Subscribe to Our Youtube Channel

Summary of Contents for Renkforce RF100 XL

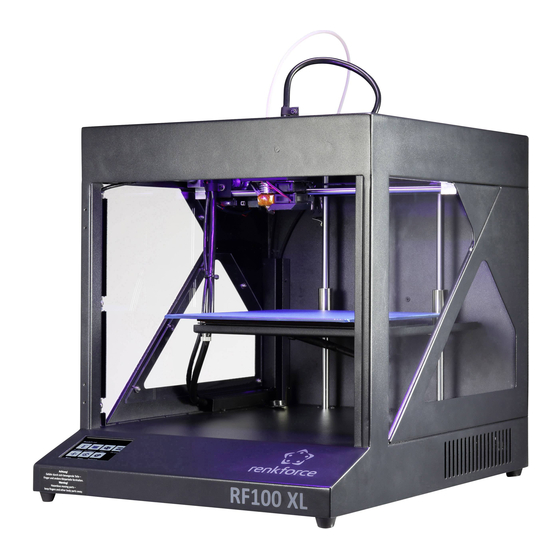

- Page 1 Operating Instructions RF100 XL 3D printer, fully-assembled Item No. 1592461 RF100 XL Plus Item No. 1592620 RF100 XL Page 2 - 61...

-

Page 2: Table Of Contents

Table of contents Page Introduction ................................4 Explanation of symbols ............................4 Intended use ................................5 Package contents ..............................5 SD card contents ..............................6 a) 3D models ..............................6 b) Config ................................6 c) Operating instructions ............................7 d) Software ................................7 Features and functions ............................7 Working principles of the 3D printer ........................8 Safety instructions ...............................9 a) General information ............................9 b) Setup ................................10... - Page 3 Removing the filament ..........................57 f) Storing the 3D printer ..........................57 19. Troubleshooting ..............................58 20. Disposal ................................60 21. Technical data ..............................60 a) General information .............................60 b) RF100 XL Plus (item no. 1592461) ......................61 c) RF100 XL (item no. 1592620) ........................61...

-

Page 4: Introduction

1. Introduction Dear customer, Thank you for purchasing this product. This product complies with statutory national and European regulations. To ensure that the product remains in this state and to guarantee safe operation, always follow the instructions in this manual. These operating instructions are part of this product. -

Page 5: Intended Use

4. Package contents • Fully-assembled 3D printer • 2.5 mm hex key • 250 g original Renkforce PLA filament (1.75 mm, • 2x screws to secure the filament spool holder white) • Glass print bed with pre-installed print bed film (with •... -

Page 6: Sd Card Contents

5. SD card contents • The SD card contains the following folders: - "3D models" - "Config" - "Manual" (user manual) - "Software" To view the contents of the SD card, connect the 3D printer (with the SD card inserted) to your computer. The control panel on the printer only gives you limited access to the SD card. -

Page 7: C) Operating Instructions

• Load the configuration file in "Cura" to print an object using the corresponding material (see “e) Loading configuration files (Windows )” on page 52 for details). ® The contents of this folder are not displayed on the control panel. These config files are recommended for use with the supplied filaments. -

Page 8: Working Principles Of The 3D Printer

7. Working principles of the 3D printer • The 3D printer requires a file containing the three-dimensional data of the object that you wish to print (.stl is a standard format). • You can create these files using suitable software or a 3D scanner. You can also download ready-to-use print files from the Internet to print objects quickly. -

Page 9: Safety Instructions

8. Safety instructions Read the operating instructions and safety information carefully. If you do not follow the safety instructions and information on proper handling in this manual, we will assume no liability for any resulting personal injury or damage to property. Such cases will invalidate the warranty/guarantee. a) General information •... -

Page 10: B) Setup

• If you have questions which remain unanswered by these operating instructions, contact our technical support service or other technical personnel. b) Setup • Place the 3D printer on a level, horizontal surface of a sufficient size. • Install the 3D printer in a location that is out of the reach of children. •... -

Page 11: D) Operation

• Before conducting any repair or modification work, disconnect the printer from the mains and computer and allow it to cool down. • Do not touch the mains cable if there are any signs of damage. If the mains cable is damaged, isolate the mains socket (e.g. -

Page 12: Control Elements And Components

9. Control elements and components a) 3D printer Front 1 Filament tube 2 Extruder 3 Nozzle 4 Printer bed (item no. 1592620) Printer bed with hot plate (item no. 1592461) 5 Levelling screw (x3) 6 Colour touchscreen display 7 USB port 8 Card reader Back 9 Filament tube holder... -

