Summary of Contents for Beckhoff EL3783

- Page 1 Documentation EL3783 EL3783 - Power monitoring oversampling terminal for 690 V Version: Date: 2019-05-10...

-

Page 3: Table Of Contents

5.6.2 Configuration data ...................... 139 5.6.3 Input data........................ 140 5.6.4 Information and diagnostic data.................. 140 5.6.5 Standard objects...................... 141 Notices on analog specifications .................... 147 5.7.1 Full scale value (FSV).................... 147 5.7.2 Measuring error/ measurement deviation .............. 148 EL3783 Version: 1.1... - Page 4 Device description ESI file/XML.................. 171 7.1.2 Firmware explanation .................... 174 7.1.3 Updating controller firmware *.efw................. 175 7.1.4 FPGA firmware *.rbf....................... 176 7.1.5 Simultaneous updating of several EtherCAT devices............ 180 Firmware compatibility ........................ 181 Restoring the delivery state ...................... 181 Support and Service ........................ 182 Version: 1.1 EL3783...

-

Page 5: Foreword

The TwinCAT Technology is covered, including but not limited to the following patent applications and patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries. ® EtherCAT is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany. Copyright © Beckhoff Automation GmbH & Co. KG, Germany. -

Page 6: Safety Instructions

All the components are supplied in particular hardware and software configurations appropriate for the application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG. Personnel qualification This description is only intended for trained specialists in control, automation and drive engineering who are familiar with the applicable national standards. -

Page 7: Documentation Issue Status

• Addenda & corrections • Addenda & corrections • preliminary documentation for EL3783 Version identification of EtherCAT devices Designation A Beckhoff EtherCAT device has a 14-digit designation, made up of • family key • type • version • revision Example... - Page 8 Production lot/batch number/serial number/date code/D number The serial number for Beckhoff IO devices is usually the 8-digit number printed on the device or on a sticker. The serial number indicates the configuration in delivery state and therefore refers to a whole production batch, without distinguishing the individual modules of a batch.

-

Page 9: Fig. 1 El5021 El Terminal, Standard Ip20 Io Device With Serial/ Batch Number And Revision Id (Since 2014/01)

Examples of markings Fig. 1: EL5021 EL terminal, standard IP20 IO device with serial/ batch number and revision ID (since 2014/01) Fig. 2: EK1100 EtherCAT coupler, standard IP20 IO device with serial/ batch number Fig. 3: CU2016 switch with serial/ batch number EL3783 Version: 1.1... -

Page 10: Fig. 4 El3202-0020 With Serial/ Batch Number 26131006 And Unique Id-Number 204418

Fig. 5: EP1258-00001 IP67 EtherCAT Box with batch number/ date code 22090101 and unique serial number 158102 Fig. 6: EP1908-0002 IP67 EtherCAT Safety Box with batch number/ date code 071201FF and unique serial number 00346070 Fig. 7: EL2904 IP20 safety terminal with batch number/ date code 50110302 and unique serial number 00331701 Version: 1.1 EL3783... -

Page 11: Fig. 8 Elm3604-0002 Terminal With Unique Id Number (Qr Code) 100001051 And Serial/ Batch Num- Ber 44160201

Foreword Fig. 8: ELM3604-0002 terminal with unique ID number (QR code) 100001051 and serial/ batch number 44160201 EL3783 Version: 1.1... -

Page 12: Start

Foreword Start For commissioning: • Install the EL3783 as described in section Mounting and wiring [} 28]. • configure the EL3783 in TwinCAT as described in the chapter Commissioning. Version: 1.1 EL3783... -

Page 13: Product Overview

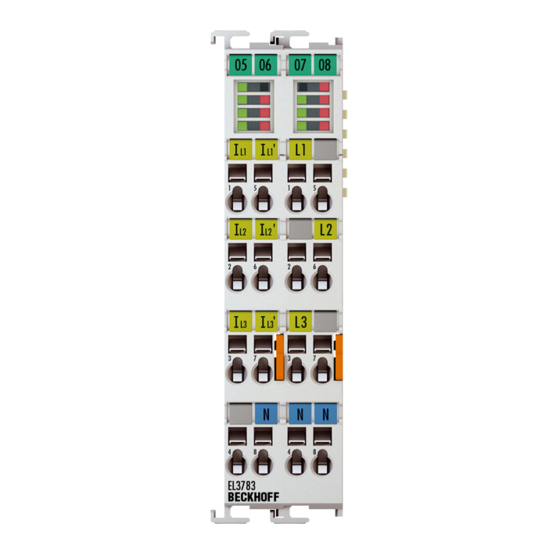

Fig. 9: EL3783 Power monitoring oversampling terminal for 690 V The EL3783 EtherCAT Terminal is designed as a power monitoring terminal for the state monitoring of a 3- phase AC voltage system (rated mains voltage 400/690 V ). For each phase voltages up to 520 V currents up to 6.5 A... -

Page 14: Technical Data

All AC value specifications in this documentation such as RMS specifications (rms) refer to a 50/60 Hz 3-phase mains network with a sinusoidal waveform (crest factor 1.414). Technical data EL3783 Number of inputs 3 x current, 3 x voltage Oversampling factor n = 1…100 selectable... -

Page 15: Technology

• all 6 analog input channels are measured simultaneously • the EL3783 is an oversampling terminal and can therefore record not just 1, but up to 100 samples per channel in each PLC/EtherCAT cycle. These are sent as a data packet to the controller via the cyclic process data. - Page 16 Product overview • The voltage and current curve can have any form; the EL3783 is thus suitable only for AC measurements • the EL3783 can be synchronized with other EtherCAT device over Distributed Clocks, but can also be operated without Distributed Clocks with oversampling •...

-

Page 17: Basics Communication

EtherCAT devices from Beckhoff. Recommended cables Suitable cables for the connection of EtherCAT devices can be found on the Beckhoff website! E-Bus supply A bus coupler can supply the EL terminals added to it with the E-bus system voltage of 5 V; a coupler is thereby loadable up to 2 A as a rule (see details in respective device documentation). -

Page 18: General Notes For Setting The Watchdog

The PDI watchdog can be used to monitor this communication for failure. The PDI watchdog monitors correct and timely process data communication with the ESC from the application side. The settings of the SM- and PDI-watchdog must be done for each slave separately in the TwinCAT System Manager. Version: 1.1 EL3783... -

Page 19: Fig. 12 Ethercat Tab -> Advanced Settings -> Behavior -> Watchdog

The standard setting of 1000 for the SM watchdog corresponds to a release time of 100 ms. The value in multiplier + 2 corresponds to the number of basic 40 ns ticks representing a watchdog tick. The multiplier can be modified in order to adjust the watchdog time over a larger range. EL3783 Version: 1.1... -

Page 20: Ethercat State Machine

EtherCAT master to the device in each state, particularly during the bootup of the slave. A distinction is made between the following states: • Init • Pre-Operational • Safe-Operational and • Operational • Boot The regular state of each EtherCAT slave after bootup is the OP state. Version: 1.1 EL3783... -

Page 21: Fig. 13 States Of The Ethercat State Machine

Before the EtherCAT master switches the EtherCAT slave from Safe-Op to Op it must transfer valid output data. In the Op state the slave copies the output data of the masters to its outputs. Process data and mailbox communication is possible. EL3783 Version: 1.1... -

