Summary of Contents for Bosch rexroth M1-16 Series

- Page 1 Instruction manual Control blocks for mobile applications RE 64025-B/2021-08-12, replaces: 04.2019, EN...

- Page 2 © Bosch Rexroth AG 2021. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. The data specified within only serves to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from our information. The information given does not release the user from...

-

Page 3: Table Of Contents

..... 31 7.5.9 Connecting the control block electrically ........... 33 Commissioning ��������������������������������������������������������������������������������������� 34 Before initial commissioning ..............35 Initial commissioning ................. 36 Recommissioning after standstill ............... 37 RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 4 Preparing the components for storage or further use ......... 43 Disposal ������������������������������������������������������������������������������������������������� 44 Extension and conversion ����������������������������������������������������������������������� 45 Troubleshooting ������������������������������������������������������������������������������������� 46 14.1 How to proceed for troubleshooting ............46 14.2 Malfunction table ..................47 Technical data ���������������������������������������������������������������������������������������� 50 Index ������������������������������������������������������������������������������������������������������ 52 Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 5: About This Documentation

Open-center control block SM 64122 Closed-center control block RCS30 64155 Closed-center control block RCS35 64157 Load-sensing control block M4-12 64276 Load-sensing control block M4-15 64283 Load-sensing control block M4-22 64279 Load-sensing control block SP-08 64139 RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 6 Rexroth hydraulic components, and provides support for selection of suitable hydraulic fluids for the hydraulic system. 90290 Data sheet Reliability parameters MTTF for the functional safety according to ISO 13849 MTTF values for control blocks The related documentation can be obtained where necessary from Rexroth via www.boschrexroth.com/mobile-hydraulics-catalog. Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 7: Representation Of Information

Identifies a dangerous situation that may result in death WARNING or serious injury if it is not avoided. Identifies a dangerous situation that may result in minor CAUTION to moderate injury if it is not avoided. Property damage: The product or surrounding area may NOTICE be damaged. RE 64025-B/2021-08-12, Bosch Rexroth AG... -

Page 8: Symbols

Type of control spool actuation 1�3�4 Abbreviations This documentation uses the following abbreviations: Table 5: Abbreviations Abbreviation Meaning ATEX EC directive on explosion protection (Atmosphère explosible) Deutsche Industrie Norm (German Institute for Standardization) International Organization for Standardization Bosch Rexroth AG, RE 64025-B/2021-08-12... -

Page 9: Safety Instructions

The control blocks have been developed to control various hydraulic consumers on mobile and standalone working machines. Deviating use is only permitted following consultation with Bosch Rexroth. The product can be employed as a safety-relevant part of a control system. It does not however include a safety function as it is unable to provide or realize such a function independently. -

Page 10: Improper Use

2�3 Improper use Any use other than that described as intended use is considered improper. Bosch Rexroth AG is not liable for damages resulting from improper use. The user is solely responsible for any risks arising from improper use. The following foreseeable forms of faulty usage are also considered improper (this list is not exhaustive):... -

Page 11: General Safety Instructions

▶ Use your personal protective equipment (e.g. safety goggles, safety gloves, suitable working clothes, safety shoes). ▶ Use suitable lifting devices for transport. ▶ Observe the prescribed position of the lifting strap. ▶ Observe the national laws and specifications of occupational safety and health and transport. RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 12 ▶ Always connect the ground connection of the control block with the corresponding grounding system of your installation. ▶ Only use a power supply unit with a secure disconnection facility. Observe the country-specific specifications. Bosch Rexroth AG, RE 64025-B/2021-08-12...

- Page 13 ▶ Always install cables and lines in a way that nobody can fall over them, that they are not bend or twisted, do not chafe on edges and are not guided through ducts with sharp edges without sufficient protection. RE 64025-B/2021-08-12, Bosch Rexroth AG...

