probst TSZ-UNI Operating Instructions Manual

Concrete step handles

Hide thumbs

Also See for TSZ-UNI:

- Operating instructions manual (27 pages) ,

- Operating instructions manual (63 pages) ,

- Operating instructions manual (130 pages)

Subscribe to Our Youtube Channel

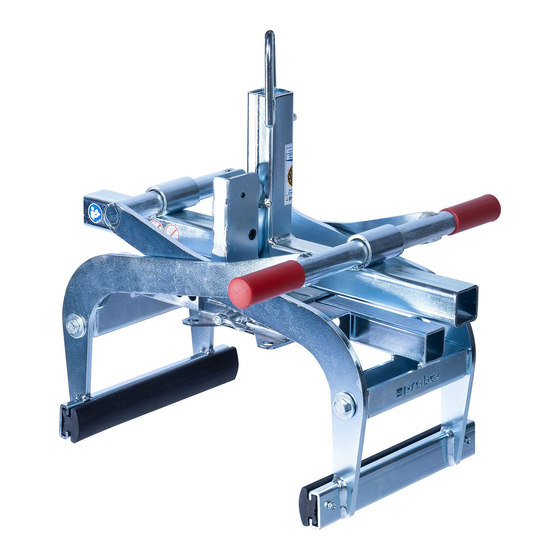

Summary of Contents for probst TSZ-UNI

- Page 1 Operating Instructions Translation of original operating instructions Concrete Step Handles TSZ-UNI 5310.0338...

-

Page 2: Table Of Contents

7.1.1 Mechanical ..............................23 7.1.2 Additional with steelfinger grippers (WB-SQ) ..................24 Trouble shooting ............................25 Repairs ................................25 Safety procedures ............................25 Hints to the type plate ..........................26 Hints to the renting/leasing of PROBST devices ..................26 5310.0338... -

Page 3: Ec-Declaration Of Conformity

Safety of machinery - safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008) Authorized person for EC-documentation: Name: J. Holderied Address: Probst GmbH; Gottlieb-Daimler-Straße 6; 71729 Erdmannhausen, Germany Signature, information to the subscriber: Erdmannhausen, 21.11.2018................ -

Page 4: Safety

Safety 4 / 26 Safety Safety symbols Danger to life! Identifies imminent hazard. If you do not avoid the hazard, death or severe injury will result. Hazardous situation! Identifies a potentially hazardous situation. If you do not avoid the situation, injury or damage to property can result. -

Page 5: Explanation Of The Pictograms

Safety 5 / 26 2.3.1 Explanation of the pictograms Automatic release is „empty“ Automatic release is „full“ Do not use damaged accessories, replace if necessary! Do not hold limbs under the lifted load! Allowed slings: hook and lifting strap. Risk of injury! Load securing chain (lashing chain) must not be used as sling If the load falls into the load securing chain, the chain must be chain! -

Page 6: Safety Marking

Safety 6 / 26 Safety Marking PROHIBITION SIGN Symbol Meaning Order-No. Size 2904.0210 Ø 30 mm It is not allowed to stand under hanging loads. Danger to life! 2904.0209 Ø 50 mm 2904.0204 Ø 80 mm 2904.0213 Ø30 mm The transportation of non-rectangular goods is not allowed! 2904.0212 Ø50 mm 2904.0211... -

Page 7: Personal Safety Requirements

Safety 7 / 26 Personal safety requirements Each operator must have read and understood the operating instructions (and all safety instructions). Only qualified, authorized personal is allowed to operate the device and all devices which are connected (lifting device/carrier). The manual guiding is only allowed for devices with handles. Protective equipment •... -

Page 8: Safety Procedures

Safety 8 / 26 Safety procedures 2.9.1 General • The use of the device is only permitted in proximity to the ground. Do not swing it over people heads. • The stay under lifted load is forbidden. Danger to Life! •... -

Page 9: General

General Authorized use The device TSZ-UNI is specially designed for gripping, transporting and the following laying of gripping goods such as, steps, kerb stones, contact angle and L-stones. Via the assembly of the accessoire “steelfinger grippers WB-SQ” ashlar rocks can also be gripped. - Page 10 General 10 / 26 NOT ALLOWED ACTIVITIES: Unauthorized alterations of the device and the use of any self-made additional equipment could cause danger and are therefore forbidden! Never exceed the carrying capacity/working load limit (WLL) and the nominal width/gripping range of the device.