Page 22: Coe Interface

Not every EtherCAT device must have a CoE list. Simple I/O modules without dedicated processor usually have no variable parameters and therefore no CoE list. If a device has a CoE list, it is shown in the TwinCAT System Manager as a separate tab with a listing of the elements: Version: 1.1 EL3783... -

Page 23: Fig. 14 "Coe Online " Tab

Data management If slave CoE parameters are modified online, Beckhoff devices store any changes in a fail-safe manner in the EEPROM, i.e. the modified CoE parameters are still available after a restart. The situation may be different with other manufacturers. -

Page 24: Fig. 15 Startup List In The Twincat System Manager

Changes in the local CoE list of the terminal are lost if the terminal is replaced. If a terminal is re- placed with a new Beckhoff terminal, it will have the default settings. It is therefore advisable to link all changes in the CoE list of an EtherCAT slave with the Startup list of the slave, which is pro- cessed whenever the EtherCAT fieldbus is started. -

Page 25: Fig. 16 Offline List

◦ The actual current slave list is read. This may take several seconds, depending on the size and cycle time. ◦ The actual identity is displayed ◦ The firmware and hardware version of the equipment according to the electronic information is displayed ◦ Online is shown in green. Fig. 17: Online list EL3783 Version: 1.1... - Page 26 • Channel 1: parameter range 0x8010:00 ... 0x801F:255 • Channel 2: parameter range 0x8020:00 ... 0x802F:255 • ... This is generally written as 0x80n0. Detailed information on the CoE interface can be found in the EtherCAT system documentation on the Beckhoff website. Version: 1.1 EL3783...

-

Page 27: Distributed Clock

4.2 seconds) • The EtherCAT master automatically synchronizes the local clock with the master clock in the EtherCAT bus with a precision of < 100 ns. For detailed information please refer to the EtherCAT system description. EL3783 Version: 1.1... -

Page 28: Mounting And Wiring

• Each assembly must be terminated at the right hand end with an EL9011 or EL9012 bus end cap, to en- sure the protection class and ESD protection. Fig. 18: Spring contacts of the Beckhoff I/O components Version: 1.1 EL3783... -

Page 29: Installation On Mounting Rails

To mount the mounting rails with a height of 7.5 mm under the terminals and couplers, you should use flat mounting connections (e.g. countersunk screws or blind rivets). EL3783 Version: 1.1... -

Page 30: Fig. 20 Disassembling Of Terminal

EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail. PE power contact The power contact labeled PE can be used as a protective earth. For safety reasons this contact mates first when plugging together, and can ground short-circuit currents of up to 125 A. Version: 1.1 EL3783... -

Page 31: Fig. 21 Power Contact On Left Side

Power Feed Terminals can be released and pulled at least 10 mm from the group of terminals. WARNING Risk of electric shock! The PE power contact must not be used for other potentials! EL3783 Version: 1.1... -

Page 32: Connection System

The familiar dimensions of the terminal only had to be changed slightly. The new connector adds about 3 mm. The maximum height of the terminal remains unchanged. A tab for strain relief of the cable simplifies assembly in many applications and prevents tangling of individual connection wires when the connector is removed. Version: 1.1 EL3783... -

Page 33: Fig. 24 High Density Terminals

Ultrasonically "bonded" (ultrasonically welded) conductors Ultrasonically “bonded" conductors It is also possible to connect the Standard and High Density Terminals with ultrasonically "bonded" (ultrasonically welded) conductors. In this case, please note the tables concerning the wire-size width [} 34] below! EL3783 Version: 1.1... -

Page 34: Fig. 25 Mounting A Cable On A Terminal Connection

0.14 ... 0.75 mm Wire size width (single core wires) 0.08 ... 1.5 mm Wire size width (fine-wire conductors) 0.25 ... 1.5 mm Wire size width (ultrasonically “bonded" conductors) only 1.5 mm (see notice [} 33]!) Wire stripping length 8 ... 9 mm Version: 1.1 EL3783... - Page 35 Mounting and wiring Shielding Shielding Analog sensors and actors should always be connected with shielded, twisted paired wires. EL3783 Version: 1.1...

-

Page 36: Positioning Of Passive Terminals

The passive terminals have no current consump- tion out of the E-Bus. To ensure an optimal data transfer, you must not directly string together more than 2 passive termi- nals! Examples for positioning of passive terminals (highlighted) Fig. 26: Correct positioning Fig. 27: Incorrect positioning Version: 1.1 EL3783... -

Page 37: Prescribed Installation Position

The terminals are ventilated from below, which enables optimum cooling of the electronics through convection. "From below" is relative to the acceleration of gravity. Fig. 28: Recommended minimum distances for standard installation position Compliance with the distances shown in Fig. Recommended distances for standard installation position is strongly recommended. EL3783 Version: 1.1... -

Page 38: Leds And Connection

If you do not connect the terminal point N with the neutral conductor of your mains supply (e.g. if the EL3783 is used purely for current measurements), terminal point N should be earthed, in order to avoid dangerous overvoltages in the event of a current transformer fault! Fig. 29: EL3783... - Page 39 Overvoltage on L2. Voltage > 737 V (L2-N) L3 OK green Voltage on L3 OK L3 error Overvoltage on L3. Voltage > 737 V (L3-N) Error Other errors (logical OR conjuction) Wiring and measurement methods Examples of wiring for measurements in the three-phase grid EL3783 Version: 1.1...

-

Page 40: Fig. 30 Measurement In A 3-Phase, 4-Conductor Grid, Asymmetrical Load

Mounting and wiring Fig. 30: Measurement in a 3-phase, 4-conductor grid, asymmetrical load Fig. 31: Measurement in a 3-phase, 4-conductor grid with 3 voltage transformers, asymmetrical load Version: 1.1 EL3783... -

Page 41: Fig. 32 Measurement In A 3-Phase, 3-Conductor Grid, Asymmetrical Load

Fig. 32: Measurement in a 3-phase, 3-conductor grid, asymmetrical load CAUTION Risk of device damage! The user must ensure proper fusing of the voltage measurement path in accordance with the measured variable as well as adequate transient protection! EL3783 Version: 1.1... -

Page 42: Commissioning

• "offline": The configuration can be customized by adding and positioning individual components. These can be selected from a directory and configured. ◦ The procedure for offline mode can be found under http://infosys.beckhoff.com: TwinCAT 2 → TwinCAT System Manager → IO - Configuration → Adding an I/O Device •... -

Page 43: Fig. 33 Relationship Between User Side (Commissioning) And Installation

• Linked via the X001 port (RJ-45): EK1100 EtherCAT Coupler • Connected to the EK1100 EtherCAT coupler on the right (E-bus): EL2008 (8-channel digital output terminal 24 V DC; 0.5 A) • (Optional via X000: a link to an external PC for the user interface) EL3783 Version: 1.1... -

Page 44: Fig. 34 Control Configuration With Embedded Pc, Input (El1004) And Output (El2008)

Note that all combinations of a configuration are possible; for example, the EL1004 terminal could also be connected after the coupler, or the EL2008 terminal could additionally be connected to the CX2040 on the right, in which case the EK1100 coupler wouldn’t be necessary. Version: 1.1 EL3783... -

