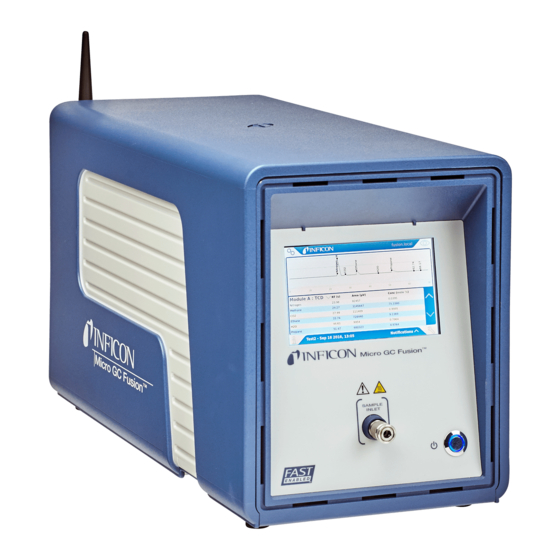

Inficon Micro GC Fusion Installation Sheet

External sample conditioner

Hide thumbs

Also See for Micro GC Fusion:

- Quick start manual (9 pages) ,

- Rack mount instruction sheet (4 pages) ,

- Installation manual (24 pages)

Table of Contents

Advertisement

Quick Links

Installation Sheet

Micro GC Fusion® External Sample Conditioner

Introduction

Micro GC Fusion can be damaged by high pressure samples, especially those containing contaminants, such as condensing aerosols. The

external sample conditioner (PN 952-004-G1) maintains the sample at > 50°C (122°F) and reduces the sample pressure from up to 5516

kPa (800 psi) down to approximately 0-172 kPa (0-25 psi) prior to the sample being introduced to Micro GC Fusion. This minimizes the

introduction of contaminants and aerosols onto Micro GC Fusion.

The external sample conditioner can be installed on the front of a 2-module Micro GC Fusion and transported into the field for direct

analysis.

1 / 19

CAUTION

Micro GC Fusion is intended for gas sampling only. Liquid injections will damage the instrument.

WARNING

Gas pressure on the external sample conditioner vent may be up to 5516 kPa (800 psi). Extreme caution must

be taken when venting the high pressure sample to avoid personal injury.

WARNING

The external sample conditioner is rated for 5516 kPa (800 psi) input sample pressure.

074-732-P1A Micro GC Fusion External Sample

Conditioner Installation Sheet

Advertisement

Table of Contents

Summary of Contents for Inficon Micro GC Fusion

- Page 1 (PN 952-004-G1) maintains the sample at > 50°C (122°F) and reduces the sample pressure from up to 5516 kPa (800 psi) down to approximately 0-172 kPa (0-25 psi) prior to the sample being introduced to Micro GC Fusion. This minimizes the introduction of contaminants and aerosols onto Micro GC Fusion.

-

Page 2: Specifications

Category II per IEC 60664 Cleaning Use a mild, non-abrasive cleaner or detergent. Ensure the cleaner does not enter the unit. NOTE: The Micro GC Fusion external sample conditioner is designed for indoor use only. 2 / 19 074-732-P1A Micro GC Fusion External Sample ... -

Page 3: List Of Required Tools

Installation Sheet Support For support and technical assistance, please contact INFICON, 2 Technology Place, East Syracuse, NY 13057-9714. External Sample Conditioner Accessory Kit Description Quantity External sample conditioner assembly Slide plate 1/4 in. male quick connect (PN 059-0808S) Screws Bottom mounting bracket... -

Page 4: Installation

The external sample conditioner can be installed on the 2-module Micro GC Fusion. The external sample conditioner is factory pre- assembled, and can be easily mounted onto Micro GC Fusion during instrument installation. - Page 5 Place the wing nuts on the bottom bracket threads and hand-tighten. Ensure that the top bracket is pressed downward and is tightly secured to Micro GC Fusion. Using a 3 mm hex driver, slightly thread the M4 screws into the holes on the bottom bracket, near the chassis of Micro GC Fusion. 5 / 19 074-732-P1A Micro GC Fusion External Sample ...