-

Page 14: Personal Protective Equipment

▶ Check how to safely get on top of the machine/system. 2�7 Personal protective equipment The personal protective equipment is the responsibility of the user of the control block. Observe the safety regulations in your country. All pieces of personal protective equipment should be intact. Bosch Rexroth AG, RE 64025-B/2021-08-12... -

Page 15: General Instructions On Property Damage And Product Damage

Ingress of fluids and foreign particles due to lacking sealings and locks! Loss of the protection class and danger of short circuit! ▶ Before the assembly, ensure that all sealings and locks of the plug-in connection are tight. RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 16 ▶ Do not direct the high-pressure cleaner to sensitive components, e.g. rubber parts (bellows), electric connections (solenoids, sensors) and actuation elements. ▶ Use fibre-free cleaning cloths for cleaning. Bosch Rexroth AG, RE 64025-B/2021-08-12...

- Page 17 • Removal of the tamper-proof caps and seals (e.g. with pressure settings), • Control of the settings at the factory, • Conversions and additional installations, • Opening of the valve, • Improper handling, • Use of non-original spare parts by Rexroth. RE 64025-B/2021-08-12, Bosch Rexroth AG...

-

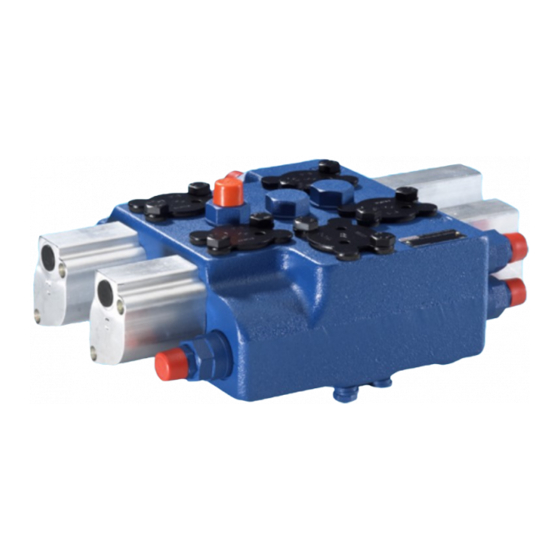

Page 18: Scope Of Delivery

Included in the scope of delivery: • Control block as per order confirmation The following parts are also assembled prior to delivery according to version: • Protective covers • Protective plugs/threaded plugs • Attachment point for transportation, e.g. an eye bolt Bosch Rexroth AG, RE 64025-B/2021-08-12... -

Page 19: About These Products

MNR: R90xxxxxxx FD: 12W20 SN: XXXX M4-G12345-20/5M4-12J_W2_MV01 CNR: 123456789 125077284000 1234567890 p(max) 250 bar Made in Germany Fig. 1: Name plate example M4 RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 20 If in doubt, please contact Bosch Rexroth. The information on the above name plate may vary depending on order-specific requirements. For instance, on customer-specific name plates, the customer logo may replace the Rexroth logo. Any other labeling on the product is just for Bosch Rexroth-internal purposes. Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 21: Transport And Storage

• Mounted eye bolts according to DIN 580. ▶ If necessary, screw an eye bolt fully into the attachment point. The thread size is indicated in the installation drawing. ▶ Make sure that the eye bolt can bear the total weight of the control block plus 20%. RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 22 ▶ Place the lifting strap around the control block such that it does not pass over the assembled parts (e.g. valves) or that the control block is hung on assembled parts. Fig. 3: Transport with lifting strap Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 23: Storing The Control Block

Bosch Rexroth service partner. If you have any questions regarding repair and spare parts, contact your responsible Bosch Rexroth service partner or the service department of the control block manufacturer's plant, see Chapter 10.5 "Spare parts" on page 42. - Page 24 7� Store the control block in a non-explosive area protected against collisions, see the Section entitled "Requirements" on page 23 in this chapter. 8� If necessary, return the control block for repair to Bosch Rexroth-Service. Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 25: Installation

▶ When removing the protective plastic threaded plugs after painting, make sure that no paint chips enter the control block. ▶ Protect name plates against application of paint using a film that can be peeled off after painting. RE 64025-B/2021-08-12, Bosch Rexroth AG... -

Page 26: Installation Conditions

If the material number for the control block does not correspond to the one in the order confirmation, contact Bosch Rexroth Service for clarification, see Chapter 10.5 "Spare parts" on page 42. 3� Before installation, empty the control block to prevent mixing with the hydraulic fluid used in the machine. - Page 27 The actually required tightening torques depend on various factors, e.g. screw material and coating, operation forces, material of the tensioned components. Generally, it is herewith referred to the parameters provided by the system supplier. Bosch Rexroth recommends a screw connection with the following parameters: Table 6: Mounting bolts Series Dimension...