Page 45: Fig. 35 Initial Twincat 2 User Interface

If the intention is to address the TwinCAT runtime environment installed on a PLC as development environment remotely from another system, the target system must be made known first. In the menu under "Actions" → "Choose Target System...", via the symbol " " or the "F8" key, open the following window: EL3783 Version: 1.1... -

Page 46: Fig. 36 Selection Of The Target System

Fig. 37: Specify the PLC for access by the TwinCAT System Manager: selection of the target system Once the target system has been entered, it is available for selection as follows (a password may have to be entered): After confirmation with "OK" the target system can be accessed via the System Manager. Version: 1.1 EL3783... -

Page 47: Fig. 38 Select "Scan Devices

Confirm the message "Find new boxes", in order to determine the terminals connected to the devices. "Free Run" enables manipulation of input and output values in "Config mode" and should also be acknowledged. Based on the sample configuration [} 43] described at the beginning of this section, the result is as follows: EL3783 Version: 1.1... -

Page 48: Fig. 40 Mapping Of The Configuration In The Twincat 2 System Manager

TwinCAT PLC Control is the development environment for the creation of the controller in different program environments: TwinCAT PLC Control supports all languages described in IEC 61131-3. There are two text- based languages and three graphical languages. • Text-based languages ◦ Instruction List (IL) Version: 1.1 EL3783... - Page 49 The following section refers to Structured Text (ST). After starting TwinCAT PLC Control, the following user interface is shown for an initial project: Fig. 42: TwinCAT PLC Control after startup Sample variables and a sample program have been created and stored under the name "PLC_example.pro": EL3783 Version: 1.1...

- Page 50 Manager has been notified, the warning no longer appears. First, integrate the TwinCAT PLC Control project in the System Manager via the context menu of the PLC configuration; right-click and select "Append PLC Project…": Fig. 44: Appending the TwinCAT PLC Control project Version: 1.1 EL3783...

- Page 51 "PLC_example" and via "Modify Link..." "Standard": Fig. 46: Creating the links between PLC variables and process objects In the window that opens, the process object for the variable “bEL1004_Ch4” of type BOOL can be selected from the PLC configuration tree: EL3783 Version: 1.1...

- Page 52 The links can also be checked by selecting a "Goto Link Variable” from the context menu of a variable. The object opposite, in this case the PDO, is automatically selected: Version: 1.1 EL3783...

- Page 53 The PLC system can then be started as described below. Starting the controller Starting from a remote system, the PLC control has to be linked with the Embedded PC over Ethernet via "Online" → “Choose Run-Time System…": EL3783 Version: 1.1...

- Page 54 This results in the message "No program on the controller! Should the new program be loaded?", which should be acknowledged with "Yes". The runtime environment is ready for the program start: Version: 1.1 EL3783...

- Page 55 (cf. "TwinCAT System Manager" of TwinCAT 2) for communication with the electromechanical components. After successful installation of the TwinCAT system on the PC to be used for development, TwinCAT 3 (shell) displays the following user interface after startup: EL3783 Version: 1.1...

- Page 56 First create a new project via (or under "File"→“New"→ "Project…"). In the following dialog make the corresponding entries as required (as shown in the diagram): Fig. 53: Create new TwinCAT project The new project is then available in the project folder explorer: Version: 1.1 EL3783...

- Page 57 If the intention is to address the TwinCAT runtime environment installed on a PLC as development environment remotely from another system, the target system must be made known first. Via the symbol in the menu bar: expand the pull-down menu: and open the following window: Fig. 55: Selection dialog: Choose the target system EL3783 Version: 1.1...

- Page 58 The TwinCAT System Manager may first have to be set to "Config mode" via or via the menu "TwinCAT" → "Restart TwinCAT (Config mode)". Fig. 57: Select "Scan" Confirm the warning message, which follows, and select "EtherCAT" in the dialog: Version: 1.1 EL3783...

- Page 59 The whole process consists of two stages, which may be performed separately (first determine the devices, then determine the connected elements such as boxes, terminals, etc.). A scan can also be initiated by selecting "Device ..." from the context menu, which then reads the elements present in the configuration below: EL3783 Version: 1.1...

- Page 60 The following section refers to Structured Text (ST). In order to create a programming environment, a PLC subproject is added to the project sample via the context menu of "PLC" in the project folder explorer by selecting "Add New Item….": Version: 1.1 EL3783...

- Page 61 Fig. 62: Specifying the name and directory for the PLC programming environment The "Main" program, which already exists by selecting "Standard PLC project", can be opened by double- clicking on "PLC_example_project" in "POUs”. The following user interface is shown for an initial project: EL3783 Version: 1.1...

- Page 62 Commissioning Fig. 63: Initial "Main" program of the standard PLC project To continue, sample variables and a sample program have now been created: Version: 1.1 EL3783...

- Page 63 "Assignments" in the project folder explorer: Assigning variables Via the menu of an instance - variables in the "PLC” context, use the "Modify Link…" option to open a window for selecting a suitable process object (PDO) for linking: EL3783 Version: 1.1...

- Page 64 4 of the EL1004 terminal is selected for linking. In contrast, the checkbox "All types" must be ticked for creating the link for the output variables, in order to allocate a set of eight separate output bits to a byte variable. The following diagram shows the whole process: Version: 1.1 EL3783...

- Page 65 PDO, it is possible to allocate this a set of bit-standardised variables (type "BOOL"). Here, too, a "Goto Link Variable” from the context menu of a PDO can be executed in the other direction, so that the respective PLC instance can then be selected. EL3783 Version: 1.1...

- Page 66 Fig. 70: TwinCAT development environment (VS shell): logged-in, after program startup The two operator control elements for stopping and logout result in the required action (accordingly also for stop "Shift + F5", or both actions can be selected via the PLC menu). Version: 1.1 EL3783...

-

Page 67: Twincat Development Environment

5.1.2.1 Installation of the TwinCAT real-time driver In order to assign real-time capability to a standard Ethernet port of an IPC controller, the Beckhoff real-time driver has to be installed on this port under Windows. This can be done in several ways. One option is described here. - Page 68 Alternatively an EtherCAT-device can be inserted first of all as described in chapter Offline configuration creation, section “Creating the EtherCAT device” [} 77] in order to view the compatible ethernet ports via its EtherCAT properties (tab „Adapter“, button „Compatible Devices…“): Fig. 74: EtherCAT device properties(TwinCAT 2): click on „Compatible Devices…“ of tab “Adapter” Version: 1.1 EL3783...

- Page 69 (Windows Start → System Properties → Network) Fig. 75: Windows properties of the network interface A correct setting of the driver could be: Fig. 76: Exemplary correct driver setting for the Ethernet port Other possible settings have to be avoided: EL3783 Version: 1.1...

- Page 70 Commissioning Fig. 77: Incorrect driver settings for the Ethernet port Version: 1.1 EL3783...

- Page 71 DHCP. In this way the delay associated with the DHCP client for the Ethernet port assigning itself a default IP address in the absence of a DHCP server is avoided. A suitable address space is 192.168.x.x, for example. Fig. 78: TCP/IP setting for the Ethernet port EL3783 Version: 1.1...

- Page 72 The files are read (once) when a new System Manager window is opened, if they have changed since the last time the System Manager window was opened. A TwinCAT installation includes the set of Beckhoff ESI files that was current at the time when the TwinCAT build was created.

