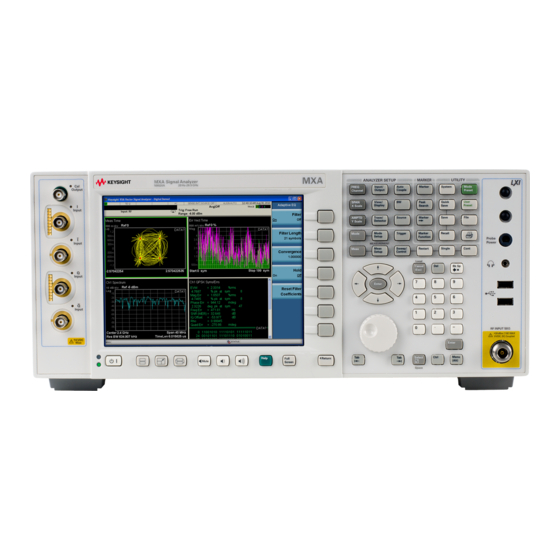

Keysight X Series Installation Notes

Signal analyzer

Hide thumbs

Also See for X Series:

- User & programmers manual (3096 pages) ,

- User reference (2852 pages) ,

- Programmer's reference manual (2650 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Keysight X Series

- Page 1 X-Series Signal Analyzer N9042B Power Supply Upgrade Option HW1 INSTALLATION NOTE...

- Page 2 The information contained in this document is subject to change without notice. Keysight Technologies makes no warranty of any kind with regard to this material, including but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

- Page 3 Option HW1 – Power Supply Upgrade Option HW1 – Power Supply Upgrade Products Affected: UXA N9042B To Be Performed By: (X) Keysight Service Center ( ) Advanced User ( ) User Estimated Installation Time: 2.0 Hours Estimated Adjustment Time: 0.0 Hours Estimated Verification Time: 1.0 Hours...

-

Page 4: Table Of Contents

What You Will Find in this Document What You Will Find in this Document Information......................page 5 Upgrade Contents ......................page 7 Tools Required ......................page 7 Initial Instrument Functionality Check ................ page 8 Option G2H Check.....................page 8 Option ST1/ST2 Check ....................page 8 Option R40 Check......................page 8 Upgrade Instructions .................... -

Page 5: Esd Information

ESD Information ESD Information Protection from Electrostatic Discharge Electrostatic discharge (ESD) can damage or destroy electronic components. All work on electronic assemblies should be performed at a static-safe workstation. Figure 1 shows an example of a static-safe workstation using two types of ESD protection: —... - Page 6 ESD Information Handling of Electronic Components and ESD The possibility of unseen damage caused by ESD is present whenever components are transported, stored, or used. The risk of ESD damage can be greatly reduced by paying close attention to how all components are handled.

-

Page 7: Upgrade Contents

Upgrade Contents Upgrade Contents Table 1 Upgrade Contents Part Number Description Quantity 0515-0372 Screw, Panhead, TORX-T10 M3X0.5 8mm-LG 0515-1946 Screw, Flathead, TORX-T10 M3X0.5 6mm-LG 0515-2032 Screw, Flathead, TORX-T10 M3X0.5 8mm-LG 0515-2151 Screw, Flathead, TORX-T6 M2X0.4 4mm-LG 0535-0031 Nut-HEX W/Lock-Washer M3X0.5 0950-6424 Power Supply, AC-DC Switching, 695 W N9041-00043... -

Page 8: Initial Instrument Functionality Check

Initial Instrument Functionality Check Initial Instrument Functionality Check Power on the instrument and allow it to complete its boot up process. Verify that there are no instrument messages that would indicate that there is an issue with either the instrument hardware or software. -

Page 9: Upgrade Instructions

Upgrade Instructions Upgrade Instructions Hardware Removal Dress Cover Removal 1. Turn the instrument off and disconnect the power cord. 2. Referring to Figure 2, remove the two screws (1) that attach the strap handles (2) from both sides of the instrument and remove the strap handles. Figure 2 Dress Cover Removal 3. - Page 10 Upgrade Instructions Top Brace Removal 6. Referring to Figure 3, remove the fourteen flathead screws (1) and three panhead screws (2) attaching the top brace (3) to the instrument and set it aside. Figure 3 Top Brace Removal Installation Note N9042-90012...

- Page 11 Upgrade Instructions Rear Panel Removal 7. If the instrument has Option ST1 or ST2, remove the four panhead screws (1) that attach the power supply adapter plate (2) to the rear panel, as seen in Figure 4. This plate can be discarded.

- Page 12 Upgrade Instructions 8. Referring to Figure 5, remove the four flathead screws (1) at the corners, the eight large panhead screws (3), and the twelve panhead screws (2) that attach the rear panel to the instruments. Figure 5 Rear Panel Removal 9.

- Page 13 Upgrade Instructions 10.Referring to Figure 6, if the instrument has Option ST1 or ST2, carefully remove the ODI cable (1) from the rear panel ODI connector (2) by sliding the locking tab up. Figure 6 Rear Panel ODI Cable Removal - Option ST1 or ST2 11.Carefully remove the rear panel from the instrument.

- Page 14 Upgrade Instructions Rear Brace Removal 12.Referring to Figure 7, remove the four panhead screws (1) and the two flathead screws (2), then remove the rear brace (3) from the instrument. Figure 7 Rear Brace Removal If the instrument has Option ST1, ST2, or R40 the rear brace removal will also require that the optical cables also be disconnected and detached from the rear brace before it can be removed, as seen in Figure...

