Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for FARGO electronics HDP820

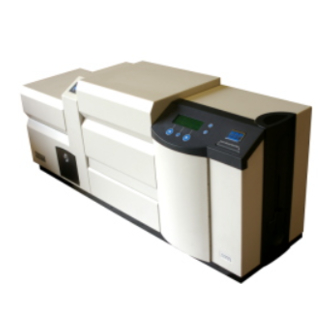

- Page 1 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) • HDP820 (Dual-Sided Card Printer/Encoders) • HDP820-LC (Dual-Sided Card Printer/Encoders) • HDP825 (Dual-Sided Card Printer/Encoders) • HDP825-LC (Dual-Sided Card Printer/Encoders) Part Number: L000307...

- Page 2 RESTRICTED USE ONLY 800 Series Card Printer/Encoders Service Manual (Rev. 5.0), property of FARGO Electronics, Incorporated Copyright 2002, 2003, 2004, 2005, 2006 by FARGO Electronics, Incorporated. All rights reserved. Printed in the United States of America. Exclusive permission is granted to authorized resellers of FARGO products to reproduce and distribute this copyrighted document to authorized FARGO customers, who have signed a “no disclosure agreement”...

- Page 3 RESTRICTED USE ONLY Reviewing the HDP800 Series Printers Overview table HDP800 Series Input Hoppers HDP820 (Dual-Sided Card Printer/Encoders) HDP820-LC (Dual- Sided Card Printer/Encoders) HDP825 (Dual-Sided Card Printer/Encoders) HDP825-LC (Dual- Sided Card Printer/Encoders) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

-

Page 4: How To Use The Manual

How to use the manual The HDP 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) is designed to provide installers and technicians with quick, efficient lookup of related procedures, components and terms. The manual can be used effectively either in soft or hard copy, depending on the preference of the installer or technician. - Page 5 • To prevent equipment or media damage, always remove the Ribbon and Cards from the Printer before making any repairs, unless otherwise specified. • To prevent equipment or media damage, take jewelry off of fingers and hands, as well as thoroughly clean hands to remove oil and debris before working on the Printer.

- Page 6 Print Stepper Lamination Headlift Film Supply Film Take Up Ribbon Supply Ribbon Take Up Print Headlift Stacker Lift 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Sensors Card Low Card Detection Flipper Table Card Encoding TOF Flipper Home Card TOF...

- Page 7 The following sequence describes a dual sided full color print job with magnetic encoding. This Printer also has an optional Card Stacker installed. (Note: The HDP825/825-LC Printers have two (2) Card Input Hoppers that load 100 cards in each Hopper.) Step Process The File information is received from the PC.

- Page 8 RESTRICTED USE ONLY Reviewing HDP 800 Series Card Printer - Sequence of Operations (cont.) Step Process The Fan turns ON as required to keep head cool. The Ribbon Drives, Film Ribbon Drive and Stepper turn ON and the Printhead burns the image data until the image data is depleted. All stop. (Note: The Ribbon Encoders are active during this step.)

- Page 9 The Ribbon Drive stays ON for a certain number of additional clicks after turns OFF to create a slack region between the Printer and Laminator sections. All stop. (Note: Ribbon encoders and dancer zero position switch are active during this step.)

- Page 10 The Heater and Thermocouple are maintained at a set temperature at all times when the Printer is ON. The cooling fan is ON when the Printer is ON. The Stacker Lift Motor engages until the Stacker Lift Sensor is activated.

- Page 11 Transfer Film Sensor senses 1 mark up on the Film). The Transfer Ribbon reverses for one panel onto supply (reverses until the Print Film Sensor senses 1 mark on the Film). 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) FARGO Electronic, Inc. 800 Series Card...

-

Page 12: Top Cover

RESTRICTED USE ONLY Reviewing the Lamination Module Sequence of Operations The LAM sequence of operations begins after printing has occurred with the Card Printer. Step Process The card is fed onto the Lamination Module Flipper Table. The card is fed to the Card Position Sensor. - Page 13 The Flipper Table Motor activates until the Flipper Table is homed. The Flipper Table Clutch disengages. Repeat Steps 2 through 7. The card is fed out of the Printer. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) FARGO Electronic, Inc.

- Page 14 The Lamination Ribbon Motor activates to determine the presence of a roll of lamination. The Lamination Flipper table homes itself. The Card Sensor checks for the presence of a card and ejects it if found. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) FARGO Electronic, Inc.

-

Page 15: Table Of Contents

Printer Components: Centronics-Type Parallel Interface _____________________ 31 Printer Components: Print Ribbons _____________________________________ 32 Printer Components: Blank Cards_______________________________________ 33 Printer Components: Card Input Hopper (HDP820/820-LC) __________________ 34 Printer Components: Card Input Hopper (HDP825/825-LC) __________________ 35 Printer Components: Card Output Hopper ________________________________ 36... - Page 16 Resolving the Failed Magnetic Encode Error Message _______________________ 77 Removing the Card jam in the Printer’s Magnetic Encoding Area ______________ 78 Resolving the Printer being unable to read Encoded Magnetic track Data problem _ 79 Resolving the magnetic stripe Data being printed on a Card problem ___________ 80...

- Page 17 Printing on Alternate Card stocks ________________________________________ 178 Selecting the Right Cards and optimize the HDP Print Process _______________ 178 Selecting the Appropriate HDP Printer Driver settings ______________________ 179 Conducting the Tape Adhesion Test ____________________________________ 181 Printer Driver Options _________________________________________________ 184...

- Page 18 Selecting the Lamination Side _________________________________________ 240 Selecting the Lamination Type ________________________________________ 241 Adjusting the Transfer Dwell Time and Transfer Temperature________________ 242 Selecting the Sensors button and Defaults button __________________________ 242 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 19 Replacing the Ribbon Supply Motor Assembly (D840980) __________________ 290 Replacing the Ribbon Take-Up Motor Assembly (D840980) _________________ 291 Replacing the Headlift Motor Assembly (D840980) ________________________ 292 Replacing the Ribbon Supply Encoder Sensor Assembly (D840982)___________ 293 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 20 Replacing the Card Feed Motor Assembly (D841105) ______________________ 360 Replacing the Flipper Table Card Sensor Assembly (D840625)_______________ 361 Replacing the Card Feed Sensor (D840624) ______________________________ 362 Replacing the Magnetic Encoder Head (840104) __________________________ 363 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 21 Replacing the Lamination Module Platen Motor (D870218) _________________ 386 Replacing the Lamination Module Flipper Table Motor (D870217) ___________ 388 Replacing the HDP820-LC/HDP825-LC Lamination Lid Hinge Bracket _______ 390 Adjusting the HDP820-LC/HDP825-LC Lamination Heat Shield Adjustment ___ 408 HDP820/HDP820-LC Magnetic and Smart Card Module Replacement___________ 414...

- Page 22 Reviewing Example No. 2: Serial Number A1280224______________________ 479 Section 12: Reviewing Spare Parts Lists___________________________________ 480 Reviewing Spare Parts List for HDP 800 Series Card Printer _________________ 480 Reviewing Spare Parts List for Card Lamination Module____________________ 494 Glossary of Terms _____________________________________________________ 502...

- Page 23 RESTRICTED USE ONLY Appendix B: Technical Updates _________________________________________ 535 Appendix C: Miscellaneous _____________________________________________ 535 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 24: Section 1: Specifications

Compliances, Agency Listings, Technical Specifications and Functional Specifications for the 800 Series Card Printer/Encoders. Reviewing the HDP800 Series Printers Overview table HDP800 Series Input Hoppers HDP820 (Dual-Sided Card Printer/Encoders) HDP820-LC (Dual- Sided Card Printer/Encoders) HDP825 (Dual-Sided Card Printer/Encoders) HDP825-LC (Dual-... -

Page 25: Regulatory Compliances

Card Printer as CSA Certified under CSA Standard 22.2. File Number: E145118 The Card Printer complies with the requirements in Part 15 of the FCC rules for a Class B digital device. (Note: These requirements are designed to provide reasonable protection against harmful interference in a residential installation.) -

Page 26: Technical Specifications

HDP825/HDP825-LC: 200 cards (.030"/.762mm) auto or manual feed • Dimensions HDP820/825: 15” H x 26.1” W x 14"D/381mm H x 663mm W x 356mmD • HDP820-LC/825-LC: 15” H x 34.75” W x 14"D/381mm H x 883mm W x 356mmD •... - Page 27 Custom Holographic, special order HDP Film Storage 77ºF (25ºC) or lower for no longer than 1.5 years. Temperature Humidity 20% to 80% Non-Condensing. HDP820/HDP820-LC: 250 cards (.030"/.762mm) Input Hopper Card Capacity HDP825/HDP825-LC: 200 cards (.030"/.762mm) • Interface Centronics parallel, IEEE-1284 Compliant •...