- Page 73 1018 in the configuration. This is also stated by the Beckhoff compatibility rule. Refer in particular to the chapter ‘General notes on the use of Beckhoff EtherCAT IO components’ and for manual configuration to the chapter ‘Offline configuration creation’ [} 77].

- Page 74 Faulty ESI file If an ESI file is faulty and the System Manager is unable to read it, the System Manager brings up an information window. Fig. 84: Information window for faulty ESI file (left: TwinCAT 2; right: TwinCAT 3) Version: 1.1 EL3783...

- Page 75 Commissioning Reasons may include: • Structure of the *.xml does not correspond to the associated *.xsd file → check your schematics • Contents cannot be translated into a device description → contact the file manufacturer EL3783 Version: 1.1...

- Page 76 Commissioning 5.1.2.3 TwinCAT ESI Updater For TwinCAT 2.11 and higher, the System Manager can search for current Beckhoff ESI files automatically, if an online connection is available: Fig. 85: Using the ESI Updater (>= TwinCAT 2.11) The call up takes place under: “Options” → "Update EtherCAT Device Descriptions"...

- Page 77 EL6601/EL6614 terminal select “EtherCAT Automation Protocol via EL6601”. Fig. 88: Selecting the EtherCAT connection (TwinCAT 2.11, TwinCAT 3) Then assign a real Ethernet port to this virtual device in the runtime system. Fig. 89: Selecting the Ethernet port EL3783 Version: 1.1...

- Page 78 Fig. “Selection dialog for new EtherCAT device”. If the preceding device has several free ports (e.g. EK1122 or EK1100), the required port can be selected on the right-hand side (A). Overview of physical layer • “Ethernet”: cable-based 100BASE-TX: EK couplers, EP boxes, devices with RJ45/M8/M12 connector Version: 1.1 EL3783...

- Page 79 (i.e. highest) revision and therefore the latest state of production is displayed in the selection dialog for Beckhoff devices. To show all device revisions available in the system as ESI descriptions tick the “Show Hidden Devices” check box, see Fig. “Display of previous revisions”.

- Page 80 If current ESI descriptions are available in the TwinCAT system, the last revision offered in the selection dialog matches the Beckhoff state of production. It is recommended to use the last device revision when creating a new configuration, if current Beckhoff devices are used in the real application. Older revisions should only be used if older devices from stock are to be used in the application.

- Page 81 Commissioning Fig. 96: EtherCAT terminal in the TwinCAT tree (left: TwinCAT 2; right: TwinCAT 3) EL3783 Version: 1.1...

- Page 82 This scan mode attempts to find not only EtherCAT devices (or Ethernet ports that are usable as such), but also NOVRAM, fieldbus cards, SMB etc. However, not all devices can be found automatically. Fig. 99: Note for automatic device scan (left: TwinCAT 2; right: TwinCAT 3) Version: 1.1 EL3783...

- Page 83 [} 87] with the defined initial configuration.Background: since Beckhoff occasionally increases the revision version of the delivered products for product maintenance reasons, a configuration can be created by such a scan which (with an identical machine construction) is identical according to the device list;...

- Page 84 Likewise, A might create spare parts stores worldwide for the coming series-produced machines with EL2521-0025-1018 terminals. After some time Beckhoff extends the EL2521-0025 by a new feature C. Therefore the FW is changed, outwardly recognizable by a higher FW version and a new revision -1019. Nevertheless the new device naturally supports functions and interfaces of the predecessor version(s);...

- Page 85 Fig. 108: Displaying of “Free Run” and “Config Mode” toggling right below in the status bar Fig. 109: TwinCAT can also be switched to this state by using a button (left: TwinCAT 2; right: TwinCAT 3) The EtherCAT system should then be in a functional cyclic state, as shown in Fig. “Online display example”. EL3783 Version: 1.1...

- Page 86 The connections and devices should be checked in a targeted manner, e.g. via the emergency scan. Then re-run the scan. Fig. 111: Faulty identification In the System Manager such devices may be set up as EK0000 or unknown devices. Operation is not possible or meaningful. Version: 1.1 EL3783...

- Page 87 A ‘ChangeTo’ or ‘Copy’ should only be carried out with care, taking into consideration the Beckhoff IO compatibility rule (see above). The device configuration is then replaced by the revision found; this can affect the supported process data and functions.

- Page 88 If current ESI descriptions are available in the TwinCAT system, the last revision offered in the selection dialog matches the Beckhoff state of production. It is recommended to use the last device revision when creating a new configuration, if current Beckhoff devices are used in the real application. Older revisions should only be used if older devices from stock are to be used in the application.

- Page 89 This function is preferably to be used on AX5000 devices. Change to Alternative Type The TwinCAT System Manager offers a function for the exchange of a device: Change to Alternative Type Fig. 117: TwinCAT 2 Dialog Change to Alternative Type EL3783 Version: 1.1...

- Page 90 Comment Here you can add a comment (e.g. regarding the system). Disabled Here you can deactivate the EtherCAT device. Create symbols Access to this EtherCAT slave via ADS is only available if this control box is activated. Version: 1.1 EL3783...

- Page 91 CANopen process data objects (Process Data Objects, PDOs). The user can select a PDO via PDO assignment and modify the content of the individual PDO via this dialog, if the EtherCAT slave supports this function. EL3783 Version: 1.1...

- Page 92 For Beckhoff EtherCAT EL, ES, EM, EJ and EP slaves the following applies in general: • The input/output process data supported by the device are defined by the manufacturer in the ESI/XML description.

- Page 93 (CoE) or Servo drive over EtherCAT protocol. This tab indicates which download requests are sent to the mailbox during startup. It is also possible to add new mailbox requests to the list display. The download requests are sent to the slave in the same order as they are shown in the list. EL3783 Version: 1.1...

- Page 94 (CoE) protocol. This dialog lists the content of the object list of the slave (SDO upload) and enables the user to modify the content of an object from this list. Details for the objects of the individual EtherCAT devices can be found in the device-specific object descriptions. Version: 1.1 EL3783...

- Page 95 The Update list button updates all objects in the displayed list Auto Update If this check box is selected, the content of the objects is updated automatically. Advanced The Advanced button opens the Advanced Settings dialog. Here you can specify which objects are displayed in the list. EL3783 Version: 1.1...

- Page 96 Offline - via EDS File If this option button is selected, the list of the objects included in the object list is read from an EDS file provided by the user. „Online“ tab Fig. 126: „Online“ tab Version: 1.1 EL3783...

- Page 97 Fig. 127: "DC" tab (Distributed Clocks) Operation Mode Options (optional): • FreeRun • SM-Synchron • DC-Synchron (Input based) • DC-Synchron Advanced Settings… Advanced settings for readjustment of the real time determinant TwinCAT- clock Detailed information to Distributed Clocks are specified on http://infosys.beckhoff.com: EL3783 Version: 1.1...

- Page 98 Sync Manager! Consequently, this PDO cannot be deleted from the PDO Assignment list Sync Manager to which this PDO is assigned. If this entry is empty, this PDO does not take part in the process data traffic. Sync unit to which this PDO is assigned. Version: 1.1 EL3783...

