Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Renkforce RF100 v2

- Page 1 Operating Instructions RF100 v2 3D printer fully-assembled Item No. 1548286...

-

Page 2: Table Of Contents

Table of contents Page Introduction ................................4 Explanation of symbols ............................4 Intended use ................................5 Delivery content ..............................5 SD card content ..............................6 a) 3D Models ..............................6 b) Config ................................6 c) Manual ................................7 d) Software ................................7 Features and functions ............................7 7. Working principle of the 3D printer ........................8 Safety instructions ...............................9 a) General information ............................9 b) Connecting the mains ..........................10... - Page 3 d) Change / Replace filament ..........................24 e) Install “Cura“ software (optional) .........................24 15. Print from SD card .............................25 a) Start printing ..............................25 b) Pause printing ..............................26 c) Adjust parameters during printing ........................26 d) Stop printing ..............................26 e) Perform < Emergency stop > ........................26 f) Restart the 3D printer ..........................27 16. Print from “Cura“ software ..........................27 a) General notes ..............................27 b) Installation ..............................28 c) Setup of the Software - Windows .......................28...

-

Page 4: Introduction

1. Introduction Dear customer, Thank you for purchasing this product. This product complies with the statutory national and European requirements. To maintain this status and to ensure safe operation, you as the user must observe these operating instructions! These operating instructions are part of this product. They contain important notes on commissioning and handling. Also consider this if you pass on the product to any third party. Therefore, retain these operating instructions for reference! If there are any technical questions, please contact: International: www.conrad.com/contact United Kingdom: www.conrad-electronic.co.uk/contact 2. Explanation of symbols The lightning symbol inside a triangle is a warning to inform you of potential risks of personal injury, such as electric shock. The symbol with the exclamation mark in the triangle is used to indicate important information in these operating instructions. Always read this information carefully. This symbol warns of hot surfaces the contact with which may cause injury. This symbol warns of hand injury that may occur when reaching into the device in operation. This symbol warns of hand injury that may occur by belt drive. Only designed for indoor use. Read the operating instructions carefully! The arrow symbol indicates special information and advice on operation. -

Page 5: Intended Use

Download the latest operating instructions, 3D model files and configuration files at www.conrad.com/downloads or scan the QR code shown. Follow the instructions on the website. 4. Delivery content • 3D printer fully-assembled • Filament tube • 250 g Genuine Renkforce filament • USB cable (1,75 mm, white) • Scraper • 8GB SD card with • Tweezers - Manual •... -

Page 6: Sd Card Content

5. SD card content • The SD card contains the following main folders: - 3D Models - Config - Manual - Software To view the complete SD card content, connect the 3D printer with the inserted SD card to your computer. Via the control panel, you will have limited access to the SD card. a) 3D Models • The folder “3D Models“ contains several subfolders with “Basic shape“, “Capital letters (A-Z), “Constellation“, “Mathematical symbols“, “Numbers“, “VariousObjects“ etc. • There are over 100 ready-to-print 3D models available. • Each model is available in .gcode, .jpg, .stl format. For example “RF100“: •... -