-

Page 11: Survey And Construction

Rubber gripper (exchangeable) 6. Montageplatte für HVA Automatic release for the fully automatic switch over from “full” to “empty” Accessoires HVA-FTZ/TSZ TSZ-UNI-WB-SQ TSZ-UNI-ET Laying in batch operation Gripping of roughly-cut ashlar rocks Fork sleeve Technical data Carrying capacity Type... -

Page 12: Installation

Installation 12 / 26 Installation Mechanical connection Use only original accessories, in case of doubt consult the manufacturer. Take care that the carrying capacity / working load limit (WLL) of the lifting device/carrier is not exceeded, through the load of the device, the attaching devices (turning device, fork sleeves etc.) and the additional load of the gripping goods! Gripping devices always have to be gimballed, so they can swing freely in any position. -

Page 13: Fork Sleeves (Optional)

Installation 13 / 26 4.1.4 Fork sleeves (optional) To establish a mechanical connection between the fork lift truck and the fork sleeves you have to put the forks into the fork sleeves and fix it with the locking bolt or with a chain/rope, connected to the eyelet on the fork sleeves and the lift frame. - Page 14 Installation 14 / 26 5310.0338...

-

Page 15: Adjustments

Adjustments 15 / 26 Adjustments Adjustment of the gripping range 5310.0338... - Page 16 Adjustments 16 / 26 5310.0338...

-

Page 17: Accessoires- Hva For Batch Processing

Adjustments 17 / 26 Accessoires– HVA for batch processing 5310.0338... -

Page 18: Operation

Operation 18 / 26 Operation Gripping, moving and laying of gripping goods 5310.0338... - Page 19 Operation 19 / 26 5310.0338...

-

Page 20: Picture Of The Automatic Release

Operation 20 / 26 Picture of the automatic release The device is equipped with an automatic release, that means the OPENING and CLOSING of the gripping arms results through the set down and lifting of the device. Pictures of the positions of the automatic release: •Device is lifted through the lifting •Device is set up on the gripping good •Device is lifted through the lifting... -

Page 21: Operation: Steelfinger Grippers Wb-Sq

Operation 21 / 26 Operation: Steelfinger grippers WB-SQ 5310.0338... - Page 22 Operation 22 / 26 5310.0338...

-

Page 23: Maintenance And Care

Maintenance and care 23 / 26 Maintenance and care Maintenance To ensure the correct function, safety and service life of the device the following points must be executed in the maintenance interval. Used only original spare parts, otherwise the warranty expires. All operations may only be made in closed state of the device! For all operations you have to make sure, that the device will not close unintended. -

Page 24: Additional With Steelfinger Grippers (Wb-Sq)

Maintenance and care 24 / 26 Rubber gripper bar Regular control for dirt (e.g. little stone particles) in the upper area (see points in figure detail „X“ in Fig. 2) of the rubber gripper bar (6) → see Fig. 1 / Fig. 2 Problem: Dirt can damage the rubber gripper bar (6) when gripping (when little stone particles are pressed into the rubber gripper bar). -

Page 25: Trouble Shooting

• The corresponding legal regulations and the regulations of the declaration of conformity must be observed! • The expert inspection can also be done by the manufacturer Probst GmbH. Contact us at: service@probst-handling.com • We recommend affixing the inspection sticker "„Sachkundigenprüfung / Expert inspection" in a clearly visible place (order no.: 2904.0056+Tüv sticker with year number) after the inspection has been done. -

Page 26: Hints To The Type Plate

Example: Hints to the renting/leasing of PROBST devices With every renting/leasing of PROBST devices the original operating instructions must be included unconditionally (in deviation of the users country's language, the respective translations of the original operating instructions must be delivered additionally)! - Page 27 After each completed performance of a maintenance interval the included form must be fill out, stamped, signed and send back to us immediately 1) via e-mail to service@probst-handling.com / via fax or post Operator: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _...

- Page 28 Bkl 350 W max. 600 Tragfähigkeit / Working Load Limit WLL: kg / 1320 Eigengewicht / Dead Weight: kg / Product Name: Concrete Step Handles TSZ-UNI © all rights reserved conform to ISO 16016 Datum Name Benennung Trittstufenversetzzange Erst. 18.10.2004 Klaus.Scholl Gepr.

- Page 29 43100859 36370019 © all rights reserved conform to ISO 16016 20030011 Datum Name Benennung Trittstufenversetzzange Erst. 18.10.2004 Klaus.Scholl Gepr. TSZ-uni m. WA 3.6.2014 Joerg.Werner Greifweite 50 - 600mm Et. 185 mm, Tk 600 kg Artikelnummer/Zeichnungsnummer Blatt E53100338 Zust. Urspr. 53100251 Ers.

- Page 30 40110154 20530050 40110054 © all rights reserved conform to ISO 16016 Datum Name Benennung Einsatz für WA-L,komplett Erst. 24.8.2011 Perumal.Hurth Gepr. 24.9.2013 Joerg.Werner Artikelnummer/Zeichnungsnummer Blatt E40110040 Zust. Urspr. N236-1 Ers. f. Ers. d.

- Page 31 A53100338/364 TSZ-UNI/MAXI 29040629 Auf beiden Seiten / on both sides 29040056 P 16.10.2017_V3 1 / 1 Einige der Abbildungen sind möglicherweise optionales Zubehör des Gerätes/Some of pictures may be optional equipment of the device.

Need help?

Do you have a question about the TSZ-UNI and is the answer not in the manual?

Questions and answers