Route Setup apply to measurements in the 'Route' / 'Template' mode. The Route Setup can be called up and adjusted at any time in the route/template. For clarity, the numerous settings in the Route Setup are grouped into three submenus (see below): Route display settings... - Page 28 2-15 Getting started - Basic settings - Enabled: Display of machine images. The position of the measurement locations and the measurement direction is indicated by symbols. - Disabled: The route is processed in the set display mode (tree / list) Display all hierarchies This option applies to the tree view only.

- Page 29 2-16 Getting started - Basic settings Measurement settings • Click on 'Measurement' to set up the following options: Autostart measurement This shortens the duration of the entire measurement. - Enabled: Clicking the measurement location starts the first measurement automatically. If multiple measurement tasks are defined for the same accelerometer at a single measurement location, these measurement tasks are automatically run consecutively, provided that the 'Auto Save' option is enabled...

- Page 30 2-17 Getting started - Basic settings Advanced VIBCODE handling When measurement tasks performed at a VIBCODE measurement location are not only taken by the VIBCODE sensor but by another vibration sensor, VIBXPERT recognizes these and assigns them to another measurement channel. - Enabled: Measurement tasks with the VIBCODE sensor are performed on the VIBCODE sensor channel.

- Page 31 2-18 Getting started - Basic settings Standard vibration sensor Here you define the sensor to be used for all vibration measurements on a route. The settings in OMNITREND are ignored. The 'Triax sensor' option is disabled. Standard sensor is active when, in the task selection screen - Channel A / Channel B is marked red, ...

-

Page 32: Transducers

2-19 Getting started - Basic settings Transducers The transducer menu (see below) contains all of the functions and pre settings for the transducer. Click on 'Transducers' to open the menu. Available transducers in VIBXPERT The measurement-relevant parameters for many transducers are stored in VIBXPERT. - Page 33 2-20 Getting started - Basic settings Transducer parameters To check the parameters for transducers that have already been set up, proceed as follows: • Select the transducer. • Press the MENU key. • Click on 'Show'* or 'Edit' to open the parameter screen (see *'Show' appears for factory-defined transducers whose parameters cannot below).

- Page 34 2-21 Getting started - Basic settings measurement must be adapted to one another. Resonance frequency The resonant frequency of the sensor is an important influencing quantity in the shock pulse measurement (bearing condition). Settling time (RPM) Settling time of the RPM sensor Filtering the transducer list The transducer list can be can filtered according to specific criteria: •...

- Page 35 2-22 Getting started - Basic settings Transducer detection and Hardware settling In this menu, the transducer detection feature and the settling of the amplifier stages in VIBXPERT can be switched on and off. Additional information can be found in the 'Route Setup' section (p. 2-17). The settling of the amplifier can only be activated when the trans- ...

-

Page 36: Language

2-23 Getting started - Basic settings Default sensor is active, when • Channel A / Channel B is marked red in the task selection Note screen • the sensor icon at the top edge of the task selection screen is orange •... -

Page 37: Registration

2-24 Getting started - Basic settings Communication Settings for network communication, see page 2-34. Registration The functions and operating modes in VIBXPERT are distributed in individual modules* that can be enabled by password as required. *The attachment on page 6-20 con- VIBXPERT is supplied in the 'Basic' version with which overall values tains an overview of the modules and as well as (limited) spectra can be measured. -

Page 38: Key Controls

2-25 Getting started - Basic settings Key controls Additional functions are activated for some keys in VIBXPERT as standard that are intended to ease working on-site on the machine or to increase data security. • Click on 'Key controls'. The following options can be activated or deactivated in the next screen: Additional key on the rear panel VIBXPERT has an additional input key on the rear panel which... -

Page 39: Printer (For Older Devices - Serial Number 30000 - 39999)

2-26 Getting started - Basic settings Printer (for older devices — serial number 30000 – 39999) With VIBXPERT (SN 30000 – 39999), you can print out measurement results, reports and PDF file directly on a USB-printer. • Click on the 'Printer settings' icon to open the Printer menu. Setting up a printer To set up a new printer, proceed as follows: •... - Page 40 2-27 Getting started - Basic settings Deleting a print job • Click on 'Print queue' in the 'Printer settings' menu. • Select the print job in the list. • Press the MENU key and click on 'Delete job'. If a print job is being processed, a print icon appears at the top edge of the screen.

-

Page 41: Analog Out/Headphones

2-28 Getting started - Basic settings Analog out/headphones At the analog output (yellow connector), the vibration signal can be picked up with a suitable analysis device (oscilloscope) or listened to via headphones (e.g. VIB 6.671-2 (5312369)). The output is always the pure, non-integrated signal without the DC component. To use the yellow connector as the analog output, it must be enabled and parameterized in the Device Setup: •... -

Page 42: Service Menu

2-29 Getting started - Basic settings Service menu • Click on 'Service' to open the Service main menu (see below). A series of functions are available for service, maintenance and training purposes. For clarity, the settings are grouped into submenus: Device Info This menu contains device information for service and repair as well as the date of the next offset compensation and calibration (for more... - Page 43 2-30 Getting started - Basic settings • Click on the respective tree entry and confirm the resulting prompt with 'OK'. • For reasons of security, the word 'OK' must be entered a second time in the text editor before the action can be carried out. Demo For training or demonstration purposes, the VIBXPERT screen display can be shown on a PC monitor with the aid of the VIBXPERT...

