Leuze electronic MLC 500 Original Operating Instructions

Safety light curtains

Hide thumbs

Also See for MLC 500:

- Original operating instructions (61 pages) ,

- Original operating instructions (56 pages)

Summary of Contents for Leuze electronic MLC 500

- Page 1 MLC 520 Host/Guest Safety Light Curtains S A F E I M P L E M E N T A T I O N A N D O P E R A T I O N O r i g i n a l o p e r a t i n g i n s t r u c t i o n s...

- Page 2 © 2019 Leuze electronic GmbH & Co. KG In der Braike 1 D-73277 Owen / Germany Phone: +49 7021 573-0 Fax: +49 7021 573-199 http://www.leuze.com info@leuze.com Leuze electronic MLC 520 Host/Guest...

-

Page 3: Table Of Contents

Fastening via BT-NC60 sliding blocks................ 32 6.2.4 Fastening via BT-2HF swivel mount.................. 32 6.2.5 Fastening via BT-2SB10 swiveling mounting brackets ............. 33 6.2.6 One-sided mounting on the machine table................ 34 Mounting accessories ...................... 35 6.3.1 MLC-PS protective screen .................... 35 Leuze electronic MLC 520 Host/Guest... - Page 4 11.3 Error messages 7-segment display .................. 50 Disposing...................... 52 Service and support ................... 53 Technical data ..................... 54 14.1 General specifications ...................... 54 14.2 Dimensions, weight, response time .................. 56 14.3 Dimensioned drawings: Accessories .................. 60 Order guide and accessories................ 62 EU/EC Declaration of Conformity.............. 69 Leuze electronic MLC 520 Host/Guest...

-

Page 5: About This Document

LED, display element in transmitter and receiver Brief description of the safety sensor, consisting of transmitter and receiver MTTF Mean time to dangerous failure (Mean Time To dangerous Failure) OSSD Safety-related switching output (Output Signal Switching Device) Leuze electronic MLC 520 Host/Guest... -

Page 6: Checklists

They replace neither testing of the complete machine or system prior to initial commissioning nor their peri- odic testing by a qualified person (see chapter 2.2 "Necessary competencies"). The checklists contain mini- mum testing requirements. Depending on the application, other tests may be necessary. Leuze electronic MLC 520 Host/Guest... -

Page 7: Safety

• The construction of the safety sensor must not be altered. When manipulating the safety sensor, the protective function is no longer guaranteed. Manipulating the safety sensor also voids all warranty claims against the manufacturer of the safety sensor. Leuze electronic MLC 520 Host/Guest... -

Page 8: Foreseeable Misuse

• In addition, a task related to the subject matter is performed in a timely manner and knowledge is kept up to date through continuous further training ‑ Competent person in terms of the German Betrieb- ssicherheitsverordnung (Ordinance on Industrial Safety and Health) or other national legal regulations. Leuze electronic MLC 520 Host/Guest... -

Page 9: Responsibility For Safety

• Periodic testing by a competent person (see chapter 2.2 "Necessary competencies") Disclaimer The liability of Leuze electronic GmbH + Co. KG is to be excluded in the following cases: • Safety sensor is not used as intended. • Safety notices are not adhered to. -