Page 13: B) Accessories

E USB cable F Scraper G SD card H Tweezers 2 / 2.5 mm hex key J 2x screws K Wire cutter L Filament tube M Filament spool holder N 5x Original Renkforce filament samples O Original Renkforce PLA filament with spool... -

Page 14: Before Installation

10. Before installation • Carefully remove all parts from the packaging. • Remove the protective film from the colour touch display. • Cut the cable ties on both sides using a wire cutter. • Ensure that no parts are missing or damaged. Do not use the printer if parts are missing or damaged. 11. - Page 15 Only for item no. 1592461 • Insert the print bed. • Remove the protective cover on the hot plate power socket ( • Plug the hot plate power cable into the socket • Secure the connection: Turn the lock nut onto the hot plate connection.

-

Page 16: Control Panel

• The 3D printer can be controlled using the control panel on the colour touchscreen display. • Some options are highlighted in yellow after confirmation. The hot plate settings only apply to the RF100 XL Plus (item no. 1592461). a) General functions... -

Page 17: B) Menu Options And Functions

b) Menu options and functions Icon Menu option Function Main menu < ReadyPrint > (3D printer is ready for use) < Preheat > Go to the < Preheat > menu to adjust the temperature of the nozzle or hot plate. <... - Page 18 Icon Menu option Function < 10°C > The temperature can be set in 10/5/1 % increments. Touch an icon to select one of these < 5°C > options. < 1°C > Switches off the nozzle (for item no. 1592461, 1592620) or the hot plate (for item <...

- Page 19 Icon Menu option Function < 50% > Reduces the fan speed by half. < 75% > Reduces the fan speed by 25%. < 100% > Sets the fan speed to maximum (default setting). < Back > Return to the main menu (< ReadyPrint >). <...

- Page 20 Icon Menu option Function < Printing > menu, displayed during the printing process < Pause > Pause the printing process. < Resume > Resume the printing process. Stop the printing process. The nozzle and print bed will return to their initial position. The <...

- Page 21 Icon Menu option Function The filament loading speed can be set from 10 to 300 %. The standard setting is 100%. < Flow> The loading speed depends on the print speed. The nozzle may become blocked if the loading speed is too high. <...

- Page 22 Icon Menu option Function Select the amount of movement for the Z-axis: < Z- > The extruder will move upwards along the Z-axis. < Back > Return to the main menu (< ReadyPrint >). < Home > menu < Home All > The print bed and extruder will return to their initial position. <...

- Page 23 Icon Menu option Function < FileSys > menu Select "Print from the SD card" (default setting). Touch to confirm your selection. The icon will be highlighted in yellow. < SD Card > The 3D printer must be disconnected from your computer. If necessary, unplug the USB cable from your computer.

-

Page 24: C) Display Layout During The Printing Process

Icon Menu option Function Set the third calibration point for the print bed. The extruder will move to the third < Third > calibration point. Set the fourth calibration point for the print bed. The extruder will move to the fourth <... -

Page 25: D) Menu Overview

d) Menu overview The menu structure may vary depending on the firmware version. Extruder Heatbed Preheat 10°C 1°C 5°C TurnOff Back Load Unload Filament Normal Fast Slow Filament Preheat Change Stop Back Turnoff 100% Back Ready Resume Print Pause Stop -->... - Page 26 10 mm 0,1 mm 1 mm Move Back Home All Home X Home Home Y Home Z Back Motor Ready Print SD Card Settings drive FileSys Back 115200 Select Source 25000 Connect Back Setting First Second Leveling Third Fourth Back About Back...

-

Page 27: Tips For 3D Printing

• The optimum nozzle temperature depends on the filament material and the layer thickness. The printing temperature for the filament varies depending on the material and manufacturer. Always check the specifications of the filament before printing. For best results, use Renkforce Original filaments. • Use the standard temperature for the first test print. -

Page 28: C) Layer Thickness

c) Layer thickness • The layer thickness determines the height of the individual layers and therefore the resolution and quality of the printed object. • Thinner layers produce higher quality prints, but result in longer printing times. • Thicker layers result in lower quality prints and shorter printing times. Experiment with the aforementioned parameters until the printer produces a satisfactory result for your chosen material. -

Page 29: Preparation

14. Preparation a) Calibrating the print bed • Tighten the 3 levelling screws under the print • Place an A4 sheet of paper between the nozzle bed as far as they will go. and the print bed to use as a measurement guide. -

Page 30: B) Attaching The Filament

b) Attaching the filament • Mount the filament on the spool holder. • Insert the filament tube into the tube holder. • Insert the filament into the tube until approximately 5 cm is visible at the end of the extruder. c) Loading the filament •... - Page 31 • Go to the < Filament Change > menu and wait • <Filament changing > will appear on the until the current temperature (in this case 221 °C) touchscreen display. The 3D printer is now ready has reached the target temperature (220 °C). to load the filament.