Page 7: C) Manual

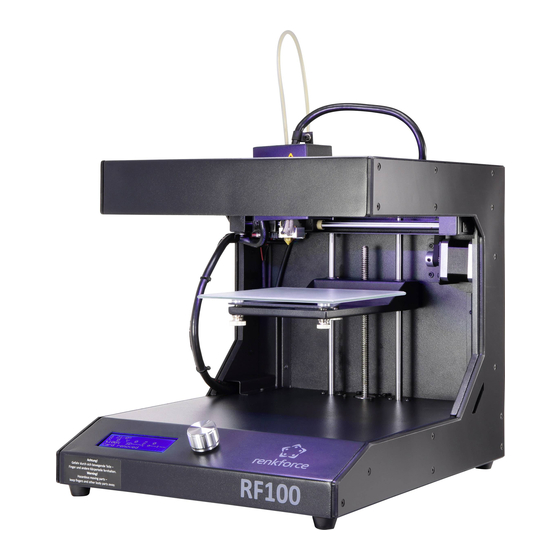

c) Manual • The folder “Manual“ contains the Quick-Start-Guide. The content of this folder cannot be reviewed on the control panel. d) Software • The folder “Software“ contains the “Cura” software in form of an executable (.exe) for Windows and a disk image ® (.dmg) for Mac OS, as well as the USB driver. The content of this folder cannot be reviewed on the control panel. 6. Features and functions • 3D printer completely assembled and ready to use • Max. printed object size: 120 x 120 x 120 mm • Highly precise extruder with 0.4 mm printing nozzle • LC display with control knob for device operation right at the device • Operation via computer (USB) or stand-alone operation with SD card • Support printing from SD card and PC • Manual adjustment of the printing parameters possible even during operation • Extremely stable due to metal construction •... -

Page 8: Working Principle Of The 3D Printer

7. Working principle of the 3D printer • For 3D print, you need a file, which contains the three-dimensional data of the object to be printed (a common format of such a file is, e.g., STL). • This file can be produced with the corresponding software or with a 3D-scanner. There are also many printing files already online that can be downloaded to print an object as quickly as possible. • The actual printer software has the task to render the above three-dimensional file into a file that the printer can print. This is a file in which the individual print layers, the print temperatures for nozzle etc. are specified. The file has the extension “.gcode”. • This GCODE printing file is sent to the 3D printer either via the USB interface by the computer, or saved on SD card, inserted into SD card slot of the 3D printer for standalone operation. • The 3D printer creates the object layer by layer (Fused filament fabrication procedure), the filament material is transported from the filament spool to the nozzle. • In the extruder, the filament material is melted and then applied to the build bed via a fine nozzle layer by layer. • The build bed moves in the Z (upwards/downwards) direction, the extruder moves in the X (left/right) and Y (forwards/ backwards) directions. Thus, all prerequisites to produce a threedimensional object by horizontal application of the present layers are created. A 3D printer is a highly complex device in which many parameters must be set depending on the printer, printed object and filament material used. -

Page 9: Safety Instructions

8. Safety instructions Read the operating instructions carefully and especially observe the safety information. If you do not follow the safety instructions and information on proper handling in this manual, we assume no liability for any resulting personal injury or damage to property. Such cases will invalidate the warranty/guarantee. -

Page 10: B) Connecting The Mains

• Do not move the product during operation. Turn off the product before moving, transporting or storing it. • Never use the 3D printer outdoors. • Never place containers containing liquids, e.g. glasses, vases, etc. on the device or in its vicinity and do not pour any liquids out over the device. Liquids may get into the housing and impair electrical safety. This also poses great danger of fire or potentially fatal electric shock! If this is the case, first power down the respective mains socket on all poles (e.g. switch off circuit breaker and FI switch) and then pull the mains cable from the socket. Disconnect all lines from the device. Do not operate any part of the product anymore afterwards, but take it to a specialist workshop. • Never place any sources of open fire, such as lit candles, on or right next to the device. • Never connect the mains plug to a mains socket immediately after the device has been taken from a cold to a warm environment. The resulting condensation may destroy the device. Allow the device to reach room temperature before connecting it. Wait until the condensation has evaporated. • Do not cover the openings on the bottom of the product. Do not insert any sharp objects into the product as this may cause an electric shock! • Do not operate the product unattended. • Under no circumstances should you service any of the components in the interior of the 3D printer therefore never disassemble the motor unit. - Page 11 • Completely unwind the power cable before use. A power cable that is not completely unwound can lead to overheating and constitutes a fire hazard! • The mains outlet must be located near to the device and be easily accessible. • Never unplug the mains plug from the socket by pulling on the cable. Always use the grips on the sides of the plug. • Unplug the mains plug from the mains socket if you do not intend to use the 3D printer for a prolonged period of time. • For safety reasons, unplug the mains plug from the mains socket during thunderstorms. • Unplug the mains plug from the mains socket after use. • Always unplug the product when it is unattended. • Unplug the product from the mains and computer before maintenance work or modification and let it cool down. • Make sure that the power cable is not squeezed, bent, damaged by sharp edges or put under mechanical stress. Avoid excessive thermal stress on the power cable from extreme heat or cold. Do not modify the power cable. Otherwise the power cable may be damaged. A damaged power cable can cause a deadly electric shock. • Do not touch the power cable if it is damaged. First, power down the respective mains socket (e.g. via the respective circuit breaker) and then carefully pull the mains plug from the mains socket. Never use the product if the power cable is damaged.