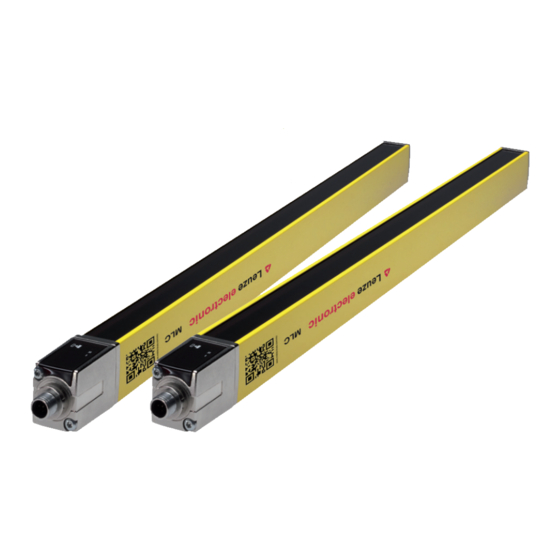

Page 10: Device Description

Device description Device description The safety sensors from the MLC 500 series are active opto-electronic protective devices. They satisfy the following standards: MLC 500 Type in accordance with EN IEC 61496 Category in accordance with EN ISO 13849 Performance Level (PL) in accordance with EN ISO 13849-1:2015 Safety Integrity Level (SIL) in accordance with IEC 61508 and SILCL in ac-... - Page 11 For the correct synchronization and function of the safety sensor, at least one of the two syn- chronization beams must be free during synchronization and operation. Optically active area, housed in yellow Synchronization beams Fig. 3.1: Transmitter-receiver system Leuze electronic MLC 520 Host/Guest...

-

Page 12: Connection Technology

Connection technology The transmitter and receiver feature an M12 connector as an interface to the machine control with the fol- lowing number of pins: Device model Device type Device plug MLC 500 Transmitter 5-pin MLC 520 Standard receiver 8-pin Host devices are also equipped with an interconnection cable, 400 mm long, with M12 connector for con- necting Middle Guest or Guest devices. - Page 13 Guest transmitter Host receiver Guest receiver Fig. 3.3: Cascaded system with 2 MLC safety light curtains Host transmitter Middle Guest transmitter Guest transmitter Host receiver Middle Guest receiver Guest receiver Fig. 3.4: Cascaded system with 3 MLC safety light curtains Leuze electronic MLC 520 Host/Guest...

-

Page 14: Display Elements

Operating indicators on the MLC 500 transmitter Located in the connection cap on the transmitter are two LEDs which serve as function indicators: LED1, green/red LED2, green Fig. 3.5: Indicators on the MLC 500 transmitter Tab. 3.2: Meaning of the LEDs on the transmitter Color State... -

Page 15: Operating Indicators On The Mlc 520 Receiver

In normal operation, the 7-segment display shows the number of the selected transmission channel. In ad- dition, it helps during the detailed error diagnostics (see chapter 11 "Troubleshooting") and serves as an alignment aid (see chapter 8.2 "Aligning the sensor"). Leuze electronic MLC 520 Host/Guest... - Page 16 The 7-segment display switches to alignment mode when the device has not yet been aligned or when the protective field has been interrupted (after 5 s). In this case, a fixed beam area from the protective field is assigned to every segment. Leuze electronic MLC 520 Host/Guest...

-

Page 17: Alignment Display

At least one, but not all beams in the beam area are uninterrupted. Switched off All beams in the beam area are interrupted. When the protective field has been free for about 5 s, the device switches back to the display of the operat- ing mode. Leuze electronic MLC 520 Host/Guest... -

Page 18: Functions

After the reset button has been actuated, the safety sensor switches to the ON state. EDM contactor monitoring NOTICE The contactor monitoring of the MLC 520 safety sensors can be activated through appropriate wiring (see chapter 7.1.1 "MLC 500 transmitter")! Leuze electronic MLC 520 Host/Guest... -

Page 19: Operating Range Selection

Ä Do not use this configuration option for safety purposes. Ä Note that the distance to reflective surfaces must always be selected so that no reflection bypass can occur even at maximum transmitting power (see chapter 6.1.4 "Minimum dis- tance to reflective surfaces"). Leuze electronic MLC 520 Host/Guest... -

Page 20: Applications

Fig. 5.1: Point of operation guarding protects reaching into the danger zone, e.g. for cartoners or filling systems Fig. 5.2: Point of operation guarding protects reaching into the danger zone, e.g. for a pick & place robot applica- tion Leuze electronic MLC 520 Host/Guest... -

Page 21: Access Guarding

Depending on the mounting height, resolutions of 40 or 90 mm are used (Link destination: order guide and accessories). Fig. 5.4: Danger zone guarding on a robot Leuze electronic MLC 520 Host/Guest... -

