Summary of Contents for Copley Controls Accelnet Plus AEV-090-14

- Page 1 Accelnet Plus Micro Modules AEV/APV User Guide 16-01687 Rev 03 AEV/APV AEZ/APZ-50 AEZ/APZ-50-C Copley Controls Page 1 of 139...

-

Page 2: Table Of Contents

Connections and Wiring – EZ Boards ....................55 Safe Torque Off ........................... 64 RS-232 Serial Communications ..................... 67 Network Ports ..........................68 Control I/O ..........................70 EZ Board Indicators ........................79 EZ Development Board Indicators ....................81 Copley Controls Page 2 of 139... - Page 3 Protection ..........................126 Position and Velocity Errors ......................128 Digital Inputs ......................... 130 Analog Inputs ......................... 131 Outputs ..........................131 Appendix ............................132 Connecting AEZ/APZ for Serial Control .................... 134 Ordering Guide and Accessories ..................... 135 Copley Controls Page 3 of 139...

-

Page 4: About This Manual

This manual describes the operation and installation of the AEV and APV Accelnet Plus Micro Module drives manufactured by Copley Controls. All Accelnet Plus Micro Module products have serial numbers that incorporate the week and year of production into the first 4 digits (WWYY) of the serial number. -

Page 5: Ec Declaration Of Conformity

Accelnet Plus Micro Modules User Guide 16-01687 Rev 03 EC D ECLARATION OF ONFORMITY Copley Controls Page 5 of 139... -

Page 6: Abbreviations And Acronyms

SIL CL Safety Integrity Level Claim Limit, SIL Capability Safe Torque Off Volts DC (Direct Current) Copley Controls Related Accelnet Plus Micro Module EtherCAT Accelnet Plus Micro Module EtherCAT + EZ board Accelnet Plus Micro Module CANopen Accelnet Plus Micro Module CANopen + EZ board... -

Page 7: Comments

We reserve the right to modify our products. The information in this document is subject to change without notice and does not represent a commitment by Copley Controls. Copley Controls assumes no responsibility for any errors that may appear in this document. -

Page 8: Product Warnings

National Electrical Code (NEC) or its national equivalent, and all prevailing local codes. There are no user serviceable parts in the Accelnet Plus Micro Module servo drives. Copley Controls Page 8 of 139... -

Page 9: Introduction

Pulse-to-position ratio is programmable for electronic gearing. • Controlled directly over an RS-232 serial link with simple ASCII format commands. • All models can work as stand-alone controllers running CVM control programs with Indexer 2. Copley Controls Page 9 of 139... -

Page 10: Accelnet Plus Micro Module Models

* AEZ-090-50 is an AEV-090-50 soldered into an AEV EZ Board APZ-090-50 is an APV-090-50 soldered into an APV EZ Board ** AEZ-090-50-C is an AEV-090-50-C soldered into an AEV EZ Development Board APZ-090-50-C is an APV-090-50-C soldered into an APV EZ Development Board Copley Controls Page 10 of 139... -

Page 11: Specifications

Unit is Adc. ** VLOGIC supply current depends on the number of encoders connected to the drive. The maximum current draw given assumes that the encoder +5V output is loaded to 500mA Unit is Vdc Copley Controls Page 11 of 139... -

Page 12: Output Power

Adc is peak of sine, Arms is RMS of sine ** Heat sinking and/or forced air cooling may be required for continuous output power rating *** Consult factory for operation with inductance lower than 400 µH Copley Controls Page 12 of 139... -

Page 13: Control Loops

RS-232 *, 9600~230,400 Baud, 3-wire Format is RS-232, TxD, RxD, Gnd but voltage levels are TTL. An external circuit is required if RS-232 voltages are needed. This circuit is provided in the EZ Boards and EZ Development Boards. Copley Controls Page 13 of 139... -

Page 14: Analog Inputs

0.68~1.6 Vdc 0.55~1.30 Vdc Voltage Logic High Input 1.42~2.38 Vdc 1.30~2.0 Vdc Voltage Input Hysteresis 0.44~1.26 Vdc 0.40~0.79 Vdc IN1 – Enable * Default Function MISO input for SLI mode * IN2 – Not Configured Copley Controls Page 14 of 139... -