- Page 28 65ºF to 80ºF (18ºC to 27ºC). Temperature Options The options are the 32MB RAM Upgrade Kit, Printer Cleaning Kit, External Print Server (Windows only; required for stand-alone networking of printer/encoders), Card Lamination Module and USB- to-Parallel Interface Cable (Windows 98/Me/2000/XP only).

- Page 29 Warranty Printer: One year; optional Extended Warranty Program (U.S. only) Printhead: Lifetime; unlimited pass Weight HDP820/825: 70 lbs. (31.8kg). HDP820-LC/825-LC: 87 lbs./39.5kg LC Module: 21 lbs./9.5 kg 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) ™ class 133 MHz computer with 32 MB of RAM or higher,...

-

Page 30: Functional Specifications

RESTRICTED USE ONLY Functional Specifications The Card Printer utilizes two different, yet closely related printing technologies to achieve its remarkable direct-to-card print quality for dye-sublimation and resin thermal transfer. The Card Printer will print from any IBM-PC® or compatible running Windows® 98Se/Me, Windows NT 4.0, Windows 2000 or Windows XP Pro. -

Page 31: Printer Components: Access Card Slot To Parallel Interface Port

Printer Components: Access Card Slot to Parallel Interface Port Component Description Resin Thermal Resin Thermal Transfer is the print method the Printer uses to print Transfer sharp black text and crisp bar codes that can be read by both infrared and visible-light bar code scanners. - Page 32 Component Description Card Output If the Printer is equipped with an optional Card Output Stacker, adjust Guide the stacker's Card Output Guide to the proper card size prior to printing, as shown below. (Note: This will ensure consistent card ejecting and stacking.)

- Page 33 RESTRICTED USE ONLY Printer Components: Access Card Slot to Parallel Interface Port (continued) Component Description Film Tension Allows you to manually tighten the HDP film after loading or whenever Knobs the Transfer Station is opened, as shown below. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 34 RESTRICTED USE ONLY Printer Components: Access Card Slot to Parallel Interface Port (continued) Component Description Front Access Opens to allow access to the inside of the Printer. Door LCD Display Displays the current status of the Printer. LED Light Indicates the Printer ON, OFF, pause and error conditions.

-

Page 35: Print Station

RESTRICTED USE ONLY Printer Components: Access Card Slot to Parallel Interface Port (continued Component Description Scroll Buttons Used to scroll through menus and sub-menus and to adjust certain menu options. Transfer Station Transfers printed images and the HDP film to blank cards. - Page 36 RESTRICTED USE ONLY Printer Components: Access Card Slot to Parallel Interface Port (continued) Component Description Card Thickness Adjusts the Printer to feed varying card thicknesses. Adjustment Knob Card Cleaning Automatically cleans cards for higher print quality. (Note: Clean this Assembly assembly after every 250 cards or as needed.)

- Page 37 RESTRICTED USE ONLY Printer Components: Access Card Slot to Parallel Interface Port (continued) Component Description Release Lever Locks and unlocks the Print and Transfer Stations so they can be opened and closed. (Note: This lever must be in its locked position in order for the Printer to begin printing.)

- Page 38 RESTRICTED USE ONLY Printer Components: Access Card Slot to Parallel Interface Port (continued) Refer to the previous table. Printhead Print Station Card Output Hopper Film Tension Knobs Transfer Station Release Lever 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 39: Printer Components: Lcd And Softkey Control Pad

RESTRICTED USE ONLY Printer Components: LCD and Softkey Control Pad The Printer provides a four line, eighty (80) character LCD Displays that can communicate helpful information about the Printer's operation. • The top three lines of the LCD Display will always be used to communicate print status, error messages and menu options. - Page 40 Component Description Ready/Printer Once the Printer has finished its system check and with the Print and Open Screens Transfer Stations closed, the Printer will display READY to indicate that the Printer is ready for operation. (Note: The Printer will stay in this mode until it receives a print job or it is turned OFF.)

- Page 41 Print Status During operation, the LCD will indicate the current Print Status by Screen showing you the area of the Printer that is active. It does this by displaying the following icons on the second line: • FDR Indicates the Feeder Station is feeding a blank card into the Printer.

- Page 42 Printer Components: LCD and Softkey Control Pad (continued) Component Description The Cancel Use this button to cancel print jobs and reset the Printer for the next print button job. • This Cancel function will cancel all print jobs in the Printer and will completely reset the Printer.

- Page 43 Printer Components: LCD and Softkey Control Pad (continued) Component Description Error/Attention The Printer is capable of communicating two similar yet different types of Screens message or prompt screens: The first is called an ERROR screen. (Note: This screen appears if an error occurs and will completely stop Printer operation.

- Page 44 This is the slot in which a SmartGuard Access Card is inserted if you are Slot using the Printer's SmartGuard Security Feature. (Note: This unique feature prevents the Printer from operating unless a custom access card is inserted.) • To use the SmartGuard feature, refer to the instructions included with it for information on how to enable and use this security feature.

-

Page 45: Printer Components: Centronics-Type Parallel Interface

The Card Printer is equipped with a standard 8-bit centronics-type parallel interface port. (Note: This communication port is the means through which the Printer receives data from the computer. This section describes the pin assignments and signal specifications for this port.) -

Page 46: Printer Components: Print Ribbons

RESTRICTED USE ONLY Printer Components: Print Ribbons The Card Printer utilizes both dye-sublimation and/or resin thermal transfer methods to print images directly onto blank cards. Since the dye-sublimation and the resin thermal transfer print methods each provide their own unique benefits, Print Ribbons are available in dye- sublimation-only and combination dye-sublimation/resin versions. -

Page 47: Printer Components: Blank Cards

(3.375” L x 2.125” W/85.6mm L x 54mm W) with a thickness of 30 mil (.030"/.762mm) to 70 mil. The HDP820 Card Printers accept CR-80 to CR-100 sized cards. Card The Printer will print onto any card with a clean, level and polished PVC Design surface. -

Page 48: Printer Components: Card Input Hopper (Hdp820/820-Lc)

(HDP820/820- loading simple and closes securely to help protect the card stock. (Note: The Printer will hold a maximum of 250 cards (HDP820/820-LC) in its LC printer) one (1) Card Input Hopper, based on a standard 30 mil. card thickness.) See the Technical Specification. -

Page 49: Printer Components: Card Input Hopper (Hdp825/825-Lc)

Card Input The Card Input Hopper is where cards are initially loaded for printing. Hopper Your printer's hopper provides a large door that opens widely to make (HDP825/825- card loading simple and closes securely to help protect your card stock. -

Page 50: Printer Components: Card Output Hopper

Both the Card Input Hopper and the Card Output Stacker are initially configured to automatically feed and print standard CR-80 sized cards. (Technician Note #1: The HDP820 Printer is also capable of printing onto CR-90 and CR-100 sized cards.) (Technician Note #2: The Optional Output stacker is not compatible with the Card Lamination Module.) -

Page 51: Printer Components: Lamination Roller

Danger: The Printer’s Lamination Roller can reach temperatures exceeding 350 degree F (175 C). Use extreme caution when operating the Laminator. Never touch the Lamination Roller unless the Printer Power has been turned off for at least 20 to 30 minutes. Type... -

