Summary of Contents for Bosch Rexroth SB11

- Page 1 Instruction manual Load-sensing control block SB11 for mobile applications RE 66177-B/2022-05-03, EN...

- Page 2 © Bosch Rexroth AG 2022. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. The data specified within only serves to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from...

-

Page 3: Table Of Contents

5.5.2 Control block for fixed pump ..............34 Transport and storage ���������������������������������������������������������������������������� 35 Transporting the control block/control block segment ....... 35 6.1.1 Transport by hand ..................35 6.1.2 Transport with lifting devices ..............35 Storage of control block/control block segment ........36 RE 66177-B/2022-05-03, Bosch Rexroth AG... - Page 4 Preparing the components for storage or further use ......... 53 Disposal ������������������������������������������������������������������������������������������������� 54 Extension and conversion ����������������������������������������������������������������������� 55 Troubleshooting ������������������������������������������������������������������������������������� 56 14.1 How to proceed for troubleshooting ............56 14.2 Malfunction table ..................57 Technical data ���������������������������������������������������������������������������������������� 58 Alphabetical index ��������������������������������������������������������������������������������� 59 Bosch Rexroth AG, RE 66177-B/2022-05-03...

-

Page 5: About This Documentation

About this documentation | Load-sensing control block SB11 5/60 1 About this documentation 1�1 Validity of the documentation This documentation applies to load-sensing control blocks SB11 of Bosch Rexroth including the following control block segments: • Connecting plate, intermediate plate and end plate • Control valves SB11-EHS4 •... -

Page 6: Representation Of Information

For further documentation on installation and repair, refer to Table 16 on page 52 or consult your Bosch Rexroth Sales. 1�3 Representation of information Uniform safety instructions, symbols, terms and abbreviations are used throughout this documentation to ensure safe and proper use of the product. -

Page 7: Symbols

Control valve with CAN bus-controlled electro-hydraulic actuating unit EHR11-EHS4 Control valve with CAN bus-controlled electro-hydraulic actuating unit for electrohydraulic hitch control Control valve Directional valve type SB Hitch control valve Directional valve type EHR Control spool Main spool Actuation Type of control spool actuation RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 8: Abbreviations

Electro-hydraulic actuating unit End valve (with LS signaling direction from left to right) End plate Individual pressure compensator International Organization for Standardization (Internationale Normierungsorganisation) Check valve Check valve Directional valve (with LS signaling direction from left to right) Intermediate plate Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 9: Safety Instructions

The control blocks/control block segments have been developed for applications in the working hydraulics of agricultural machinery. Deviating use is only permitted following consultation with Bosch Rexroth. ▶ Observe the technical data, the application and operating conditions and the performance limits as specified in the data sheet and in the order confirmation. -

Page 10: Improper Use

2�3 Improper use Any use other than that described as intended use is considered improper. Bosch Rexroth AG is not liable for damage resulting from improper use. The user is solely responsible for any risks arising from improper use. The following foreseeable forms of faulty usage are also considered improper (this list is not exhaustive): •... -

Page 11: Product-Specific Safety Instructions

▶ Please note that the hydraulic system might still be pressurized even after separation from the actual pressure supply. ▶ Do not disconnect any line connections, ports or components as long as the hydraulic system is under pressure. RE 66177-B/2022-05-03, Bosch Rexroth AG... - Page 12 ▶ Depressurize the relevant machine/system component and repair the leak. ▶ Never attempt to block or seal the leak or hydraulic fluid jet with a cloth. Bosch Rexroth AG, RE 66177-B/2022-05-03...

-

Page 13: Personal Protective Equipment

▶ Check how to safely get on top of the machine/system. 2�7 Personal protective equipment The personal protective equipment is the responsibility of the user of the control block/control block segment. Observe the safety regulations in your country. All pieces of personal protective equipment must be intact. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 14: General Instructions On Property Damage And Product Damage

Loss of protection class and danger of short circuit! The connector only satisfies the type of protection in the plugged and locked state! ▶ Prior to installation as well as during cleaning and painting operation, make sure that all seals and plug-in connections are tight. Bosch Rexroth AG, RE 66177-B/2022-05-03... - Page 15 ▶ Dispose of the control block/control block segment, hydraulic fluid, and packaging in accordance with the national regulations in your country. ▶ Dispose of the hydraulic fluid in accordance with the applicable safety data sheet for the hydraulic fluid. RE 66177-B/2022-05-03, Bosch Rexroth AG...