-

Page 12: Operating Elements And Parts

Accessories A 5x Genuine Renkforce filament samples B Power cable C USB cable D Scraper E SD card F Tweezers G 2 / 2,5 mm hex keys H 2x Screws Side Cutter J Filament tube H G F K Filament spool holder L Genuine Renkforce PLA filament with spool... -

Page 13: Before Installation

10. Before installation • Remove all the components carefully from the packaging. • Remove protection foils from LC display and the housing. • Cut the cable ties on each side with the side cutter. • Check that no parts are missing or damaged. Do not use the device if any parts are missing or damaged. 11. Installation a) Set up 3D printer When setting up the 3D printer, observe that the power switch must be easy to reach so that the device can be switched off quickly and easily in case of malfunction. Ensure proper ventilation when setting up the device. Do not put the device down on soft supports such as a carpet or bed, etc. the air circulation also must not be impaired by other objects. This prevents heat dissipation from the product and may lead to overheating (danger of fire). Make sure that the device has a stable footing and place it on a stable underground. Persons may be injured if the 3D printer drops. Ensure that the power and USB cables are neither pinched nor damaged by sharp edges. Always place cables so that no one can trip over them or be caught in them. There is a danger of injury. • Place the 3D printer on a dry, flat, non-vibration-sensitive and stable surface. There are anti-slip feet on the bottom of the device. If necessary, place a protective mat underneath the device in order to protect the surface of the worktop. b) Installation and connection The mains outlet must be located near to the device and be easily accessible, so that in case of an error, the device can be quickly separated from the mains voltage. - Page 14 • Place the build bed. • Use two screws and the hex key to install filament spool holder at the back of the 3D printer. The ‘nose’ at the end of the holder faces upwards. • Insert SD card with sticker facing downwards. • Connect the power cable with the power supply socket. • Fully unwind the power cable and insert the mains plug into a wall-mounted socket. • Switch the 3D printer on by moving the power switch to the I position. • The printing area is lit up. • < Info screen > appears on the LCD display. It indicates that the 3D printer is now ready to use.

-

Page 15: Control Panel

12. Control panel • The 3D printer is operated by the control knob. • The LC display shows the menu options and the operation status via an < Info screen >. a) Initial operation Description Action Navigate in the menu structure Rotate the control knob anticlockwise / clockwise. Adjust the parameter Select / enter the menu Confirm a menu option / parameter Press the control knob. Return to previous menu b) Menu options and functions Following refers to the Printer Firmware V2.1 and functions may change with updated versions. Menu option Function < Info screen > is shown after switching on the 3D printer and during printing. For details, < Info screen > refer to section „c) < Info screen >“ on page 18. < Main > menu (during standby mode) < Info screen > Return to < Info screen >. <... - Page 16 Menu option Function Confirm this menu option and the nozzle starts heating up to the default temperature of 220°C. < Preheat PLA > If there is no action during the following 5 minutes, heating will be turned off and the nozzle will be cooled down to prevent filament overheating and blockage of nozzle. Select this function to load filament into the extruder. < Load filament > The 3D printer will draw 80 mm of filament into the extruder. Nozzle temperature must be higher than 170°C. Select this function to unload filament from extruder. The 3D printer will draw 10 mm of filament into the extruder, afterwards 80 mm out of < Unload filament > the extruder. Nozzle temperature must be higher than 170°C. < Move axis > Enter the < Move axis > menu. < Disable steppers > Switch off all motors. Extruder and build bed can be moved along X , Y, Z axis by hand. <...

