probst TSZ-UNI Operating Instructions Manual

Concrete step handles

Hide thumbs

Also See for TSZ-UNI:

- Operating instructions manual (63 pages) ,

- Operating instructions manual (31 pages) ,

- Operating instructions manual (130 pages)

Summary of Contents for probst TSZ-UNI

- Page 1 Operating Instructions Translation of original operating instructions Concrete Step Handles TSZ-UNI 53100338...

-

Page 2: Table Of Contents

Accessories – height adjustable support .................. 13 6.1.1 Operation ..........................15 Operating for devices with automatic release ................15 Picture of the automatic release ....................15 Gripper change (steelfinger grippers TSZ-UNI-WB-SQ) ..............16 Handling with steelfinger grippers (WB-SQ) ................17 2 / 22... - Page 3 MECHNICAL .......................... 19 Additional with steelfinger grippers (WB-SQ) ................20 8.2.1 Trouble shooting ........................20 Repairs ..........................21 Safety procedures ........................21 Hints to the identification plate ....................22 Hints to the renting/leasing of PROBST devices ............... 22 3 / 22...

-

Page 4: Ec-Declaration Of Conformity

DIN EN 349 Minimum distance to avoid squeezing any parts of the body (ISO 13854). Authorized person for EC-dokumentation: Name: J. Holderied Address: Probst GreiftechnikVerlegesysteme GmbH; Gottlieb-Daimler-Str. 6; D-71729 Erdmannhausen Signature, informations to the subscriber: Erdmannhausen, 14.01.2015................(M. Probst, Managing director) -

Page 5: Safety

Operating Instructions Safety TSZ-UNI 3 Safety Safety symbols Danger to life! Identifies imminent hazard. If you do not avoid the hazard, death or severe injury will result. Hazardous situation! Identifies a potentially hazardous situation. If you do not avoid the situation, injury or damage to property can result. -

Page 6: Safety Marking

Operating Instructions Safety TSZ-UNI Safety Marking PROHIBITION SIGN Symbol Meaning Order-No.: Size: 2904.0213 30 mm The transportation of non rectangular goods is not allowed! 2904.0212 50 mm 2904.0211 80 mm 2904.0210 30 mm It is not allowed to be under hanging loads. Danger to life! 2904.0209... -

Page 7: Personal Safety Requirements

Operating Instructions Safety TSZ-UNI Personal safety requirements ● Each operator must have read and understood the operating instructions. ● Only qualified, authorized personal is allowed to operate the device and all devices which are connected (lifting equipment). ● The manual guiding is only allowed for machines with handles. -

Page 8: Safety Procedures

Operating Instructions Safety TSZ-UNI Safety procedures 3.4.1 General ● The use of the device is only permitted in proximity to the ground. Do not swing it over peoples heads. ● The manual guiding of is only allowed for devices with handles. -

Page 9: General

4 General Authorized use The device (TSZ-uni) is specially designed for gripping, transporting and the following laying of gripping goods such as, steps, kerb stones, contact angle, L-stones, as well ashlar rocks (via the assembly of the accessories “steelfinger grippers WB-SQ”) in conjunction with a corresponding lifting device (e.g. excavator). - Page 10 Operating Instructions General TSZ-UNI Only stone elements with parallel and plane surface are allowed to be picked-up and handled. Because the gripping good could fall down. NOT ALLOWED AKTIVITIES: Unauthorized alterations of the device and the use of any self-made additional equipment could cause danger and are therefore forbidden!! Never exceed the carrying capacity and the nominal width/gripping range of the device.

-

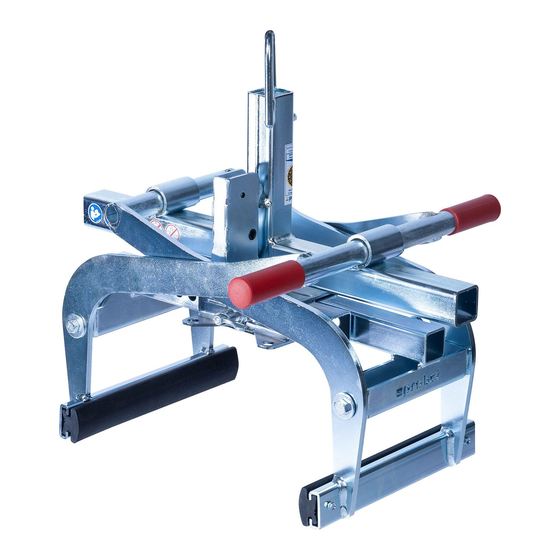

Page 11: Survey And Construction

Assembly plate for height adjustable support (43100867) Spring bolt (for gripping range adjustment) Rubber gripper bar (PGL3) Automatic release TSZ-uni (standard) TSZ-uni (with accessories A 43100867 ) Height adjustable support (43100867) Fig. 3 Fig. 2 Technical Data Type: Gripping range W... -

Page 12: Installation

Operating Instructions Installation TSZ-UNI 5 Installation Mechanical connection 5.1.1 Suspension lug ● The device is equipped with a suspension lug and can be mounted on various support frames/lifting devices. ● Take careful that the suspension lug is safety joined with the crane hook and can not slip down. -

Page 13: Accessories - Height Adjustable Support

6.1.1 Accessories – height adjustable support When using the device (TSZ-uni) in batch operation, for gripping of single stone slabs (batched one upon the other), we advise to use the accessories “height adjustable support” (43100867)! – see Fig. 1 Therefore, the inside height must not always adjusted again for gripping goods with the same dimensions (see Figure 1). - Page 14 Operating Instructions Adjustments TSZ-UNI ● The “height adjustable support (A) is attached to the “mounting plate of the height adjustable support” see Fig. 2 (and Fig. 3) ● Adjust the “height adjustable support (A) with the adjusting screws and regard the both “height adjustable supports (A)”...