- Page 16 • Removal of the tamper-proof caps and seals (e.g. with pressure settings), • Control of the settings at the factory, • Unauthorized conversions and additional installations, • Opening of the directional valve, • Improper handling, • Use of non-original spare parts by Rexroth. Bosch Rexroth AG, RE 66177-B/2022-05-03...

-

Page 17: Scope Of Delivery

4 Scope of delivery Included in the scope of delivery: • Control blockIn control block segment according to order confirmation The following parts are also assembled prior to delivery according to version: • Protective covers • Protective plugs/threaded plugs RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 18: About These Products

JJ w WW = Year w calendar week 3 Designation of origin 5 Data Matrix code 6 Range/serial number The information on the above name plate may vary depending on order-specific requirements. Any other labeling on the product is just for Bosch Rexroth-internal purposes. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

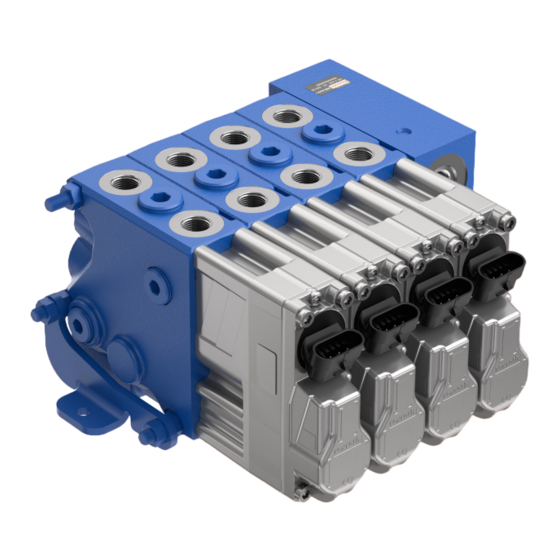

Page 19: Product Description

The SB11 control block segments shown below are described by means of dummies. For a precise overview of all available combinations, refer to the respective data sheet. For the precise position and designation of external ports, refer to the data sheet or the offer drawing. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 20: Types Of Actuation

Side Consumer port side Side Flange surface O-ring opposite side or AP outer side Side Lower side Side Front face side A (EHS side) Side Front face side B Side Flange surface O-ring side and/or EP outer side Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 21: Port Designations

LS signal output Block fastening thread 5�3�5 Flange figure Denomination Port for Information Inlet Return flow reservoir EHR11 pressure limitation return flow optional LS signal Pilot oil return Pilot oil supply Tie rod thread or tie rod bore continuous RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 22: Connecting Plate For Fixed Pump (C2 And C4)

LS chain. AP C2/C4 does not have a manual operating element or external control. Operation / control Unloading of the secondary pressure relief valve in the EHR11-EHS via AP C2/ C4 is not possible for design reasons (return flow RfB). Bosch Rexroth AG, RE 66177-B/2022-05-03... - Page 23 About these products | Load-sensing control block SB11 23/60 Fluid plan Connecting plate C2 Connecting plate C4 Connecting plate C4 with Yin1 RE 66177-B/2022-05-03, Bosch Rexroth AG...

-

Page 24: Connecting Plate For Variable Pump (C6)

X and supplies this line with the flow from the block-internal line P. Pressure reducing valve control coil : Electrical activation and deactivation of the pressure reduction function. Optional return flow RfB: For unloading the secondary pressure relief valve in the EHR11-EHS. Bosch Rexroth AG, RE 66177-B/2022-05-03... - Page 25 Fluid plan Connecting plate C6 Connecting plate C6 with pressure relief valve R2 Yo2 P2 X2 Connecting plate C6 with pressure relief valve and pressure reducing valve Connecting plate C6 with pressure relief valve, pressure reducing valve and RfB RE 66177-B/2022-05-03, Bosch Rexroth AG...

-

Page 26: Hitch Control Valve Ehr11-Ehs4

• With internal return flow: Controls the inlet flow and return flow via working port Port is plugged by threaded plug Check valve : Prevents valve-internal return flow in working port Bosch Rexroth AG, RE 66177-B/2022-05-03... - Page 27 Fluid plan RfB on the O-ring opposite side, external consumer return RfB on O-ring opposite side, internal consumer return RfB on the O-ring side (for unloading RfB via end plate), internal consumer return RE 66177-B/2022-05-03, Bosch Rexroth AG...