Page 15: Safe Torque Off (Sto)

Input Voltage Hysteresis 25 mV Differential Input Threshold ±200 mVdc AEV, APV: None. AEZ, APZ: 121 Ω, with 1 kΩ pull-up to +5V from X, Termination Resistance 1 kΩ pull-down to Sgnd from /X Copley Controls Page 15 of 139... - Page 16 Sin(+), Sin(-), Cos(+), Cos(-) Nominal Voltage 1 Vpk-pk ±20% Maximum Voltage ±0.6 Vdc Differential 0 to +3.5 Vdc Input to Ground Termination Resistance 121 Ω Bandwidth 300 kHz Interpolation 1 to 1024, programmable Resolution 16 bit Copley Controls Page 16 of 139...

-

Page 17: Multi-Port Input / Output

PWM / Direction, PWM Magnitude 50% Secondary Encoder Input Incremental digital A/B/X, Absolute bidirectional or Clock / Data Buffered Encoder Digital incremental A/B/X channels Output Emulated Encoder Emulated A/B channels from Sin/Cos or digital absolute encoder Copley Controls Page 17 of 139... -

Page 18: Serial Interface

AEZ, APZ: RS-232 transceiver Signals Rxd, Txd, Gnd 9600, 19200, 57600, 115,200, 230,400 Baud Rate (defaults to 9600 on power up or reset) Data Format N, 8, 1 Flow Control None Protocol Binary or ASCII format Copley Controls Page 18 of 139... -

Page 19: Network Interfaces

CAN_L on last node in the chain. A 121 resistor across CAN_H and Bus Termination No termination required. CAN_L at the CAN master, and at the last device on the CAN network. Copley Controls Page 19 of 139... -

Page 20: Ethercat Interface: Aev Models

The fixed address and station alias are always available. If the switch-based station alias is used, it is the responsibility of the user to ensure that each drive has a unique station alias. Copley Controls Page 20 of 139... -

Page 21: Can Architecture: Apv Models

Use programmed Program address into flash only. value For more information on CAN addressing, see the CME User Guide. For more information on CANopen operations, see the following Copley Controls documents: • CANopen Programmer’s Manual • CML Reference Manual •... -

Page 22: Fault Levels

+HV > +185 ±1 Vdc PWM outputs turn off until +HV is < +185 ±1 Vdc (180 V models) Encoder Power +5 Vdc, 500 mA maximum, protected for overload or shorts. Shared by dual encoders Encoder Loss AEZ, APZ Only Detection Copley Controls Page 22 of 139... -

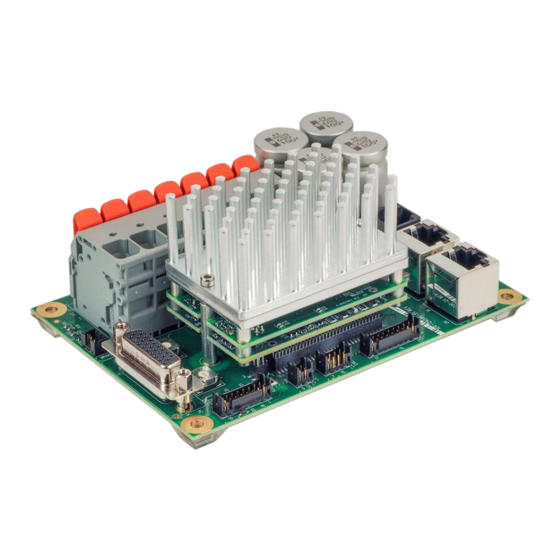

Page 23: Dimensions

16-01687 Rev 03 IMENSIONS Modules AEV-090-14, -090-30, -180-10, -180-20 & APV-090-14, -090-30, -180-10, -180-20 DIMENSIONS Dimensions: Inch [mm] AEV-090-50, AEV-090-50-C & APV-090-50, APV-090-50-C DIMENSIONS These pins are longer for soldering into the user PC board. Copley Controls Page 23 of 139... - Page 24 Accelnet Plus Micro Modules User Guide 16-01687 Rev 03 EZ Boards AEZ-090-50 EZ B OARD IMENSIONS EZ Development Boards AEZ-090-50-C EZ D EVELOPMENT OARD IMENSIONS Copley Controls Page 24 of 139...

