Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operating Manual

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Oce Colorado 1640

-

Page 1: Operation Guide

Operation guide Océ Colorado 1640... -

Page 2: Copyright And Trademarks

Copyright and Trademarks Copyright Copyright 2017 Océ. Illustrations and specifications do not necessarily apply to products and services offered in each local market. No part of this publication may be reproduced, copied, adapted or transmitted, transcribed, stored in a retrieval system, or translated into any language or computer language in any form or by any means, electronic, mechanical, optical, chemical, manual, or otherwise, without the prior written permission of Océ. -

Page 3: Table Of Contents

Chapter 3 Handle the media......................23 General workflow for using media....................... 24 Configure media in the RIP..........................25 Download an Océ Colorado 1640 media profile..................25 Manage media profiles in Onyx......................26 Manage media profiles in Caldera......................33 Choose a media category........................42 Change the media settings........................44 Select a print mode ..........................47... - Page 4 Replace the knife............................ 120 Replace the filters (optional)......................... 123 Refill the chiller............................126 Vacuum the chiller..........................131 List of Océ Colorado 1640 maintenance materials..................134 Chapter 6 Improve quality....................... 137 General workflow for solving quality problems..................138 Print a quality check chart..........................140 Analyze the printhead quality check chart....................

- Page 5 Contents Chapter 8 Troubleshooting and support..................173 General support............................174 Change the regional settings........................ 174 Move the printer.............................175 Turn the printer on and off........................176 General troubleshooting..........................177 Stop the printer............................177 Restart the printer..........................178 Turn the printer on after a power cut....................179 Remove media from the paper path....................

- Page 6 Contents...

-

Page 7: Chapter 1 Introduction

Chapter 1 Introduction... -

Page 8: About This Guide

About this guide About this guide Introduction The guide addresses the Océ Colorado 1640 and is written for the printer operator. It describes the complete workflow of the printer: from setup to the operation, maintenance and troubleshooting of the machine. -

Page 9: About The Users

About the users Introduction There are various types of users who can use the Océ Colorado 1640 each with its own role in the complete workflow. The various roles can be filled in by the same person or by multiple people. This manual is mainly written for the Printer operator. -

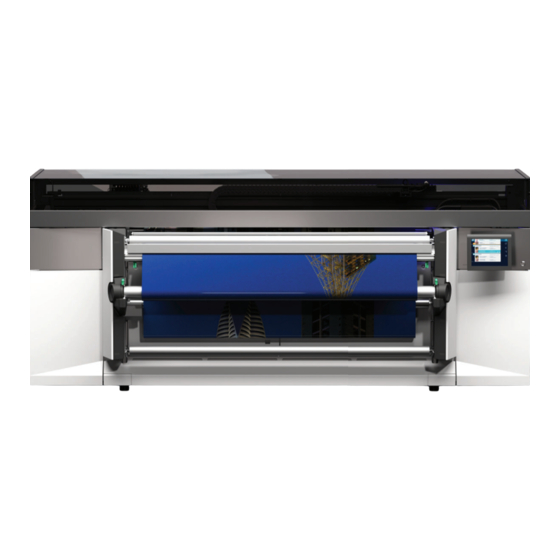

Page 10: About The Océ Colorado 1640

About the Océ Colorado 1640 About the Océ Colorado 1640 Introduction The Océ Colorado 1640 is a 64 inch roll to roll production printer that uses a unique UV gel ink technology. Chapter 1 - Introduction... -

Page 11: Safe Use

Safe use Safe use Introduction When you operate the Océ Colorado 1640 you have to take note of the safety precautions and follow the guidelines. Safety documents Before you operate the printer read the following documents and follow the instructions: •... -

Page 12: Notes For The Reader

Names of options to be used in a fixed order Safety symbols Before you use this product, make sure you read and understand the safety information that http://downloads.oce.com belongs to the product. Find the safety information on . Also be sure to follow all warnings and instructions marked on the product. - Page 13 Notes for the reader Symbol Type of symbol Indicates CAUTION Laser beam Indicates a caution concerning operations that may lead to in- jury to persons if not performed correctly. To use the ma- chine safely, always pay attention to these cautions. IMPORTANT Indicates operational requirements and restrictions.

-

Page 14: Available Documentation

This manual is part of a complete documentation set. The following table shows a complete overview of the available documentation. Available documentation NOTE "http://downloads.oce.com" For up-to-date documentation: visit the Océ downloads website select your printer and language, and find all the support information. Documentation... -

Page 15: Explore The System

Chapter 2 Explore the system... -

Page 16: The Components Of The Printer - Media Output Side

The components of the printer - media output side The components of the printer - media output side Introduction From the media output side you can access the operator panel, access the roll winder, collect your print, or replace the knife. Number Component Knife compartment... -

Page 17: The Components Of The Roll Winder

The components of the roll winder The components of the roll winder Introduction The roll winder is located on the media output side and can be used to wind the printed media. Number Component Power switch winder Guide plate Take-up media shaft Tension bar Chapter 2 - Explore the system... -

Page 18: The Components Of The Printer Sides

The components of the printer sides The components of the printer sides Introduction On both printer sides you can perform maintenance actions. Filter configuration (optional) Exhaust configuration Number Component Filter fan (filter configuration) Chiller Exhaust (exhaust configuration) Ink bottle Chapter 2 - Explore the system... -

Page 19: The Components Of The Printer - Media Input Side

The components of the printer - media input side The components of the printer - media input side Introduction From the media input side you can load media, open the top cover, get access to the maintenance tray and printhead maintenance. Number Component Manual maintenance door... -

Page 20: The Components Of The Media Drawer

The components of the media drawer The components of the media drawer Introduction You can open the media drawer on the media input side to load your media rolls. Number Component Roll loading station Media roll (position 1) Media roll (position 2) Number Component Locking mechanism... - Page 21 The components of the media drawer Number Component Feed media shaft Roll clamp Chapter 2 - Explore the system...