-

Page 28: Completion Of Assembly

Use a suitable tool for this to prevent damage to the sealing and functional surfaces. If sealing or functional surfaces are damaged, contact your Bosch Rexroth service partner or the service department of the manufacturer's plant for the control block. Ports intended for connecting lines come with protective plugs or threaded plugs, which serve as transport protection. -

Page 29: Connecting The Control Block Hydraulically

• Drain line – Always route the drain lines in a way that the control block is always filled with hydraulic fluid and even during extended standstill periods cannot be emptied hydraulically. RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 30 5� Properly tighten the fittings (observe tightening torques!). Mark all properly tightened fittings, e.g. with a permanent marker. 6� Check all pipes and hose lines and every combination of connecting pieces, couplings or connecting points with hoses or pipes to ensure they are in safe working condition. Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 31: Connecting The Pressure Relief/Feed Valve With Pressure Sequencing Stage Or Pressure Cut-Off Stage Hydraulically

Lock nut Adjustment screw with hydraulic port The pressure relief/feed valve consists of the visible components To avoid an unintentional change of the pressure setting, the screw connections to each other must not be adjusted! RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 32 3� Turn the screw fitting clockwise into the thread of the adjustment screw When doing so, counter the lock nut and the adjustment screw with an open-end wrench. 4� Tighten the screw fitting correctly (observe tightening torque!). Bosch Rexroth AG, RE 64025-B/2021-08-12...

-

Page 33: Connecting The Control Block Electrically

1� Undo the mounting nut (1) of the solenoid using a suitable tool. To do this, turn the mounting nut (1) one turn counter-clockwise. 2� Turn the solenoid body (2) to the desired position. 3� Re-tighten the mounting nut. Tightening torque of the mounting nut: 4 Nm. RE 64025-B/2021-08-12, Bosch Rexroth AG... -

Page 34: Commissioning

In the case of control blocks without self-air bleeding, it may be necessary to air bleed the cover using the air bleed screw. ▶ Always observe the parameters for the air bleed in the instruction manual of the machine. Bosch Rexroth AG, RE 64025-B/2021-08-12... -

Page 35: Before Initial Commissioning

▶ Make sure that the union nuts on the pipe fittings and flanges are tightened to the correct standards. ▶ Set the pressure valves, flow control valves, pump controller, signal sensors, pressure switches, position switches and thermostats to the switching positions and setting values in the sequence program. RE 64025-B/2021-08-12, Bosch Rexroth AG... -

Page 36: Initial Commissioning

36/54 Control blocks for mobile applications | Commissioning 8�2 Initial commissioning Bosch Rexroth defines initial commissioning as the initial testing and release of the product. It is recommend that points 1 up to and including 7 are adopted for the series production of the hydraulic system. -

Page 37: Recommissioning After Standstill

Check whether the measured temperature is within the product-specific limits. If the temperature is outside of the specified limits, the Bosch Rexroth warranty is invalidated. 9� After the initial commissioning, have a hydraulic fluid sample analyzed for the required cleanliness level. -

Page 38: Operation

• When installing new components in a cold machine, they must first be filled at higher temperatures so that sufficient lubrication is assured in all areas. Bosch Rexroth AG, RE 64025-B/2021-08-12... - Page 39 The temperature difference between the operating fluid and the individual components may be a maximum of 20 °C. 10� Our control blocks can be fully loaded from a circuit temperature of ≥ 0 °C in the machine onwards. RE 64025-B/2021-08-12, Bosch Rexroth AG...