-

Page 99: General Notes - Ethercat Slave Application

Those diagnostic elements that are helpful to the controlling task for diagnosis that is accurate for the current cycle when in operation (not during commissioning) are discussed below. Fig. 128: Selection of the diagnostic information of an EtherCAT Slave EL3783 Version: 1.1... - Page 100 Fig. “Basic EtherCAT Slave Diagnosis in the PLC” shows an example of an implementation of basic EtherCAT Slave Diagnosis. A Beckhoff EL3102 (2-channel analogue input terminal) is used here, as it offers both the communication diagnosis typical of a slave and the functional diagnosis that is specific to a channel.

- Page 101 The CoE parameter directory (CanOpen-over-EtherCAT) is used to manage the set values for the slave concerned. Changes may, in some circumstances, have to be made here when commissioning a relatively complex EtherCAT Slave. It can be accessed through the TwinCAT System Manager, see Fig. “EL3102, CoE directory”: EL3783 Version: 1.1...

- Page 102 Commissioning interfaces are being introduced as part of an ongoing process for EL/EP EtherCAT devices. These are available in TwinCAT System Managers from TwinCAT 2.11R2 and above. They are integrated into the System Manager through appropriately extended ESI configuration files. Version: 1.1 EL3783...

- Page 103 The target state wanted by the user, and which is brought about automatically at start-up by TwinCAT, can be set in the System Manager. As soon as TwinCAT reaches the status RUN, the TwinCAT EtherCAT Master will approach the target states. EL3783 Version: 1.1...

-

Page 104: Fig. 132 Default Behaviour Of The System Manager

Fig. 132: Default behaviour of the System Manager In addition, the target state of any particular Slave can be set in the "Advanced Settings" dialogue; the standard setting is again OP. Fig. 133: Default target state in the Slave Version: 1.1 EL3783... -

Page 105: Fig. 134 Plc Function Blocks

The pre-calculated theoretical maximum E-Bus current is displayed in the TwinCAT System Manager as a column value. A shortfall is marked by a negative total amount and an exclamation mark; a power feed terminal is to be placed before such a position. EL3783 Version: 1.1... -

Page 106: Fig. 135 Illegally Exceeding The E-Bus Current

Fig. 136: Warning message for exceeding E-Bus current NOTE Caution! Malfunction possible! The same ground potential must be used for the E-Bus supply of all EtherCAT terminals in a terminal block! Version: 1.1 EL3783... -

Page 107: Basic Function Principles

The 3 analog input channels for current measurement have different measuring ranges. These can be set via CoE or selected automatically by the EL3783 on the basis of the momentary measured values. Each channel has an anti-aliasing low-pass filter with a limit frequency of 5.5 KHz. However, the high sampling rate of 20 KSps also allows frequency components up to higher than 9 KHz to be detected. -

Page 108: Fig. 137 Opening The *. Tnzip Archive

• The EtherCAT device of the example should usually be declared your present system. After selection of the EtherCAT device in the “Solutionexplorer” select the “Adapter” tab and click on “Search...”: Fig. 138: Search of the existing HW configuration for the EtherCAT configuration of the example Version: 1.1 EL3783... - Page 109 The settings DYN1, DYN2 and DYN3 are intended for current measurements in grids in which temporary current peaks occur. However, these peaks should not cause any direct switchover of the terminal. If there should be an error that results in a lengthy fault current, however, the terminal will switch over. EL3783 Version: 1.1...

-

Page 110: Fig. 139 Switchover Characteristic, Dyn0 - Dyn3

Fig. 139: Switchover characteristic, DYN0 - DYN3 Rated voltages, list of grids The tables below show suitable rated grid voltages according to EN60664-1:2003 for the voltage measuring inputs of the EL3783 three-phase, 4-conductor grid with earthed protective conductor 66 V 115 V... -

Page 111: Oversampling Terminals/Boxes And Twincat Scope

Changes in the CoE directory In case of changes to the CoE default parameters, it is essential that corresponding values are en- tered in the start-up list, so that in the case of exchange the EL3783 operates again as foreseen in the application. -

Page 112: Twincat 3 Procedure

ForceOversampling automatically. The array as a whole must be selected using AddSymbol (see description in the next section).The extended PDO name provides the basis for this. Since a specific revision of the respective terminal ScopeView is able to detect the array type of a set of variables autonomous. Version: 1.1 EL3783... -

Page 113: Fig. 141 Adding A Scope Project Into An Already Existing Project

Commissioning Terminal Revision EL4732 EL4712 EL3783 EL3783-0000-0017 EL3773 EL3773-0000-0019 EL3751 EL3742 EL3702 EL3632 EL2262 EL1262-0050 EL1262 EP3632-0001 EPP3632-0001 Recording a PLC Variable with the TwinCAT 3 – ScopeView By a precondition of an already created TwinCAT 3 – project and a connected PLC with an oversampling able terminal/box within the configuration it will be illustrated how an oversampling variable can be represented by the Scope (as a standard part of the TwinCAT 3 environment). -

Page 114: Fig. 142 Representation Of A Created Plc Array Variable („Aui_Samples") To Link With Oversampling Pdos Of El3773

When a POU is not needed onto the particular system, a referenced variable could be applied via a free task also. If a free task is not existing still yet, it can be created by a right-click to “Task” of the project within SYSTEM with “Add New Item…”. Version: 1.1 EL3783... -

Page 115: Fig. 143 Insertion Of A Free Task

Scope, if applicable, later on. By a right click on “Inputs” that oversampling based variable can now be appended with the fitting datatype of an array. „ARRAY [0..9] OF DINT“ referred to as „Var 1“ in this case: EL3783 Version: 1.1... -

Page 116: Fig. 145 Insertion Of Variable "Var 1" Fitting To The Oversampling (-Factor)

Fig. 146: Set up the link of the PLC array variable (left: for the last preceding paragraph Step 2a, right: for the last preceding paragraph Step 2b) Fig. 147: Select the EL3773 PDO "L1 Voltage Samples" to create a link to the PLC array variable „aUI_Samples“ Version: 1.1 EL3783... -

Page 117: Fig. 148 Selection Of The Oversampling Variable With The Target Browser

If „ROUTES“ don’t offer a possibility for selection of the provided variables, the corresponding port should be declared for the target browser: Using “Add symbol” displays the variable "aUI_Samples“ below “axis” within the scope project of the solution explorer directly. EL3783 Version: 1.1... -

Page 118: Fig. 150 Example Of Recording A Sine Signal With 10 X Oversampling At 1 Ms Measurement Cycle Time

In former TwinCAT 3 versions (or a lower revision as specified in the table [} 112] above) the oversampling PDO of the respective oversampling able terminal/box can be made visible for the ScopeView by activation of the ADS server. Version: 1.1 EL3783... -

Page 119: Fig. 151 Activation Of The Ads Server Of The Ethercat Device (Twincat 3)

„Create symbols“ then (the port entry is done automatically). Thereby it is possible to access process data without an embedded POU and accordingly without a linked variable: Fig. 152: Direct access to PDOs of the terminal by ScopeView EL3783 Version: 1.1... -

Page 120: Twincat 2 Procedure

PDO (according to an array variable usually). In this case it can be changed by the channel properties: TwinCAT 3: Activate the ADS Server of an EtherCAT device Also see Beckhoff Information System: 5.4.2 TwinCAT 2 procedure The TwinCAT Scope2 supports the import and display of oversampling process data such as is used by oversampling-able terminals/boxes. -