-

Page 22: The Components Of The Printer - Top Cover Open

The components of the printer - top cover open The components of the printer - top cover open Introduction When you open the top cover you can access the carriages, the platen area and perform several maintenance actions. Number Component Filter (optional) Knife Curing carriage... -

Page 23: Chapter 3 Handle The Media

Chapter 3 Handle the media... -

Page 24: General Workflow For Using Media

General workflow for using media General workflow for using media Introduction Use the following workflow to handle the media correctly. Step Action Configure media in the RIP on page 25. Download and install a media profile, and manage the profiles in the RIP. Prepare media for printing on page 48. -

Page 25: Configure Media In The Rip

Download an Océ Colorado 1640 media profile Introduction When you install an Océ Colorado 1640 supported RIP and driver a set of media profiles is automatically installed. Next to that, you can also download the available Océ Colorado 1640 media profiles via the website. -

Page 26: Manage Media Profiles In Onyx

• Create a new media profile NOTE In order to get the best results it is strongly advised to use the Océ Colorado 1640 media profiles. Install a downloaded media profile You have to download a Océ Colorado 1640 media profile before, saved in a media library file Download an Océ... - Page 27 Open the Onyx RIP queue. Click on [Media Manager]. The Media Manager application opens. Click on the Océ Colorado 1640 printer icon and click on [Media library] above. Select the media profile from the list and click on [Make Copy].

- Page 28 A new window opens. Follow all the steps. For more information on the general steps use the Onyx documentation. You can change the Océ Colorado 1640 specific media category and media settings under [Basic Media Profile Settings]. Click on [Media options].

- Page 29 Manage media profiles in Onyx Step Action Follow the steps. You can change the Océ Colo- rado 1640 specific print mode settings under [Basic Print Mode Settings]. You can change the print mode and fill in the Select a print mode. For more information, see print mode on page NOTE Fill in the same name as the selected...

- Page 30 Manage media profiles in Onyx Step Action Click on the Océ Colorado 1640 printer icon and click on [Create profiles] above. Click on [Create a new media profile]. A new window opens. Click on [Ok] for the new ICC workflow.

- Page 31 42 Change the media settings on page Click on [Ok] the window closes. Follow the steps. Change the Océ Colorado 1640 specific print mode settings under [ Basic Print Mode Settings]. Select a print Fill in the print mode name and...

- Page 32 Manage media profiles in Onyx Step Action Finish all the steps to create the media profile. Chapter 3 - Handle the media...

-

Page 33: Manage Media Profiles In Caldera

• Copy and edit an existing media profile NOTE In order to get the best results it is strongly advised to use the Océ Colorado 1640 media profiles. Install a downloaded media profile You have to download a Océ Colorado 1640 media profile before, saved in a calpatch file for Caldera (*.calpatch). - Page 34 Manage media profiles in Caldera Step Action Select your printer and click on [Next]. Click on [Import...]. Click on [Install patch]. The file selection window opens. Browse to your calpatch file (*.calpatch) and click on [Load]. A window with profiles opens. Chapter 3 - Handle the media...

- Page 35 Manage media profiles in Caldera Step Action Select the profiles you want to install and click on [Install selection]. A message appears with the number of installed profiles, click on [Ok]. Copy and edit an existing media profile Step Action Open Caldera.

- Page 36 A window opens. Fill in the values in the media window. For more information on the general settings use the Cal- dera documentation. You can change the Océ Colorado 1640 specific settings: Choose a media category • Under [Parameters]: Change the media settings on...

- Page 37 Manage media profiles in Caldera Step Action Click on [Ok]. The window closes. Click on [Next]. Chapter 3 - Handle the media...

- Page 38 Manage media profiles in Caldera Step Action You can change the Océ Colorado 1640 specific settings: Select a print mode on • Under [Resolution]: page Change the media set- • Under [Parameters]: tings on page Click on [Ok]. Create a new media profile NOTE Only experienced users or color experts can create a new media profile.

- Page 39 Select the printer icon and click on [Next]. Select your printer and click on [Next]. Click on [New..]. A window opens. For the Océ Colorado 1640 specific settings: Choose a media category on page Click on [Ok]. Fill in the values in the media window. For more information on the general settings use the Cal- dera documentation.

- Page 40 Manage media profiles in Caldera Step Action Click on [Ok]. The window closes. Click on [Next]. Chapter 3 - Handle the media...

- Page 41 Manage media profiles in Caldera Step Action For the Océ Colorado 1640 specific settings: Select a print mode on • Under [Resolution]: page Change the media set- • Under [Parameters]: tings on page Click on [Ok]. Chapter 3 - Handle the media...

-

Page 42: Choose A Media Category

Only when you edit an existing media profile or when you create a new media profile you can change the media category. It is advised to use the Océ Colorado 1640 media profiles and not change the media category. Only experienced users should edit or create new media profiles and have to choose a media category. - Page 43 Choose a media category Media category Characteristics Polymeric & cast self-adhe- • Smooth surface sive vinyl • Usually have a liner • Self-adhesive NOTE As an exception, wallcovering (polymeric and cast self- adhesive vinyl), perforated media (with liner) and trans- parent media (with opaque liner) are classified under this media category.

-

Page 44: Change The Media Settings

Only when you edit an existing media profile or when you create a new media profile you can change the media settings. It is advised to use the Océ Colorado 1640 media profiles and not change the media settings. Only experienced users should edit or create new media profiles and have to change the media settings. - Page 45 Changing the following curing settings can result in insufficient curing of the UV-ink layer. When you have changed the settings, wear Océ Colorado 1640 approved nitril gloves the first time you handle the printed output to prevent any possible contact with uncured ink.

- Page 46 Change the media settings Media settings Description [Advance correc- Controls the average step size for the selected media and print mode. Only tion] change this setting when media calibration and [Automatic advance correc- tion] do not help enough in improving the print quality. Decrease, smaller step, to minimize light lines.