- Page 17 Menu option Function Select Y- Axis movement and enter the < Move Y> menu to adjust the Y-axis movement in the range +120 to 0 mm. < Move Y > The extruder moves forwards/backwards along the Y axis (*backwards: toward to control panel). Select Z- Axis movement and enter the < Move Z > menu to adjust the Z-axis movement in the range 0 to +120 mm. < Move Z > The extruder moves up/down along Z axis. This option is not available, when < Move 10MM > has been selected. < Temperature > menu < Prepare > Return to < Prepare > menu. Adjust temperature of nozzle between the range of 0 to 260 °C.

-

Page 18: C) < Info Screen

Menu option Function Adjust fan speed between the range of 0 to 255 RPM. Default setting is 255 RPM. < Fan speed > When nozzle temperature reaches 40°C, the fan will be automatically switched ON at default setting 255 RPM. Adjust extruder filament feeding speed between the range of 10 to 300 Default setting is 100%. < Flow > Feeding speed depends on print speed. If the flow rate is too high, the nozzle may be clogged. c) < Info screen > 1 % of printing process 2 Working time counting from print task start 3 3D printer status information 4 Print speed (can be adjusted by control knob) 5 Current position X-, Y-, Z- axis 6 Current temperature / target temperature... -

Page 19: General Notes On 3D Printing

Nozzle temperature • The best nozzle temperature depends on the filament material as well as the printer layer thickness. The printing temperature of the filament varies depending on filament material and filament manufacturer. Always check the specification of the filament before printing. For best results it is recommended to use genuine Renkforce filament. • Perform the first test prints at the default temperature. • To optimize the print quality, print the same object with the same printing layer thickness but different nozzle temperatures. Select temperatures each different by 5 °C from the previous one. Compare the results. This way you can find suitable nozzle temperatures for different filaments and printing layer thicknesses more easily. -

Page 20: C) Print Layer Thickness

c) Print layer thickness • The print layer thickness determines the height of the individual print layers and thus the resolution and quality of the printed object. • The thinner the printed layers, the better the print quality and the longer the print duration. • The thicker the printed layers, the lower the print quality and the shorter the print duration. Experiment with the above parameters to find satisfying print results depending on the material used. For the first print attempts, use the PLA filament. Since it is a material that can be mastered easily as it does not shrink while cooling down and adheres very well to the build bed. -

Page 21: Preparation

14. Preparation a) Calibrate build bed • In < Main > menu select • Select < Auto home >. • Press the control knob in < Info < Prepare > . screen > to enter < Main Page >. Prepare First point Second point Third point • Return to < Prepare > menu. • Repeat STEPS 1-4 for second • Adjust 3 screws under build bed and third points (calibration to adjust the gap between build •... -

Page 22: B) Set Up Filament

• If the printer does not print properly after the build bed calibration, following steps are needed: • Gently turn the thread (Z-axis) • ... until there is a “click“ sound • First select < Auto home > in clockwise ... at the upper left part of the build < Prepare > menu, then select bed. < Disable steppers > to unlock motor. • Calibrate the build bed, by repeating step 1 to 6 in section • Adjust a 5 mm distance between “a) Calibrate build bed“ on page nozzle and build bed by turning the thread (Z-axis) anticlockwise by hand. b) Set up filament •... -

Page 23: C) Load Filament

c) Load filament Unload filament Move axis Move X Move axis Move Y Disable steppers Move Z Temperature • Select < Move 1mm > . • Select < Move Z >. • In < Prepare > menu, select first < Auto Home >, then <... -

Page 24: D) Change / Replace Filament

d) Change / Replace filament • Change the filament, if you want to switch to another filament color or material. • Replace the filament, if the existing filament is used up and a new filament shall be used. • Before changing or replacing filament, the extruder must be heated so that the old filament can be cleanly replaced from the extruder. Do not touch the hot extruder nozzle. Danger of burns! • Select < Preheat PLA >. • Place the new filament onto the • Cut the existing filament in the filament spool holder. extruder. • Remaining filament is extruded. • Feed the new filament into the •... -

