Grundfos CIM 300 User Manual

Bacnet for grundfos level control lc 2x1 and lc 2x2

Hide thumbs

Also See for CIM 300:

- Installation and operating instructions manual (88 pages) ,

- Instructions manual (49 pages)

Summary of Contents for Grundfos CIM 300

- Page 1 GRUNDFOS INSTRUCTIONS BACnet for Grundfos Level Control LC 2X1 and LC 2X2 CIM/CIU 300 BACnet MS/TP CIM/CIU 500 Ethernet for BACnet IP Functional profile and user manual...

- Page 3 BACnet for Grundfos Level Control LC 2X1 and LC 2X2 English (GB) Functional profile and user manual ............4...

-

Page 4: Table Of Contents

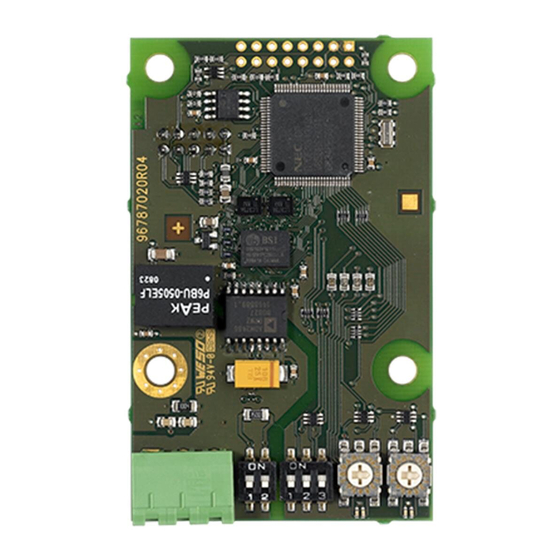

BACnet bus topology ......8 CIM 300 BACnet module ..... . 8 WARNING Connecting to the BACnet network . -

Page 5: About This Functional Profile

These systems use encryption and other LC 2X2 in this document. security mechanisms to ensure that only authorised users Grundfos cannot be held responsible for any problems caused can access the network and that the data cannot be intercepted. -

Page 6: Bacnet

MS/TP CIM 500 solution for LC 2X1. One or two pumps can be connected. Pos. Description Digital and analog input/output CIM 300 solution for LC 2X1. One or two pumps can be connected. LC 2X2 Pos. Description CIM 500 Digital and analog input/output... -

Page 7: Specifications

Auto-detected Industrial Ethernet protocols PROFINET IO, BACnet IP etc. Selected with rotary switch. BACnet protocol revision CIM 300 and 500 Dimensions [w x h x d] [mm] 50 x 19 x 80 Power supply Supplied by the LC 2XX controller. -

Page 8: Bacnet Ms/Tp, Cim 300 Setup

2. BACnet MS/TP, CIM 300 setup 2.2 CIM 300 BACnet module 2.1 BACnet bus topology Grundfos CIM/CIU 300 is connected as a BACnet MS/TP master directly to the BACnet MS/TP network. Example of BACnet MS/TP network Pos. Description Master Slave... -

Page 9: Connecting To The Bacnet Network

The Instance Number is a numeric code that is used to identify the 2.4 Setting the BACnet transmission speed device. It must be unique inter-network-wide, i.e. on all Set the transmission speed correctly before CIM 300 is ready to interconnected networks. communicate on the BACnet MS/TP network. Use DIP switches CIM 300 offers two different approaches to setting the BACnet SW4 and SW5 to set the transmission speed. -

Page 10: Selecting The Device Object Name

2.8 Termination resistor A termination resistor for line termination is fitted on CIM 300 and has a value of 120 Ω. It is to be cut in if CIM 300 is set as the last station on the network. CIM 300 has two DIP switches, SW1 and SW2, for cutting the termination resistor in and out. -

Page 11: Bacnet Ip, Cim 500 Setup

Pos. Description EtherNet/IP Ethernet switch GRM IP (requires a contract with Grundfos) Reserved, LED1 will be permanently red to indicate an invalid configuration. Reset to factory default. Note: The rotary switch must to be set in this position for 20 seconds to reset to factory default. -

Page 12: Establishing Connection To The Webserver

CIM 500 is switched off. Change username and password at first login. No internal communication between CIM 500 Flashing red and the Grundfos product. CIM 500 does not support the Grundfos product Permanently red connected. Internal communication between CIM 500 and Permanently green the Grundfos product is OK. -

Page 13: Supported Services

CIM 300 and 500 allow multiple values to be changed over the WritePropertyMultiple DS-WPM-B ● network. SubscribeCOV ● CIM 300 and 500 can be a provider of "Change Of Value" data. It ConfirmedCOVNotification DS-COV-B supports up to 10 simultaneous COV subscriptions. Subscription ● lifetime can be limited or unlimited. UnconfirmedCOVNotification ●... -

Page 14: Object Overview

BACnetARRAY[N]of Object_List An array of objects available. BACnetObjectIdentifier CIM 300: The maximum number of bytes that may be contained in a single APDU. Fixed to 480. Max_APDU_Length_Accepted Unsigned CIM 500: The maximum is 1476. Indicates if segmentation of messages is possible. Will... -