-

Page 25: Mechanical And Environmental

≤ 2000 m (6560 ft) Vibration 2 g peak, 10~500 Hz (Sine), IEC60068-2-6 Shock 10 g, 10 ms, half-Sine pulse, IEC60068-2-27 Contaminants Pollution degree 2 Cooling Heat sink and/or forced air cooling required for continuous power output Copley Controls Page 25 of 139... -

Page 26: Thermals

VLOGIC power dissipation. Add these together to produce the total Watts of losses. AEV-090-14 AEV-090-30 APV-090-14 APV-090-30 AEV-090-50, AEZ-090-50 AEV-090-50-C, AEZ-090-50-C APV-090-50, APZ-090-50 APV-090-50-C, APZ-090-50-C In this example, the application output current is 22 Adc. At +HV = 85 Vdc the PWM loss is 20.5 Watts. Copley Controls Page 26 of 139... - Page 27 Dual encoders are used, each using 125 mA for a total of 250 mA. The total VLOGIC dissipation is ~3.5 W. Adding the dissipations of VLOGIC and +HV = 20.5 + 3.5 = 24 Watts. Copley Controls Page 27 of 139...

- Page 28 HSF100 HSF100 Example The dashed lines above show that at an output current of 20 Adc, the maximum operating temperature with a heatsink and fan at 100 CFM would be 32 °C (89 °F) Copley Controls Page 28 of 139...

-

Page 29: Operating Temperature And Cooling Configurations

LFM is Linear Feet per Minute, the velocity of air flow produced by a fan directed in line with the heatsink fins. EATSINK EATSINK IRFLOW EATSINK IRFLOW EATSINK IRFLOW EATSINK IRFLOW Note:Tall pins heatsink not shown Copley Controls Page 29 of 139... -

Page 30: Ez Board Pins Heatsink Mounting

Torque the M2.5 mounting screws to 4 in-lb, 64 in-oz, 0.45 Nm. Note: The instructions above apply to all models. This illustration is just an example that shows the components and their placements. Copley Controls Page 30 of 139... -

Page 31: Connections And Wiring - Modules

Remarks For J1, refer to this document: http://suddendocs.samtec.com/processing/through-hole-printing.pdf Socket Strip Samtec CLP-132-02-L-D-BE-A-K-TR 0.050" (1.27 mm) pitch Socket Strip Samtec CLT-102-2-G-D-BE 2.00 mm (0.0787 in) pitch Standoff hex, 19 mm long, M 2.5 mm thread Copley Controls Page 31 of 139... -

Page 32: Aev Pc Board Connectors And Pinout

J1: HV & Motor Dual row, 2 mm centers 38 position female header SAMTEC: SQT-119-01-G-D (Enable) IN1 SGND SGND REFIN(-) REFIN(+) J2: Signal Dual row, 0.050 inch centers 64 position female header SAMTEC: FLE-132-01-G-DV-K-TR Copley Controls Page 32 of 139... -

Page 33: Apv Pc Board Connectors And Pinout

DOUT4 (SLI-MOSI) Dual row, 2 mm centers (SLI-MISO) IN7 DOUT2 38 position female header SAMTEC SQT-119-01-G-D (Enable) IN1 SGND SGND REFIN(-) REFIN(+) J2: Signal Dual row, 0.050 inch centers 64 position female header SAMTEC FLE-132-01-G-DV-K-TR Copley Controls Page 33 of 139... -

Page 34: Mounting Configurations

AEV-090-14, AEV-090-30, AEV-180-10, AEV-180-20, APV-090-14, APV-090-30, APV-180-10, APV-180-20 All connections shown socketed. With the pins heatsink the 35 mm screws are used. With the long pins heatsink the 40 mm screws are used. Tall Pins Heatsink Pins Heatsink Copley Controls Page 34 of 139... - Page 35 Metric, M2.5, lock IMPORTANT: The example shown here using the EZ Board does not apply to panel mounting of these drives: AEV-090-50, AEV-090-50-C, APV-090-50, and APV-090-50-C. THESE MODELS ARE INCOMPATIBLE WITH THE EZ BOARD. Copley Controls Page 35 of 139...

