Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Fluke VIBXPERT II

- Page 1 VIBXPERT ® Operating Instructions Balancing...

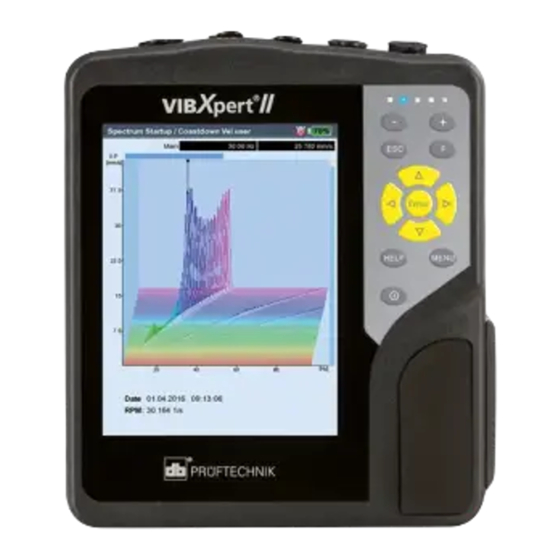

- Page 2 VIBXPERT ® Dual channel FFT data collector and signal analyzer 'Balancing' Operating Instructions Series: VIB 5.310 Firmware version: 3.2x Edition: December 2019 Order no.: LIT 53.202.EN Translation of the german manual...

- Page 3 The trademarks mentioned in this manual are generally noted as such and are the prop- erty of their owners. Lack of such designation does not imply, however, that names are not protected by trademark laws. © Fluke Corporation, all rights reserved...

- Page 4 Foreword Congratulations! And thank you for choosing the dynamic balancing * Also called 'VIBXPERT' and 'measure- option in one or two planes to expand your VIBXPERT II FFT data col- ment instrument' in this manual. lector and signal analyzer*. The balancing module is based on the well-known "influencing coef- ficients method"...

-

Page 5: Table Of Contents

Contents Contents Chapter 1: Introduction ..........1-5 Safety ....................1-5 Symbols ......................1-5 Intended use ....................1-5 Conformity .....................1-5 General safety ....................1-6 Registration ..................1-7 Chapter 2: Balancing ..........2-1 Balancing on machines with rotating masses ..........2-3 Diagnosis ..................2-4 Preparatory activities ..............2-5 Assembly ......................2-5 Operation ..................2-9 Balancing in one plane ..............2-11 Measuring the initial imbalance ..............2-12 Trial run ......................2-12... -

Page 6: Chapter 1: Introduction

Introduction Chapter 1: Introduction Safety You must carefully read and understand the safety instructions in the VIBXPERT operating manual (LIT 53.201.EN) as well as the follow- ing safety instructions for balancing before starting work with the measurement device. Symbols Danger to life and limb. WARNING! Danger of improper operation which can cause damage. -

Page 7: General Safety

Safety General safety • The applicable safety regulations must be observed when per- forming measurements on running machines. • When assembling measurement components, make sure that no holders, cables, etc. project into the range of movement of rotat- ing machine parts. •... -

Page 8: Registration

Registration Registration The balancing software is already contained in the instrument and must be activated by entering a password. Changes to the instrument or the loading of additional software are not necessary. Entering the password The password is given on the certificate contained in the scope of de- livery of the balancing module. - Page 9 Empty page...

-

Page 10: Chapter 2: Balancing

Introduction Chapter 2: Balancing Increased vibrations on machines are undesirable phenomena. They impair product quality, place additional strain on components and, last but not least, reduce operational safety. The most frequent cause for these increased vibrations is imbalance. The high centrifugal forc- es that result lead to premature wear of machine components such as bearings and seals, for example. - Page 11 Introduction If an individual imbalance which does not lie on the center of grav- ity is added to a completely balanced rotor in one plane, it is called a quasi static imbalance. It corresponds to the combination of a static imbalance and a couple imbalance and is usually compensated in two planes.

-

Page 12: Balancing On Machines With Rotating Masses

Introduction Balancing on machines with rotating masses The VIBXPERT balancing module is based on the well-known 'influ- ence coefficients method': First, VIBXPERT measures the vibration amplitude and phase angle and the vibration caused by the imbalance or so-called 'initial imbal- ance'. -

Page 13: Diagnosis

Introduction Diagnosis Before beginning the balancing procedure, first make sure that the cause for the adversely affected smooth running of the rotors is actu- ally an imbalance. Furthermore, a vibration diagnosis indicates which balancing method is the most suitable. A series of coordinated measurement tasks are available for the diag- nosis of an imbalance: •... -

Page 14: Preparatory Activities

Preparations Preparatory activities Preparations include the mounting of the measurement components. The machine must be..disconnected before carrying out any work on the machine..protected against being switched on again inadvertently! WARNING! Assembly 1. Find out the cause of the imbalance visually and fix it if possible, e.g.: Remove any coatings from the impeller, fasten any loose bal- ancing weights or tighten any loose screws on the foundation. - Page 15 Preparations High axial amplitudes indicate a large imbalance of torque which cannot be balanced using the methods described here. N ote 4. Attach a reference mark on the shaft for the trigger sensor while the machine is at a standstill. •...