Page 52: Reviewing The Card Lamination Module

(175° C). Use extreme caution when operating the Laminator. Never touch the Lamination Roller unless the Printer has been turned off for at least 20 to 30 minutes. Select Printer models support the attachment of an optional Card Lamination Module. This Module can be ordered pre-installed on your Printer from the factory or can be ordered separately as a field upgradeable Module. -

Page 53: Reviewing The Lamination Top Cover And Station

Latches Cancel Button Resume (pause) Button Card Output Hopper Rejection Card Hopper 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Opening the Card Lamination Module procedure in Section 3, page 137. See the Loading the Overlaminate Section 3, page 140. -

Page 54: Reviewing The Securing Latches And Lamination Led Light

Lamination Module is in need of attention due to an error or an error condition. Refer to the Printer's LCD Display for information. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Using the... -

Page 55: Reviewing The Cancel Button

(Note: This will cancel all jobs in the Printer. Any card currently laminating will finish and eject. The Lamination Module's Cancel button cancels only the Lamination job.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Using the... -

Page 56: Reviewing The Resume (Pause) Button

Pause button can also be used to manually rotate the feed rollers backward. This is helpful when cleaning the rollers or when clearing jammed media.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Using the Lamination... -

Page 57: Reviewing The Rejection Card Hopper And Card Output Hopper

• There is a printing error, laminating error or encoding error. • There is a card is left in the Printer after a print job is canceled or the Printer restarted. Card Output Stores up to 100 printed cards (30 mil Hopper cards). -

Page 58: Reviewing The Module And Printer Interaction

Module laminates another card for maximum efficiency.) In fact, you can even open the Lamination Module to replace the overlaminate while the Printer is printing or encoding and vice versa. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 59: Reviewing The Module And Lcd Display Interaction

Cancel button to cancel the current Lamination job and accept the next. (Note: If canceled, the canceled card will eject into the Rejection Card Hopper.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Using the Lamination... -

Page 60: Reviewing The Module's Programmed Default Temperature

When the Lamination Module has reached its target temperature, Lamination will begin.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Using the Lamination tab (only with the Card... -

Page 61: Reviewing The Laminator Temperature Adjustment

• Consistent Temperature: The temperature setting within the Printer Driver stays the same until it is changed. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Reference See the Using the Lamination tab (only with the Card... -

Page 62: Reviewing The Overlaminates

Reviewing the Overlaminates IMPORTANT! Fargo Card Printers require highly specialized overlaminates to function properly. To maximize Printer life, reliability, printed card quality and durability, you must use only Fargo Certified Supplies. For this reason, the Fargo warranty is void, where not prohibited by law, if you use non-Fargo Certified Supplies. -

Page 63: Reviewing The Cr-90 Or Cr-100 Patch Size

Please contact the authorized reseller for more information about custom Overlaminates.. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Cross Reference See the Loading the Overlaminate procedure in Section 3, page 140. -

Page 64: Section 2: General Troubleshooting

LCD/SmartGuard Messages The LCD display shows the current status of the Printer. Refer to the cause and solution tables in this section for all possible LCD messages. (Note: These tables display the LCD messages in alphabetical order. If the LCD message is communicating an error or requires an action, these tables will also offer a solution to what should be done.) - Page 65 Cards Low Indicates there is not an adequate supply of cards in the Card Input Hopper. Data Input The print data sent to the Printer is corrupt or has been interrupted. Data The print data sent to the Printer is Timeout corrupt or has been interrupted.

- Page 66 FPGA An unexpected hardware error has occurred. FPGA Load Indicates an unexpected hardware Fail error has occurred. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Solution See the Resolving the EE Checksum Error procedure in Section 7, page 438.

- Page 67 Indicates the Printer is beginning its startup system check. The Feed Module is out of sequence Mismatch with the Transfer section. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Solution If this appears as an error, see the Resolving the Film Sensor...

- Page 68 Encoder type. Output The output stacker is full of cards; Hopper Full empty the output stacker to avoid a jam. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Solution See the Resolving the Failed Magnetic Encode Error Message procedure in Section 2, page 77.

- Page 69 Message Cause Pause... Indicates the Printer is paused. Print Data The print data sent to the Printer is corrupt or has been interrupted. Print Ribbon The print ribbon is not installed properly or has run out, jammed, broken or been damaged.

- Page 70 The Printer was unable to raise or lower the transfer roller. Transfer The Printer was unable to complete Timeout image transfer. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Solution No action required. See the Resolving the Failed Smart Encode Error Message procedure in Section 2, page 84.

- Page 71 Reviewing LCD Messages (continued) Message Cause Transfer The Transfer Roller is warming to the Warming proper temperature. Unable To The Printer is unable to feed a card Feed Card from the Card Hopper. Update The system Firmware MUST be Firmware updated. Unknown...

-

Page 72: Reviewing Smartguard™ Error And Status Messages

SmartGuard password. Reading Indicates the Printer is reading the data Access Card from the SmartGuard Access Card. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Solution Press the OK button to continue. Press the OK button to continue. - Page 73 Printer. Writing Access Indicates the SmartGuard Access Card Card is being encoded. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Solution Press the OK button to continue. Press the OK button to continue.

-

Page 74: Communications Errors

Close the software program and check the Printer Driver. b. Reboot the computer. c. Make sure the Printer Driver is installed correctly. (Note: Especially if an obsolete Driver was recently removed.) d. Be sure the correct setup options within the Printer Driver are selected. - Page 75 Determine the problem with printing from the application. a. Print a self-test from the Printer as described in the procedure in Section 8, page 132, to verify that the Printer (itself) is functioning properly. b. Print the Windows test page that is located in the General tab of the Driver.

- Page 76 Printer.) a. Disconnect the Printer from the network jack. b. Directly connect the Printer to a parallel port on a computer to determine if the network is the source of communications problems. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

-

Page 77: Firmware Errors

Be sure to follow the instructions on the attached HDP Firmware Upgrade Guide to insure that the correct data is being transferred to the Printer. b. It is possible that the Firmware Update Program is corrupt. In this case, the entire program should be uninstalled from the PC and the newest version of the program should be downloaded and installed from Fargo’s web site:... - Page 78 Be sure to follow the instructions on the attached HDP Firmware Upgrade Guide to insure that the correct data is being transferred to the Printer. a. It is possible that the Firmware Update Program is corrupt. In this case, the entire program should be uninstalled from the PC and the newest version of the program should be downloaded and installed from Fargo’s web site:...

-

Page 79: Card Feeding Errors

RESTRICTED USE ONLY Card Feeding Errors Resolving the Card Feeding problem (HDP820/820-LC) Symptom: Two or more cards are feeding at the same time or cards are not feeding properly Step Procedure Remove the stack of cards. (Note: Ensure that the cards are not sticking together. - Page 80 Step Procedure When loading cards, ensure that Card Thickness Adjustment Knob is properly set to ensure that the Printer feeds in only one card at a time. a. Open the Front Access Door b. Locate the Card Thickness Adjustment Knob.

- Page 81 RESTRICTED USE ONLY Resolving a Card Feeding problem (HDP820/820-LC) (continued) Step Procedure Clean the Cleaning Rollers. a. Open the Front Access Door of the Printer. b. Depress the Cleaning Roller Lock. c. Pull the Cleaning Roller Assembly out of the Printer.

-

Page 82: Resolving The Card Feeding Errors (Hdp825/825-Lc)

Step Procedure Clean the Input Roller. a. Open the Printer's top covers and remove all cards and print Ribbons from the Printer. b. Leave the Printer power ON and the top covers open throughout this procedure. (Note: The card-cleaning cartridge can also remain within the Printer during this cleaning process.) - Page 83 (if the Printer seems unable to feed cards at the selected setting). c. Move the slide slightly toward a lower setting (if the Printer seems to double-feed cards). (Note: The card thickness slide is adjustable to accommodate card thickness variations that often occur even within standard card sizes.)

- Page 84 Ensure that the cards are loaded properly in the Input Hopper. a. Load the cards into the Printer by inserting them straight into the hopper and setting them on the feed Roller. Verify that the Hopper Lift (A000124) is operational.