-

Page 44: Memory Card (Cf)

2-31 Getting started - Basic settings To backup the log file on the memory card in the VIBXPERT, click on the 'Backup Log' icon and confirm the prompt with 'Yes'. The log file can be transferred to the PC using the 'VIBXPERT update tool'. Memory card (CF) In this menu, you can format, check and repair the memory card. -

Page 45: Data Transfer

2-32 Getting started - Data transfer Data transfer The following data is transferred between VIBXPERT and the PC either via a direct connection or a network connection: - Measurement tasks to VIBXPERT (route) - Measurement results to the PC (route, multimode, templates) - Machine templates to VIBXPERT - Software (update) - Printer drivers to VIBXPERT... -

Page 46: Network Connection

USB flash drive To save PDF files to a USB flash drive, you need the following accessories: - Cable for USB flash drives (VIB 5.330AMEM) - USB flash drive for VIBXPERT II (VIB 5.350-USB2 (5269372) ) VIB 5.330AMEM VIB 5.350-USB2 (5269372) In the file manager the USB flash drive is shown as an additional directory next to ‘Results’... -

Page 47: Setting Up The Network Communication

2-34 Getting started - Data transfer Setting up the network communication • Connect VIBXPERT to the network (see previous page). • Switch on VIBXPERT. • Click on 'Device Setup' in the start screen, and then on 'Ethernet': • Enter a valid IP address for VIBXPERT: Take the first three numbers of your PC's IP address and change the last number only (see also the following instructions). -

Page 48: Ip Address Of The Local Pc In The Network

2-35 Getting started - Data transfer IP address of the local PC in the network If the IP address and the subnet mask of the PC are not known, ask your network administrator or find it yourself on the PC: •... -

Page 49: Update

2-36 Getting started - Update Update Technical developments and improvements to the firmware are transferred to the device via an update. The current version can be obtained from your PRÜFTECHNIK sales partner. Preparation: • Backup the measurement data into the OMNITREND database. •... - Page 50 2-37 Getting started - Update • In the next step ('3') select the update file on the PC. • Click on <Next>: • In the next step (‘4’) click on <Download> to start the data transfer to VIBXPERT. • After the data transfer has finished, click on <Close> to close the program.

- Page 51 2-38 Empty page...

-

Page 52: Chapter 3: Measurement

Measurement Chapter 3: Measurement VIBXPERT can carry out measurements in the following operating modes: Multimode: VIBXPERT can be used as a multimeter to measure characteristic overall values or signals for the diagnosis of machine conditions. The results can be saved and read in for evaluation and archiving by the OMNITREND PC software. -

Page 53: What Is A Measurement Task

Measurement What is a measurement task? *Measurement quantity: Vibration acceleration, To carry out a measurement, VIBXPERT requires information on Vibration velocity the type of measurement quantity*, the sensor being used and, if Vibration displacement as overall necessary, data for the evaluation of the result. Information as to value, time signal or spectrum respec- whether the RPM must be recorded with each measurement is also tively... -

Page 54: Multimode: Measurement, Analysis, Diagnosis

Measurement - Multimode Multimode: Measurement, Analysis, Diagnosis To activate the 'Multimode' mode, click on the corresponding symbol in the start screen. The measurement tasks appear in the selection screen (see below). The measurement task for the selected icon is displayed below the icon field. The measurement tasks are grouped into three tabs: Overall (characteristic) Values, Signals, Advanced (measurements). -

Page 55: Continuous Measurement (Live Mode)

Measurement - Multimode Before every measurement, VIBXPERT checks that the sensor and cables are correctly connected if sensor detection is activated in Note the device setup (p. 2-22). In measurements with trigger (phase, orbit,...) the trigger signal is monitored. If the trigger signal fails during measurement, the green LED flashes after the measurement. -

Page 56: Measurement Of A Route

Measurement - Route Measurement of a route The 'Route' mode processes a specified number of measurement tasks which are carried out regularly according to a specific schedule with VIBXPERT. The measurement tasks for a route are compiled on the PC using the OMNITREND software. Preliminary remarks A route can be carried out in the specified sequence or in any order;... - Page 57 Measurement - Route As well as the standard measurement tasks*, the following route- *For more information, see also Chapter 5 ‘Measurement tasks’ specific measurement tasks can be included: Adaptive measurement task An adaptive measurement task automatically adapts the sequence of the route to the condition of the machines. If these run within the permissible range, the data collector only records overall values.

-

Page 58: Notes About Routes

Measurement - Route Notes about routes A route can contain the following information: - Alarm and warning thresholds - Reference results that define the good machine condition. - Historic measurement results - Frequency marks - Master data of the route (name, user, version, ...) To display the master data, highlight the route in the route list (see below), press the MENU button and click on ‘Info’. - Page 59 Measurement - Route Notes about the tree view: - If the 'Graphic Route' option is activated (p. 2-14), you can select the measurement location using the machine graphic. Note - If the branch cannot be opened up to the measurement location level, press the MENU key and select 'Expand' ->...

-

Page 60: Icons

Measurement - Route Icons Measurement task Measurement task completed / skipped Task with status icons Adaptive task / Diagnostic task Reference RPM Result exceeds alarm, warning, prewarning threshold Status in Tree view / List view (empty) Partly/ not processed Completely processed / partly processed and skipped / Skipped contains Multimode result contains Event / Comment... -

Page 61: Menu Functions In The Tree / List View

3-10 Measurement - Route MENU functions in the tree / list view • Press the MENU key in the tree / list view (see below): Skip / Unskip If a machine is not in operation during a route, you can skip all measurement tasks planned at this machine. - Page 62 3-11 Measurement - Route Info The following information is displayed for the highlighted element - Path in the OMNITREND database - Hierarchy type (e.g. train) - ID (identification number in the database) - Sequence number = order of the elements in the route list view - Task statistics (measured, skipped, not measured) - VIBCODE code number and code ring pattern (‘Show VIBCODE’).