- Page 15 Upgrade Instructions Figure 8 Rear Brace Removal - Optional Hardware Installation Note N9042-90012...

- Page 16 Upgrade Instructions A21 Wideband Digital IF Removal 13.Referring to Figure 9, unplug all the coax cables that are connected to the A21 Wideband Digital IF assembly in the area shown (1). 14.Pull on the two board extractors (2) and remove the A21 Wideband Digital IF assembly from the instrument.

- Page 17 Upgrade Instructions Figure 10 A22 Ultra-Wideband Analog IF Removal - Option R40 Installation Note N9042-90012...

- Page 18 Upgrade Instructions A4 System Processor Removal 15.Referring to Figure 11, remove the two panhead screws (1) from each side that attaches the A4 System Processor (3) to the instrument. 16.Remove the two panhead screws (2) that secure the extractors. 17.Remove the A4 System Processor by pulling on the two extractors and sliding it out the rear of the instrument.

- Page 19 Upgrade Instructions A6 Power Supply Removal 18.Referring to Figure 12, remove the 9 flathead screws (1) attaching the A6 Power Supply to the instrument. 19.Slide the A6 Power Supply out the rear of the instrument and discard it. Figure 12 A6 Power Supply Removal Installation Note N9042-90012...

-

Page 20: Hardware Installation

Upgrade Instructions Hardware Installation A6 Power Supply Installation 1. Referring to Figure 13, slide the new A6 Power Supply into the rear of the instrument until it fully engages the mating connectors on the A7 Midplane board. 2. Install the nine new flathead screws (0515-2032) (1) to attach the A6 Power Supply to the instrument through the power supply bracket. - Page 21 Upgrade Instructions A4 System Processor Installation 3. Referring to Figure 14, use the two extractors to insert the A4 System Processor (3) into the rear of the instrument. 4. Install the two panhead screws (1) on each side to attach the A4 System Processor to the instrument.

- Page 22 Upgrade Instructions A21 Wideband Digital IF 6. Referring to Figure 15, use the extractors (2) to insert the A21 Wideband Digital IF back into the instrument, being careful not to damage any of the coax cables that attach to it. 7.

- Page 23 Upgrade Instructions Figure 16 A22 Ultra-Wideband Analog IF Installation - Option R40 Installation Note N9042-90012...

- Page 24 Upgrade Instructions Rear Brace Installation 8. Referring to Figure 17, install the rear brace (3) and attach it to the chassis with two panhead screws (1) on each end. Torque the screws to 9 in-lbs. 9. Attach the rear brace to the A21 Wideband Digital IF with the two flathead screws (2). Torque the screws to 9 in-lbs.

- Page 25 Upgrade Instructions Figure 18 Rear Brace Installation - Optional Hardware Installation Note N9042-90012...

- Page 26 Upgrade Instructions Rear Panel Installation If the instrument has Option ST1 or ST2 the original rear panel will be reused to avoid having to move the serial number label or the rear panel optical connector to the new one. 10.If the instrument does not have Option ST1 or ST2, attach the nut plate (1) to the rear frame using the two hex nuts (2), as seen in Figure 19.

- Page 27 Upgrade Instructions 12.If the instrument has Option ST1 or ST2, connect the optical cable (1) to the rear panel optical connector (2), as seen in Figure 20. Be sure to insert it all the way, until a click is heard. Figure 20 Rear Panel Installation - Optional Hardware Installation Note N9042-90012...

- Page 28 Upgrade Instructions 13.Referring to Figure 21, feed the two SMA cables (4) and the one BNC cable (5) through the new rear panel and attach them with their lock washers and hex nuts. Torque the SMA cable hex nuts to 10 in-lbs and the BNC hex nut to 21 in-lbs. Figure 21 Rear Panel Installation 14.Install the rear panel onto the instrument and secure it with the eight M4.0 panhead screws...

-

Page 29: Verify Operation

Upgrade Instructions Top Brace Installation 15.Referring to Figure 22, install the top brace (3) using the fourteen new flat screws (1) and the three panhead screws (2). Torque all screws to 9 in-lbs. Figure 22 Top Brace Installation Verify Operation The operation of the power supply should be verified before installing the instrument dress cover. -

Page 30: Instrument Button Up

Upgrade Instructions Instrument Button Up Dress Cover Installation 1. Referring to Figure 22, carefully slide the outer cover (5) onto the instrument. Figure 23 Dress Cover Installation 2. Attach the four rear feet (4) using the four panhead screws and washers (3). Torque the screws to 21 in-lbs. -

Page 31: Rear Panel Labels

Upgrade Instructions Rear Panel Labels If the instrument that was upgraded does not have Option ST1 or ST2 the rear panel will have been changed during the upgrade process and will need to have two rear panel labels attached to it. These would be the following: 1. -

Page 32: Adjustments And Performance Verification

Adjustments and Performance Verification Adjustments and Performance Verification Manual Procedures Required None Automated Utilities Required None Automated Adjustments Required None Automated Performance Verification Testing Required Noise Density Residual Response Displayed Average Noise Level Spurious Responses IF Frequency Response Average Noise Level IF Amplitude Accuracy Installation Note N9042-90012... - Page 33 This information is subject to change without notice. © Keysight Technologies 2023 Edition 1, January 2023 N9042-90012 www.keysight.com...

Need help?

Do you have a question about the X Series and is the answer not in the manual?

Questions and answers