-

Page 32: D) Removing The Filament

d) Removing the filament • Ensure that the nozzle temperature is not higher than 170 °C. Do not touch the nozzle – burn hazard! • Go to the < Home > menu and select < Home • In the < ReadyPrint > menu, select < Move > and All >. -

Page 33: E) Changing/Replacing The Filament

• If the filament can be pulled out of the top of the • Go back to the < Preheat > menu and select extruder, select < Stop >. < Turn off >. • Carefully remove the filament and filament tube •... -

Page 34: Printing From The Sd Card/Usb Stick

15. Printing from the SD card/USB stick The printer may produce smoke or steam during the heating process. This is normal. Ensure that there is sufficient ventilation. Never expose the print bed to mechanical stress, as this may cause it to break. Printing directly from an SD card/USB stick (USB stick not included) is only possible via the control panel. -

Page 35: B) Printing From A Usb Stick

• Select < 115200 > to control the 3D printer via the control panel. b) Printing from a USB stick By default, the printing source is set to the SD card. If you want to print from a USB stick, follow the steps below. •... -

Page 36: C) Starting The Printing Process

• Select < 115200 > to control the 3D printer via the control panel. • The icon will be highlighted in yellow for confirmation. c) Starting the printing process • Go to the < ReadyPrint > menu and select • Select a ready-to-print model (e.g. < RF100. <... -

Page 37: D) Pausing The Printing Process

• Touch < OK > to confirm. • < Printing > will appear on the touchscreen display. • The print bed will move towards zero along the Z-axis. The nozzle will move to the starting position and start to heat up. •... -

Page 38: E) Configuring Parameters During The Printing Process

e) Configuring parameters during the printing process Only recommended for experienced users. • Go to the < Option > menu and select < Printing > to set the print speed, nozzle/hot plate temperature and fan/ filament loading speed. Print speed: Observe the printing process and adjust the print speed accordingly. The print speed affects the print quality for certain objects and filaments. -

Page 39: Printing With The "Cura" Software

16. Printing with the "Cura" software General information • The 3D printer is compatible with the "Cura" software, which is available for Windows and Mac OS. ® Visit https://ultimaker.com/ for more information on operating system and hardware requirements. Ensure that your computer meets the minimum requirements. -

Page 40: B) Setting Up The Software (Windows ® )

4 Follow the onscreen instructions to complete the update. Starting the software The configuration wizard will launch when the installation is complete. This provides step-by-step instructions for configuring the 3D printer. Enter the information specific to your 3D printer model (RF100 XL or RF100 XL Plus). - Page 41 1 Select the desired language (e.g. English). 2 Click "Next".

- Page 42 3 Select "Other". 4 Click "Next". 5 Select "Custom...". 6 Click "Next".

- Page 43 7 Enter the parameters as shown. For the RF100 XL Plus, select "Heat bed" (hot plate). 8 Click "Finish" to close the configuration wizard.

-

Page 44: C) Setting Up The Software (Mac Os)

"Cura" symbol in the "Applications" folder. Select "Show Package Contents". 2 Search for "Resources/ machine_profiles". 3 Select the profile file ("RF100 XL.ini" or "RF100 XL plus.ini") on the SD card and copy it to the "machine_profiles" folder. - Page 45 4 Launch the "Cura" software. 5 Go to the "Machine" menu and select "Add new machine", 6 Click "Next >".

- Page 46 7 Select "Other". 8 Click "Next >".

- Page 47 9 Select the 3D printer model. 10 Click "Next >".

-

Page 48: D) Software Settings (Windows ® )

11 Click "Finish". This completes the installation process. d) Software settings (Windows ® You can also configure additional settings. These settings are intended for experienced users. Refer to the online software help for more information on these functions. Configuring the incorrect settings can damage the 3D printer or result in defective prints. Beginners should use the basic settings. - Page 49 3D printer” on page 40 for details). Set the "Baud rate" to "115200" (for both 3D printer models). Set the "Serial port" to "COM3" (for the RF100 XL) or "AUTO" (for the RF100 XL Plus). 5 Click "OK". "Machine settings"...