-

Page 63: Menu Functions In The Measurement Task Selection Screen

3-12 Measurement - Route MENU functions in the measurement task selection screen • Press the MENU key in the task selection screen (see below): Skip/ Unskip A measurement task can be skipped if it cannot be measured. Event / Comment Enter the event and, if necessary, a supplementary comment to explain the result. -

Page 64: Measuring With A Machine Template

3-13 Measurement - Machine template Measuring with a machine template A 'Machine template' is used if it is necessary to carry out measurements on machines of the same type. The measurement locations are always at the same position and the measurement tasks are identical for each machine. -

Page 65: Preliminary Remarks

3-14 Measurement - Machine template Preliminary remarks In principle, a machine template is set up like a route and resembles a route in operation and workflow (see previous section). The differences to a route are described in the following points: Machine description This must be identified with a name before the first measurement. -

Page 66: Start Measurement

3-15 Measurement - Machine template Start measurement • Click on 'Machine template' in the start screen. A list of the available machine templates appears (see below). Machines where measurements have already been carried out appear subordinate to the associated template. The number of the measured measurement location and the total number of measurement locations is indicated in the right column ('Done') for each machine. - Page 67 3-16 Measurement - Machine template The template then appears, which – like a route – is displayed as a tree structure or in the form of a list* (see section ‘Route’). The * not in the case of templates for pro- following steps are identical to those in the ‘Route’...

-

Page 68: Options Before, During And After A Measurement

3-17 Options Options before, during and after a measurement In addition to the information given in the previous sections, the options for the measurement are described here. Aborting a measurement • Press the ESC key during the measurement. Repeating a measurement •... -

Page 69: Changing The Sensor

3-18 Options Changing the measurement channel Route/machine template: • In the tree/list view, press the MENU key and click on ‘Runtime Setup: Route’ (see below). • Select the measurement channel (A, B, Auto = the channel set in OMNITREND). ‘Auto’ is required when the route uses the ‘Near location’... -

Page 70: Changing The Measurement Task (M)

3-19 Options Use this option when you do not have an RPM sensor on the route and need to perform measurements that require the RPM (e.g. roller bearing condition, order-based spectra). If the measurement task already has information on the RPM, this option is ignored. M = in Multimode only Changing the measurement task (M) •... -

Page 71: Creating A New Setup (M)

3-20 Options Creating a new setup (M) M = in Multimode only You can only create a new setup for the measurement, evaluation or rpm for user-defined measurement tasks. You can also create a new sensor setup for measurement tasks preset at the factory. How to create a new setup: •... - Page 72 3-21 Options A1: Meas. setup parameters in the 'Overall values' & 'Advanced' tab Measurement quantity: Fixed; selection is carried out via the measurement icon. Exception: The measurement quantity can be changed for the ‘Orbit’, ‘Phase’ and ‘Coastdown’ measurement tasks. Sample frequency (Timewave Recorder): The sample frequency for the time signal defines the maximum upper frequency and influences the maximum measurement time.

- Page 73 3-22 Options Order (with Phase, Orbit, Coastdown measurement) Order filter for the harmonic vibration components of the signal. For example, only the signal components of the 1st harmonic are *'Fixed range', e.g. for a runup / coast- filtered out and displayed by the first order filter. A half order is down curve or impact test.

- Page 74 3-23 Options event via the Trigger start time. Start / Stop RPM (Runup / Coastdown): Rotational speed at which the measurement should start or stop. RPM deviation (Runup/Coastdown): The current, averaged measurement value is not saved until the rpm has changed by * up to max.

- Page 75 3-24 Options Sample frequency (Timewaveform): The sample frequency for the time signal defines the upper frequency. Measurement time (Timewaveform): The length of the time window depends on the sample frequency. The maximum measurement time is 640 s. Number of lines (Spectrum, Cepstrum): Number of lines displayed. Together with the 'upper frequency', this parameter specifies the resolution of the spectrum (∆f).

- Page 76 3-25 Options B. Setup parameters for sensors The sensor parameters to be set up are described on P. 2-20 If you have defined a default sensor for vibration measurements (see p. 2-22), the ‘Sensor Setup’ menu is deactivated. C. Evaluation parameters for overall value / time waveform meas. For characteristic overall value measurement tasks, which are measured according to ISO 10816-3, the corresponding thresholds are stored in fixed evaluation setups.

-

Page 77: Entering An Event/Comment

3-26 Options Entering an Event/Comment You can record information relating to data collection using predefined events* and freely editable comments. Up to 10 events * Import user-defined events via OMNI- can be assigned to every measurement result and every element in TREND. -

Page 78: Signal Sensitivity On Analog Output/Headphones

3-27 Options To delete an event/ comment in the route • Press the F key in the event editor to open the bottom event or comment window. • Select the event or comment o be deleted. • Press the MENU key and click on 'Delete'. Signal sensitivity on analog output/headphones The analog output is activated and configured in the device setup (see p. -

Page 79: Trend

3-28 Trend Trend The standard procedure for monitoring machine conditions is the regular recording of characteristic overall values over a longer period of time. The trend of the machine condition can be traced back from the resulting trend curve and its probable development in the future can be predicted. - Page 80 3-29 Trend Trend in the ‘Multimode’ To start a trend, first open the file in which the measurements that were already carried out are stored: • Click on 'File manager' in the start screen. • Click on the file that was saved as a trend measurement. •...

- Page 81 3-30 Trend Comparing the current measurement with historical data/ reference data The following requirements must be met to be able to use this feature: - Historical data for the respective measurement task exist in the OMNITREND database. - A data set has been declared as a reference in the OMNITREND database.

- Page 82 3-31 Trend Prewarning if measurement values deviate excessively In the ‘Route’ mode, VIBXPERT recognizes by how much the current measurement value differs from the last recorded historical measurement value. If this deviation is large, the green LED on the device lights up and the symbol R! appears in the results screen. For this prewarning to appear, the following requirements must be met: - The maximum permissible deviation of the measurement values...