-

Page 47: Select A Print Mode

Select a print mode Select a print mode Introduction You can select a print mode that best suits your application. Select the print mode in the RIP software. The location of the print modes differs, depending on the RIP you are using. For more Manage media profiles in Onyx on page Manage media profiles in Caldera information, see... -

Page 48: Prepare Media For Printing

Prepare media for printing Prepare media for printing Load a media roll (position 1) Introduction You can load multiple media rolls on your printer for optimal productivity. Before you begin Before you load a roll on the printer: • Make sure you have added a media profile with the correct media type via the RIP. For more information, see Configure media in the RIP on page •... - Page 49 Load a media roll (position 1) 3. Pull the lever and open the clamp. 4. Take the feed media shaft out of the drawer. 5. Pull (1) the handle of the locking mechanism towards you. Slide (2) the media shaft into the side of the core of the new media roll. Chapter 3 - Handle the media...

- Page 50 Load a media roll (position 1) 6. Accurately align the roll on the media shaft. Place it on the corresponding media size with the help of the ruler. Check on the left and right side of the roll if both are aligned on the same size. 7.

- Page 51 Load a media roll (position 1) 10. Use both hands to turn the media roll backwards (1) until the media flap has passed the metal paper guide. Chapter 3 - Handle the media...

- Page 52 Load a media roll (position 1) 11. Use both hands to move the media forward and slide the media under the metal paper guide (2). Make sure the printer takes the media and transports it automatically. It has worked when you hear a beeping sound.

- Page 53 Load a media roll (position 1) 15. Tap on Save. NOTE For the highest output quality, it is advised to always perform a media calibration when Calibrate you load a new media type or a new media width. For more information, see the media on page Chapter 3 - Handle the media...

-

Page 54: Load A Media Roll (Position 2)

Load a media roll (position 2) Load a media roll (position 2) Introduction You can load multiple media rolls on your printer for optimal productivity. Before you begin Before you load a roll on the printer: • Make sure you have added a media profile with the correct media type via the RIP. For more Configure media in the RIP on page information, see •... - Page 55 Load a media roll (position 2) 3. Pull the lever and open the clamp. 4. Take the feed media shaft out of the drawer. 5. Pull (1) the handle of the locking mechanism towards you. Slide (2) the media shaft into the side of the core of the new media roll. Chapter 3 - Handle the media...

- Page 56 Load a media roll (position 2) 6. Accurately align the roll on the media shaft. Place it on the corresponding media size with the help of the ruler. Check on the left and right side of the roll if both are aligned on the same size. 7.

- Page 57 Load a media roll (position 2) 10. Use both hands to turn the media roll backwards (1) until the media flap has passed the metal paper guide. Chapter 3 - Handle the media...

- Page 58 Load a media roll (position 2) 11. Use both hands to move the media forward and slide the media under the metal paper guide (2). Make sure the printer takes the media and transports it automatically. It has worked when you hear a beeping sound.

- Page 59 Load a media roll (position 2) 15. Tap on Save. NOTE For the highest output quality, it is advised to always perform a media calibration when Calibrate you load a new media type or a new media width. For more information, see the media on page Chapter 3 - Handle the media...

-

Page 60: Calibrate The Media

Calibrate the media Calibrate the media Introduction It is advised to calibrate media: • When you have loaded a new media type or media width. • When you want to improve the quality. NOTE Media calibration is type and width dependent. When you have two different sizes of the same media type you must perform calibration for each size. -

Page 61: Load A Take-Up Roll Core Onto The Roll Winder

Load a take-up roll core onto the roll winder Load a take-up roll core onto the roll winder Introduction When you want to wind media, you must load a take-up roll core onto the roll winder first. IMPORTANT Make sure you use the core of an empty media roll with the same width or wider as the media you are printing on. - Page 62 Load a take-up roll core onto the roll winder 3. Pull the handle of the locking mechanism inside the core towards you. Take the empty media roll core and slide it on the media shaft. 4. Center the core on the media shaft. 5.

-

Page 63: Print With Or Without Winding

Print with or without winding Winding options Introduction For the Océ Colorado 1640 there are several winding options depending on the type of media you are using. Overview In a media profile a media category is used that corresponds with the loaded media type. Each media category uses default media settings. -

Page 64: Print And Wind Without A Tension Bar

Print and wind without a tension bar Print and wind without a tension bar Introduction Winding media without a tension bar, loose winding, is used for most media that can be transported well and is not too weak. Before you begin •... - Page 65 Print and wind without a tension bar 2. Make sure [Wind the output] is set to [Yes]. 3. Start a print job. The printer will continue printing. The clamp closes when the media reaches the tape position, and the operator panel gives a message indicating you can tape the media. 4.

- Page 66 Print and wind without a tension bar 6. Tape first the center and then the sides of the media to the core. 7. Move the media guides towards the middle to align with the media. 8. On the operator panel tap on [Ready]. The printer continues printing while winding the job.

-

Page 67: Print And Wind With A Tension Bar

Print and wind with a tension bar Print and wind with a tension bar Introduction Winding media with a tension bar, tight winding, is only used for weaker media in order to prevent media transportation issues. Media that is weak and sensitive for buckling, but not too stiff, can be wound with a tension bar in unlocked position. - Page 68 Print and wind with a tension bar 3. Make sure the media is flat on the platen. 4. Take the leading edge of the media and align it on the core. 5. Tape first the center and then the sides of the media to the core. Chapter 3 - Handle the media...

- Page 69 Print and wind with a tension bar 6. Place the tension bar lever in unlocked position. 7. Lift up the tension bar and place it correctly on top of the media. 8. On the operator panel tap on [Ready]. The printer starts printing while winding the job. Make sure the tension bar follows the media when the blouse is formed.

- Page 70 Print and wind with a tension bar After you finish Cut the When you want to stop winding you have to cut the media. For more information, see media on page Cut the media (manual) on page Chapter 3 - Handle the media...