Page 121: Fig. 153 Plc Declaration

Fig. 155: Add Variable Type An ARRAY variable of the type as known by the PLC must be created in the syntax as known from the PLC. In this example an array of 0..9 of type INT, i.e. with 10 fields. EL3783 Version: 1.1... -

Page 122: Fig. 156 Definition Of The Variable Type

It appears in the overview, sorted according to bit size. Fig. 157: Overview of declared types In this example the variable Var152 is created. It can now be linked with the PDO-Array of the respective channel of the terminal/box. Version: 1.1 EL3783... -

Page 123: Fig. 158 Linking

This array variable must be defined and created manually; see above [} 121]. You can now browse to the variable concerned in the Scope2. EL3783 Version: 1.1... -

Page 124: Fig. 161 Variable Browser Up To The Array Var152

In order to check that individual oversampling values are really being logged, the Marks can be activated in the Scope2. Please observe the interrelationships between task cycle time, sampling time of the Scope2 channel and oversampling factor. Version: 1.1 EL3783... -

Page 125: Fig. 164 Activation Of The Marks

Commissioning Fig. 164: Activation of the marks An additional example illustrates the following image by representation of an oversampling – variable from the EL3751 with 10 x oversampling: EL3783 Version: 1.1... -

Page 126: Fig. 165 Illustration Of A 10 X Oversampling Variable Of The El3751 By The Scope2

PDO of the respective oversampling able terminal/box can be made visible for the Scope2 by activation of the ADS server. So the creation of a PLC variable can be disclaimed as well. Therefore the ADS server of the EtherCAT Device where the oversampling able terminal/box is connected with have to be activated. Version: 1.1 EL3783... -

Page 127: Fig. 166 Activation Of The Ads Server Of The Ethercat Device (Twincat 2)

„Create symbols“ then (the port entry is done automatically). Thus with the Scope2 process data can be accessed via the target browser without an embedded POU and without a variable reference respectively. Fig. 167: Direct access of the Scope2 to the terminal's PDOs EL3783 Version: 1.1... -

Page 128: Fig. 168 Automatically Calculated Array Variable (Red) In The Scope2

TS3300 | TwinCAT Scope 2 → Annex → Oversampling record: Beckhoff TwinCAT supports the Scope2 with some oversampling devices in a special way by automatically calculating a special ADS array symbol in the background, which appears in the Scope2 in the variable browser. -

Page 129: Process Data

Fig. 169: Process data flow EL3783 Data processing The data processing is done simultaneously for all channels in the EL3783 with 16-bit conversion in the ADC. Scaling related to the respective (constant) measuring range: Output value presentation Voltage MBE = 737,2575 V(~= 130% * 400V * Wurzel(2)) -->... -

Page 130: Fig. 170 Linking Of 2-Bit Variable To Additional Task

2-bit variables can be created in the System Manager. Fig. 170: Linking of 2-bit variable to additional task Example of voltage measurement with EL3783: Channel 1; Limit 1 and Limit 2 enabled, Limit 1 = 100 V, Limit 2 = 200 V, representation: signed integer Entry in index (Limit 1): 0x8000:13 [} 139]... -

Page 131: Fig. 171 User Settings And Vendor Calibration In The Coe Online Directory

Changes in the CoE directory In case of changes to the CoE default parameters, it is essential that corresponding values are en- tered in the start-up list, so that in the case of exchange the EL3783 operates again as foreseen in the application. - Page 132 0x1A00, 0x1A0D, 0x1A10, 0x1A1D, 0x1A20, 0x1A2D, 0x1A30, 0x1A3D, 0x1A40, 0x1A4D, 0x1A50, 0x1A5D 0x1A61 "Synchronous, with 64-fold oversampling" DC (activate Mode on DC 0x1A00, 0x1A05, 0x1A10, 0x1A15, 0x1A20, 0x1A25, 0x1A30, 0x1A35, tab) 0x1A40, 0x1A45, 0x1A50, 0x1A55 0x1A60, 0x1A61 "Distributed Clocks, settings via DC tab [} 136]" Version: 1.1 EL3783...

- Page 133 Commissioning Fig. 172: EL3783 Selection dialog "Predefined PDO Assignment" Process image The EL3783 is inserted into the configuration by default with the 10-fold oversampling process image and DC timestamp: EL3783 Version: 1.1...

-

Page 134: Fig. 173 Process Image Of The El3783 In The Twincat System Manager

Commissioning Fig. 173: Process image of the EL3783 in the TwinCAT System Manager In particular the EL3783 offers the following cyclic information: Version: 1.1 EL3783... - Page 135 Example: With a cycle time of 1 ms (= 1,000,000 ns) and an oversampling factor of 20 in the regarded cycle, the EL3783 supplies a StartTimeNextLatch = 7,777,216 and 2 x 20 measured values at 16 bits each as process data. The time of measurement of the 5 supplied sample is now to be determined, i.e.

-

Page 136: Fig. 172 El3783 Selection Dialog "Predefined Pdo Assignment

• accurate time stamp of the individual samples Cycle times The minimum EtherCAT cycle time for the EL3783 is 50 µs (see table in chapter “Quickstart”). In order to activate Distributed Clocks, "DC" is to be selected in the Predefined PDO list, so that amongst others the time stamp PDO is selected Fig. 174: EL3783 Selection dialog "Predefined PDO Assignment"... - Page 137 Fig. 175: Setting of the oversampling rates via System Manager, "DC" tab Distributed Clocks not activated • the EL3783 operates according to an internal clock, which is synchronized to the EtherCAT cycle time. The trigger point in this case is the access to the input Sync Manager SM3.

-

Page 138: Object Description And Parameterization

EtherCAT XML Device Description The display matches that of the CoE objects from the EtherCAT XML Device Description. We rec- ommend downloading the latest XML file from the download area of the Beckhoff website and in- stalling it according to installation instructions. -

Page 139: Configuration Data

Calibration phase off- reserved INT16 set range 1 80pF:07 Calibration offset Offset Range 2 (Herstellerabgleich) INT16 range 2 80pF:08 Calibration gain range Gain Range 2 (Herstellerabgleich) INT16 16384 80pF:09 Calibration phase off- reserved INT16 set range 2 EL3783 Version: 1.1... -

Page 140: Input Data

New Messages Avail- Indicates that a new message is available BOOLEAN FALSE able 10F3:05 Flags not used UINT16 0x0000 (0 10F3:06 Diagnosis Message Message 1 OCTET- STRING[28] Diag Mes- sages 10F3:15 Diagnosis Message Message 16 OCTET- STRING[28] Version: 1.1 EL3783... -

Page 141: Standard Objects

Index (hex) Name Meaning Data type Flags Default 1008:0 Device name Device name of the EtherCAT slave STRING EL3783-0000 Index 1009 Hardware version Index (hex) Name Meaning Data type Flags Default 1009:0 Hardware version Hardware version of the EtherCAT slave... - Page 142 1Ap0:09 SubIndex 009 9. PDO Mapping entry (object 0x60p0 (AI Inputs), entry UINT32 0x60p0:0F, 1 0x0F (TxPDO State)) 1Ap0:0A SubIndex 010 10. PDO Mapping entry (object 0x60p0 (AI Inputs), en- UINT32 0x60p0:10, 1 try 0x10 (TxPDO Toggle)) Version: 1.1 EL3783...