-

Page 85: Resolving The Stalled Cards On Or At The Feed Rollers

Adjust the Flipper Offset. a. Select the Menu on the LCD Display. b. Select the Setup Printer. Scroll down to the Flipper Offset. c. Change the setting on small increments. (Note: A positive adjustment will lower the side of the Flipper Table closest to the Exit Hopper.) d. -

Page 86: Resolving The Flipper Alignment Error Message

Verify Motor Operation. a. Test the Flipper Table Home Sensor (140407) by entering the FLIPPER OFFSET in the PRINTER SETUP menu on the LCD display. b. Without making any adjustment, press the Select button. (Note: This should cause the Flipper Table to attempt to home itself. If this is not the case, continue to Step 3, below.) -

Page 87: Resolving The Cards Being Fed Improperly Off The Flipper Table

Test the Flipper Home Sensor (140407). a. Remove the screws from the rear cover. b. Tilt the back cover outwards from the Printer c. Using a digital voltmeter, connect the negative lead to its ground. d. Connect the positive lead to Pin 4 of J58 on the Lamination Board. -

Page 88: Resolving The Card Jam Error Message

RESTRICTED USE ONLY Resolving the Card Jam Error Message Symptom: If a card becomes jammed inside the Printer, the LCD Display will indicate approximately where it is jammed. At this point you can either try to correct the problem and continue printing with the same card or remove the card completely and start the print job over. -

Page 89: Resolving The Card Jam: Lam Error Message

Open the Printer’s top cover. b. Remove the ribbon from the Printer. c. Check to see if a card is jammed in the Lam Station of the Printer. d. If a card is jammed in the Printer, use the Pause/Resume button and the Cancel buttons to move the feed rollers and free the card. -

Page 90: Magnetic Encoding Errors

(140402) procedure in Section 5, page 368. b. See if the error repeats itself. Resolving the No Magnetic Encoder Error Message Symptom: The Printer is receiving encoding data, but the Printer is not configured with this Encoder type. Step Procedure Verify if the LCD Setting is incorrect. -

Page 91: Resolving The Failed Magnetic Encode Error Message

Printer. Check the Magnetic Offset Setting. a. Press Menu on the LCD b. Select Setup Printer. Scroll down to Encoder Settings. c. Select Magnetic TOF d. Verify that the current value matches the default value listed on the back of the Printer. -

Page 92: Removing The Card Jam In The Printer's Magnetic Encoding Area

RESTRICTED USE ONLY Removing the Card jam in the Printer’s Magnetic Encoding Area Symptom: A card is jammed in the magnetic encoding area of the Printer. Step Procedure Clear the jammed card. a. Open the Print and Transfer Station. b. Use the arrows on the LCD panel to move the card forward or backward to free the card. -

Page 93: Resolving The Printer Being Unable To Read Encoded Magnetic Track Data Problem

Change all the margin settings to zero (0) and click OK. e. Select File > Print on the Menu Bar. Go to File on Menu Bar and select Print. (Note: The Printer should then feed a card into the Encoder and magnetically encode it.) Ensure that the coercivity of the cards matches the setting in the Driver. -

Page 94: Resolving The Magnetic Stripe Data Being Printed On A Card Problem

Change all the margin settings to zero (0) and click OK. e. Select File > Print on the Menu Bar. Go to File on Menu Bar and select Print. (Note: The Printer should then feed a card into the Encoder and magnetically encode it.) 800 Series Card Printer/Encoders Service Manual (Rev. -

Page 95: E-Card Encoding Errors

Step Procedure Cancel the current print job. Remove any cards that are still in the Printer. Visually check the last card that was printed properly. Restart the print job using the last successfully printed card as a reference for where to start. -

Page 96: Removing The Card Jam In The Printer's Smart Card Encoding Area

RESTRICTED USE ONLY Removing the Card jam in the Printer’s Smart Card Encoding Area Symptom: A card is jammed in the smart card encoding area of the Printer. Step Procedure Clear the jammed card. a. Open the Print and Transfer Station. -

Page 97: Resolving The No Prox Encoder Error Message

RESTRICTED USE ONLY Resolving the No Prox Encoder Error Message Symptom: The Printer is receiving encoding data, but the Printer is not configured with this Encoder type. Step Procedure Verify that the LCD Settings are correct. a. Press Select on the LCD. -

Page 98: Resolving The Failed Smart Encode Error Message

Open the front access door. b. Send an encoding print job from the computer. c. Watch the card feed into the Printer and enter the E-card Docking Station. d. If the card is not feeding into the E-card Docking Station properly, the Flipper Offset may need to be adjusted. -

Page 99: Printing Process Errors

Repair the ribbon by taping it back on to the take-up core if the ribbon is broken. b. Press the Resume button to continue or Cancel to reset the Printer. Ensure that the ribbon is not stuck to the film. -

Page 100: Resolving The Print Ribbon Jam

RESTRICTED USE ONLY Resolving the Print Ribbon Jam Symptom: If the print ribbon becomes stuck to the HDP film or jammed inside the Printer, the LCD Display will indicate that it is jammed. Refer to the following steps to clear the jam:... -

Page 101: Resolving The Print Ribbon Out Error Message

Step Procedure Install a new ribbon and press Resume to continue. Resolving the Wrong Print Ribbon Error Message Symptom: The Print Ribbon installed in the Printer does not match the ribbon type selected in the Printer Driver. Step Procedure Verify that the ribbon is installed properly. -

Page 102: Resolving The Unknown Ribbon Type Error Message

Procedure Verify the ribbon type. a. Ensure that the print ribbon installed in the Printer is an HDP ribbon. (Note: Although similar in appearance, a DTC ribbon installed in an HDP Printer will produce an Unknown Ribbon Type error message.) Test the Ribbon Sensor. -

Page 103: Resolving The Printer Pausing Between Panels Problem

If problem persists, replace with a new Printhead, as described in the Replacing the Printhead (D840854) Ensure that the Printer has received data (at the speed that it requires). See Communication Errors 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) procedure in Section 5, page 281. -

Page 104: Resolving The Printhead Temp Error Message

Replacing the Main Print Board (A000271) 367 for instructions. Resolving the Printer Open Error Message Symptom: The Printer is operating with the Print and/or Transfer Station open. Step Procedure Ensure that both the Print and Transfer Stations are completely closed and that the release lever is secured. -

Page 105: Transfer Process Errors

Section 5, page 367 for instructions. b. Replace the Lamination Board. See the (140402) procedure in Section 5, page 368. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. photograph to see the location of Replacing the Main Print Board (A000271) - Page 106 Procedure Verify Film placement on the core. a. Remove the transfer film from the Printer. b. Ensure that the film is straight on the core. c. If the film is not between 5 and 15mm from the ribbon drive side of the transfer station, replace the film with a new roll using the Ribbon Telescopic process.

-

Page 107: Resolving The Film Sensor Errors

(Technician Note #2: Ribbon tension can be set higher than +5 if it is observed that the Ribbon is sticking to the Film during printing.) a. Verify the base Film Drive Idler Roller (D840867) moves freely (see picture). 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. - Page 108 Check for cracked Film Drive Hubs (D840952). (Note: A cracked Film Drive hub will not allow the film to be moved at the appropriate speed resulting in Sensor errors.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 109 Check for broken Lamination Roller Cover Hinges. (Note: A broken Lamination Roller Cover Hinge (840255) will not allow the Lamination doors to open properly which will result in poorly printed cards and film errors.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 110 10mm (+/-) .5mm.) Update to the latest version of Firmware. See the Application Program 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) procedure in Section 6 on page 328. Firmware Updater procedure in Section 10, page 468.