Page 25: Print From Sd Card

15. Print from SD card When heating, there may be slight development of smoke or steam. This is normal. Please ensure the corresponding ventilation. Do not apply any mechanical force on the build bed. Danger of build bed breakage. • Printing directly from the SD card can be performed only via the control panel. It does not require installation of the software. The 3D printer must be disconnected from the PC. If connected, please unplug the USB cable. a) Start printing Main Software Info screen Manual Prepare Config RF100.gcode Print from SD 3D Model • Navigate in the menu and select • Select a printable model for • Press the control knob and select < 3D Model >. example < RF100.gcode >. -

Page 26: B) Pause Printing

b) Pause printing While printing is paused, the nozzle continues to heat. Therefore, pause the print only for a short period, otherwise the nozzle will overheat and may become clogged. • Press the control knob to leave the < Info screen > and enter the < Main > menu. • Select < Pause print > to pause printing. • To continue printing, select < Resume print >. c) Adjust parameters during printing Recommended for advanced users only. • Press the control knob to leave the < Info screen > and enter the < Main > menu. • Enter < Tune > menu to adjust print speed, nozzle temperature, fan speed and extruder fillament feeding speed. Print speed: Observe the printing and adjust the print speed. The print speed may influence the print quality against different print object and different filament for example if the print speed is too high, the printing object may not adhere to the build bed. Nozzle temperature: Do not keep nozzle temperature at 260 °C for more than 10 minutes. After 10 minutes, decrease it to 230 °C and keep it at this temperature for at least 10 minutes before increasing it again. If you consistently operate the 3D printer at temperatures over 230 °C, the life time of the extruder will drastically be shortened. -

Page 27: F) Restart The 3D Printer

f) Restart the 3D printer • Restart the 3D printer, - when LC display does not show any correct information or the LC display is empty. - after an < Emergency stop > has been perfomed. - when the 3D printer is not working properly. • If any, unplug the connected USB cable. • Switch off the 3D printer. After a short while, switch it on again and operate the 3D printer as usual. 16. Print from “Cura“ software a) General notes • The 3D printer is compatible with the “Cura“ software package and is available for Windows and Mac OS. For ® specific operating system and hardware requirements refer to the website at https://ultimaker.com/ and make sure your computer meets the minimum requirements. • It is unfortunately not possible to explain all the functions of the enclosed software in the scope of these operating instructions. Full instructions are available from https://ultimaker.com/. •... -

Page 28: B) Installation

b) Installation • Install the file “Cura_15.04.6.exe“ (for Windows ) or “Cura-15.04.6-MacOS.dmg“ (for Mac OS) from the directory ® “Software” from the SD card. • Follow the on-screen instructions during the installation process. For details, refer to instructions provided on https://ultimaker.com/. c) Setup of the Software - Windows ® Connect to the 3D printer • Connect the 3D printer to a free USB port on your computer with the help of the supplied USB cable. Switch the printer on. When the printer is connected to the computer, ensure the printer remains switched on at all times. - Page 29 Start the software After installation, the “Configuration Wizard“, which will guide you through the set up process of the 3D printer, appears: 1 Select your preferred language (e.g. English). 2 Click “Next >”.

- Page 30 3 Select “Other”. 4 Click “Next >”. 5 Select “Custom...“ 6 Click “Next >”.

- Page 31 7 Input parameters as shown. 8 Click “Finish” to complete the wizard.

-

Page 32: D) Setup Of The Software - Mac Os

d) Setup of the Software - Mac OS • It is important that you make the printer’s profile available to the software before you connect printer and computer. 1 After installation, locate the “Cura” icon in the “Applications” folder of your computer and right click it. Select “Show Package Contents”. 2 Locate “Resources/machine_ profiles”. 3 Locate the “ RF100 v2.ini” profile file on the SD card and copy it to “machine_profiles” folder. 4 Start the “Cura” application. 5 In “Machine“ menu, select “Add new machine...“. - Page 33 6 Click “Next >”. 7 Select “Other”. 8 Click “Next >”.

- Page 34 9 Select “RF100 v2”. 10 Click “Next >”. 11 Click “Finish“. Installation is done.