-

Page 71: Print And Wind With A Locked Tension Bar

Print and wind with a locked tension bar Print and wind with a locked tension bar Introduction Winding media with a locked tension bar is only used for stiff media, in order to prevent media transportation issues. Before you begin •... - Page 72 Print and wind with a locked tension bar 2. Move the media guides to the sides. 3. Make sure the media is flat on the platen. 4. Take the leading edge of the media and align it on the core. 5.

- Page 73 Print and wind with a locked tension bar 6. Place the tension bar lever in locked position. 7. Lift up the tension bar and place it correctly on top of the media. 8. On the operator panel tap on [Ready] and move the media guides towards the middle to align with the media.

- Page 74 Print and wind with a locked tension bar After you finish Cut the When you want to stop winding you have to cut the media. For more information, see media on page Cut the media (manual) on page Chapter 3 - Handle the media...

-

Page 75: Print Without Winding

Print without winding Print without winding Introduction You can also print without winding. Media that is printed without winding can be transported well and is not too weak. Before you begin • Check the media category of your media. Media categories that need a tension bar cannot be printed without winding. - Page 76 Print without winding After you finish When you want to stop printing without winding you have to cut the media. For more Cut the media on page Cut the media (manual) on page information, see Chapter 3 - Handle the media...

-

Page 77: Cut And Unload Media

Cut and unload media Cut and unload media Cut the media Introduction When you cut media, the printer uses the embedded knife. You can also cut the media manually with your own knife. How the media is cut depends on the Change the media settings on media type configuration in the RIP. - Page 78 Cut the media After you finish Unload a You can now remove the take-up roll from the roll winder. For more information, see take-up media roll from the roll winder on page Chapter 3 - Handle the media...

-

Page 79: Cut The Media (Manual)

Cut the media (manual) Cut the media (manual) Introduction When you manually cut media, the printer does not use the embedded knife but you have to use your own knife or pair of scissors. How the media is cut depends on the media type configuration in the RIP. For more information, Change the media settings on page Before you begin Use a knife or pair of scissors that is sharp enough to cut the media. - Page 80 Cut the media (manual) 5. Tape the trailing edge to the take-up media roll in case of winding. 6. After you finish, tap on [Completed] on the operator panel. After you finish You can now remove the take-up media roll from the roll winder. For more information, see Unload a take-up media roll from the roll winder on page Chapter 3 - Handle the media...

-

Page 81: Unload A Take-Up Media Roll From The Roll Winder

Unload a take-up media roll from the roll winder Unload a take-up media roll from the roll winder Introduction When you want to collect the printed output you have to unload the take-up media roll from the roll winder. Before you begin Cut the media on page 77 Make sure you have cut the media. - Page 82 Unload a take-up media roll from the roll winder 2. Push the green levers on both sides of the take-up media roll. Remove the take-up media roll from the winder. 3. Place the take-up media roll on a sturdy surface. 4.

- Page 83 Unload a take-up media roll from the roll winder 6. Push to place the media shaft back on the winder. Make sure it clicks in place. Chapter 3 - Handle the media...

-

Page 84: Unload A Media Roll From The Drawer

Unload a media roll from the drawer Unload a media roll from the drawer Introduction Unload a media roll from the drawer when you want to load a new media roll. CAUTION • Watch your fingers when you handle the media roll. •... - Page 85 Unload a media roll from the drawer 3. Pull the lever and open the clamp. 4. Lift up and take out the media shaft with the media roll, and put it on the roll loading station. 5. Pull (1) the handle of the locking mechanism towards you. Remove (2) the media shaft from the core of the media roll.

- Page 86 Unload a media roll from the drawer 6. Load a new media roll, for more information see Load a media roll (position 1) on page 48. Or put the feed media shaft back into the drawer and firmly close the clamp. Make sure you close the clamp completely until you hear a click.

-

Page 87: Chapter 4 Print A Job

Chapter 4 Print a job... -

Page 88: General Workflow For Printing A Job

General workflow for printing a job General workflow for printing a job Introduction There is a general workflow for using the Océ Colorado 1640 explained in this manual. Operator Panel Printing 1. RIP Prepare and submit a job in one of the supported RIP software applications. You can install media profiles and also add or change media profiles and types here. -

Page 89: Print A Job

Print a job Print a job Introduction You can submit and print a job via the RIP. When to do Make sure you have one of the supported RIP applications installed and connected to the printer. Procedure 1. Open the RIP. 2. -

Page 90: Pause, Resume, Cancel Or Stop A Job

Pause, resume, cancel or stop a job Pause, resume, cancel or stop a job Introduction On the operator panel you can control your job. Procedure 1. Submit a job to the printer. 2. On the operator panel, you see the job appearing in the queue, at the top of the screen. The job on top is the active job. -

Page 91: Status On The Operator Panel

Status on the operator panel Status on the operator panel Introduction The operator panel indicates when an operator attention is required via colors and symbols. Colors on the operator panel When you see an orange or red color indication on the operator panel, tap the tile with the color to see what action is required. - Page 92 Status on the operator panel Chapter 4 - Print a job...

-

Page 93: Chapter 5 Maintain The System

Chapter 5 Maintain the system... -

Page 94: Maintain The Printheads

Maintain the printheads Maintain the printheads Guidelines for printhead maintenance Introduction To keep the printer in optimal condition it is very important to perform printhead maintenance regularly. Next to that, printhead maintenance can be performed at any time to solve quality issues. - Page 95 Guidelines for printhead maintenance Initiated by Performed by Action Printer Printer and oper- 1. The operator must clean the maintenance station, includ- ator ing the wiper and clean wall. 2. The operator must clean the matrix plate. 3. The operator can clean the platen. 4.

-

Page 96: Start Automatic Maintenance

Start automatic maintenance Start automatic maintenance Introduction Start automatic maintenance in case of quality issues. The printer performs a purge and wipe and optionally you can print a nozzle classification chart to optimize the nozzles. Procedure 1. On the operator panel tap on the [Tools] icon on the right. 2. -

Page 97: Start Manual Maintenance

Start manual maintenance Start manual maintenance Introduction Start manual maintenance in case of quality issues. You can clean the maintenance station, wiper, clean wall, matrix plate and you can print a nozzle classification chart to optimize the nozzles. Procedure 1. On the operator panel tap on the [Tools] icon on the right. 2. - Page 98 Start manual maintenance IMPORTANT Wait until the [Completed] button turns black and the printhead carriage is in maintenance position, before you open the top cover and start cleaning. Chapter 5 - Maintain the system...