- Page 143 2. PDO Mapping entry (object 0x6062 (Synchron Over- UINT32 0x6062:03, 32 sampling Diagnosis), entry 0x03 (Internal Cycle Time)) 1A62:03 Subindex 003 3. PDO Mapping entry (object 0x6062 (Synchron Over- UINT32 0x6062:04, 16 sampling Diagnosis), entry 0x04 (Internal Buffer)) EL3783 Version: 1.1...

- Page 144 RxPDO assign PDO Assign Outputs UINT8 > 0 < Index 1C13 TxPDO assign For operation on masters other than TwinCAT it must be ensured that the channels are entered in the PDO assignment (“TxPDO assign”, object 0x1C13) successively. Version: 1.1 EL3783...

- Page 145 12. allocated TxPDO (contains the index of the associ- UINT16 0x1A56 ated TxPDO mapping object) (6742 1C13:0D SubIndex 013 13. allocated TxPDO (contains the index of the associ- UINT16 0x1A61 ated TxPDO mapping object) (6753 1C13:13 SubIndex 019 EL3783 Version: 1.1...

- Page 146 Modular device profile General information for the modular device profile UINT8 > 2 < F000:01 Module index distance Index distance of the objects of the individual channels UINT16 0x0010 (16 F000:02 Maximum number of Number of channels UINT16 0x0010 (10 modules Version: 1.1 EL3783...

-

Page 147: Notices On Analog Specifications

For analog I/O devices from Beckhoff the rule is that the limit with the largest value is chosen as the full scale value of the respective product (also called the reference value) and is given a positive sign. This applies to both symmetrical and asymmetrical measuring spans. -

Page 148: Measuring Error/ Measurement Deviation

• Measuring range -200...1370°C: asymmetric bipolar, full scale value = 1370°C, measuring span = 1570°C • Measuring range -10...+10 V: symmetric bipolar, full scale value = 10 V, measuring span = 20 V This applies to analog output terminals/ boxes (and related Beckhoff product groups). 5.7.2 Measuring error/ measurement deviation The relative measuring error (% of the full scale value) is referenced to the full scale value and is calculated as the quotient of the largest numerical deviation from the true value (‘measuring error’) referenced to the full... - Page 149 Commissioning The temperature coefficient, when indicated, specified by Beckhoff allows the user to calculate the expected measuring error outside the basic accuracy at 23 °C. Due to the extensive uncertainty considerations that are incorporated in the determination of the basic accuracy (at 23 °C), Beckhoff recommends a quadratic summation.

-

Page 150: Single-Ended/Differential Typification

In particular this also applies to SE, even though the term suggest that only one wire is required. • The term "electrical isolation" should be clarified in advance. Beckhoff IO modules feature 1..8 or more analog channels; with regard to the channel connection a distinction is made in terms of: ◦... - Page 151 The property of electrical isolation indicates whether the channels are directly connected to each other. ◦ Beckhoff terminals/ boxes (and related product groups) always feature electrical isolation between the field/analog side and the bus/EtherCAT side. In other words, if two analog terminals/ boxes are not connected via the power contacts (cable), the modules are effectively electrically isolated.

- Page 152 +signal can be connected to +supply or –signal to –supply. - Yes: then you can connect accordingly to a Beckhoff ‘single-ended’ input. - No: the Beckhoff ‘differential’ input for +Signal and –Signal is to be selected; +Supply and – Supply are to be connected via additional cables.

- Page 153 Commissioning Fig. 181: Connection of externally supplied sensors Classification of the Beckhoff terminals/ boxes - Beckhoff 0/4-20 mA terminals/ boxes (and related product groups) are available as differential and single-ended terminals/ boxes (and related product groups): Single-ended Differential EL3x4x: 0-20 mA, EL3x5x: 4-20 mA; KL and related product EL3x1x: 0-20 mA, EL3x2x: 4-20 mA;...

- Page 154 Commissioning Single-ended Differential Fig. 182: 2-, 3- and 4-wire connection at single-ended and differential inputs Version: 1.1 EL3783...

-

Page 155: Common-Mode Voltage And Reference Ground (Based On Differential Inputs)

Reference ground samples for Beckhoff IO devices: 1. Internal AGND fed out: EL3102/EL3112, resistive connection between the channels 2. 0V power contact: EL3104/EL3114, resistive connection between the channels and AGND; AGND connected to 0V power contact with low-resistance 3. -

Page 156: Temporal Aspects Of Analog/Digital Conversion

The conversion of the constant electrical input signal to a value-discrete digital and machine-readable form takes place in the analog Beckhoff EL/KL/EP input modules with ADC (analog digital converter). Although different ADC technologies are in use, from a user perspective they all have a common characteristic: after the conversion a certain digital value is available in the controller for further processing. - Page 157 This is the “external” view of the “Beckhoff AI channel” system – internally the signal delay in particular is composed of different components: hardware, amplifier, conversion itself, data transport and processing.

- Page 158 A meaningful range must be selected for the test frequency, e.g. 1/20 of the maximum sampling rate. Fig. 187: Diagram signal delay (linear) 3. Additional Information May be provided in the specification, e.g. Version: 1.1 EL3783...

- Page 159 Commissioning • Actual sampling rate of the ADC (if different from the channel sampling rate) • Time correction values for run times with different filter settings • etc. EL3783 Version: 1.1...

-

Page 160: Diagnosis

The DiagMessages are explained in text form in the ESI/XML file belonging to the EtherCAT device: on the basis of the Text ID contained in the DiagMessage, the corresponding plain text message can be found in the languages contained in the ESI/XML. In the case of Beckhoff products these are usually German and English. - Page 161 As a remedy, external synchronization of the DC time can be used, or a manual correction calculation can be applied, as required: The current DC time can be determined via the EtherCAT master or from register x901 of the DC slave. EL3783 Version: 1.1...

- Page 162 Structure of the Text ID The structure of the MessageID is not subject to any standardization and can be supplier-specifically defined. In the case of Beckhoff EtherCAT devices (EL, EP) it usually reads according to xyzz: 0: Systeminfo 0: System...

- Page 163 0x170C Information Calibration data saved Calibration data were saved 0x170D Information Calibration data will be Calibration data are not applied and saved until the applied and saved after command "0x5AFE" is sent sending the command “0x5AFE” EL3783 Version: 1.1...

- Page 164 0x2007 Information System %s: UDP handler initial- UDP handler initialized ized 0x2008 Information System %s: TCP handler initial- TCP handler initialized ized 0x2009 Information System %s: No more free TCP No free TCP sockets available. sockets available Version: 1.1 EL3783...

- Page 165 Activation of the out- put stage is prevented 0x4413 Warning Drive I2T-Model Amplifier - The amplifier is being operated outside the specifica- overload (Warning) tion - The I2T-model of the amplifier is incorrectly parame- terized EL3783 Version: 1.1...

- Page 166 Processor usage at %d Processor load at %d %% 0x470A Warning EtherCAT Frame missed EtherCAT frame missed (change DC Operation Mode (change Settings or DC or Sync0 Shift Time under Settings) Operation Mode or Sync0 Shift Time) Version: 1.1 EL3783...