- Page 16 Preparations 5. Mount the laser trigger sensor (VIB 6.631) with the trigger bracket (VIB 6.632) on the machine. 6. Connect the vibration transducer to the measurement instrument. Vibration transducer on the magnetic adapter (VIB 6.142R + VIB 3.420) Reflective tape (VIB 3.306) Trigger Bracket Laser Trigger Sensor...

- Page 17 Empty page...

-

Page 18: Operation

Operation Operation If you are not yet familiar with operation in balancing mode, please note the following instructions: Settings All settings necessary for the measurement and evaluation of a bal- ancing run are made in setup menus. The following setups can only be changed before a balancing run is begun: - Measurement setup: measurement settings (see p. - Page 19 2-10 Operation The respective balancing step appears on the upper left of both screens: 0. Initial imbalance Measurement of the original imbalance; if the vibration values are within the tolerance range, the rotor is balanced. Otherwise, the bal- ancing weights must be placed on the rotor according to the following balancing steps.

-

Page 20: Balancing In One Plane

2-11 1-plane balancing Balancing in one plane On the basis of an example, the next section illustrates the steps that are needed to balance in one plane: Requirements - In the following example, the machine setup is not used. - The default settings in the 'Tools' menu item are not changed: - Correction mode: free - "Add"... -

Page 21: Measuring The Initial Imbalance

2-12 1-plane balancing Measuring the initial imbalance 1. Switch the machine on. Wait until the machine has reached the balancing RPM and operating temperature if necessary. 2. Press 'Enter' to start the measurement. First, VIBXPERT records the RPM. The green LED flashes with each trigger pulse. -

Page 22: Trim Run

2-13 1-plane balancing 4. Switch the machine on. 5. Press 'Enter' to start the measurement. 6. If the measurement values are stable, press 'Enter' to stop the mea- surement. 7. Switch the machine off. In the trial run the imbalance should change enough to steadily reduce the residual imbalance in the subsequent balancing runs. -

Page 23: Undoing Balancing Runs

2-14 1-plane balancing In the following trim runs VIBXPERT checks whether the imbalance has sufficiently reduced from one run to the next. If this is not the case, the following message appears: ‘No Improvement’. The run con- cerned must be repeated with a different balancing weight. ... -

Page 24: Balancing In Two Planes

2-15 2-plane balancing Balancing in two planes In principle, the process here corresponds to the previous section. Therefore, only the specific features of balancing in two planes are described in the following section: Overview of the measurement procedure Select plane A: Determine the measurement and balancing plane A. 0. -

Page 25: Trial Run

2-16 2-plane balancing Trial run The trial run is divided into two parts which are marked in the main screen as "1A" or "1B": The trial weight is attached in and its influence is mea- plane A sured in both planes. The trial weight is attached in and its influence measured plane B... -

Page 26: Evaluation Of The Data

2-17 Evaluation Evaluation of the data The following data are listed in the data screen for each completed balancing run: : Mass of the balancing weight : Fixing angle ngle : Vibration overall values (RMS, 0-p, p-p*) ibration * see Display setup, p. 2-24 : Phase angle ngle If you entered the rotor mass and the balancing radius in the machine... -

Page 27: Options For Balancing

2-18 Evaluation Options for balancing 1. Combining balancing weights If several weights have already been placed on the rotor, they can be combined into one single weight. VIBXPERT vectorially adds the weights of the completed balancing runs and displays the resulting weight and fixing angle in the 'Data' screen and the 'Data View' screen. -

Page 28: Changing The Correction Mode (Tools Menu / Machine Setup)

2-19 Options 2. Changing the correction mode (Tools menu / Machine setup) The correction mode describes how the balancing weight is attached to the rotor. Normally the correction mode is set to 'Free & add', i.e. the weight can have any mass and be placed at any angular position. •... - Page 29 2-20 Options 2.2 Fixed weight Activate the "Fixed weight" option if only specific masses (e.g. 2g, 5g, 10g) are available for balancing. Then enter the mass of the "Fixed weight". VIBXPERT calculates two angular positions at which the two equal weights must be placed. "Free"...

-

Page 30: Removing The Balancing Weight (Tools Menu/ Machine Setup)

2-21 Options 3. Removing the balancing weight (Tools menu/ Machine setup) If the balancing weights cannot be attached to the rotor by clamping, welding, screwing or similar, the imbalance can also be compensated by grinding material off the rotor. To do this, select the "Trial/ Trim weights ->... -

Page 31: Entering The Balancing Radius And Rotor Mass Later (Tools)

2-22 Options 5. Entering the balancing radius and rotor mass later (Tools) If you start the balancing procedure without the machine setup, you can enter the balancing radius and the rotor mass later in the Tools menu. VIBXPERT then calculates the balancing quality and the cen- trifugal force for the current trim run. - Page 32 2-23 Options 2. Load the coefficient from the file: • Click on 'Load'. • Select the coefficient file. Here, the coefficient must be saved after the trial run. Note 3. Adopting the influence coefficient by restarting from a file: •...