-

Page 111: Resolving The Transfer Cooling Error

LCD is set too high. Adjust the Transfer Temperature setting a. Press Menu on the LCD. b. Select Setup Printer, scroll down, and then select Transfer Temp from the menu. c. Reduce the current value by 5. -

Page 112: Resolving The Card Jam Error Message

Try not to move the card too far from where it was just before the jam occurred. c. Once the jam is cleared, close the Printer and press the Resume button to resume printing. Remove the jammed card from the Printer by leaving the power ON and opening the Print Station and Transfer Station. -

Page 113: Resolving The Temperature Timeout Error Message

204, for instructions on how to adjust the transfer settings. Resolve the Transfer Roller not being able to reach the optimum temperature. a. Turn the Printer OFF and ON to reset and try reprinting. b. If the problem persists, see the procedure in Section 2, page 97, to test the Thermocouple. -

Page 114: Resolving The Output Stacker Errors

Replace the motor if it does not turn. d. Replace the Lam Board as needed if the motor does turn. See the Replacing the Lamination Board (140402) 368. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. procedure in Section 5, page... -

Page 115: Card Lamination Errors

Card Lamination Errors Resolving the Overlaminate Jam Symptom: This section only applies if the Printer is equipped with an optional Card Lamination Module. If the overlaminate becomes stuck to the card or jammed inside the Printer, the LCD Display will indicate that it is jammed. - Page 116 Module for the next card. (Note: The Lamination Module buttons only affect the card in the Lamination section.) The Printer's LCD softkey buttons affect any card in either the Print Station or the Lamination Station (e.g., the Lamination Module's Cancel button cancels only the Lamination job;...

-

Page 117: Resolving The Card Lamination Placement Errors

Lamination closer to the leading edge of the card. d. Press OK to save the new value. Calibrate the Lamination Sensor. a. Reset the Printer to clear any Error Messages by removing Power and reapplying it. b. Open the Printer control panel from the Computer. -

Page 118: Resolving The Lam Error/Out Error Message

RESTRICTED USE ONLY Resolving the Lam Error/Out Error Message Symptom: The Printer seems to skip PolyGuard overlaminate patches or simply wind the overlaminate until the Printer's Ready LED flashes. Step Procedure Check that the proper Over-Laminate type is installed according to the Lamination Type option selected in the Printer Driver. - Page 119 If blocked, the voltage should read 4.9 to 5.5 VDC. • If unblocked, the Sensor should read 0.15 to 0.18 VDC. d. If the voltages do not read correctly the Sensor should be replaced. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 120: Resolving The Lamination (Not Adhering To The Card Surface) Problem

Procedure Ensure the Card quality by verifying that these requirements are met: a. Requirement 1: That the Printer does print onto any card with a clean, level and polished PVC surface. (Note: Although the Printer is equipped with card cleaning rollers, it is very important to always print onto cards specifically designed for direct-to-card dye-sublimation printing to ensure proper print quality.) - Page 121 Resolving the Lamination (not adhering to the card surface) problem (cont.) Step Procedure Check the Lamination Temperature. a. Open the Printer Control Panel from the Computer. • If using Windows 98Se/ME, right click on the HDP800 Series-LC Card Printer Icon and select Properties.

-

Page 122: Diagnosing The Image Problems

Remove watches, rings, bracelets and other jewelry. b. Open the Print Station. c. Use a Printhead Cleaning Pen from the Printer Cleaning Kit to firmly wipe back and forth across the surface of the Printhead. d. Close the Print Station once the Printhead is completely dry. - Page 123 Remove the print ribbon and HDP Film. c. Locate the Print Platen Roller, as shown below. d. Use a Cleaning Pad from the Printer Cleaning Kit to wipe the roller clean. e. Locate the Transfer Platen Roller, as shown below.

-

Page 124: Resolving The Card Surface Debris Problems

Open the Print Station and Transfer Station. b. Remove the print ribbon and HDP Film from the Printer. c. Use a can of compressed air to blow out all visible areas of the Printer interior. d. If you do not have a can of compressed air, use a cleaning pad from the Printer Cleaning Kit to wipe out all visible areas inside the Printer. - Page 125 Open the Front Access Door of the Printer. b. Depress the Cleaning Roller Lock. c. Pull the Cleaning Roller Assembly out of the Printer. d. Clean the rollers with one of the adhesive-backed Cleaning Cards from the Printer Cleaning Kit.

- Page 126 Remove the print ribbon and HDP Film. c. Locate the Print Platen Roller, as shown below. d. Use a Cleaning Pad from the Printer Cleaning Kit to wipe the roller clean. e. Locate the Transfer Platen Roller, as shown below.

-

Page 127: Resolving The Incorrect Image Darkness Problems

If the self test card does appear to have the same darkness issues, continue to step 3 (Adjusting the image darkness). Adjust the Dye-Sub Intensity setting within the Image Color tab of the Printer Driver. a. Open the Printer control panel from the computer. - Page 128 RESTRICTED USE ONLY Fargo Electronics, Inc. Resolving the incorrect Image Darkness problems (continued) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

-

Page 129: Resolving The Ribbon Wrinkle Problems

Step Procedure Confirm that the Printer is using the most current Driver from: http://www.fargo.com Adjust the Dye-Sub Intensity setting within the Image Color tab of the Printer Driver. a. Open the Printer control panel from the computer. • If using Windows 98Se/ME, right click on the HDP800 Series Card Printer Icon and select Properties. - Page 130 Loosen and adjust the screws so there is equal Spring pressure on each side of the print head. b. Tighten the screws and reprint the card that is exhibiting the issue. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 131: Resolving The Excessive Resin Printing Problems

Symptom: Black resin text and barcodes appear smeared or too thick. Step Procedure Reduce the Resin Heat setting within the Image Color tab of the Printer Driver a. Open the Printer control panel from the computer. • If using Windows 98Se/ME, right click on the HDP800 Series Card Printer Icon and select Properties. -

Page 132: Resolving The Incomplete Resin Printing Problems

Symptom: Black resin text and barcodes appear faded or too light. Step Procedure Reduce the Resin Heat setting within the Image Color tab of the Printer Driver a. Open the Printer control panel from the computer. • If using Windows 98Se/ME, right click on the HDP800 Series Card Printer Icon and select Properties. -

Page 133: Resolving The Hdp Film Wrinkle Problems

If using Windows 98Se/ME, right click on the HDP800 Series Card Printer Icon and select Properties. • If using Windows NT 4.0, right click on the HDP800 Series Card Printer and select Document Defaults. • If using Windows 2000/XP, right click on the HDP800 Series Card Printer and select Printing Preferences. - Page 134 Step Procedure Adjust the Film Tension. a. Select Menu from the LCD. b. Select Setup Printer and then select Film Tension. c. In increments of one, lower the Film Tension through the LCD Setup Menu and print a card. •...

-

Page 135: Resolving The Incomplete Transfer Problems

If using Windows 98Se/ME, right click on the HDP800 Series Card Printer Icon and select Properties. • If using Windows NT 4.0, right click on the HDP800 Series Card Printer and select Document Defaults. • If using Windows 2000/XP, right click on the HDP800 Series Card Printer and select Printing Preferences. -

Page 136: Resolving An Incomplete Transfer On The Leading Edge Problem

Decrease the Transfer Tension through the LCD. a. Select the Menu from the LCD b. Select the Setup Printer and then select Transfer Tension. c. In increments of one, decrease the Transfer Tension through the LCD Setup Menu and print a card. -

Page 137: Resolving The Image Placement Problems

Verify that the Dancer Rollers spin freely by opening the top and middle Modules and manually spinning the Dancer Rollers. Confirm that the correct Card Size option is selected in the Printer Driver setup. a. Open the Printer control panel from the computer. - Page 138 Check to ensure that the Card Size Knob in the base Module is set to the proper card size if it is not feeding straight into the Print section. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 139 Procedure Confirm that the Flattener is not impeding the card. a. Manually feed a card into the Printer using the Forward and Back buttons on the display. (Note: The card should move freely under the Flattener.) b. If the card is hitting the Flattener, adjust the width of the Flattener Guides by loosening the two (2) screws that hold the Flattener.

- Page 140 Verify that the Peel-Off Bar and the Ribbon Peel Bar height is correct. (Note: From the front of the HDP Card Printer, the Peel-Off Bar on the input side. See drawing D841085) should be flush with the frame. The Ribbon Peel Bar on the output side should have a 3/16-inch (4.5mm) gap between the frame and the...