Page 22: Mounting

Approach speed Total time of the delay, sum from (t + t + t Response time of the protective device Response time of the safety relay Stopping time of the machine [mm] Additional distance to the safety distance Leuze electronic MLC 520 Host/Guest... -

Page 23: Calculation Of Safety Distance If Protective Fields Act Orthogonally To The Approach Direction

500 mm; this is why the calculation may not be repeated with 1600 mm/s. NOTICE Implement the stepping behind protection required here, e.g., through the use of an additional or cascaded safety sensor for area protection. Leuze electronic MLC 520 Host/Guest... - Page 24 [mm] The safety light curtain with a 40 mm resolution is thus suitable for this application. NOTICE For the calculation with K = 2000 mm/s, safety distance S equals 736 mm. The adoption of ap- proach speed K = 1600 mm/s is therefore permitted. Leuze electronic MLC 520 Host/Guest...

- Page 25 Height b of the upper edge of the protective field of the electro-sensitive protective of the equipment point of 1000 1100 1200 1300 1400 1600 1800 2000 2200 2400 2600 opera- tion Additional distance C to the danger zone [mm] [mm] 2600 2500 2400 2200 Leuze electronic MLC 520 Host/Guest...

- Page 26 ð In this line, go to the left column: here you will find the permitted height of the point of operation. Ä Now calculate safety distance S using the general formula acc. to ISO 13855 (see chapter 6.1.1 "Cal- culation of safety distance S"). ð The larger of the two values S and S is to be used. Leuze electronic MLC 520 Host/Guest...

-

Page 27: Calculation Of Safety Distance S For Parallel Approach To The Protective Field

Stopping time of the machine [mm] Additional distance for danger zone guarding with approach reaction H = height of the protec- tive field, H = minimum installation height permitted, but no smaller than 0, d = resolution of the protective device C = 1200 mm - 0.4 × H; H = 15 × (d - 50) Leuze electronic MLC 520 Host/Guest... -

Page 28: Minimum Distance To Reflective Surfaces

IEC 61496-2 (see the following diagram “Minimum distance to reflective surfaces as a function of the protective field width”). Ä Check that reflective surfaces do not impair the detection capability of the safety sensor be- fore start-up and at appropriate intervals. Leuze electronic MLC 520 Host/Guest... - Page 29 Minimum distance to reflective surfaces as a function of the protective field width Tab. 6.2: Formula for calculating the minimum distance to reflective surfaces Distance (b) transmitter-receiver Calculation of the minimum distance (a) to reflective sur- faces b ≤ 3 m a [mm] = 131 b > 3 m a [mm] = tan(2.5°) × 1000 × b [m] = 43.66 × b [m] Leuze electronic MLC 520 Host/Guest...

-

Page 30: Preventing Mutual Interference Between Adjacent Devices

Ä Mount adjacent devices with a shield between them or install a dividing wall to prevent mutual interfer- ence. Ä Mount the adjacent devices opposite from one another to prevent mutual interference. Fig. 6.5: Opposite mounting Receiver 1 Transmitter 1 Transmitter 2 Receiver 2 Leuze electronic MLC 520 Host/Guest... -

Page 31: Mounting The Safety Sensor

Can the entire danger zone be seen from the installation site of the reset button? Can reflection caused by the installation site be ruled out? NOTICE If you answer one of the items on the checklist above with no, the mounting location must be changed. Leuze electronic MLC 520 Host/Guest... -

Page 32: Definition Of Directions Of Movement

• Turning by 360° around the longitudinal axis by fixing on the screw-on cone • Pitching in the direction of the protective field with horizontal threaded holes in the wall mounting • Tilting around main axis Leuze electronic MLC 520 Host/Guest... -

Page 33: Fastening Via Bt-2Sb10 Swiveling Mounting Brackets

(see chapter 15 "Order guide and accessories"). For increased mechanical requirements, these are also available as vibration-damped version (BT-2SB10-S). Depending on the installation situation, envi- ronmental conditions and protective field length (> 1200 mm), other mounting brackets may also be neces- sary. Leuze electronic MLC 520 Host/Guest... -