- Page 36 Copley non-threaded spacer 20.5 mm Heatsink Tall Pins Heatsink, 2 inch tall MOUNTING BOARD CONNECTORS FOR SOCKETING Part Manufacturer Part Number Power Socket J1 Samtec SQT-119-01-G-D Signal Socket J2 Samtec FLE-132-01-G-DV-K-TR STO Socket J3 Samtec TLE-102-01-G-DV-TR Copley Controls Page 36 of 139...

-

Page 37: Integration Guidelines For Aev & Apv Modules

The AEV & APV are designed for Pollution degree 2: • Pollution Degree 2: Normally only nonconductive pollution occurs. Occasionally, however, a temporary conductivity caused by condensation is to be expected, when the drive is out of operation. Copley Controls Page 37 of 139... - Page 38 Between Low Voltage circuits and chassis 0.200 mm Between High Voltage circuits and chassis 0.500 mm ECOMMENDED ESIGN ULES These rules are good practice in the PC board design but are not requirements to any standard. Copley Controls Page 38 of 139...

-

Page 39: Grounding Considerations

User equipment connecting to the drive’s non-isolated circuits should have a circuit ground that is at the same potential as the drive Signal Ground. & G – AEV/APV E ONNECTIONS ROUNDING XAMPLE The networking CAN and EtherCAT connections are not shown in this diagram. Copley Controls Page 39 of 139... - Page 40 Doing so will minimize noise currents flowing in the mounting plate or the cabinet. PE V SE V AEV APV V OGIC VC OM eatplate Standoff Equipment Ground rame Ground Copley Controls Page 40 of 139...

- Page 41 Frame Ground at the drive end, and to the motor frame on the motor end. Motors are typically grounded to equipment frames, too. EEDBACK ABLE HIELDING Shields on feedback cables reduce emissions from the drive and help protect internal circuits from interference due to external sources of electrical noise.. Copley Controls Page 41 of 139...

-

Page 42: Ethercat Communications

ANSI RS-232 levels which are the VC 2G1 AS NC T D Tx D S232T standard for serial communications TO UT and computer COMM ports. PADD E SGND 3.3V RS-232 Signal J2 Pins ASYNC_RXD ASYNC_TXD SGND SGND Copley Controls Page 42 of 139... -

Page 43: Digital Command Inputs: Position

I N 3 I N 3 unc tion no connection Direc tion Sgnd SGN D PWM/DIRECTION INPUTS 50% PWM Command Options Signal J2 Pins PWM Vel/Trq, 50% PWM +/- Vel/Trq Hi/Lo Direction, No connection Copley Controls Page 43 of 139... -

Page 44: Multi-Mode Port As An Input

• Full-Duplex: SSI, BiSS, EnDat encoders Quad Encoder X, Full-Duplex /CLOCK /ENCX2 (4-wire). The X channel sends the Clock signal to the encoder, which initiates data transmission to the A-channel J2 Sgnd Pins (APV) 3,4,18,31,32,33,34,42,49,50,59,60 (19~24) Copley Controls Page 44 of 139... -

Page 45: Multi-Mode Port As An Output

MA 3362 Enc2 B ENCB2 Enc2 /B /ENCB2 5V output 500 m A Enc2 X ENCX2 SGND Enc2 /X /ENCX2 J2 Sgnd Pins (APV) 3,4,18,31,32,33,34,42,49,50,59,60 (19~24) BUFFERED QUAD A/B/X OUTPUTS EMULATED QUAD A/B OUTPUTS Copley Controls Page 45 of 139... -