-

Page 83: Near Location (Route)

3-32 Near location Near location (Route) Data collection on a route progresses more rapidly when measurement tasks at near measurement locations are performed simultaneously. For this purpose, VIBXPERT and OMNITREND provide the ‘Near location’ function: Description - The measurement channels are assigned and the two measurement locations are spatially allocated when the route is established in OMNITREND: Near location... - Page 84 3-33 Near location Restrictions - The grouping of measurement tasks to a 1+1 measurement is only possible if firmware module ‘2 channels’ (VIB 5.381) has been registered in the device. - For ‘Near locations’, the "Multitask" measurement task is disabled. - In the route runtime setup, a standard sensor should not be set up and the measurement channel must be set to 'Auto' (p.

-

Page 85: Triaxial Sensor (Route)

VIBXPERT into a 1+1 measurement and simultaneously recorded in channels A and B. VIBXPERT then records the measurements in the Z axis. Triaxial sensor Mount with magnetic holder VIB 6.657. Triaxial sensor Connect to VIBXPERT II with cable VIB 5.336 One measurement location for every measurement direction... - Page 86 3-35 Triaxial sensor Requirements Before starting a measurement, check the following requirements: - Measurement settings in the Route Setup (p. 2-17): the 'Use triax sensor' option is enabled (see below). - Route Runtime Setup (p. 3-18): Option 'Use default sensor' must be disabled, and option 'Measurement channel' must be set to 'Auto'.

-

Page 87: Recording

3-36 Recording Recording With the ‘Recording’* function, you can perform measurements * Firmware module ‘Recording’ (VIB 5.385) must be registered. dependent on time or rotational speed. For example, this method can be used to record measurement values under certain operating conditions (= rpm range) or at fixed time intervals. - Page 88 3-37 Recording The configuration screen appears (see below). Start conditions Immediately: The recording starts immediately (MENU -> Start). Start in: The measurement recording begins after a set period (0 s ... 23:59:59 h). Start at: The measurement recording begins at the set time (time, date) or when the set rpm is reached (0 ...

-

Page 89: Starting The Measurement Recording

3-38 Recording Testing the rpm sensor To test the function and the positioning of the rpm sensor, a test measurement can be performed prior to the measurement recording: • Press the MENU key and click on ‘Test speed’. • To return to the configuration screen after the test measurement, press the ESC button. -

Page 90: Ending The Measurement Recording

3-39 Recording Ending the measurement recording The measurement recording is ended when - the stop condition is fulfilled - the ESC button is pressed - the memory card is full - the maximum number of results is reached (65535). Special cases The recording function is used in a wide range of applications and is intuitive in use. -

Page 91: Time Waveform Recorder

3-40 Time waveform recorder Time waveform recorder The time waveform recorder can be used to record time waveforms over very long* times. In contrast, the maximum recording length for * Dep. on the sample rate and memory capacity; a 2 GB memory card and a time waveforms using the recording function is approx. -

Page 92: Data Acquisition At The Vibronet Multiplexer

3-41 Multiplexer Data acquisition at the VIBRONET multiplexer For automatic data acquisition at many measurement locations of the same type or hard-to-access measurement locations, VIBXPERT and OMNITREND feature the function ‘Multiplexer measurement’. The respective measurement tasks are processed within a route or as a machine template. -

Page 93: Connecting The Vibxpert To The Multiplexer

3-42 Multiplexer Connecting the VIBXPERT to the multiplexer Install the BNC connecting adapter (VIB 5.346-MUX) on the 1st multiplexer in the string line as follows: • Open the cover of the multiplexer. Do not touch strip conductors and components on the PCB! Electro- static charges can damage or destroy them. -

Page 94: Automatic Data Acquisition

3-43 Multiplexer Automatic data acquisition • Connect the VIBXPERT to the multiplexer (see previous section). • Connect an RPM sensor to the VIBXPERT, if necessary. • In the route setup (measurement), select the option ‘Autostart MUX’ (see p 2-16). • Open the route* with the multiplexer measurement locations. -

Page 95: Diagnostic Measurement At Vibronet Multiplexer

3-44 Multiplexer Diagnostic measurement at VIBRONET multiplexer For machinery fault diagnosis you can conduct the following measurement tasks at a multiplexer measurement location: • Vibration-based measurement types in Multimode • Only with ‘Current Linedrive’ acceleration sensor • 1- or 2-channel 2-channel measurement tasks, such as Orbit, are possible only with two string lines, since only one line is connected and can be processed for each measuring channel. -

Page 96: Chapter 4: Results

Results Chapter 4: Results After each measurement, it is possible to save the results and to evaluate them on the device. Numerous functions that can be called up with the MENU key in the results screen are available for this purpose (see below). -

Page 97: Evaluating Results

Results Evaluating results Before a result is evaluated, make sure that the measurement is valid and no error message is present (see page 2-2). Result details The following information can be displayed: - Measurement Task, Measurement Channel, Measurement Range, - Sensor Type, Date/Time, Status - Statistical Data (for overall values only) •... -

Page 98: Characteristic Overall Values - Trending

Results Characteristic overall values - trending If more than two measurements are saved in a file, the results for each overall value are displayed as a trend curve (see p. 3-28f). Markers on the trend curve indicate each individual measurement. The measurement values at the cursor position, the date, the rpm if applicable, and assigned events and comments are specified below the diagram. -

Page 99: Time Waveform

Results Time waveform The measurement results are displayed as an XY diagram in the top section of the window (see the standard setting). The data field in the lower half lists the two highest amplitudes (positive & negative). If a threshold value is exceeded, the absolute value and the difference to the measurement value is displayed ('delta', see below). - Page 100 Results Delta: Show/hide delta cursor Press 'Enter' to switch over between main and delta cursor. In this case the measurement can only be repeated via the MENU key (MENU - 'Remeasure')! The cursor coordinates indicate the distance to the main cursor. The data field specifies the frequency which corresponds to the distance between the main and delta cursor (see below).