-

Page 141: Resolving The Poor Image Quality Problems

(Note: If a small or low-resolution image is stretched or blown up, a pixilated or grainy effect will occur when printing, as shown below.) Good 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 142: Resolving The Image Washout On Film Problems

Reinstall the Printhead and print a self-test. Increase Image Darkness in the LCD. a. Select Menu from the LCD. b. Select Setup Printer and then select Image Darkness. c. Increase (in increments of five) the Image Darkness through the LCD Setup Menu and print a card. -

Page 143: Resolving The Registration Problems

Back the potentiometer OFF slowly until the LED just turns OFF. (Note: Ensure that when performing this procedure that there is no direct light shining into the Printer. Excessive ambient light in the vicinity of the Printer may also affect the calibration of the Sensor.) Adjust the Ribbon Tension by +1 and print a sample card. - Page 144 Reinstall the Printhead and print a self-test. Verify that the Upper and Middle Modules are seated properly and the Modules are completely locked down. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Replacing the Printhead (D840854)

-

Page 145: Resolving The Card Skewed Image Problems

Verify that the Peel-Off Bar and the Ribbon Peel Bar height is correct. (Note: From the front of the HDP Card Printer, the Peel-Off Bar on the input side, the drawing D841085, should be flush with the frame. The Ribbon Peel Bar on the output side should have a 3/16-inch (4.5mm) gap between the frame... -

Page 146: Printing A Test Image

Reviewing the Gray/Align YMC/K Self-Test Step Procedure Use this card to determine Image Placement and confirm that the Printer is working properly. See consists of sixteen (16) gray scale boxes and alignment arrows. The gray boxes are composed from a composite of YMC color panels.)) 800 Series Card Printer/Encoders Service Manual (Rev. -

Page 147: Reviewing The Color/Resin Ymck Self-Test

Use this card to confirm that image colors are properly reproduced. Image consists of sixteen graduated steps of RGB and YMCK. (Note: This print will provide maximum image size, giving complete card coverage on a CR-80 sized card.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 148: Reviewing The Card Count Self-Test

Procedure Use this option only applies if a Magnetic Encoding Module is installed in the Printer. (Note: The Printer will feed, encode and eject a card. Be sure to have high coercivity cards installed when running this test.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) -

Page 149: Reviewing The Lamination Color/Resin Ymck+L Self-Test

(b) the Resin Panel is printing properly. (Note: The Image consists of twelve spot colors, YMC and RGB, as well as gray density bars and thin resin lines.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 150: Section 3: Card Lamination Module

RESTRICTED USE ONLY Section 3: Card Lamination Module The purpose of this section is to provide the User with specific information on Printer adjustment procedures. Safety Messages (review carefully) Symbol Critical Instructions for Safety purposes Danger: Failure to follow these installation guidelines can result in death or serious injury. -

Page 151: Opening The Card Lamination Module

Open the Top Cover of the Lamination Module by lifting up on its bottom edge and tilting it back into its fully open position. (Note: The Top Cover is designed to hold its last position to prevent it from falling shut.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. - Page 152 Lamination Station up and back into its fully upright position. Note the Lamination Station is also designed to hold its last position to prevent it from falling shut. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 153 To close the Lamination Station, push the Lamination Station down until its blue Securing Latches close securely. (Note: The Lamination Station must be closed securely in order for your Printer to operate. It is also recommended that the Top Cover be closed whenever laminating for reliability and safety reasons.)

-

Page 154: Loading The Overlaminate

The supply end of the overlaminate roll is the side containing the fresh, unused portion of the overlaminate. The take-up end is the other side. Supply Roll 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Take-Up Roll... - Page 155 Use the end of the supply roll with the black core plug to push this hub in when inserting the overlaminate roll. (Note: Make certain the overlaminate material is fed from beneath the roll as shown.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 156 Close the Lamination Module. (Note: When you start to print, the Lamination Drive Hubs will automatically engage the overlaminate core notches.) Caution: Do not reverse the overlaminate roll. Damage may occur to the Lamination roller! 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 157: Adjusting The Card Lamination Module

The HDP800 Series Card Printer supports the attachment of an optional Card Lamination Module. This Module can be ordered pre-installed on the Printer from the factory or can be ordered separately as a field upgradeable Module. Once attached, the Card Lamination Module allows you to apply Fargo certified overlaminates for more secure, tamper-resistant cards. - Page 158 If the card is bowing downward, the reverse bending pressure may be too great. In this case, rotate the adjustment knob counter-clockwise. (Note: Some card types have very low heat resistance and may not be acceptable for laminating.) Adjustment Knob 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 159: Adjusting The Card Guide Rail

Lamination Module's Resume button. b. Manually position the card so its edge is flush with the Card Guide Rail. Card Guide Rail Blank Card 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page Screws... - Page 160 Adjusting the Card Guide Rail (continued) Step Procedure Slightly loosen the two screws which fasten the Card Guide Rail to the Printer's main chassis. If the PolyGuard patch is being placed more toward a card's top edge (as shown), move the Card Guide Rail slightly toward the rear of the Printer (opposite the direction you would like the patch to move).

- Page 161 Procedure If the PolyGuard patch is being placed more toward a card's bottom edge (as shown), move the Card Guide Rail slightly toward the front of the Printer (opposite the direction you would like the patch to move). Always make very slight adjustments to the Card Guide Rail and run a test print after each adjustment until the optimum patch position is found.

- Page 162 .010"/.25mm between the card edge and the Internal Card Guide as indicated here: If necessary, adjust the Internal Card Guide as described in the remainder of this section. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. .010“/.25mm space...

-

Page 163: Adjusting The Internal Card Guide

Lamination Module. This guide is factory-set to handle standard CR-80 sized cards. To adjust this guide, please refer to the following steps. (Note: If adjusting for an oversized card, you must also adjust the Printer’s Internal Card Guide.) Step Procedure Slightly loosen the two (2) screws which fasten the Internal Card Guide to the Printer's main chassis. - Page 164 Be sure the Internal Card Guide always remains parallel with the Card Guide Rail when adjusting. If necessary, adjust the Internal Card Guide as described in the remainder of this section. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 165 (Note: Be sure the Internal Card Guide always remains parallel to the card path and that the screws loosened in step 1 are retightened after each adjustment.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. .010“/.25mm...

-

Page 166: Attaching The Card Lamination Module

This section applies only if you are installing the field upgradeable Card Lamination Module onto a Printer. (Note: The Printer model must be capable of accepting this Module as not all Printer models are compatible with this field upgradeable option. HDP800 Series Printers with a serial number greater than A2360028 are compatible with the Card Lamination Module.) - Page 167 Attaching the Card Lamination Module (continued) Step Procedure Remove the three (3) screws fastening the Card Output Hopper's main enclosure to the Printer. Remove 3 screws 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 168 Attaching the Card Lamination Module (continued) Step Procedure Remove the four (4) black screws fastening the Card Output Hopper's main enclosure to the black Baseplate. Remove 4 screws 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 169 Attaching the Card Lamination Module (continued) Step Procedure Remove the Card Output Hopper's main enclosure by lifting it up and off of the Printer. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 170 Step Procedure Remove the one (1) screw which fastens the Card Output Bin to the Baseplate and lift the bin up and off of the Printer. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 171 Output Bin should now be removed from the Printer. (Note: Set these items aside.) Set the Card Lamination Module just to the left of the Printer and at a slight angle as shown. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 172 Attaching the Card Lamination Module (continued) Step Procedure a. Connect the Lamination Module's Power Cable to the Printer's Power Port. (Note: Both are labeled with a red Power label.) b. Push firmly to ensure both are securely connected. (Note: The port and cable are keyed for one way installation.)

- Page 173 Latches. (Note: This will hold them out of the way for the next steps.) Set the Card Lamination Module onto the Printer by lifting it up about 4- inch/10cm off the table top and sliding it down onto the Printer's Baseplate.