- Page 50 7 Configure the parameters under "Advanced" as shown. These are the possible parameters for a PLA filament. 8 Select "Open expert settings" under "Expert".

-

Page 51: Filament Diameter

9 Configure the parameters under "Support" as shown. 10 Click "OK". Filament diameter The filament diameter is specified by the filament manufacturer. If the filament diameter is not specified (e.g. there is no label on the filament spool) you can calculate the diameter as follows: •... -

Page 52: E) Loading Configuration Files (Windows ® )

• Load the configuration files by repeating the steps in “c) Setting up the software (Mac OS)” on page 44. Ensure that the downloaded configuration files start with "RF100 XL-xxx" or "RF100 XL Plus-xxx". Only these files are compatible with Mac OS. Files that start with "Config-xxx" are only compatible with Windows ®... -

Page 53: G) Loading Model Files (Windows ® And Mac Os)

g) Loading model files (Windows and Mac OS) ® • The "3D models" folder on the SD card contains a few examples for your first prints. You can also download a wide range of 3D models from the Internet. Alternatively, you can use a 3D program to design your own model. Ensure that the 3D model is in .stl format. -

Page 54: H) Disabling The Control Icons On The 3D Printer

h) Disabling the control icons on the 3D printer • By default, the printer is controlled via the control panel. • If you wish to control the printer using the software, the connection source must be changed. • Go to the <ReadyPrint> menu and select < •... -

Page 55: J) Stopping The Printing Process

j) Stopping the printing process Select "Cancel print" in the "Cura software" to stop printing. Data is buffered by the software, therefore it may take up to 1 minute for the 3D printer to stop printing. Do not select "Cancel print" when the nozzle is heating, otherwise you may have to remove the USB cable and restart the 3D printer. -

Page 56: Cleaning And Maintenance

• By default, the printer is controlled via your computer when the firmware update is complete. If you wish to control the printer via the control panel and print from the SD card, enable "Control the 3D printer via the control panel" and set the print source: - Go to the <... -

Page 57: C) Cleaning The Inside Of The Extruder

Cleaning the inside of the nozzle • Heat the nozzle. Load/remove the filament until the filament flows normally. If the nozzle does not eject enough filament, let the nozzle cool down to the melting temperature stated by the filament manufacturer (the filament must be viscous) and carefully extract the filament until it has been removed from the extruder (including impurities). -

Page 58: Troubleshooting

19. Troubleshooting Problem Possible solution The 3D printer does not switch on. The Check that the mains cable is connected properly. touchscreen display and printer light do Check the mains socket. Is it supplied with electricity? not turn on. Check that the USB cable is connected. Have you selected the correct USB port in the software? Are the required drivers installed? Disconnect and then reinsert the USB cable. - Page 59 Problem Possible solution When printing from the SD card, the 3D printer must be disconnected from your computer. Printing stops unexpectedly. Check the settings on your computer. It must not enter standby mode (check the power settings) or shut down (after installing software or software updates) during printing.

-

Page 60: Disposal

Problem Possible solution Check the connection source. Go to the < ReadyPrint > menu. Select You cannot configure any settings on the < SelectSource >, and then select < 115200 > (to control the 3D printer control panel. via the control panel). Check whether the SD card contains the update files for the last The firmware does not update. -

Page 61: B) Rf100 Xl Plus (Item No. 1592461)

RF100 XL Plus (item no. 1592461) Operating voltage/current .....12 V/DC, 15 A Output power ........Max. 180 W Hot plate temperature ......+50 to +120 °C Compatible filament materials ....PLA, elastic material, wood, copper, aluminium, ABS Power adapter Input voltage/current ......100–240 V/AC, 50/60 Hz, 2.5 A Output voltage/current ......12 V/DC, 15 A... - Page 64 This is a publication by Conrad Electronic SE, Klaus-Conrad-Str. 1, D-92240 Hirschau (www.conrad.com). All rights including translation reserved. Reproduction by any method, e.g. photocopy, microfilming, or the capture in electronic data processing systems require the prior written approval by the editor. Reprinting, also in part, is prohibited. This publication represent the technical status at the time of printing.

Need help?

Do you have a question about the RF100 XL and is the answer not in the manual?

Questions and answers