-

Page 28: Control Valve Sb11-Ehs4

The discharged volume is very low. Shuttle valve : Directs the higher LS pressure through the control block/control block segment. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 29: Intermediate Plate

Control is realized via CAN bus pilot signal Fluid plan SB11 EHS4 standard valve (SVR) SB11-EHS4 end valve (EVR) 5�3�10 Intermediate plate Application The intermediate plate does not have any internal function and serves as spacer. Fluid plan Intermediate plate without RfB RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 30: Intermediate Plate With Rfb

The intermediate plate serves as a spacer and unloads the secondary pressure relief valve in the EHR11-EHS (RfB). Fluid plan Intermediate plate with RfB on the O-ring side 5�3�12 End plate (E1) Table 11: Internal functions Position Designation Information Connection Y → R Fluid plan End plate E1 Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 31: End Plate (E6)

This way, the pressure in the block-internal EHS pilot oil line X is increased to the pressure value of the pressure reduction function. If the control coil is not energized, the block-internal EHS pilot oil line X is unloaded to the return flow. Fluid plan End plate E6 with pressure reducing valve RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 32: Control Block Versions

SB11 EHS4 control block for fixed pump, SB11 EHS4 control block for for fixed pump with secondary pressure relief valve variable displacement pump unloading (RfB) via intermediate plate For detailed of the individual control block segments, refer to chapter 5.5 "Combination options" on page 33. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 33: Combination Options

About these products | Load-sensing control block SB11 33/60 5�5 Combination options 5�5�1 Control block for variable pump RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 34: Control Block For Fixed Pump

34/60 Load-sensing control block SB11 | About these products 5�5�2 Control block for fixed pump Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 35: Transport And Storage

▶ Place the lifting strap around the control block/control block segment in such a way that it does not pass over assembled parts (e.g. valves) and that the control block/control block segment is not suspended at attachments. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 36: Storage Of Control Block/Control Block Segment

4� If the storage time of two years is exceeded, external seals must be replaced. After expiration of the maximum storage time, we recommend having the control block/control block segment inspected by the responsible Bosch Rexroth service partner. Bosch Rexroth AG, RE 66177-B/2022-05-03... - Page 37 Transport and storage | Load-sensing control block SB11 37/60 In case of any questions regarding repair and spare parts, please contact the responsible Bosch Rexroth service partner or the service department of the control block/control block segment manufacturer's plant, see chapter 10.4 "Spare parts" on page 52.

-

Page 38: Installation

4 "Scope of delivery" on page 17. 3� Dispose of the packaging in accordance with the regulations in your country. 4� Return any reusable packaging to the corresponding sending Bosch Rexroth plant. 7�2 Assembly of control block segments to form a control block Assembly of directional valve sections and plates to form a control block is... -

Page 39: Installation Conditions

If the material number of the control block/control block segment does not correspond to the one in the order confirmation, contact the Bosch Rexroth service for clarification, see chapter 10.4 "Spare parts" on page 52. 7�6�2 Fastening of the control block/control block segment •... -

Page 40: Completion Of Installation

7�6�4 Mechanical connection of the control block/control block segment Connection of actuation elements including tolerances is illustrated in the offer drawing. The tightening torques are to be selected according to the actuation elements. There must not occur any radial forces during actuation! Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 41: Hydraulic Connection Of The Control Block/Control Block Segment

For an overview of line connections, refer to the respective data sheet and the offer drawing. Fitting for hydraulic • Fittings with seal: connections – O-ring ISO 6149-1 – Flat sealing DIN 3852-1 or DIN 3852-2 • Lightly grease the fitting and tighten clockwise. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 42: Customer-Specific Coupling Connection

4� Tighten the coupling housing with the four socket-head screws at the coupling port of directional valve . Tightening torque M 5� Tighten socket-head screws = 11+1 Nm. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 43: Tightening Torques For Hydraulic Ports

M26 × 1.5 103+34 Nm M27 × 2 103+34 Nm M30 × 2 170+57 Nm M33 × 2 200+67 Nm M36 × 2 245+82 Nm M38 × 2 245+82 Nm M39 × 2 310+103 Nm M42 × 2 380+127 Nm RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 44: Electric Connection Of The Control Block/Control Block Segment

1� De-energize the plug-in connections at the control block/control block segment. 2� Before establishing the connection, check the connector and all seals for damage. 3� Establish the electrical connection of the control block/control block segment. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 45: Commissioning