- Page 174 RESTRICTED USE ONLY Attaching the Card Lamination Module (continued) Step Procedure Insert three (3) screws into the top of the Card Lamination Module, shown below. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 175 Attaching the Card Lamination Module (continued) Step Procedure Insert one (1) black screw into the bottom, front of the Card Lamination Module, as shown below. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Continued on the next page Insert 1 screw Fargo Electronics, Inc.

- Page 176 Attaching the Card Lamination Module (continued) Step Procedure Insert two (2) screws into the bottom, rear of the Card Lamination Module, as shown below. 2 screws 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Insert Fargo Electronics, Inc. Continued on the next page...

- Page 177 Attaching the Card Lamination Module (continued) Step Procedure Move the Printer's Release Lever to the Unlocked position and close the Print Station and Transfer Station. Installation of the field upgradeable Card Lamination Module is now complete. To ensure a successful installation, install cards, Print Ribbon, HDP Film and overlaminate and run the Lamination Self Test (color/Resin YMCK+L).

-

Page 178: Section 4: Printer Adjustments

RESTRICTED USE ONLY Section 4: Printer Adjustments The purpose of this section is to provide the User with specific information on Printer adjustment procedures. Safety Messages (review carefully) Symbol Critical Instructions for Safety purposes Danger: Failure to follow these installation guidelines can result in death or serious injury. -

Page 179: Adjusting The Card Size

(Note: When loading cards which vary from this standard size or the standard 30 mil thickness, it is necessary to make simple adjustments to the Printer.) • Wider Cards: If loading wider cards into the Printer, adjust the Card Input Guide, Card Output Guide and Internal Card Guide. •... -

Page 180: Adjusting The Card Input Guide

Before moving the Card Input Guide, loosen the guides Locking Knob. (Note: To do this, open the Front Access Door and loosen the Locking Knob by turning it counter-clockwise.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page... - Page 181 Adjusting the Card Input Guide (continued) Step Procedure Open the Card Input Hopper Door and locate the Card Input Guide closest to the front of the Printer. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 182 Adjust this guide is adjustable and move it slightly to the left or right. Push the Card Input Guide out of the way and insert a stack of at least 100 cards. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 183 Push the Card Input Guide back into position so that it rests flush against the side of the card stack. Once the Card Input Guide is adjusted properly, retighten the Locking Knob loosened in step 1. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 184: Adjusting The Card Stacker Output Guide

(Note: This will ensure consistent card ejecting and stacking.) • If the Card Stacker Output Guide is not set prior to printing, it can cause jams. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page... - Page 185 This guide is adjustable. Move the Card Output Guide to the CR-80, CR-90 or CR-100 setting according to the specific size of the cards. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 186 Procedure Close the Card Output Hopper Door. (Note: To make sure the cards remain neatly stacked in the Card Output Hopper, always keep the hopper door closed during printing.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 187: Adjusting The Internal Card Guide

RESTRICTED USE ONLY Adjusting the Internal Card Guide Adjust the Printer's Internal Card Guide to the proper card size prior to printing to ensure consistent card feeding throughout the printing process. If you do not set this guide prior to printing, you could experience card jams. - Page 188 RESTRICTED USE ONLY Adjusting the Internal Card Guide (continued) Step Procedure Pull the Internal Card Guide toward the front of the Printer until it stops. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 189 Release the Internal Card Guide. (Note: If you adjusted to the CR-90 or CR- 100 position, the Internal Card Guide will now rest against the Card Size Adjustment Knob as shown in the above illustration. This allows the Printer to consistently feed and print onto the wider card stock.) 800 Series Card Printer/Encoders Service Manual (Rev.

-

Page 190: Adjusting The Card Thickness Knob

When loading thicker or thinner cards, it is important that the Card Thickness Adjustment Knob be set accordingly to ensure the Printer feeds only one card at a time. (Note: If the Printer is equipped with the Card Lamination Module, only cards with a thickness ranging from 30 mil to 40 mil can be laminated. -

Page 191: Fine-Tuning The Card Separator Adjustment Assembly (D840995)

Feed a card with a few other cards into the hopper. d. Place a full stack of cards in the Card Input Hopper and feed a few cards. e. Continue to adjust the Card Separator Adjustment Assembly (as needed). 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 192: Printing On Alternate Card Stocks

Printing on Alternate Card stocks Selecting the Right Cards and optimize the HDP Print Process In order to optimize the HDP Card Printer’s capabilities for cards with hard-to-print surfaces, we recommend evaluating the card stock selection before installation of the Printer. -

Page 193: Selecting The Appropriate Hdp Printer Driver Settings

These defaults automatically configure based on the card type, ribbon type and whether printing single- or dual-sided. (Note: The default Dwell Time of the HDP820 and HDP820-LC Printer Drivers has been changed or modified from two (2) seconds per inch to three (3) seconds per inch in order to improve adhesion and media handling capabilities, as well as to reduce printer errors.) - Page 194 RESTRICTED USE ONLY Selecting the appropriate HDP Printer Driver settings (continued) Card/Ribbon Type Transfer Temp UltraCards-Glossy PVC + non-H Panel ribbon HDP Cards-Matte PVC + non-H Panel ribbon UltraCards-Glossy PVC + H Panel ribbon HDP Cards-Matte PVC + H Panel ribbon Based on 30-mil card thickness.

-

Page 195: Conducting The Tape Adhesion Test

(50mm/sec)) pulling it up at a perpendicular (90 degree) angle to the card. (Note: The IPC recommends a minimum of three tests for each card type evaluation.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page... - Page 196 RESTRICTED USE ONLY Conducting the Tape adhesion Test (continued) FAIL: Significant transfer to tape PASS: Very slight transfer to tape PASS: Absolutely NO transfer to tape 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page...

- Page 197 PVC surfaces.) • Ensure that the cards (in use) have a surface roughness (Ra) of 60 micro inches or less. This information should be available from the card manufacturer. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 198: Printer Driver Options

Click OK, then choose the folder in which you would like to save the Printer Driver file. (Note: You may want to save it in an empty folder to prevent mingling its files with others already on the computer.) - Page 199 Installing Printer Driver Updates (continued) Step Procedure Click on Browse, navigate to the folder containing the Printer Driver files you just downloaded and unzipped and click on OK. Click on OK again to close the Install From Disk window and then click on NEXT.

-

Page 200: Setting Up The Printer Driver

RESTRICTED USE ONLY Setting Up the Printer Driver Once the appropriate Printer Driver for the computer has been installed, you will need to set the Driver up with the proper print options. To open the Printer Driver setup window, please... -

Page 201: Using The Device Options Tab

Using the Device Options tab The HDP825-LC Card Printer Printing Preferences window is used throughout this section for consistency within this document for the entire HDP 800 Series. See the HDP820, HDP820-LC and HDP825 Card Printer Printing Preferences windows (as needed for your specific printer). -

Page 202: Adjusting The Ribbon Type

• YMC: Yellow, Magenta, Cyan YMCK: Yellow, Magenta, Cyan, Resin Black • YMCKK: Yellow, Magenta, Cyan, Resin Black, Resin Black • YMCKH: Yellow, Magenta, Cyan, Resin Black, Heat Seal 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 203: Adjusting The Film Type

Use the Ribbon Type dropdown menu to match ribbon type. Step Procedure Adjust to match the Film Type selection with the film type that is loaded in the Printer. • Clear • Holographic 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 204: Adjusting For The Color Matching

Printer Driver. It also allows further customization of the printed color of the cards through the Image color tab.) Select Monitor to allow the Printer Driver to make color corrections similar to the Algebraic option but through a more complex color matching algorithm. (Note: This option shifts colors more radically so the colors in the image will more closely match how they appear on screen.) -

Page 205: Adjusting For The Resin Dither

Panel of a YMCK or YMCKK Print Ribbon.) Step Procedure Select Optimized for Photo when printing photo quality images with resin. Select Optimized for Graphics when printing lower quality images (e.g., clipart, logos, etc.) with resin. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 206: Using The Print Both Sides Option