- Page 167 0x8283 Error Communication Key Creation failed: %X 0x8284 Error Communication Key loading failed 0x8285 Error Communication Reading Public Key failed: %X 0x8286 Error Communication Reading Public EK failed: %X 0x8287 Error Communication Reading PCR Value failed: %X EL3783 Version: 1.1...

- Page 168 The internal temperature of the motor exceeds the pa- rameterized error threshold. The motor stops immedi- ately. Activation of the output stage is prevented. 0x8417 Error Drive Maximum rotating field Rotary field speed exceeds the value specified for dual velocity exceeded use (EU 1382/2014). Version: 1.1 EL3783...

- Page 169 Saturationtime was ma- Saturation time was manipulated nipulated 0x870A Error Channel range error Measuring range error for the channel 0x870B Error no ADC clock No ADC clock available 0xFFFF Information Debug: 0x%X, 0x%X, 0x Debug: 0x%X, 0x%X, 0x%X EL3783 Version: 1.1...

-

Page 170: Appendix

Appendix Appendix Firmware Update EL/ES/EM/ELM/EPxxxx This section describes the device update for Beckhoff EtherCAT slaves from the EL/ES, ELM, EM, EK and EP series. A firmware update should only be carried out after consultation with Beckhoff support. Storage locations An EtherCAT slave stores operating data in up to 3 locations: •... -

Page 171: Device Description Esi File/Xml

The device revision is closely linked to the firmware and hardware used. Incompatible combinations lead to malfunctions or even final shutdown of the device. Corresponding updates should only be carried out in consultation with Beckhoff support. Display of ESI slave identifier... - Page 172 In this example in Fig. Change dialog, an EL3201-0000-0017 was found, while an EL3201-0000-0016 was configured. In this case the configuration can be adapted with the Copy Before button. The Extended Information checkbox must be set in order to display the revision. Version: 1.1 EL3783...

- Page 173 Most EtherCAT devices read a modified ESI description immediately or after startup from the INIT. Some communication settings such as distributed clocks are only read during power-on. The Ether- CAT slave therefore has to be switched off briefly in order for the change to take effect. EL3783 Version: 1.1...

-

Page 174: Firmware Explanation

• offline: The EtherCAT Slave Information ESI/XML may contain the default content of the CoE. This CoE directory can only be displayed if it is included in the ESI (e.g. "Beckhoff EL5xxx.xml"). The Advanced button must be used for switching between the two views. -

Page 175: Updating Controller Firmware *.Efw

Switch to the Online tab to update the controller firmware of a slave, see Fig. Firmware Update. Fig. 197: Firmware Update Proceed as follows, unless instructed otherwise by Beckhoff support. Valid for TwinCAT 2 and 3 as EtherCAT master. • Switch TwinCAT system to ConfigMode/FreeRun with cycle time >= 1 ms (default in ConfigMode is 4 ms). -

Page 176: Fpga Firmware *.Rbf

The TwinCAT System Manager indicates the FPGA firmware version. Click on the Ethernet card of your EtherCAT strand (Device 2 in the example) and select the Online tab. The Reg:0002 column indicates the firmware version of the individual EtherCAT devices in hexadecimal and decimal representation. Version: 1.1 EL3783... - Page 177 Fig. 199: Context menu Properties The Advanced Settings dialog appears where the columns to be displayed can be selected. Under Diagnosis/Online View select the '0002 ETxxxx Build' check box in order to activate the FPGA firmware version display. EL3783 Version: 1.1...

- Page 178 Older firmware versions can only be updated by the manufacturer! Updating an EtherCAT device The following sequence order have to be met if no other specifications are given (e.g. by the Beckhoff support): • Switch TwinCAT system to ConfigMode/FreeRun with cycle time >= 1 ms (default in ConfigMode is 4 ms).

- Page 179 • In the TwinCAT System Manager select the terminal for which the FPGA firmware is to be updated (in the example: Terminal 5: EL5001) and click the Advanced Settings button in the EtherCAT tab: • The Advanced Settings dialog appears. Under ESC Access/E²PROM/FPGA click on Write FPGA button: EL3783 Version: 1.1...

-

Page 180: Simultaneous Updating Of Several Ethercat Devices

The firmware and ESI descriptions of several devices can be updated simultaneously, provided the devices have the same firmware file/ESI. Fig. 201: Multiple selection and firmware update Select the required slaves and carry out the firmware update in BOOTSTRAP mode as described above. Version: 1.1 EL3783... -

Page 181: Firmware Compatibility

Note on EL3783 firmware update Secondary voltage necessary for firmware updates In order to change the firmware of the EL3783, the permissible operating voltages must be applied both to the fieldbus side (E-Bus) and to the load side (power contacts), otherwise the terminal re- mains in INIT_ERROR or cannot be switched to BOOTSTRAP mode. -

Page 182: Support And Service

1819238756, Hexadecimal value: 0x6C6F6164An incorrect entry for the restore value has no effect. Support and Service Beckhoff and their partners around the world offer comprehensive support and service, making available fast and competent assistance with all questions related to Beckhoff products and system solutions. Version: 1.1... - Page 183 Beckhoff's branch offices and representatives Please contact your Beckhoff branch office or representative for local support and service on Beckhoff products! The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages: http://www.beckhoff.com You will also find further documentation for Beckhoff components there.

- Page 184 Startup list in the TwinCAT System Manager ................Fig. 16 Offline list ............................. Fig. 17 Online list ............................ Fig. 18 Spring contacts of the Beckhoff I/O components................. Fig. 19 Attaching on mounting rail ......................Fig. 20 Disassembling of terminal......................Fig. 21 Power contact on left side......................

- Page 185 Fig. 84 Information window for faulty ESI file (left: TwinCAT 2; right: TwinCAT 3)........Fig. 85 Using the ESI Updater (>= TwinCAT 2.11).................. Fig. 86 Using the ESI Updater (TwinCAT 3).................... Fig. 87 Append EtherCAT device (left: TwinCAT 2; right: TwinCAT 3) ........... EL3783 Version: 1.1...

- Page 186 Fig. 128 Selection of the diagnostic information of an EtherCAT Slave ........... Fig. 129 Basic EtherCAT Slave Diagnosis in the PLC................100 Fig. 130 EL3102, CoE directory ........................ 102 Fig. 131 Example of commissioning aid for a EL3204 ................103 Version: 1.1 EL3783...

- Page 187 Fig. 171 User settings and vendor calibration in the CoE online directory ..........131 Fig. 172 EL3783 Selection dialog "Predefined PDO Assignment" ............133 Fig. 173 Process image of the EL3783 in the TwinCAT System Manager..........134 Fig. 174 EL3783 Selection dialog "Predefined PDO Assignment" ............136 EL3783 Version: 1.1...

- Page 188 Fig. 175 Setting of the oversampling rates via System Manager, "DC" tab..........137 Fig. 176 Deactivation of the Distributed Clock in the "DC" tab ..............137 Fig. 177 EL3783 Selection dialog "Predefined PDO Assignment" ............137 Fig. 178 Full scale value, measuring span ....................148 Fig.

Need help?

Do you have a question about the EL3783 and is the answer not in the manual?

Questions and answers