-

Page 35: E) Software Settings - Windows

e) Software settings - Windows ® Further settings can be made optionally here; however, this should only be done by advanced users. For functions, see the online help documentation of the software. The use of wrong settings can result in damage to the 3D printer or defective printouts. Beginners should first work with the basic settings. 1 Start the software. 2 Select “Machine“ 3 Select “Machine settings“ 4 Select the serial port to which the 3D printer is connected. The port number is system-independent (for details refer to the chapter “Connect to the 3D printer“ on page 28). Set “Baudrate” to 115200. 5 Click “Ok”. “Machine settings“... - Page 36 7 Set up the parameters in “Advanced“ as shown. These are possible parameters for a PLA filament. 8 Under “Expert“, select “Open expert settings“.

- Page 37 9 Set up the parameters in “Support” settings as shown. 10 Click “Ok“. Filament diameter: The filament diameter is provided by the filament manufacturer. If you are unable to locate the diameter of the filament you intend to use (e.g. there is no label on the filament spool), you have the possibility of calculating the diameter yourself. Follow the below steps: Measure 1 m of filament for sampling. With the help of a calliper, take at least 10 diameter measurements evenly spread over 1 m. Calculate the average of all measurements, which will give you the diameter of the filament Since ideal temperatures vary among filament manufacturers, you are encouraged to run your own tests based on the pre-settings to determine the best temperature – filament combination. When performing tests, use 5 °C increments and compare the results during or after printing with other settings. The first layer should always be printed at a slightly higher temperature and more slowly for better adhesion on the build bed.

-

Page 38: F) Load Configuration File - Windows

f) Load configuration file – Windows ® • In order to ease the process of setting parameters for different materials (Wood/Elastic/Copper/PLA), you can load pre-configured material configuration files from the SD card. Such configuration files are also available from www.conrad.com. 1 Click “File” 2 Select “Open Profile...“. 3 Select a filament configuration file for the filament used by you in the selection window and confirm your selection. There are several configuration files on the enclosed SD card in the main folder “Config”. Alternatively, skip this step and follow the settings in last section (for details refer to chapter “e) Software settings - Windows ” ® on page 35) for starting the first print. g) Load configuration file – Mac OS •... -

Page 39: H) Load Model File - Windows ® And Mac Os

h) Load model file – Windows and Mac OS ® • In the main folder “3D Models” on the enclosed SD card, you will find a few examples for the first printing attempts. However, there are already many places online where you can download 3D model files. Alternatively, you can also use a 3D programme to make your own. Ensure that the 3D model file is in .stl format (STL-file). • Load the model file by dragging it onto the virtual build bed in the main window or by clicking the button. The file will be converted automatically to .gcode format. When the SD card is not inserted in the computer, click the button to save the GCODE file on the computer. • For off-line printing, save the GCODE file onto the SD card. Then insert the SD card into the printer and directly start printing from the printer’s control panel. • When the SD card is connected to the computer, the button turns into enabling you to save the file onto the SD card. -

Page 40: I) Start Printing

i) Start printing • Once the printer is connected to the computer via the USB cable, print icon appears. 1 Right click the icon . Select “Print from COM3“ to start printing. (Alternatively you can save the g.code to SD card) 2 Click “Print”. The nozzle heats up. Once the “Printing temperature“ is reached, the 3D printer is ready to start printing. -

Page 41: J) Stop Printing

j) Stop printing Select “Cancel print“ in “Cura“ software to abort the printing process. Since there is a buffer setting of data streaming in the software, it can take up to 1 minute for the printer to stop after the button is pressed. While nozzle is heating, do not select “Cancel print“; otherwise, you have to unplug the USB cable and restart the printer. Nozzle temperature will be maintained after cancelling the print job. Let the nozzle cool down by setting the temperature to 0 °C and move the build bed down through the < Move axis > menu in the printer. Then, unplug the USB cable and restart the printer. k) Perform < Emergency Stop > • Select < Emergencey Stop > at the control knob to terminate any running tasks immediately. • Restart the 3D printer (for details refer to “f) Restart the 3D printer” on page 27). 17. Cleaning and maintenance Never use aggressive detergents, rubbing alcohol or other chemical solutions, as these could damage the casing or even impair the functioning of the product. Never submerge the product in water. Danger of burns! Do not touch the hot nozzle directly with bare hands. a) Clean the device • Use a dry, soft cloth or brush to clean the outside of the 3D printer. b) Clean the nozzle Cleaning of the outside of the nozzle •... -