Page 34: One-Sided Mounting On The Machine Table

Ä Make sure that reflections on the machine table are prevented reliably. Ä After mounting and every day after that, check the detection capability of the safety sensor in the entire protective field using a test rod (see chapter 9.3.1 "Checklist – periodically by the operator"). Leuze electronic MLC 520 Host/Guest... -

Page 35: Mounting Accessories

10%. Mounting bracket sets with 2 and 3 clamp brackets are available. NOTICE If the length equals 1200 mm or higher, 3 clamp brackets are recommended. Fig. 6.11: MLC-PS protective screen fastened with MLC-2PSF clamp bracket Leuze electronic MLC 520 Host/Guest... -

Page 36: Electrical Connection

NOTICE For special EMC stress, the use of shielded cables is recommended. Pin assignment transmitter and receiver 7.1.1 MLC 500 transmitter MLC 500 transmitters are equipped with a 5-pin M12 connector. MLCx00T Fig. 7.1: Pin assignment and connection diagram transmitter Leuze electronic... - Page 37 MLCx00T + 24V + 24V + 24V + 24V MLCx00T MLCx00T Transmission channel C1, reduced range Transmission channel C1, standard range Transmission channel C2, reduced range Transmission channel C2, standard range Fig. 7.2: Connection examples transmitter Leuze electronic MLC 520 Host/Guest...

-

Page 38: Mlc 520 Receiver

Wired in device interior on the housing FE - functional earth, shield The polarity of the supply voltage selects the transmission channel of the receiver: • VIN1 = +24 V, VIN2 = 0 V: transmission channel C1 • VIN1 = 0 V, VIN2 = +24 V: transmission channel C2 Leuze electronic MLC 520 Host/Guest... -

Page 39: Circuit Diagram Examples

Electrical connection Circuit diagram examples 7.2.1 MLC 520 circuit diagram example +24V +24V MLCx00T MLCx20R MSI-RM2 Fig. 7.4: Circuit diagram example with downstream MSI-RM2 safety relay Leuze electronic MLC 520 Host/Guest... -

Page 40: Starting Up The Device

• the transmitter and receiver connections point in the same direction. • the transmitter and receiver are arranged parallel to each other, i.e. they are the same distance from each other at the beginning and end of the device. Leuze electronic MLC 520 Host/Guest... -

Page 41: Aligning Of Deflecting Mirrors With The Laser Alignment Aid

The laser beam must strike the transmitter in both cases if the receiver has been correctly aligned. Ä Remove the laser alignment aid from the safety sensor. ð The protective field is free. LED1 on the receiver is permanently lit green. The OSSDs switch on. Leuze electronic MLC 520 Host/Guest... -

Page 42: Unlocking Start/Restart Interlock

• Starting at 4 s: the reset request is ignored. • Starting at 30 s: a +24 V short circuit is assumed on the reset input and the receiver switches to the in- terlock state (see chapter 11.1 "What to do in case of failure?"). Leuze electronic MLC 520 Host/Guest... -

Page 43: Testing

Is the safety sensor operated acc. to the specific environmental condi- tions that are to be maintained (see chapter 14 "Technical data")? Is the safety sensor correctly aligned and are all fastening screws and connectors secure? Leuze electronic MLC 520 Host/Guest... - Page 44 Are settings that could result in an unsafe state possible only by means of key, password or tool? Are there incentives that pose stimulus for tampering? Were the operators instructed prior to starting work? Leuze electronic MLC 520 Host/Guest...

-

Page 45: To Be Performed Periodically By Competent Persons

9.3.1 Checklist – periodically by the operator NOTICE Ä If you answer one of the items on the following check list with no, the machine must no longer be operated. Leuze electronic MLC 520 Host/Guest... - Page 46 – are the obviously dangerous machine parts stopped with- out noticeable delay? Protective device with presence detection: the protective field is interrupted with the test object – does this prevent operation of the obviously dangerous machine parts? Leuze electronic MLC 520 Host/Guest...