-

Page 40: Maintenance And Repair

10�2 Inspection In order to enable long and reliable operation of the control block, Bosch Rexroth recommends testing the hydraulic system and the control block on a regular basis, and documenting and archiving the following operating conditions:... -

Page 41: Maintenance

Please also observe the parameters on hydraulic fluid in the machine's instruction manual. 10�4 Repair Bosch Rexroth offers a comprehensive range of services for the repair of Rexroth control blocks. Repairs on the control block must only be performed by service centers certified by Bosch Rexroth or the machine manufacturer. -

Page 42: Spare Parts

When ordering spare parts, quote the material and serial number of the control block as well as the material numbers of the spare parts. Address all queries about spare parts to your responsible Bosch Rexroth Service partner or the service department of the manufacturer's plant for the control block. -

Page 43: Removal And Replacement

7� Place the product on a clean surface with sufficient load-bearing capacity. 8� Drain the control block completely. 9� Plug all openings. 11�4 Preparing the components for storage or further use ▶ Proceed as described in chapter 6.2 "Storing the control block", section "After removal" on page 24. RE 64025-B/2021-08-12, Bosch Rexroth AG... -

Page 44: Disposal

3� Dispose of the hydraulic fluid in accordance with the regulations of your country. 4� Disassemble the control block into its individual parts and recycle them. 5� For example, separate the parts into: – Metals – Electronic waste – Plastic Bosch Rexroth AG, RE 64025-B/2021-08-12... -

Page 45: Extension And Conversion

13 Extension and conversion Conversions and changes to the settings on the control block are not permissible. The warranty from Bosch Rexroth only applies to the product in the delivered configuration. The warranty will be voided if the unit is modified or extended. Changing the settings will void the warranty. If you need to change settings, contact your Bosch Rexroth service partner (for the address, see Chapter 10.5... -

Page 46: Troubleshooting

– How does the malfunction appear? ▶ Try to get a clear idea of the cause of the fault. Directly ask the (machine) operator. ▶ Document the work carried out. ▶ If the fault cannot be corrected, please refer to one of the contract addresses at: https://addresses.boschrexroth.com or in chapter 10.5 "Spare part". Bosch Rexroth AG, RE 64025-B/2021-08-12... -

Page 47: Malfunction Table

Remove the oil and contaminants from the control control block block; when doing this, do not use any cleaning agents that can adversely affect plastics or whose properties can change, can adversely affect metals or react with them or leave residues. RE 64025-B/2021-08-12, Bosch Rexroth AG... - Page 48 Bosch Rexroth AG, RE 64025-B/2021-08-12...

- Page 49 In case of malfunctions caused by contamination, it is essential to check and possibly improve the quality of the hydraulic fluid through appropriate measures, such as purging, exchange or additional installation of filters in addition to carrying out repairs. RE 64025-B/2021-08-12, Bosch Rexroth AG...

-

Page 50: Technical Data

Table 1 "Required and supplementary documentation" on page 5. The data sheets can be found online under www.boschrexroth.com/various/utilities/mediadirectory Additional information can be found in the online product catalogue Mobile hydraulics: www.boschrexroth.com/mobile-hydraulics-catalog The order-related technical data of your control block can be found in the order confirmation. Bosch Rexroth AG, RE 64025-B/2021-08-12... - Page 51 Technical data | Control blocks for mobile applications 51/54 RE 64025-B/2021-08-12, Bosch Rexroth AG...

-

Page 52: Index

Completion ........ 28 Storage ......... 23 Preparation ........ 26 Storage time ......... 23 Installation conditions ....26 Symbols ......... 8 Installation position...... 26 Intended use ........9 Lifting devices ......21 Lifting strap ........22 Bosch Rexroth AG, RE 64025-B/2021-08-12... - Page 53 ........21 with eye bolt ......21 with lifting devices ..... 21 with lifting strap ......22 Troubleshooting ......46 Malfunction table ....... 47 Unpacking ........25 Warranty ......17, 23, 45 Weight .......... 21 RE 64025-B/2021-08-12, Bosch Rexroth AG...

- Page 54 Bosch Rexroth AG Zum Eisengießer 1 97816 Lohr am Main Germany Tel. +49 93 52 18-0 info.ma@boschrexroth.de www.boschrexroth.com Your local contact person can be found at: https://addresses.boschrexroth.com Subject to change RE 64025-B/2021-08-12...

Need help?

Do you have a question about the rexroth M1-16 Series and is the answer not in the manual?

Questions and answers