- Page 6 Loosely thread the front screws into the slide plate using a 3.0 mm hex driver. Tighten the transfer line nut to the front inlet of Micro GC Fusion one-quarter turn past finger-tight using a 5/16 in. wrench. 6 / 19 074-732-P1A Micro GC Fusion External Sample ...

- Page 7 Attach a 1/8 in. vent line to the HIGH PRESSURE VENT. Tighten it with a 7/16 in. open-ended wrench. WARNING Gas pressure on the HIGH PRESSURE PURGE VENT may be up to 5515 kPa (800 psi). Extreme caution must be taken to avoid personal injury. 7 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet...

- Page 8 Plug in the power cord to the power supply and connect to an AC power source. CAUTION Only replace the power cord with proper approved cords or contact INFICON to purchase a replacement cord. WARNING Safely vent sample stream vent ports using the appropriate sized tubing for each connection. Potentially toxic, noxious, asphyxiant (oxygen displacing) or flammable gasses should be vented outside Micro GC Fusion and away from the operating area.

-

Page 9: Operation

Safely vent sample stream vent ports using the appropriate sized tubing for each connection. Potentially toxic, noxious, asphyxiant (oxygen displacing) or flammable gasses should be vented outside Micro GC Fusion and away from the operating area. Vent toxic gases to a fume hood, chemical trap, or reaction medium. - Page 10 Turn the manual valve to the Sample position. Conduct a run using Micro GC Fusion software. When finished with the sample, shut off the gas source. To depressurize the system, slowly turn the manual valve halfway towards the Vent position.

-

Page 11: Spare Parts

Transfer line kit (includes one 1/16 in. sample transfer tubing with rubber insulation sleeve and 1/16 in. nut and ferrules) 952-019-G1S Filter element kit (includes six 7 µm filters and one gasket) 033-0074S Power supply kit (includes one) 11 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet... - Page 12 Part Number Description 952-515-P1S Filter cover kit (includes one) 059-0809S Bonnet nut kit (includes one) 144-374S M5 wing nut kit (includes four) 059-0808S Quick stem connector kit (includes one) 12 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet...

- Page 13 Replacing the Internal Filter on the External Sample Conditioner To replace the filter (part of PN 952-019-G1S): Remove the power cord from the Micro GC Fusion external sample conditioner. Ensure the handle is in the vent position and disconnect any sample line(s).

- Page 14 The filter assembly nut is tightened 1/8 turn past finger-tight for high pressure applications. Remove the filter. Replace the 7 µm filter ensuring the 7 is facing outward. Re-install the bonnet nut and hand-tighten. 14 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet...

- Page 15 Cover the bonnet nut by reattaching the cover door using the thumb screw on the side of the device. Reattach the power cord to the external sample conditioner. 15 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet...

- Page 16 Replacing the Gasket on the External Sample Conditioner To replace the gasket (part of PN 952-019-G1S): Remove the power cord from the Micro GC Fusion external sample conditioner. Ensure the handle is in the vent position and disconnect any sample line(s).

- Page 17 Remove the bonnet nut. The filter assembly nut is tightened 1/8 turn past finger-tight for high pressure applications. Remove the filter. Using a pick, remove the old gasket. 17 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet...

- Page 18 Installation Sheet Old gasket New gasket Using a pick, insert and seat the new gasket. Replace the 7 µm filter ensuring the 7 is facing outward. 18 / 19 074-732-P1A Micro GC Fusion External Sample Conditioner Installation Sheet...

- Page 19 Installation Sheet Re-install the bonnet nut and hand-tighten. Using a 1 in. open-ended wrench, tighten 1/8 of a turn past finger-tight. Cover the bonnet nut by reattaching the cover door using the thumb screw on the side of the device. Reattach the power cord to the external sample conditioner.

Need help?

Do you have a question about the Micro GC Fusion and is the answer not in the manual?

Questions and answers