-

Page 47: Maintenance

• The system is safely shut down and protected against restart. Ä Clean the safety sensor periodically depending on the degree of contamination. NOTICE Prevent electrostatic charging of the front screens! Ä To clean the front screens of transmitter and receiver, use only damp cloths. Leuze electronic MLC 520 Host/Guest... -

Page 48: Troubleshooting

Ä Analyze and eliminate the cause of the fault using the following table. Ä If you are unable to rectify the fault, contact the Leuze electronic branch responsible for you or call the Leuze electronic customer service (see chapter 13 "Service and support"). - Page 49 - ready for unlocking Yellow flashing The control circuit is open in Close the input circuit with the correct po- operating mode 1, 2 and 3 larity and timing. Leuze electronic MLC 520 Host/Guest...

-

Page 50: Error Messages 7-Segment Display

Automatic reset ditions Interference detected on plug Check the wiring. Automatic reset pin 3. Signal output: output sig- nal is not equal to the signal in- put read-back value: it switches simultaneously with the other signal line. Leuze electronic MLC 520 Host/Guest... - Page 51 Operating mode changed Check the wiring. Restart the sen- Locking sor. Faulty connection on HOST or Check connection, e.g., connect Locking Middle Guest terminating plug Leuze electronic MLC 520 Host/Guest...

-

Page 52: Disposing

Disposing Disposing Ä For disposal observe the applicable national regulations regarding electronic components. Leuze electronic MLC 520 Host/Guest... -

Page 53: Service And Support

Service and support Service and support 24-hour on-call service at: +49 7021 573-0 Service hotline: +49 7021 573-123 E-mail: service.protect@leuze.de Return address for repairs: Servicecenter Leuze electronic GmbH + Co. KG In der Braike 1 D-73277 Owen/Germany Leuze electronic MLC 520 Host/Guest... -

Page 54: Technical Data

Relative humidity (non-condensing) 0 … 95 % Vibration resistance 50 m/s acceleration, 10 - 55 Hz in acc. with IEC 60068-2-6; 0.35 mm amplitude Shock resistance 100 m/s acceleration, 16 ms acc. to IEC 60068-2-6 Profile cross section 29 mm x 35.4 mm Dimensions see chapter 14.2 "Dimensions, weight, response time" Leuze electronic MLC 520 Host/Guest... - Page 55 (RC elements, varistors or recovery diodes), since these con- siderably extend the decay times of inductive switching elements. Leuze electronic MLC 520 Host/Guest...

-

Page 56: Dimensions, Weight, Response Time

Dimensions, weight and response time are dependent on • the resolution • the length L = 340 Fig. 14.1: Dimensions of Host transmitter and Host receiver L = 340 L = 340 output input Fig. 14.2: Dimensions of Middle Guest transmitter and Middle Guest receiver Leuze electronic MLC 520 Host/Guest... - Page 57 Dimensions (nominal protective field height), weight and response time for Host devices Device type Host transmitter and Host Host receiver receiver Dimensions Weight Response time [ms] acc. to resolution [mm] [kg] Type 14 mm 20 mm 30 mm 40 mm 90 mm MLC…-300 0.53 MLC…-450 0.68 Leuze electronic MLC 520 Host/Guest...

- Page 58 Device type Guest transmitter and Guest Guest receiver receiver Dimensions Weight Response time [ms] acc. to resolution [mm] [kg] Type 14 mm 20 mm 30 mm 40 mm 90 mm MLC…-150 0.28 MLC…-225 0.35 MLC…-300 0.43 MLC…-450 0.58 MLC…-600 0.72 Leuze electronic MLC 520 Host/Guest...