-

Page 99: Clean The Maintenance Station, Wiper And Clean Wall

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. IMPORTANT Use the prescribed cleaning liquid. Do not use any other cleaners. - Page 100 Clean the maintenance station, wiper and clean wall IMPORTANT • Make sure you do not damage the rubber wiper tips. • Make sure the wiper is still correctly placed, after cleaning. For more information, Replace the wiper on page 117. 6.

- Page 101 Clean the maintenance station, wiper and clean wall 8. Take a lint free cloth and clean the clean wall until all residue ink is gone. If necessary, dampen a swab with the cleaning liquid to remove any remaining ink. IMPORTANT Make sure the clean wall does not click out of the holder.

- Page 102 Clean the maintenance station, wiper and clean wall 11. When all residue ink is removed, remove all tools from the machine and dispose the gloves, cloths and swabs as chemical waste according to local regulations. 12. Close the top cover. IMPORTANT Make sure all covers are closed correctly to prevent cured ink in your system.

-

Page 103: Clean The Matrix Plate

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. IMPORTANT Use the prescribed cleaning liquid. Do not use any other cleaners. - Page 104 Clean the matrix plate 5. Open the media cover (1) and lift the lever of the manual maintenance door on the left (2). 6. Open the manual maintenance door (3). A light is switched on. IMPORTANT Do not use any external light source to prevent curing of the ink and damage to the printheads.

- Page 105 Clean the matrix plate 10. Take out the matrix plate cleaning tool and check the stamp on the foam for ink accumulation. When accumulated ink between the printheads is visible, you have to perform the cleaning action again from step 8 with a new foam.

- Page 106 Clean the matrix plate 13. Dampen a new swab with the cleaning liquid and clean the plate again to remove any remaining or non-visible ink. 14. Locate the black protection cover and inspect if it is polluted with ink, media dust or fibers. 15.

- Page 107 Clean the matrix plate 18. Remove all tools from the machine and dispose the gloves, foam and swabs as chemical waste according to local regulations. 19. Close the manual maintenance door and the media cover. IMPORTANT Make sure all covers are closed correctly to prevent cured ink in your system. 20.

-

Page 108: Maintain The Printer

Maintain the printer Maintain the printer Refill ink Introduction You can refill ink easily without the risk of spilling ink. On the operator panel tap on the [Inks] icon on the right. You see an overview of the ink bottles and levels of remaining ink: •... - Page 109 Refill ink Before you begin IMPORTANT • Make sure you use official Océ Colorado 1640 ink. UNDER CERTAIN CONDITIONS, INCLUDING WHEN A USED, REFILLED OR THIRD PARTY INK HAS BEEN DETECTED, THE PRINTER WILL OPERATE UNDER SAFE MODE. THIS MODE IS...

- Page 110 Refill ink 8. Place the bottle on the slot. The LED light under the handle slot starts blinking fast, wait until the light stops blinking. When the light stays on you can continue. 9. Hold the bottle with one hand and move the green handle back up with the other hand. The ink will pour out of the bottle.

-

Page 111: Replace The Maintenance Tray

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. IMPORTANT Only open the maintenance drawer when the operator panel displays a message allowing you to open it. - Page 112 Replace the maintenance tray 5. Go to the media input side and locate the maintenance drawer on the right. 6. Pull to open the maintenance drawer. 7. Take the lid out of the drawer. 8. Push the handle of the inner drawer and pull carefully to slide the maintenance tray to the front. Make sure to extend the drawer completely.

- Page 113 Replace the maintenance tray 9. Lift the metal holder up. Chapter 5 - Maintain the system...

- Page 114 Replace the maintenance tray 10. Put the lid on the tray. 11. For both hands, put your thumb on the lid and your other fingers under the side reel. Squeeze to click and seal the lid completely. 12. Lift the maintenance tray out with both hands on the sides of the tray. Dispose the sealed maintenance tray as chemical waste according to local regulations.

- Page 115 Replace the maintenance tray 15. Close the metal holder. 16. Push to slide the inner drawer to the back and let it click to close. Chapter 5 - Maintain the system...

- Page 116 Replace the maintenance tray 17. Take a new lid and place it in the outer drawer. 18. Dispose the gloves as chemical waste according to local regulations. 19. Push and close the maintenance drawer. 20. On the operator panel tap [Replaced] to confirm you replaced a full maintenance tray with an empty maintenance tray and end the action.

-

Page 117: Replace The Wiper

CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. - Page 118 Replace the wiper 8. Locate the maintenance station with the wiper on the right hand side. 9. Hold the wiper with your left hand and use your right hand to pull the wiper holder on the right (1). Take the wiper out (2). CAUTION Be careful to touch, the wiper can be hot.

- Page 119 Replace the wiper 12. Place a new wiper back. Put the left side in first and click the right side into the holder. Make sure the wiper is fully clicked into the holder. 13. Clean the matrix plate. For more information, see Clean the matrix plate on page 103.

-

Page 120: Replace The Knife

Replace the knife Introduction Replace the knife when the knife does not cut your media correctly anymore. Before you begin Use Océ Colorado 1640 prescribed: • Screwdriver (Torx-20) for the cover • Screwdriver (Torx-6) for the knife • Knife NOTE List of Océ... - Page 121 Replace the knife 4. Unscrew the screw on top of the cover. CAUTION Mind your head. 5. Lift the cover up and take it out. 6. Locate the knife in the top right part of the compartment. 7. Unscrew the two screws of the knife (1-2). NOTE Hold a piece of paper under the knife to collect any falling screws.