1 of the document • the backside on page 2. (Note: The Printer Driver will always place all odd numbered pages on the front side of the card and all even numbered pages on the back side with this option selected.) 800 Series Card Printer/Encoders Service Manual (Rev. -

Page 207: Using The Split 1 Set Of Ribbon Panels Option

(Note #2: The Print Both Sides option is automatically enabled when this option is selected.) (Note #3: This option is not available if using a YMCKH or YMC Print Ribbon.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 208: Using The Print Back Side First Option

Select this option if you need to print the first page of a two-page document on the backside of the card. The second page of the document will be printed on the front side of the card. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 209: Using The Print On Back Side Only Option

• The second page of the document will then be printed on the back of a second card. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 210: Using The Rotate Front 180 Degrees Or Rotate Back 180 Degrees Options

180 degrees when printed. Select the Rotate Back 180 Degrees option to rotate the image on the back of the card by 180 degrees when printed. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 211: Using The Print In Single Card Mode Option

RESTRICTED USE ONLY Using the Print in Single Card Mode option Use this option to force the Printer's memory to buffer or to hold only one print job at a time. Step Procedure Select this option only when printing to multiple Printers sharing print jobs over a network. -

Page 212: Using The Link Card To Print Job Option

Step Procedure Select this option to cause the Printer to dispense with the print job if a blank card is removed or ejected. (Note: The next card is then fed into the Printer and the next coinciding print job then printed.) 800 Series Card Printer/Encoders Service Manual (Rev. -

Page 213: Using The Disable Printing Option

RESTRICTED USE ONLY Using the Disable Printing option Use this option to disable the printing capabilities of the Printer, yet still allows the Printer to encode cards. (Note: This option is useful to encode or re-encode preprinted cards without wasting additional time or printing supplies.) -

Page 214: Using The Image Color Tab

Contrast and Gamma of the printed image, as well as the individual color balance of Yellow, Magenta and Cyan (see Image color tab, shown below). 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. - Page 215 Move the slide to the right to cause more heat to be used, thus generating a darker print. (Note: This slide only affects those images printed with dye-sublimation ribbon Panels (YMC).) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

- Page 216 Using the Image color tab (continued) Step Procedure Control the amount of heat the Printer uses when printing with the resin black Panel by adjusting the Resin Heat slide. • Move the slide to the left to cause less heat to be used in the printing process, causing resin images to be lighter or less saturated.

- Page 217 RESTRICTED USE ONLY Using the Image color tab (continued) Step Procedure Return all options to their factory settings by clicking on the Default button. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc.

-

Page 218: Using The Image Transfer Tab

RESTRICTED USE ONLY Fargo Electronics, Inc. Using the Image Transfer tab Use this tab to adjust the Image Position, Transfer Dwell Time, Transfer Temperature and Flattener Temperature. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) -

Page 219: Adjusting The Image Position Controls

• These values ensure that the Cards always remain in the same position as they travel through the Printer (regardless of image orientation). • The Card Illustration (shown in the Image Position box) will flip and rotate according to the selection of Portrait, Landscape or Rotate 180 Degrees. - Page 220 Step Procedure Use the Vertical adjustment to move the image toward the rear of the Printer if a positive number is entered and toward the front of the Printer if a negative number is entered.

-

Page 221: Adjusting The Transfer Dwell Time And Temperature

Card Type option. • Changes made to the Dwell Time and temperature settings are saved for the selected Card Type option (upon exiting the Printer Driver setup in the Printer’s Control Panel). Step Procedure Return to the factory default settings for the selected Card Type by clicking on the Default button. -

Page 222: Adjusting The Flattener Temperature

Any changes made to the Flattener temperature will be saved upon exiting the Printer Driver setup. (Note: If the Printer is equipped with a Lamination Module and Lamination is being used, the Flattener will be disabled.) Click on the Default button to return to the factory default setting. -

Page 223: Using The K Panel Resin Tab

Use this tab to adjust the CR-80 Card Size, the Direction the Card Travels through the Printer, the Print All Black With K Panel (options) and the Defined Areas. Use this tab to control where the resin black (K) Panel of a full-color ribbon is printed. -

Page 224: Selecting The Full Card With The K Panel Resin Tab

Selecting the Full Card with the K Panel Resin tab Step Procedure Select the Full Card option to print the resin black (K) Panel for all black found within all areas of the image, as shown below. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 225: Selecting The Defined Area(S) With The K Panel Resin Tab

Selecting the Defined Area(s) with the K Panel Resin tab Step Procedure Select the Defined Area(s) option to print the resin black (K) Panel for all black found only in an area or areas defined, as shown below. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 226: Selecting The Undefined Area(S) With The K Panel Resin Tab

Step Procedure Select the Undefined Area(s) option to print the resin black (K) Panel for all black found only in the space outside the areas defined, as shown below. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 227: Defining The Area To Activate The Card Grid

.2" x .2" (5mm x 5mm) and at its default location in the lower left-hand corner (0,0). (Note: This square represents the first defined area.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 228: Measuring The Total Card Area

Printer.) Measure the total area and enter those dimensions into the dimension boxes. (Note: The minimum size an area can be is .2" x .2" (5mm x 5mm).) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 229: Measuring The Area To Be Positioned On The Card

Enter these values into the X and Y boxes, as shown below. c. Note that the card grid lines are spaced at .2” (5mm) intervals. X=1.4“ 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Karen Atkins... -

Page 230: Selecting The Print Ymc Under The K And Print K Only Options

Select the Print K Only option to print all black in the designated areas only with the resin black (K) Panel or to print resin black onto a white background to maximize the sharpness of printed text and barcodes. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. Continued on the next page... - Page 231 RESTRICTED USE ONLY Fargo Electronics, Inc. Selecting the Print YMC under the K and Print K Only options (continued) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

-

Page 232: Using The Magnetic Encoding Tab

RESTRICTED USE ONLY Using the Magnetic Encoding tab Use these options only if the Printer has an optional Magnetic Stripe Encoding Module installed. Step Procedure Select the Magnetic Encoding tab to display options for controlling the Magnetic Stripe encoding process. (Note: The following describes these options and the Printer's magnetic encoding process.) -

Page 233: Using The Encoding Mode Option

Type II cards commonly used in Japan. No encoding customization options are available with the JIS II mode.) (Note #2: A JIS II Magnetic Head must be installed in the Printer to use any of the JIS II options in the Driver.) 800 Series Card Printer/Encoders Service Manual (Rev. - Page 234 RESTRICTED USE ONLY Fargo Electronics, Inc. Using the Encoding Mode option (continued) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0)

-

Page 235: Encoding The Mode/Coercivity/Magnetic Track Selection

Set these options back to the ISO standard settings once they have been changed by selecting the Default button for each of the separate tracks. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 236: Reviewing The Magnetic Track Options

After making the required selection, the Magnetic Track Options box displays the current set of customization options for the selected track. • Remember that each track must be customized independently of the other two. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 237: Reviewing The Enable Mle Support Checkbox

Multi-Language Extension (MLE) support in Windows XP can cause text strings to be broken up into fragments. This fragmentation of the text string prevents magnetic encoding. Step Procedure Check this box to allow the Driver to process the fragmented text. 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 238: Reviewing The Verification Options

RESTRICTED USE ONLY Reviewing the Verification options Use this option, which instructs the Printer to verify that all magnetic data has been correctly encoded on each card. (Note: With either of these options, the number of verification retries may be specified. A range of 1-5 retries is available.) -

Page 239: Reviewing The Shift Data Left

Select this option to shift the recorded magnetic data to the left-hand side of the card's Magnetic Stripe. (Note: This is useful in situations that require cards to be readable with insert type readers.) 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. -

Page 240: Reviewing The Iso Track Locations

The magnetic Encoding Module encodes onto tracks in accordance with an ISO 7811-2 Magnetic Stripe. For track locations, review the display below. 0.223" 0.353" 0.493" TRACK1 0.110" TRACK2 0.110" TRACK3 0.110" 800 Series Card Printer/Encoders Service Manual (Rev. 5.0) Fargo Electronics, Inc. 0.130" 0.140"... -

Page 241: Sending The Track Information