- Page 101 Results Calculating the spectrum Based on the time waveform, you can calculate a spectrum that you can save and measure again. • Press the MENU key in the result screen. • Select ‘Postprocessing’ and click on ‘Compute spectrum’. • Set the parameters in the lower window pane (see below): - Input signal Entire signal: the entire signal is used to calculate the spectrum.

- Page 102 Results Time-synchronous average (Postprocessing) If a trigger signal is recorded in addition to the time waveform, further information can be obtained. For example, the time waveform can be determined synchronously with every rotation of the shaft. In this way, events in the signal that are synchronous with the RPM are emphasized and stochastic results are suppressed.

-

Page 103: Spectrum, Cepstrum

Results Spectrum, Cepstrum The measurement result is displayed in the upper pane. The measured time waveform is displayed in the lower pane during the measurement. After the measurement, the following information can be displayed: Amplitude, Envelope, Order - Max 10 (10 highest amplitudes in the spectrum) - Alarms - Frequency marker (only in Route / Template mode) - Trending values (only in TrendingSpectrum) - Page 104 Results Info / Alarms This function checks if a threshold value was exceeded. If so, one of the LEDs lights up. To display the thresholds in the spectrum,... • Press the F key to activate the lower window pane. • Select the corresponding check box in the tree view. Info / Frequency marker Frequency markers can be used to more easily identify the characteristic machine and component frequencies in a spectrum.

- Page 105 4-10 Results Info / Trending values (in the TrendingSpectrum only) A TrendingSpectrum contains, in addition to the time waveform and the corresponding spectrum, up to 30 characteristic overall values. The overall values are formed using frequency bands that are set up in the OMNITREND PC software.

- Page 106 4-11 Results The following functions can be called up directly in the MENU: Stroboscope Enable this feature if you want to control a strobe light with the frequency at the main cursor position. Move the cursor in the spectrum, to change the flash rate. ...

- Page 107 4-12 Results Reference (only in the route / machine template mode) Here you can compare the current spectrum with a reference spectrum or a historical spectrum. The spectra are displayed in a ‘waterfall’ diagram (see also p. 4-13). Zoom / Scaling See 'Time waveform', page 4-4. Cursor •...

-

Page 108: Display Of Spectra: Waterfall Diagram

4-13 Results 3D display of spectra: Waterfall diagram If several spectra were recorded for one measurement task (max. 75), these appear in a 3-dimensional diagram - the waterfall diagram. Navigation Navigate through the individual spectra. Move the cursor along the frequency axis. Change view To rotate the waterfall diagram change the display mode: •... - Page 109 4-14 Results Which of the two axes (X or Z) can be zoomed is displayed by a flashing bar along the edge. - If the right bar flashes, the Z-axis can be zoomed with the navigation keys. - If the upper bar flashes, the X-axis can be zoomed with the + / – key.

-

Page 110: Sound Spectrum: Third-Octave And Octave Level Diagram

4-15 Results Sound spectrum: third-octave and octave level diagram VIBXPERT makes the sound spectrum available for the display and evaluation of acoustic signals. The signal picked up by the microphone is broken down in the frequency domain into bands with a constant relative band width (octave bands or third-octave bands). - Page 111 4-16 Results • Select ‘Third-octave bar’ or ‘Octave bar’ for the graph type. • Set the ‘reference value’ needed to calculate the sound pressure level (for example, for airborne sound p = 20 µPa = 2 x 10 Pa). The reference value unit corresponds to the measurement quantity set in the spectrum.

-

Page 112: Configuring The Result Display (Display Setup)

4-17 Display setup Configuring the result display (Display Setup) In the Results display, after a measurement: • Press the MENU key and click on 'Display Setup'. In the selection field of the measurement tasks (Multimode): • Highlight the measurement task symbol. •... - Page 113 4-18 Display setup B1. Display Setup for measurement: Spectrum / Time waveform Zoom: Step size when zooming the X and Y-axis. Zoom Mode: The zoom is made around the main cursor or the gap between the delta and main cursor. Cursor: Cross (short) or line cursor (long);...

- Page 114 4-19 Display setup C1. Display Setup for measurement: Coastdown, Orbit, Phase The following sections C to E only describe the parameters specific to the measurement type. Global display parameters, such as 'Zoom' and 'Cursor', can be found in sections A and B. Show overall (Coastdown - Overall value): The results screen displays the RMS value and one of three peak values in dependence on the RPM.

- Page 115 4-20 Display setup C2. Display setup for trend: phase Phase over...: When several phase measurements are saved in one file, the phase vectors can be shown depending on the time or rpm (see below). Phase trend diagram Use the F-key to open a menu in the results screen (see below) with the following options: Details: Show result of a single measurement...

-

Page 116: Printing Out Reports

4-21 Reports Printing out reports The print function in VIBXPERT enables printouts of the following reports: - Screenshots - Measurement reports - Route / template reports To be able to print directly on a printer from VIBXPERT, you require: - A printer with USB connection - A VIBXPERT USB printer cable (VIB 5.330 MUSB, accessory) Reports in PDF format can be transferred to a PC, where they can then be printed. -

Page 117: Measurement Reports

4-22 Reports Measurement reports A measurement report is used to create detailed documentation on a measurement. The report contains the results, general information on the operator and additional measurement information. Measurement reports are available for the following measurements: Spectrum, Time waveform, Overall values trend, TrendingSpectrum, Balancing. -

Page 118: Printing Out The Measurement Report

4-23 Reports • Open the customer selection menu and click on the lowest entry, <Edit>. The customer list appears. • Press the MENU key and click on 'New'. • Enter the customer data in the text editor. Inspector/Asset: Information on the inspector/asset. Click in the corresponding text field to edit the information. -

Page 119: Printing Out The Report For Route/Machine Template

4-24 Reports Printing out the report for route/machine template You can print out the following measurements as reports to document the results in a route/machine template: All overall values, Trend parameters from TrendingSpectrum, Visual inspection, All phase measurements In addition to a table of results, the report contains general information and additional data on the measurement. -