- Page 122 Replace the knife 8. Take the knife out. Make sure you position the knife in such a way it does not hit the sensor. 9. Place a new knife with the wheel top-first in the rails and let it fall into position. Test to make sure the knife slides well on the rails.

-

Page 123: Replace The Filters (Optional)

• The operator panel gives a red warning when you must replace the filters. The printing process is stopped until you have placed new filters. Before you begin Use Océ Colorado 1640 prescribed filters. NOTE List of Océ Colorado 1640... - Page 124 Replace the filters (optional) 6. Take the front filter box out by the green handles. Place it on a sturdy surface. 7. Slide the second filter box to the front and take it out by the green handles. Place it on a sturdy surface.

- Page 125 Replace the filters (optional) 10. Pick up the filter box holder by the green handles. Place the box in the filter compartment with the higher handle on the left. Slide it to the back. 11. Pick up the second filter box holder by the green handles. Place the box in the filter compartment with the higher handle on the left.

-

Page 126: Refill The Chiller

• The operator panel gives a red warning when you must refill the chiller. The printing process is stopped until you have refilled the chiller. Before you begin Use Océ Colorado 1640 prescribed: • Cooling liquid • Nitrile gloves for handling chemical liquids •... - Page 127 Refill the chiller 4. When the system has shut down, pull to open the cover under the roll winder. 5. Switch the power switch to the 'off' position. 6. Pull out the two power supply plugs from the sockets. 7. Go to the chiller side and locate the cover under the fan. Chapter 5 - Maintain the system...

- Page 128 Refill the chiller 8. Unscrew the left and right screws on top of the cover. 9. Lift the cover a little up and towards you (1), then lift it up fully and take it out (2) 10. Locate the lid on top of the chiller. 11.

- Page 129 Refill the chiller 12. Pull to remove the lid. 13. Pour the cooling liquid from the bottle in the pouring can. IMPORTANT Use the prescribed cooling liquid. Do not use any other. 14. Place the pouring can on the chiller and fill the tank with the cooling liquid. NOTE When the operator panel displays the level is low, you can fill one bottle of one liter.

- Page 130 Refill the chiller 15. Close the lid, press it firmly. 16. Dispose the gloves. 17. Place the cover back into position. 18. Fasten the left and right screws on top of the cover. 19. Plug the two power supply plugs back into the sockets. 20.

-

Page 131: Vacuum The Chiller

Vacuuming the chiller is part of periodic maintenance so the operator panel gives a warning when you should vacuum the chiller. Before you begin Use Océ Colorado 1640 prescribed: • Screwdriver (Torx-20) • Vacuum cleaner with a brush head Procedure 1. - Page 132 Vacuum the chiller 3. Lift the cover a little up and towards you (1), then lift it up fully and take it out (2). 4. Vacuum the condenser surface on the left side of the chiller, as indicated. Make sure you remove all the collected dust.

- Page 133 Vacuum the chiller 7. When you vacuumed the chiller as part of periodic maintenance, on the operator panel tap on [Completed] to end the maintenance action. Chapter 5 - Maintain the system...

-

Page 134: List Of Océ Colorado 1640 Maintenance Materials

List of Océ Colorado 1640 maintenance materials List of Océ Colorado 1640 maintenance materials The items listed below can be requested from your local representative: Maintenance material Used for Cooling liquid Refilling the chiller. Nitrile gloves Handling Océ Colorado 1640 UVgel ink. - Page 135 List of Océ Colorado 1640 maintenance materials Maintenance material Used for Nitrile gloves for handling Refilling the chiller. chemical liquids Vacuum cleaner Vacuuming the chiller. Chapter 5 - Maintain the system...

- Page 136 List of Océ Colorado 1640 maintenance materials Chapter 5 - Maintain the system...

-

Page 137: Chapter 6 Improve Quality

Chapter 6 Improve quality... -

Page 138: General Workflow For Solving Quality Problems

General workflow for solving quality problems General workflow for solving quality problems Introduction Follow the general workflow in order to solve quality problems. The pre-conditions are that you: Maintain the printheads on • Performed maintenance regularly. For more information, see page Calibrate the media on page •... - Page 139 General workflow for solving quality problems Procedure Print a quality check chart on page 140 Start automatic maintenance on page 96 Start manual maintenance on page 97 Calibrate the printhead on page 142 Calibrate the media on page 60 Calibrate the printhead carriage on page 143 Analyze the printhead quality check chart on page 141 Chapter 6 - Improve quality...

-

Page 140: Print A Quality Check Chart

Print a quality check chart Print a quality check chart Introduction When you want to improve the quality of your prints, you can print a quality check chart. With the printed chart you can check your quality and change the necessary settings to optimize the quality. -

Page 141: Analyze The Printhead Quality Check Chart

Analyze the printhead quality check chart Analyze the printhead quality check chart Introduction When you have printed the printhead quality check chart, analyze the chart to help you solve your quality problem. Printhead quality check chart Each area can indicate a quality problem. Use the chart to identify your problem and solve it: Solve specific quality problems on page 144. -

Page 142: Calibrate The Printhead

Calibrate the printhead Calibrate the printhead Introduction When you are unsure about the density of colors on your printed output, you can optimize the printhead performance. Perform a printhead calibration when you want to optimize colors. NOTE • You can only perform printhead calibration when you print without winding. For more Print without winding on page information, see •... -

Page 143: Calibrate The Printhead Carriage

Calibrate the printhead carriage Calibrate the printhead carriage Introduction When your image is blurred or fuzzy the registration can be off. Calibrate the printhead carriage to align the registration. Before you begin First perform the following actions to try and solve your problem, before you calibrate the printhead carriage: 1. -

Page 144: Solve Specific Quality Problems

Solve specific quality problems Solve specific quality problems Solve misaligned colors Introduction Solve misaligned colors on your print. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. Misalignment Procedure 1. Check if the media type you loaded is also the media type you selected on the operator panel. Make sure the two are correct. -