Page 46: Cme Defaults

Configure Faults > Optional Faults Accel / Decel Offset Counts Active Notes Homing Adjustment Counts Over Current (Latched) √ These are the default settings for Latched Faults. Using CME, these can be checked or unchecked. Copley Controls Page 46 of 139... -

Page 47: High Speed Inputs: In1, In2, In3, In4, In5, 1N6

1.6 Vdc SGND Input VC3G1 = 0.44~1.26 Voltages +6 Vdc 0 Vdc Pull-up 10 kΩ CONNECTIONS 1 kΩ Signal J2 Pins Low Pass 100 pF Filter 0.1 µs J2 Sgnd Pins (APV) 3,4,18,31,32,33,34,42,49,50,59,60 (19~24) Copley Controls Page 47 of 139... -

Page 48: Analog Input: Ain1

O U T 1 3 O U T OUT2 DOUT2 • Custom Trajectory status • Custom position-triggered OUT3 DOUT3 CT2G1 VC3G1 output OUT4 DOUT4 SG N D SG N D • Program control OUT5 DOUT5 OUT6 DOUT6 Copley Controls Page 48 of 139... -

Page 49: Sli (Switch & Led Interface) Port

Enc /X /ENCX1 1 2 1 +5VENC 57,58 M A 3 3 6 2 1 3 0 J2 Sgnd Pins (APV) 3,4,18,31,32,33,34,42,49,50,59,60 5 V E N C 1 (2 ) (19~24) SG N D Copley Controls Page 49 of 139... - Page 50 Inner shields are optional for digital /SCLK /ENCX1 encoders and should only be connected to Signal SDATA ENCA1 Ground on the drive. /SDATA /ENCA1 +5VENC 57,58 J2 Sgnd Pins (APV) 3,4,18,31,32,33,34,42,49,50,59,60 (19~24) Copley Controls Page 50 of 139...

- Page 51 SG N D *Battery optional Note: Single (outer) shields should be connected at the drive end. The inner shield is optional for digital encoders and should only be connected to Signal Ground on the drive. Copley Controls Page 51 of 139...

-

Page 52: Analog Encoder

VC3G17 SGND SGND 100 p Brake Signal J2 Pins Signal Motemp J2 Pins Halls Signal J2 Pins OUT1 DOUT1 Motemp IN5 Hall U HALLU OUT2 DOUT2 Hall V HALLV OUT3 DOUT3 Hall W HALLW Copley Controls Page 52 of 139... -

Page 53: Vlogic

VLOGIC. This maximum value can damage the VLOGIC circuits if exceeded. If motor/load deceleration can ‘pump-up’ the +HV then VLOGIC should be supplied from a regulated power supply. Signal J1 Pins VLOGIC 9,10,11 HVCOM 12,13,14 Copley Controls Page 53 of 139... -

Page 54: Typical Connections

2. [OUT2] is shown as a Fault signal to the controller and [OUT3] is shown as control for a motor brake. All outputs are programmable. 3. Encoder connections are shown for incremental types, but absolute encoders are supported on both primary and load encoder inputs. Copley Controls Page 54 of 139... -

Page 55: Connections And Wiring - Ez Boards

22~10 AWG 18~4 AWG 22~10 AWG, 600 V 18~4 AWG, 600 V Recommended Wire Shielded cable required for CE Shielded cable required for CE compliance compliance Wire Insertion/Extraction Tool Slotted screwdriver Tool not required. Copley Controls Page 55 of 139... - Page 56 Motor V MOTV Motor V MOTU Motor U MOTW Motor W +HV C ONNECTIONS EZ Board J15 EZ Development Board J17 Signal Function Signal Function DC Power HVCOMM DC Ground HVCOMM DC Ground DC Power Copley Controls Page 56 of 139...

- Page 57 RF emissions this diagram shows some recommended practice for cable shielding and grounding. AEV, APV V OGIC VC OM G reen ellow P C lip Spac er Equipment Ground rame G round AC Line Filter Manufacturer Part Number Schaffner FN2200-50-34 Copley Controls Page 57 of 139...