Page 120: Loading Reports Onto Usb Flash Drive

4-25 Reports Loading reports onto USB flash drive Reports in PDF format can be transferred to a USB flash drive and then to a PC, where they can then be printed. To do this, you need the following: - Cable for USB flash drive - VIB 5.330AMEM - USB flash drive - VIB 5.350-USB (5269372) Connect the cable to the communication channel (green jack). -

Page 121: Exporting Measurement Data In Ms Excel Format

4-26 Reports Exporting measurement data in MS Excel format - Exportable measurement data: Overall value, FFT spectrum, balancing result, time waveform, coast-down measurement (amplitude phase and overall value), 2-channel measurements - Compatible version: MS Excel 2003, MS Excel 2007 • Connect VIBXPERT to the PC. -

Page 122: Chapter 5: Measurement Tasks

Measurement tasks Chapter 5: Measurement tasks This chapter contains information on the individual measurement tasks and tips for carrying out a measurement. The '2-Channel Measurements' module must be registered if you want to measure on both channels (see P. 2-23, P. 6-22). Note Characteristic overall vibration values Overall vibration values... -

Page 123: Shock Pulse Measurement

Measurement tasks Shock pulse measurement Shock pulse signal levels are indicated as a combination of 'Carpet value' (background level, indicative of lubrication condition) and 'Maximum value' (transient peak level, indicative of damage), both expressed in logarithmic [dB] terms. Bearing condition is determined by comparing normalized signal levels and their difference with reference values. - Page 124 Measurement tasks Entering the normalization parameters Before the shock pulse measurement starts, the normalization screen appears: • Select the type of normalization: No Normalization: Shock pulse value specified in dBsv. Manual: RPM is entered manually before the shock pulse measurement. External: RPM is measured with an RPM sensor before the shock pulse measurement.

-

Page 125: Rpm Measurements

Measurement tasks RPM measurements The Laser-Trigger Sensor (VIB 6.631) is used for RPM measurement and as a trigger encoder. The sensor detects the signals optically, i.e. without contacting rotating machine parts during the measurement. Red laser light is emitted from the sensor head and strikes a measurement mark on the rotating shaft. -

Page 126: Temperature Measurement

Measurement tasks Temperature measurement For temperature measurements thermocouple type K sensors such as the VIB 8.608 handheld probe can be used. Tips for measuring Measurement range: - Hold the sensor at the measurement location until the sensor has VIB 8.608: -50°C to 500°C recorded the temperature of the measurement object. -

Page 127: Runup / Coastdown

Measurement tasks Runup / Coastdown The runup and coastdown curves record the changes in the vibration behavior of the machine when it starts up or shuts down. This analysis function can be used to determine the resonance frequencies of a machine. The following types of measurement are available for this purpose: - Phase vector (amplitude and angle), dependent on the RPM - Spectrum, dependent on the RPM... - Page 128 Measurement tasks A.1 Selecting the measurement task via the measurement task icon: • Highlight the respective icon in the 'Advanced' tab. • Press the F key to display the stored measurement tasks • Select the required measurement task using the identifier. - Dual or 2-C: 2-channel measurements - Spec or spectrum: 'Spectrum RPM' measurement type - Overall Value: 'Overall Value - RPM' measurement type...

- Page 129 Measurement tasks C. Supplementary information C.1 'Overall Value - RPM' measurement type This type of measurement records the progression of the characteristic overall vibration values relative to the RPM. Points of resonance are indicated by RPMs with increased vibration amplitudes. The Results screen displays the path of the RMS value in the upper diagram;...

- Page 130 Measurement tasks C.3 'Phase - RPM' measurement type This type of measurement records the phase amplitude and the phase angle in dependence on the RPM. Points of resonance are indicated by RPMs with increased amplitude and a simultaneous jump in phase angle by (ideally) 180°. The results are displayed either in a Bode diagram or in a Nyquist diagram.

- Page 131 5-10 Measurement tasks C.4 Two-channel measurement The following differences appear when displaying the results of two-channel measurements. Spectrum - RPM Just one spectrum per channel is displayed on the results screen. Scrolling with the '+/-' key acts on both channels. In the waterfall diagram, you must select the channel whose spectrum is to be displayed.

- Page 132 5-11 Measurement tasks C.5 Measuring rate (number of measurement points) An important criteria for the quality of the results is the number of measurement values saved. The more measurement values, the more meaningful the measurement. The decisive factor here is how quickly the machine reaches the operating RPM or how quickly it comes to a standstill.

-

Page 133: Shaft Centerline Plot

5-12 Measurement tasks Shaft centerline plot A shaft centerline plot records the movement of the shaft axis* in a * The movement of the shaft axis at a journal bearing while the machine is running up or coasting down constant rpm is recorded with an orbit (e.g. - Page 134 5-13 Measurement tasks Starting the measurement and displaying the shaft centerline plot • Click on the measurement task icon and then on 'Start' (see p. 5-6). During data collection, the values for the DC component are displayed in the measurement data dialog window (see p. 5-7). •...

-

Page 135: Phase Measurement

5-14 Measurement tasks Phase measurement The phase measurement is used to identify machine faults that cause lines at the same position in the spectrum (e.g. static/ dynamic unbalance). The synchronous phase measurement determines the amplitude and the phase angle of the vibration pointer from the RPM-synchronous components of the vibration Synchronous Phase signal. - Page 136 5-15 Measurement tasks Order filter After the measurement, the order filter can be changed with the +/- Alternative: • Press the MENU key in the results screen. • Select 'Order', press the right navigation key and click on the required order. Scaling To magnify the scaling of the diagram, press the navigation key up.