-

Page 33: Display Setup

2-24 Display-Setup Display setup In the display setup, you can define the display settings for the data screen and measurement screen. The display setup can be called up on every screen: • Press the MENU button and click on 'Display setup'. : Speed or step size when zooming. -

Page 34: Printing The Balancing Report

• Press the MENU button and click on 'Print > 'Report printouts'. • Select the printer. • Select the report configuration in the 'Reports' menu, or create a new report configuration (see VIBXPERT II manual, page 4-21). General report information can be entered in the 'Common settings' tab. -

Page 35: Setup Parameters

- Machine setup (see below) - Measurement setup (see p. 2-28) - Transducer setup (see VIBXPERT II operating manual, page 2-20) These setups are configured prior to a balancing procedure. Dur- ing balancing, only certain parameters from the machine setup can be changed. - Page 36 2-27 Machine setup Depending on the selection, the following parameters can be set: - No. of locations: 3-100. Usually the number of ventilator blades. - Fixed weight: Mass of the available balancing weight. - Outer diameter: The tape measure can be used to determine the position of the balancing weight without a reference angle (see graphic on page 2-20).

- Page 37 2-28 Machine setup : The angle between the sensor and the trigger sensor is rigger angle taken into account in the calculation of the attachment angle for the trial weight. Convention: Angle is counted against the direction of rotation of the rotor. *: Reference RPM for calculation of the peeD for balance quality achieved balance grade and centrifugal force (see p.2-22).

-

Page 38: Measurement Setup

2-29 Measurement setup Measurement setup In order to edit or create a measurement setup proceed as follows: • Mark a rotor type in the selection screen (see p. 2-11). • Press the MENU button and click on "Task manager". • Select a user-defined task. •... -

Page 39: Balancing With A Control Plane

2-30 Control plane Balancing with a control plane While balancing in one plane, the vibration pointer in a second plane - the control plane - can be recorded and displayed as well. Activating the control plane In the machine setup activate the 'Control 2nd plane' option (see p. 2-28 below). -

Page 40: Balance Calculator

2-31 Balancing calculator Balance calculator With the VIBXPERT balance calculator you can convert any arrange- ment of balance weights on a rotor to a resulting weight. The balance calculator operates as an independent functional mod- ule. The result cannot be saved or used in an ongoing balancing Note procedure. -

Page 41: Operation Of The Balance Calculator

2-32 Balancing calculator Operation of the balance calculator The calculator can be started before or during a balancing procedure. • Press MENU and click ‘’. • Press the Plus (+) key to add a new weight. In the correction modes ‘Fixed location’ and ‘Fixed weight’, two weights are possible for each line. -

Page 42: Chapter 3: Appendix

Appendix Chapter 3: Appendix This section contains the following information: - Overview of the quality classes according to DIN ISO 1940. This en- ables the user to set up the balancing quality in the machine setup. - Messages that may appear during the balancing procedure. Balancing quality classes and groups of rigid balancing bodies (excerpt from DIN ISO 1940) Qty. -

Page 43: Messages During Balancing

Appendix Messages during balancing Insufficient improvement The vibration values are greater than 1 mm/s and have not suffi- ciently improved. Check whether the cause is actually an imbalance. One-plane balancing is recommended The dynamic portion of the calculated imbalance is larger than the static portion. - Page 44 Appendix Pointer change too large The vibration pointer in the trial run has changed too much in magni- tude and phase in comparison to the initial imbalance run. Pointer change too small The vibration pointer in the trial run has not changed enough in mag- nitude and phase in comparison to the initial imbalance run.

-

Page 45: Emergency Storage

Appendix Emergency storage If the balancing procedure is stopped prematurely (e.g. battery dis- charged), the data are stored in a recovery file. When the device is switched on again, the balancing procedure can be continued with the aid of this recovery file. Opening the recovery file •... -

Page 46: Index

Index Index Assembly 2-5 Join masses 2-32 Auto average 2-28 Auto trial weight 2-27 Laser trigger sensor 2-6 Lowpass filter 2-29 Balance calculator 2-31 Balance quality 2-27 Balancing in one plane 2-11 Machine setup 2-26 Balancing in two planes 2-15 Measurement range 2-29 Balancing radius 2-22 Measurement setup 2-29... - Page 47 Productive maintenance technology Fluke Deutschland GmbH Freisinger Str. 34 85737 Ismaning, Germany + 49 89 99616-0 www.pruftechnik.com Printed in Germany LIT 53.202.12.2019.0G...

Need help?

Do you have a question about the VIBXPERT II and is the answer not in the manual?

Questions and answers