Table of Contents

Advertisement

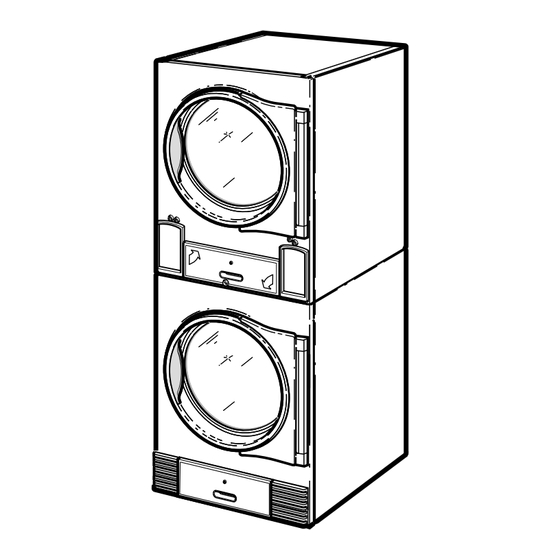

Stacked 30 Pound (13/13 Kilogram) Capacity

Stacked 45 Pound (20/20 Kilogram) Capacity

18 Digit Model Numbers with 6 in 13th Position

Original Instructions

Keep These Instructions for Future Reference.

CAUTION: Read the instructions before using the machine.

(If this machine changes ownership, this manual must accompany machine.)

30 Pound (13 Kilogram) Capacity

35 Pound (16 Kilogram) Capacity

55 Pound (24 Kilogram) Capacity

Refer to Page 12 for Model Identification

Tumble Dryers

TMB1292C_SVG

Part No. 70686701ENR4

October 2022

Advertisement

Table of Contents

Need help?

Do you have a question about the 030 Series and is the answer not in the manual?

Questions and answers