-

Page 137: Orbit

5-16 Measurement tasks Orbit The movement of the shaft axis* at constant speed is measured with two non-contact sensors that are installed in an angular distance of 90 °. This enables identification of machine faults and damage to unfiltered filtered the shaft that become apparent in the vibration behavior of the shaft and directly affect the path of the shaft (e.g. - Page 138 5-17 Measurement tasks The signals of both sensors are displayed either as individual signals or as an orbit in a polar chart. The maximum and minimum * Keyphaser point: Point in the orbit, at phase vectors and the order filter are displayed in the data field on which the reference mark on the shaft the orbit display.

-

Page 139: Envelope Analysis

5-18 Measurement tasks Envelope analysis Envelope analysis is a proven method for detecting periodic impacts in the vibration signal of a machine. It is mainly used for Envelope spectrum for roller bearing analysis the diagnosis of roller bearing damage and gearing damage and is based on the demodulation of amplitude modulated vibration signals. -

Page 140: Cepstrum Analysis

5-19 Measurement tasks Cepstrum analysis A cepstrum is the 'spectrum of a spectrum' and is particularly suitable for detecting regular structures in a frequency spectrum. Above all, in the case of complex patterns with many harmonics and sidebands - that frequently occur if roller bearings or gearings are Cepstrum damaged- a cepstrum simplifies the evaluation of the measurement data. -

Page 141: Multi-Measurement Task ('Multitask')

5-20 Measurement tasks Multi-measurement task ('Multitask') A multi-measurement task shortens the measurement times by combining several, similar measurement tasks*. It is particularly time-saving in the case of measurement tasks that are measured at the same measurement location with the same transducer and * e.g. - Page 142 5-21 Measurement tasks Creating a multi-measurement task for a route / machine template Multi-measurement tasks for this operating mode are created in the OMNITREND editor for routes or machine templates. To do this, activate the 'Multitask' option (see below). OMNITREND then automatically combines the relevant measurement tasks into a single multi-measurement task.

- Page 143 5-22 Measurement tasks Multi-measurement task in the 'Multimode' operating mode Multi-measurement tasks are created in the Task Manager: • Open the Task Manager (see P. 3-19). • Select the upper menu 'Measurement task' and press the MENU key. • Click on 'New' and enter a name for the new measurement task. •...

-

Page 144: Dual Measurement (1+1)

5-23 Measurement tasks Dual measurement (1+1) In the case of a dual measurement, vibration measurements can be carried out as a overall value, spectrum or time signal on both channels at the same time, such as - Overall value on channel A and spectrum on channel B, or - Spectrum on channel A and time signal on channel B, etc. - Page 145 5-24 Measurement tasks The 'Import wizard' appears which is used to select the measurement type, the measurement quantity and the measurement task in three steps (see previous page). Transducer setup and evaluation setup of the measurement task will be automatically applied.

-

Page 146: Impact Test - 1 Channel

5-25 Measurement tasks Impact test - 1 channel The Impact test is used to determine the resonance frequency of a structure. In the case of a rotating machine, it is possible to determine the RPM ranges in which vibrations are disproportionately amplified by resonance* and could damage the machine. - Page 147 5-26 Measurement tasks Tips for setting the measurement parameters Set the 'Trigger Start" time to a negative value in order to record the Note signal before the excitation. If the measurement starts before the excitation, increase the trig- ger threshold in the measurement setup by approximately half (P. 3-22).

-

Page 148: Modal Analysis - Two-Channel Impact Test

5-27 Measurement tasks Modal analysis - two-channel impact test The two-channel impact test is used to visualize the dynamic behavior of a structure and to detect operating-critical natural vibration forms. ODS - Operating Deflection Shape Modal / ODS To record the vibration modes of a structure, the vibrations are recorded at multiple measurement locations during operation and set in relation to a reference measurement location. - Page 149 5-28 Measurement tasks always connect the sensor for the system response to channel A. After the last individual measurement is completed, save the data set in a file. With the ODS measurement, the measurement starts without a trigger, which means that spectra are recorded until the number of measurements is reached (standard = 4).

-

Page 150: Trendingspectrum

5-29 Measurement tasks The measurement tasks described on this page are only available in the 'Route / Machine template' mode. The measurement param- Note eters are set in the OMNITREND PC software. TrendingSpectrum A TrendingSpectrum is a measurement template for the route mode. -

Page 151: Dc Measurements

5-30 Measurement tasks DC measurements For the following measurement tasks, the DC component in the signal can be recorded in addition: - Time waveform with the measuring quantity set to vibration * see page 5-19 displacement or user-defined*. - Spectrum with the measuring quantity set to vibration displacement or user-defined*. -

Page 152: Chapter 6: Appendix

Appendix - Editors Chapter 6: Appendix This chapter provides information on how to use - the numerical and text editors, - the VIBXPERT utility software, - the File Manager - the VIBCODE transducer system. Instructions on handling and maintaining the VIBXPERT as well as the technical data complete this chapter. -

Page 153: Text Editor

Appendix - Editors Text Editor Entering text • Press the F key until the cursor appears in the character table (see below). • To enter the text, click on the respective characters in the table . If the required character is not included, then press the '+' key to display further character tables. -

Page 154: File Manager

Appendix - file manager File Manager The File Manager administrates the measurements which were saved in the 'Multimode' and 'Balancing' operating modes. In the 'PDF files' folder you will find the print files generated in the PDF format. You can print out or delete these here. The File Manager is opened by ... -

Page 155: Printing Out The Pdf File

Appendix - file manager Printing out the PDF file The print files saved in the PDF format can be printed as follows: • Connect VIBXPERT to a printer. • Open the File Manager and select the file to be printed. •... -

Page 156: Vibxpert Utility

Appendix - VIBXPERT utility VIBXPERT utility The 'VIBXPERT utility' tool can be used for these tasks: - Update firmware (with the VIBXPERT update tool) - Save and restore results and settings - Format the CF memory card (for older devices — serial number 30000 –... -