Page 145: Solve Color Banding

Solve color banding Solve color banding Introduction Solve color banding on your print. Banding that shows per swath repeating variations in density, thin lines (glossy or darker) with sometimes a dash line, or differences in lightness. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. NOTE Color banding is to be expected at a high print mode, [Max speed], [High speed], [Production]. -

Page 146: Solve Gloss Banding

Solve gloss banding Solve gloss banding Introduction Solve gloss banding on your print. Banding that is a disturbance in the gloss of the print in the carriage direction, repeated every swath. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. -

Page 147: Solve Wrinkles In Black

Solve wrinkles in black Solve wrinkles in black Introduction Solve wrinkles in black on your print. Wrinkles show as rough repeating patterns especially in black. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. -

Page 148: Solve Graininess

Solve graininess Solve graininess Introduction Solve graininess on your print. Graininess is a visibility of ink drops on your print. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. Graininess Procedure 1. -

Page 149: Solve Unsharp Lines And Text

Solve unsharp lines and text Solve unsharp lines and text Introduction Solve unsharp lines and text on your print. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. Sharpness Procedure 1. Perform media calibration. Calibrate the media on page 2. -

Page 150: Solve Fisheye

Solve fisheye Solve fisheye Introduction Solve fisheye on your print. Fisheye are tiny white dots created by retraction of ink. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. Fisheye Procedure 1. -

Page 151: Solve Smudges

Solve smudges Solve smudges Introduction Solve smudges on your print. Smudging of ink occurs because the top layer is not fully cured. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. Smudging Procedure 1. -

Page 152: Prevent Media Touches

Prevent media touches Prevent media touches Introduction Prevent media touches from happening. When the media touches the printhead or printhead carriage, the print gets pollutes or smudged. Follow the procedure below. You can stop at any time in the procedure when the problem is solved. Media touches Procedure 1. -

Page 153: Configure The Network And Security Settings

Chapter 7 Configure the network and security settings... -

Page 154: Configure The Network

Configure the network Configure the network Introduction At installation, the printer is connected to the network and connectivity settings are made. If necessary, you can change the network configuration settings on the user panel. Network overview Action Connection via The printer receives jobs from the RIP worksta- RAW TCP/IP (port 9100) tion The printer connects via the internet with the... - Page 155 Configure the network 4. Tap on [IPv4] to change the TCPIP v4 parameters. 5. Tap on [IPv6] to change the TCPIP v6 parameters. 6. Tap on Save to save the settings. 7. Tap on the [Back] arrow. 8. Tap on [Remote services]. One of the settings you can change are the [Proxy settings]. NOTE •...

-

Page 156: Open The Settings Editor

Open the settings editor Open the settings editor Introduction Next to the settings on the operator panel, you can make some settings for connectivity and security in the settings editor of the printer. NOTE You can make some connectivity and security settings on the operator panel, for more Configure the network on page information see 154. -

Page 157: Log In As A System Administrator

Log in as a System administrator Log in as a System administrator Introduction The System administrator settings are password protected. You have to log in as System administrator on the operator panel or in the settings editor to be able to change the system administrator settings. - Page 158 Log in as a System administrator Log in on the settings editor 1. Open the settings editor. 2. Click on [Visitor] in the top right corner. 3. Click on [Log in], select System administrator as [user name] and fill in the [password]. 4.

-

Page 159: Change The System Administrator Password

Change the System administrator password Change the System administrator password Introduction For security reasons it is advised to change the System administrator password during installation or immediately after. Next to that, you should change the password periodically. Before you begin Log in as System administrator in the settings editor. -

Page 160: Configure A Mail Server For Password Recovery

Configure a mail server for password recovery Configure a mail server for password recovery Introduction When you have forgotten your System administrator password you can recover it, but only when you have configured an email server first. When to do Make sure you configure the mail server as soon as possible, otherwise you cannot recover your password. - Page 161 Configure a mail server for password recovery 7. In case of a secure connection, fill in the username under [Username]. If you do not know the username, ask your IT administrator. 8. In case of a secure connection, fill in the password under [Password]. If you do not know the username, ask your IT administrator.

-

Page 162: Troubleshoot The Mail Server Configuration

Troubleshoot the mail server configuration Troubleshoot the mail server configuration Introduction Follow the procedure below to troubleshoot any mail server configuration problems. When to do When in the settings editor, under [Configuration] →[Connectivity], you click on [Connection test] and the result is not [Ok]. Troubleshoot error messages Error Troubleshoot... -

Page 163: Recover The System Administrator Password

Recover the System administrator password Recover the System administrator password Introduction When you have forgotten your System administrator password you can recover it. You can only recover your System administrator password via the settings editor. Before you begin You have to configure an email server first, so an email with a special link for password recovery Configure a mail server for password recovery on can be sent to you. -

Page 164: Security In The System

Security in the system Security in the system Introduction The Océ Colorado 1640 is equipped with a Windows 10 IoT Enterprise LTSB 2016 operating system with the following security features: "http://downloads.oce.com" • OS patches released by Océ via • Several settings protected by the System administrator password on the operator panel and settings editor. -

Page 165: Certificates Overview

Certificates overview Certificates overview Introduction There are two kinds of certificates: • Trusted certificates • Identity certificates Trusted certificates Trusted certificates allow the controller to recognize Root and intermediate certificates that may be sent by : • The mail server, with secure communication via HTTPS, when configuring or using it for System administrator password recovery. -

Page 166: Import A Trusted Certificate

Import a trusted certificate Import a trusted certificate Introduction Your company can use trusted certificates to secure communication with a mail server or a proxy server. When this is the case, you must import the certificates in the settings editor to make sure the controller recognizes them. -

Page 167: Enable The Use Of Https

Enable the use of HTTPS Enable the use of HTTPS Introduction You can enable the use of HTTPS to establish a secure communication between a browser and the controller for the settings editor access. To enable the use of HTTPS you have to install a valid identity certificate on the controller. In order to do this you have to: 1. - Page 168 You can find the protocol (HTTPS only/ HTTP or HTTPS) used for access to the settings editor under [Configuration] →[Security]. Note that WebDAV is not used for the Océ Colorado 1640. Chapter 7 - Configure the network and security settings...