Page 42: C) Clean The Inside Of The Extruder

Cleaning of the inside of the nozzle • Heat up the nozzle then load and unload filament repeatedly until the filament flow is as expected. If the nozzle continues not to extrude enough material after this procedure, let the nozzle cool down to the lower melt temperature of the filament as indicated by the manufacturer (filament material must only be viscous anymore) and carefully unload the filament until the filament has been transported out of the extruder, including contamination. Cut off the contaminated part of the filament and reinsert it after heating up the nozzle again. c) Clean the inside of the extruder • For details, download the separate hints booklet “Cleaning and maintenance” at www.conrad.com/downloads or scan the QR code shown on page 5. Follow the instructions on the website. d) Clean the build bed •... -

Page 43: F) Unload Filament

f) Unload filament • Ensure the nozzle temperature reaches 170 °C or above. Unload filament Main Move axis Auto home Disable steppers Level Bed Preheat PLA Temperature • Select < Unload filament >. • Select < Preheat PLA >. • Remove filament spool from the filament spool holder. If the filament material is either wood or metal, cut it and replace it with PLA filament first as described in section“d) Change / Replace filament“ on page 24, then unload the PLA filament. The PLA filament removes possible residue left behind by the wood or metal filament. -

Page 44: Troubleshooting

18. Troubleshooting Problem Possible Solution Check the connection of the mains line. Check the mains socket. Is it properly supplied with The 3D printer does not work after switching on. current? The display and print space lighting remain dark. Check the mains fuse (for details refer to chapter „e) Replace fuse“ on page 4242. ) Check the USB line connection. Is the assigned USB port selected in the software? Check whether required drivers are installed. Unplug the USB cable and then plug it in again. No USB connection to the 3D printer is possible. Switch the 3D printer off and on again. Restart the computer. Use another USB port on your computer. Connect the 3D printer directly to a USB port on your computer. Do not use any USB hub. - Page 45 Problem Possible Solution Disconnect computer from 3D printer while printing from SD card. Check the settings of your computer. It must not switch Printings stops during the process. to standby mode while printing (energy option settings) or simply shut down (installation of software or software updates during printing).

-

Page 46: Disposal

Problem Possible Solution Switch off the 3 D printer. Remove protective case of the extruder unit and check whether all cables are connected "Temp sensor error" is shown on the display, correctly. control knob is without any function and 3 D printer Thermistor and heater are malfunctioning and cannot does not work. detect the extruder temperature correctly Replace the thermistor with heater (available under item no. 1538778). 19. Disposal Electronic devices are recyclable waste and must not be disposed of in the household waste. At the end of its service life, dispose of the product according to the relevant statutory regulations. You thus fulfil your statutory obligations and contribute to the protection of the environment. -

Page 47: Technical Data

20. Technical data Operating voltage .........100 - 240 V/AC, 50/60 Hz Power consumption ......max. 60 W Power consumption during standby ..1.08 W Fuse............F5AL, 250V Production process .......Fused filament fabrication (FFF) Model size (W x H x D) ......max. 120 x 120 x 120 mm Printing layer resolution ......0.1 - 0.2 mm Print speed ...........30 - 300 mm / s Print format ..........GCODE Nozzle (ø) ..........0.4 mm Filament (ø) ..........1.75 mm Suitable filament material .....PLA, Flexible, Wood, Pearl, Elastic, Copper, Aluminium Extruding temperature. - Page 48 This is a publication by Conrad Electronic SE, Klaus-Conrad-Str. 1, D-92240 Hirschau (www.conrad.com). All rights including translation reserved. Reproduction by any method, e.g. photocopy, microfilming, or the capture in electronic data processing systems require the prior written approval by the editor. Reprinting, also in part, is prohibited. This publication represent the technical status at the time of printing.

Need help?

Do you have a question about the RF100 v2 and is the answer not in the manual?

Questions and answers