Page 157: Register Functions

Appendix - VIBXPERT utility Register functions These functions are to be enabled by a password: - Conversion of measurement files into formats that can be pro- cessed by other analysis programs (UFF / IEEE) Registration - db Spectra for converting narrow band spectra to third octave spectra. -

Page 158: Setting Up A Connection With Vibxpert

Appendix - VIBXPERT utility Setting up a connection with VIBXPERT Data transmission takes place via a network or USB connection. • Connect VIBXPERT to the network or a PC using the cable provided (see also p. 2-32). Connection • Click on the 'Connection' button. •... -

Page 159: Transferring Files

Appendix - VIBXPERT utility Transferring files The following files can be transferred from the device to the PC: - PDF files generated with a PDF printer driver. - Screenshots generated by pressing <F> & <-> simultaneously . Get files - Results in CSV format for analysis and display in a spreadsheet program (eg MS Excel). - Page 160 Appendix - VIBXPERT utility • Click 'Format CF card/Data section' to format the memory card/ section in the device. Risk of data loss! Before proceeding, make sure that all important data and settings are backed up on an external storage device. Formatting deletes all data on the memory card.

-

Page 161: Vibcode

6-10 Appendix - VIBCODE VIBCODE VIBCODE is a vibration measurement system that uses coded measurement points for certain identification of measurement locations on the machine. The system consists of the VIBCODE sensor and the VIBCODE measurement location. Note also the respective installation and operating manuals: VIBCODE, order no.: VIB 9.834.G Note Mechanical coding... -

Page 162: Coding

6-11 Appendix - VIBCODE Coding ..or, "How are the measurement locations in the data base linked to the measurement locations on site on the machine?" The coding of the “mechanical” measurement locations is defined in the measurement location data base using the OMNITREND software and stamped into a special plastic ring using a tool. -

Page 163: Measuring With Vibcode

6-12 Appendix - VIBCODE Measuring with VIBCODE Never use the VIBCODE sensor to take a measurement directly from the machine surface. This sensor must always be locked onto the measuring pin! Attention! Do not remove the VIBCODE sensor neither from the VIBCODE mea- surement location nor from VIBXPERT during measurement. -

Page 164: Measuring Vibcode Route/ Pool

6-13 Appendix - VIBCODE Measuring VIBCODE Route/ Pool • Click on ‘Route’ in the start screen. • Open the route to be measured. • Connect the VIBCODE sensor to a VIBCODE measurement location: VIBXPERT reads the coding of the measurement location and checks if this is created in the route. -

Page 165: Technical Notes

6-14 Appendix - Technical notes Technical notes VIBXPERT is a precision instrument and should be treated as such. Storage Use the VIBXPERT carrying pouch for transporting VIBXPERT and for making on-site measurements. If VIBXPERT is not used for lengthy periods, stow the measurement instrument in the pouch and connect it regularly to the mains to avoid the battery from completely discharging. -

Page 166: Guarantee

6-15 Appendix - Technical notes Guarantee The measurement device has a guarantee period of 1 year. Any guarantee claims expire if service work is carried out by non- authorized personnel. Spare parts, accessories Only original spare parts and accessories may be used. Information on these parts is given in the VIBXPERT product catalog. -

Page 167: Technical Data

6-16 Appendix - Technical notes Technical data PARAMETER VIB 5.310 Analog, 2x Voltage (AC/DC, ±30 V max.) Current (AC/DC, ±30 mA max.) ICP-type accelerometer (2 mA, 24 V max.) Current Linedrive (CLD) accelerometer (10 V, 10 mA max.) Frequency range DC ... - Page 168 6-17 Appendix - Technical notes PARAMETER VIB 5.310 Type TFT-LCD, backlit Pixel area 116 x 87 mm Resolution VGA (640 x 480 pixel) with 140 ppi Color depth 18 bit (262144 colors) Battery type Li Ion rechargeable battery pack (7.3V / 5.3Ah - 38.7 Wh) Charging time <...

-

Page 169: Troubleshooting

6-18 Appendix - Troubleshooting Troubleshooting Symptom: VIBXPERT will not start up. The start procedure is not executed completely, the display stops at the screen showing the LINUX penguin. Cause: Failure in the flash memory. Solution: Reload the firmware. Reloading firmware Before reloading the firmware, ensure that the following components are at hand or installed on the PC: - VIBXPERT update tool version 1.47 or higher (see P. - Page 170 6-19 Appendix - Troubleshooting • In the next screen, set up the COM port to be used on the PC. • Enter the IP address that is to be used by VIBXPERT. ‘Local IP address’ appears only if the PC has access to more than one network (virtual or physical).

-

Page 171: Index

6-20 Index Index Demodulation factor 3-23 Key controls 2-25 Device Info 2-29 Keyphaser 2-23 Device Setup 2-12 Diagram type 5-17 Display 2-13 Language 2-23 Symbols Protective film 2-13 Laser-trigger sensor 5-4 Display mode 4-18 1+1 measurement (Dual) 5-23 LED indicators 2-2 Display settings 3D display 4-13 Linear from / to 2-20... - Page 172 6-21 Index Options - Measurement 3-17 RS 232 2-32 Transducer Orbit 5-16 Runtime setup 3-11 new 2-21 Order-based spectrum 5-29 Runup / Coastdown 5-6 Parameter 2-19 Order filter 5-15 used in 2-19 Order scaling 4-18 Tree view 3-8 Order spectrum 5-29 Trend 4-19 Safety 1-10 Overall value 4-2...

- Page 173 Fluke Deutschland GmbH Freisinger Str. 34 85737 Ismaning, Germany +49 89 99616-0 www.pruftechnik.com PN5178694 12.2019, Rev. 2 06.2022 (LIT 53.201.EN.06.2022)

Need help?

Do you have a question about the VIBXPERT II and is the answer not in the manual?

Questions and answers