-

Page 169: Install Windows Updates

Install Windows updates Install Windows updates Introduction Install Windows updates, also called security patches, when they are available for your product http://downloads.oce.com Before you begin http://downloads.oce.com Go to . Open the page for your product and click on the Security tab to download the available security patches. -

Page 170: Make A Backup

Make a backup Make a backup Introduction It is advised to make a backup with confidential data and export it to a file to save on another location than the controller. The confidential data consists of: the System administrator password, identity certificates (including private key), trusted certificates. Procedure 1. -

Page 171: Restore A Backup

Restore a backup Restore a backup Introduction When you have made a backup you can restore it. Before you begin You need to have a backup created before. It is highly recommended to have exported a backup. Make a backup on page For more information, see 170. -

Page 172: Enable System Installation From Usb

Enable system installation from USB Enable system installation from USB Introduction Installation from a USB key is used by the Service technician for system installation or reinstallation. For security reasons related to USB, it is possible to disable installation from USB. Procedure 1. -

Page 173: Troubleshooting And Support

Chapter 8 Troubleshooting and support... -

Page 174: General Support

General support General support Change the regional settings Introduction You can change the language, system of measurement, date and time, or time zone under the regional settings on the operator panel. Procedure 1. On the operator panel, tap on the [System] icon on the right. 2. -

Page 175: Move The Printer

Move the printer Move the printer You should not move the printer. When you want to move the printer, contact your local service representative. Chapter 8 - Troubleshooting and support... -

Page 176: Turn The Printer On And Off

Turn the printer on and off Turn the printer on and off Introduction The printing system is powered on by the service technician at installation. You can turn the printer on or off via the button on the media output side. Procedure 1. -

Page 177: General Troubleshooting

General troubleshooting General troubleshooting Stop the printer Introduction In case of problems or a dangerous situation you can stop the printer immediately. IMPORTANT Opening the top cover during operations, can result in uncured ink. Only perform this action when absolutely necessary. Procedure 1. -

Page 178: Restart The Printer

Restart the printer Restart the printer Introduction You can restart the printer via the operator panel. You might be asked to restart the system to activate settings, or in case of a software issue it might help to restart the system. Procedure 1. -

Page 179: Turn The Printer On After A Power Cut

Turn the printer on after a power cut Turn the printer on after a power cut Introduction When power has been cut to the machine, you have to power the machine on. The machine has to be on to keep the printer in optimal condition. Procedure 1. -

Page 180: Remove Media From The Paper Path

• Use a knife that is sharp enough to cut the media. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. - Page 181 Remove media from the paper path 2. Go to the media input side and open the media cover. 3. Take the knife and cut the media in the cutting guide. 4. Close the media cover. 5. Pull firmly to open the media drawer. Chapter 8 - Troubleshooting and support...

- Page 182 If present, do this for both media rolls. 7. Close the media drawer. 8. Put on the Océ Colorado 1640 approved nitrile gloves. 9. Open the top cover. 10. Carefully push the curing carriage to the left over the filters (1).

- Page 183 Remove media from the paper path 13. Fold the media towards you, from output side to input side, until the transport pinch. 14. Hold the folded media and pull the media from the transport pinch. 15. Dispose the media as chemical waste. 16.

-

Page 184: Cancel The Replacement Of A Maintenance Tray

Cancel the replacement of a maintenance tray Cancel the replacement of a maintenance tray Introduction When you open the maintenance drawer the operator panel displays a message that you have to replace the maintenance tray. When you did this by accident, and you do not have to replace the maintenance tray you can cancel the replacement. -

Page 185: Clean Ink Pollution On The Printer

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. IMPORTANT This cleaning liquid (IPA) is not used for cleaning the matrix plate, maintenance station, wiper and clean wall, maintenance drawer. -

Page 186: Clean The Media Cover

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. Procedure 1. Put on the Océ Colorado 1640 approved nitrile gloves. - Page 187 Clean the media cover 3. Inspect if the media cover is polluted on the inside. 4. Take a lint free cloth and clean the media cover. 5. Dampen the cloth with the cleaning liquid to remove any remaining ink. IMPORTANT Use the prescribed cleaning liquid.

-

Page 188: Clean The Platen

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. Procedure 1. Make sure the printer is not printing. - Page 189 Clean the platen 6. Dampen the cloth with the cleaning liquid to remove any remaining ink. IMPORTANT • Use the prescribed cleaning liquid. Do not use any other cleaners. • Do not wet the platen directly, as you can damage the printheads. 7.

-

Page 190: Clean The Guide Plate And Replace The Foams And Roller Assy

134. CAUTION Wear the Océ Colorado 1640 prescribed nitrile gloves. You can only wear the gloves for ten minutes. After ten minutes you must put on new gloves to prevent contact with the ink. Procedure 1. Make sure the printer is not printing and the guide plate is in open position. - Page 191 Clean the guide plate and replace the foams and roller assy 4. Go to the media output side and locate the guide plate with the roller assy and foams. 5. Locate the roller assy under the guide plate. 6. Pull to take out the roller. 7.

- Page 192 Clean the guide plate and replace the foams and roller assy IMPORTANT Use the prescribed cleaning liquid. Do not use any other cleaners. 14. Dispose the gloves and cloth as chemical waste according to local regulations. 15. Take the new foams and slide them in place. 16.

- Page 194 Canon Inc. www.canon.com Canon U.S.A., Inc. www.usa.canon.com Canon Canada Inc. www.canon.ca Canon Europa Inc. www.canon-europe.com Canon Latin America Inc. www.cla.canon.com Canon Australia PTY. Ltd www.canon.com.au Canon China Co., Ltd www.canon.com.cn Canon Singapore PTE. Ltd www.canon.com.sg Canon Hongkong Co., Ltd www.canon.com.hk ©...

Need help?

Do you have a question about the Colorado 1640 and is the answer not in the manual?

Questions and answers