-

Page 15: Operation

Operating Instructions Operation TSZ-UNI 7 Operation Operating for devices with automatic release ● The device is connected to the lifting equipment/support frame (e.g. excavator). ● Before lifting the device, the gripping range has to be adjusted. ● The device is placed over the product, set down, the device closes round the product and it can be lifted. -

Page 16: Gripper Change (Steelfinger Grippers Tsz-Uni-Wb-Sq)

Operation TSZ-UNI Gripper change (steelfinger grippers TSZ-UNI-WB-SQ) For movements of roughly-cut ashlar rocks with the device (TSZ-uni) change the standard rubber grippers (Figure A) againt stellfinger grippers (Figure B) 1.) Unscrew both standard rubber grippers and then 2.) Figure B showws the device (TSZ-uni) pull them out of the holders (Figure A) without rubber grippers. -

Page 17: Handling With Steelfinger Grippers (Wb-Sq)

Worn (no longer sharp-edged) or bent steelfinger grippers must be replaced! Otherwise it exists slipping danger of the gripping good! 1.) Position the device (TSZ-uni) direct over the gripping 2.) Put the device (TSZ-uni) at the gripping good (ashlar good (ashlar rock). rock). Then lift the device (TSZ-uni) approx. 20 cm (7.8"). - Page 18 The safety chain must never be used as a gripping good (ashlar rock), so that gripping good with "lifting tackle" to attach the device (TSZ-uni) is secured by the security chain! see Figure C on the support frame (e.g. excavators)!

-

Page 19: Maintenance And Care

Operating Instructions Maintenance and care TSZ-UNI 8 Maintenance and care Maintenance To ensure the correct function, safety and service life of the device the following points must be executed in the maintenance interval. Used only original spare parts, otherwise the warranty expires. -

Page 20: Additional With Steelfinger Grippers (Wb-Sq)

Operating Instructions Maintenance and care TSZ-UNI 8.2.1 Additional with steelfinger grippers (WB-SQ) Before each start-up: ● Check all steelfinger grippers for mobility, abrasion and contamination. Worn (no longer sharp-edged) or bent steelfinger grippers must be replaced! Regular: ● Cleaning of the device with high pressure cleaner (warm water). -

Page 21: Repairs

Operating Instructions Maintenance and care TSZ-UNI Repairs ● Only persons with the appropriate knowledge and ability are allowed to repair the device. ● Before the device is used again, it has to be checked by an expert. Safety procedures ... -

Page 22: Hints To The Identification Plate

Example: Hints to the renting/leasing of PROBST devices With every renting/leasing of PROBST devices the original operating instructions must be included unconditionally (in deviation of the users country's language, the respective translations of the original operating instructions must be delivered additionally)! - Page 23 Tragfähigkeit / load capacity: 600 kg Bei Änderungungen Rücksprache TB ! Gewicht: 31,5 kg Schutzvermerk nach DIN 34 beachten! Nachdruck nur mit unserer Genehmigung! Benennung Datum Name Trittstufenversetzzange TSZ-uni m. WA Erst. 18.10.2004 Klaus.Scholl Gepr. 3.6.2014 Joerg.Werner Blatt Artikelnummer/Zeichnungsnummer D53100338 Kunde: Urspr.

- Page 24 20000026 20440006 33100003 Bei Änderungen Rücksprache TB ! Gewicht: 31,5 kg 20030011 Schutzvermerk nach DIN 34 beachten! Nachdruck nur mit unserer Genehmigung! Benennung Datum Name Trittstufenversetzzange TSZ-uni m. WA Erst. 18.10.2004 Klaus.Scholl Gepr. 3.6.2014 Joerg.Werner Blatt Artikelnummer/Zeichnungsnummer E53100338 Kunde: Urspr.

- Page 25 After each completed performance of a maintenance interval the included form must be fill out, stamped, signed and send back to us immediately 1) via e-mail to service@probst.eu / via fax or post Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _...

- Page 26 After each completed performance of a maintenance interval the included form must be fill out, stamped, signed and send back to us immediately 1) via e-mail to service@probst.eu / via fax or post Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _...

- Page 27 After each completed performance of a maintenance interval the included form must be fill out, stamped, signed and send back to us immediately 1) via e-mail to service@probst.eu / via fax or post Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _...

Need help?

Do you have a question about the TSZ-UNI and is the answer not in the manual?

Questions and answers