- Page 59 The number of beams for a Host–Guest or Host–Middle Guest guest system is determined by adding the number of beams of the individual devices. NOTICE The total number of beams for a Host–Guest or Host–Middle Guest guest system must not ex- ceed the value 400! Leuze electronic MLC 520 Host/Guest...

-

Page 60: Dimensioned Drawings: Accessories

Technical data 14.3 Dimensioned drawings: Accessories Fig. 14.4: BT-L mounting bracket 12.1 10.8 Fig. 14.5: BT-Z parallel bracket Ø 6,2 Ø 6,2 Ø Ø Ø Ø Fig. 14.6: Swivel mount BT-2HF Leuze electronic MLC 520 Host/Guest... - Page 61 Technical data 20,5 Ø 5,3 (2x) Ø 5,3 (2x) Fig. 14.7: Swiveling mounting bracket BT-2SB10 6° 6° Fig. 14.8: Connection bracket for L-shape or U-shape Leuze electronic MLC 520 Host/Guest...

-

Page 62: Order Guide And Accessories

Protective field height: 150 … 3000: from 150 mm to 3000 mm Host/Guest (optional): H: Host MG: Middle Guest G: Guest Interface (optional): /A: AS-i Option: EX2: explosion protection (zones 2 + 22) /V: high Vibration-proof SPG: Smart Process Gating Leuze electronic MLC 520 Host/Guest... -

Page 63: Mlc

• Receiver including 2 sliding blocks, 1 self-adhesive notice sign “Important notices and notices for the machine operator”, 1 set of connecting and operating instructions (PDF file on CD-ROM) Tab. 15.3: Part numbers of MLC 500 Host transmitter depending on resolution and protective field height Protective field 14 mm 20 mm... -

Page 64: Mlc

Order guide and accessories Tab. 15.4: Part numbers of MLC 500 Middle Guest transmitter depending on resolution and protective field height Protective field 14 mm 20 mm 30 mm 40 mm 90 mm height hhhh MLC500T14- MLC500T20- MLC500T30- MLC500T40- MLC500T90- [mm] hhhhMG hhhhMG hhhhMG hhhhMG hhhhMG 68022202 68022302... - Page 65 90 mm height hhhh MLC520R14- MLC520R20- MLC520R30- MLC520R40- MLC520R90- [mm] hhhhG hhhhG hhhhG hhhhG hhhhG 68021101 68021201 68021301 68021401 68021202 68021302 68021402 68021103 68021203 68021303 68021403 68021104 68021204 68021304 68021404 68021904 68021106 68021206 68021306 68021406 68021906 Leuze electronic MLC 520 Host/Guest...

- Page 66 68021218 68021318 68021418 68021918 Tab. 15.9: Accessories Part no. Article Description Connection cables for MLC 500 Host transmitter, shielded 50133860 KD S-M12-5A-P1-050 Connection cable, 5-pin, 5 m long 50133861 KD S-M12-5A-P1-100 Connection cable, 5-pin, 10 m long 678057 CB-M12-15000E-5GF Connection cable, 5-pin, 15 m long...

- Page 67 Order guide and accessories Part no. Article Description User-configurable connectors for MLC 500 transmitter 429175 CB-M12-5GF Cable socket, 5-pin, metal housing, shield on housing User-configurable connectors for MLC 520 Host receiver 429178 CB-M12-8GF Cable socket, 8-pin, metal housing, shield on...

- Page 68 Mounting device for MLC protective screen, 2 x 429039 MLC-3PSF Mounting device for MLC protective screen, 3 x Laser alignment aids 560020 LA-78U External laser alignment aid 520101 AC-ALM-M Alignment aid Test rods 349945 AC-TR14/30 Test rod 14/30 mm 349939 AC-TR20/40 Test rod 20/40 mm Leuze electronic MLC 520 Host/Guest...

-

Page 69: Eu/Ec Declaration Of Conformity

EU/EC Declaration of Conformity EU/EC Declaration of Conformity Leuze electronic MLC 520 Host/Guest...

Need help?

Do you have a question about the MLC 500 and is the answer not in the manual?

Questions and answers