▶ The hydraulic connection fittings must be tightened with the specified tightening torque. ▶ The control block/control block segments must be filled with hydraulic fluid to the maximum level. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 46: Initial Commissioning

Pump 4� Apply air bleeding at the control block/control block segment, see chapter 8.3 on page 47. – Bosch Rexroth recommends separate air bleeding at the individual directional valves. – Also observe the parameters for air bleeding in the instruction manual of the machine. -

Page 47: Air Bleeding

3� Switch the control valve at least 20 times with a frequency of 2 Hz between 100% lifting (spool position 1) and float (spool position F). Control valves without release position are switched between 100% lifting (spool position 1) and 100% lowering (spool position 2). RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 48: Bleeding Ehr Hitch Control Valves With Ehs

3� Switch the hitch control valve at least 20 times with a frequency of 2 Hz between 100% lifting (spool position 1) and d 100% lowering (spool position 2). Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 49: Recommissioning After Standstill

• have been decommissioned for more than 12 months • have been disassembled • have been repaired • hydraulic fluid has been drained and/or changed. ▶ For recommissioning, proceed as described in chapter 8.2 "Initial commissioning" on page 46. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 50: Operation

CAN interface by means of conventional tools like VECTOR CANoe. The features of the EHS software like parameterizibility, diagnosis functions and monitoring limits are available on request from the manual "Safety-relevant project planning notes" RE 6615701B as well as from the "Technical customer information" RE 6615702B. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 51: Maintenance And Repair

• Manifold mounting, ports and leak-tightness The interval depends on the machine and its application condition. 10�3 Repair Bosch Rexroth offers a comprehensive range of services for the repair of Rexroth control blocks/control block segments. Repairs at the control block/control block segment may only be performed by service centers certified by Bosch Rexroth or the machine/system manufacturer. -

Page 52: Spare Parts

Spare parts lists are available from your responsible Bosch Rexroth service partner. When ordering spare parts, quote the material and serial number of the control block/control block segment as well as the material numbers of the spare parts. -

Page 53: Removal And Replacement

2� Place the product on a clean surface with sufficient load-bearing capacity. 3� Plug all openings. 11�4 Preparing the components for storage or further use ▶ Proceed as described in chapter 6.2 "Storage of control block/ control block segment", section "After removal" on page 37. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 54: Disposal

3� Dispose of the hydraulic fluid in accordance with the regulations of your country. 4� Disassemble the control block/control block segment into its individual parts and recycle them. 5� For example, separate the parts into: – Metals – Electronic waste – Plastic Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 55: Extension And Conversion

13 Extension and conversion For specific applications, retrofittingIn conversion of the control block/control block segment can be required. ▶ Please contact Bosch Rexroth for coordination. Possible retrofitting or conversion of the control block/control block segment is described in the specific data sheet. -

Page 56: Troubleshooting

– Has the product or machine been used as intended? – How does the malfunction appear? ▶ Document the work carried out. ▶ If the fault cannot be corrected, please refer to one of the contract addresses at: www.boschrexroth.com/addresses or in chapter 10.4 "Spare parts". Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 57: Malfunction Table

In case of malfunctions caused by contamination, it is essential to check and possibly improve the quality of the hydraulic fluid through appropriate measures, such as purging, replacement or additional installation of filters in addition to carrying out repairs. RE 66177-B/2022-05-03, Bosch Rexroth AG... -

Page 58: Technical Data

Table 1 "Required and supplementary documentation" on page 5. The data sheets can be found in the online product catalog under www.boschrexroth.com/p-SB11 The order-related technical data of your control block/control block segment can be found in the order confirmation. Bosch Rexroth AG, RE 66177-B/2022-05-03... -

Page 59: Alphabetical Index

Malfunction table ....... 57 Installation conditions ....39 Installation position...... 39 Intended use ........9 Unpacking ........38 Lifting devices ......35 Warranty ......... 16, 36 Weight .......... 35 Maintenance ......... 51 Malfunction table ......57 Operation ........50 RE 66177-B/2022-05-03, Bosch Rexroth AG... - Page 60 Bosch Rexroth AG Robert-Bosch-Straße 2 71701 Schwieberdingen Germany Phone: +49 711 811-8481 info.ma@boschrexroth.de www.boschrexroth.com Your local contact person can be found at: https://addresses.boschrexroth.com Subject to change RE 66177-B/2022-05-03...

Need help?

Do you have a question about the Rexroth SB11 and is the answer not in the manual?

Questions and answers