Page 15: Binary Inputs

5.2 Binary inputs Binary objects that provide information from a Grundfos pump. Object name Description LC 2X1 LC 2X2 0: Not acknowledged BI, 0 AcknowledgeAlarm ● ● 1: Acknowledged 0: Off (Float switch down) BI, 1 FloatSwitch1Status ● ● 1: On (Float switch up) -

Page 16: Binary Outputs

1: Alarm 0: Inactive BI, 38 Running on battery back-up ● ● 1: Active 5.3 Binary outputs Binary objects used for controlling a Grundfos pump. Object name Description LC 2X1 LC 2X2 0: No resetting BO, 0 Reset alarms ●... -

Page 17: Multistate Inputs

5.4 Multistate inputs Binary objects that provide information from a Grundfos pump. Object name Description LC 2X1 LC 2X2 0: Standby 1: Start-up delay 2: Pumping 3: Stop delay 4: Pumping max 5: Stopped 6: Foam draining 7: Daily emptying... -

Page 18: Analog Inputs

5.6 Analog inputs Objects with measured values and status information from the pump Object name Description Unit LC 2X1 LC 2X2 AI, 0 Fault code Grundfos fault code. ● ● AI, 1 Warning code Grundfos warning code. ● ● AI, 2 HighLevel High level in centimetres. -

Page 19: Analog Outputs

Object name Description Unit LC 2X1 LC 2X2 Values are transmitted in the following order: • bit 0: Flow sensor present • bit 1: Power/energy sensor present • bit 2: AI sensor 1 present • bit 3: AI sensor 2 present •... -

Page 20: Detailed Description

6.1 Fault monitoring and resetting This example shows how to monitor faults or warnings in the Grundfos pump and how to manually reset a fault. The Fault code object (AI, 0) and the Warning code object (AI, 1) can both hold a Grundfos-specific fault code. -

Page 21: Fault Finding The Product

8. Fault finding the product 8.1 CIM 300 BACnet MS/TP 8.1.1 LED status Faults in a CIM 300 can be detected by observing the status of the two communication LEDs. See the table below. Fault (LED status) Possible cause Remedy... -

Page 22: Cim 500 Bacnet Ip

CIM 500 connected to an LC 2XX. Fault (LED status) Possible cause Remedy CIM 500 is fitted incorrectly in the Grundfos product. Check that CIM 500 is fitted and connected correctly. LED1 and LED2 remain off when the power supply is connected. CIM 500 is defective. -

Page 23: Bacnet Telegrams

9. BACnet telegrams 9.1 BACnet MS/TP telegram overview All BACnet MS/TP telegrams have the following format: Preamble Telegram type Destination Source Length Header CRC Data Data CRC 2 bytes: 2 bytes, MSB Variable, 2 bytes, LSB 1 byte 1 byte 1 byte 1 byte At most 1 byte 0xFF... -

Page 24: Bacnet Mac Address, Cim 300

10. BACnet MAC address, CIM 300 BACnet BACnet BACnet address address address If the MAC address switches are set to an invalid MAC address value, a MAC address of 0 will be used. -

Page 25: Grundfos Alarm And Warning Codes

11. Grundfos alarm and warning codes This is a complete list of alarm and warning codes for Grundfos products. For the codes supported by this product, see the alarms and warnings section. Code Description Code Description Code Description Leakage current... - Page 26 Code Description Code Description Code Description Start capacitor, low Auxiliary winding current too high (single- Auxiliary winding current too low (single- phase motors) phase motors) (single-phase motors) Run capacitor, low (single-phase motors) Signal fault, outdoor temperature sensor Signal fault, air temperature sensor Signal fault, shunt relative pressure Strainer clogged sensor...

- Page 27 Code Description Code Description Code Description User-defined relay has been forced Fault, On/Off/Auto switch Pump continuous runtime too long (manually operated or commanded) Power-on notice, (device or system has Fault, battery/UPS User-defined event 1 been switched off) User-defined event 2 User-defined event 3 User-defined event 4 SMS data from DDD sensor not received...

- Page 28 Appendix A A.1. Appendix The appendix describes the parts of the CIM 500 webserver needed for the configuration of a BACnet IP Ethernet connection. For other CIM 500 webserver features, not specifically related to BACnet IP, see the installation and operating instructions for CIM 500.

- Page 29 A.1.3. Login Login Object Description Enter username. Username Default: admin. Enter password. Default: Grundfos. After the first log in, you are forced to change the password. The password must contain: • at least 8 and maximum 20 characters Password •...

- Page 30 Select the UDP port number. The default number is 47808, the standard UDP port number for BACnet IP. Select the Device Instance. The default number is 227000. The Device Instance must be unique in the BACnet network. Grundfos is Device Instance 227 and it is fixed.

- Page 31 Tel.: +387 33 592 480 Centre Turkey Fax: +387 33 590 465 29-33 Wing Hong Street & 68 King Lam GRUNDFOS Pumper A/S GRUNDFOS POMPA San. ve Tic. Ltd. Sti. www.ba.grundfos.com Street, Cheung Sha Wan Strømsveien 344 Gebze Organize Sanayi Bölgesi E-mail: grundfos@bih.net.ba...

- Page 32 99785079 09.2022 ECM: 1349851 www.grundfos.com...

Need help?

Do you have a question about the CIM 300 and is the answer not in the manual?

Questions and answers