- Page 58 Shielded cable required for CE compliance CE compliance Wire Insertion/Extraction Tool Slotted screwdriver Hand-operated spring latch Power Pin Descriptions EZ Board J15 EZ Development Board J17 Signal Function Signal Function HVCOM HV COM HVCOMM HVCOM Copley Controls Page 58 of 139...

- Page 59 AEZ, APZ must be produced by power supplies 2 AEV, APV with transformer isolation from the mains, PELV or SELV ratings, and a V OGIC maximum output voltage of 60 Vdc. DC DC SGND 5VENC Copley Controls Page 59 of 139...

- Page 60 Phase U output (brush motor Phase U output (brush motor DC(+) connection) DC(+) connection) Phase V output (brush motor Phase V output (brush motor DC(-) connection) DC(-) connection) Phase W output Phase W output Copley Controls Page 60 of 139...

- Page 61 PWM outputs. P-clamps provide the best way to ground the shield for high-frequency noise suppression. Copley Controls Page 61 of 139...

- Page 62 Connectors and contacts are included in Connector Kits AEV-EZ-CK, APV-EZ-CK Connector Tools Note: This part is shown here for convenience. It is not included in connector kits, and is not sold by Copley Controls. Description Manufacturer & PN Contact Extraction tool for contacts...

- Page 63 AEZ, APZ 10 2 V I N AEV, APV rake O U T 3 V C O M SG N D The EZ brake circuit is referenced to HVCOM and SGND in the AEZ, APZ. Copley Controls Page 63 of 139...

-

Page 64: Safe Torque Off

Connectors and contacts are included in Connector Kits AEV-EZ-CK, APV-EZ-CK Connector Tools Note: This part is shown here for convenience. It is not included in connector kits, and is not sold by Copley Controls. Description Manufacturer & PN Contact Extraction tool for contacts... - Page 65 The graphic shows how the EZ Board STO inputs can be driven from 5V or 24V sources. The AEV and APV EZ Development boards have the same connections as the EZ board example shown above. Copley Controls Page 65 of 139...

- Page 66 This is a small PCB that plugs into J6. It makes connections between the STO inputs and the internal +5V that energize the inputs, disabling the STO feature. It is included in the AEV-EZ-CK and APV-EZ-CK connector kits. 5VENC SGND STO2 IN STO2 AEV-EZ-STO STO1 IN STO1 APV-EZ-STO Copley Controls Page 66 of 139...

-

Page 67: Serial Communications

Serial Cable Kit: 9-Pin Dsub receptacle to 6-pin modular adapter, plus SER-CK modular cable for EZ board SER-USB-RJ11 Serial Interface Cable: USB to RJ11 SER-CK S ERIAL ABLE IGNALS Dsub 9F Color Green Ground Black Sgnd Copley Controls Page 67 of 139... -

Page 68: Network Ports

Transmit Data1(-) ECATTX2- Transmit Data2(-) ECATRX1+ Receive Data1(+) ECATRX2+ Receive Data2(+) +3.3V_TXRX1 Terminator 1 +3.3V_TXRX2 Terminator 2 ECATRX1- Receive Data1(-) ECATRX2- Receive Data2(-) n.c. No connection n.c. No connection FGND Frame Ground FGND Frame Ground Copley Controls Page 68 of 139... - Page 69 Dual RJ-45 sockets accept standard Ethernet cables for CAN bus communications. Ports are wired pin-to-pin making the IN and OUT ports electrically identical. The last drive on a single- string network should have a 121 Ω CAN terminator in the unused port. Copley Controls Page 69 of 139...

-

Page 70: Control I/O

IN5 Motemp OUT3 Brake OUT2 SGND IN1 Enable IN7 SLI-MISO OUT5 SLI-CLK OUT4 SLI-MOSI SGND OUT1 SGND J5 P IGNALS Signal Signal Signal REFIN1+ DOUT6 REFIN1- DOUT3 DOUT2 SGND DOUT5 DOUT4 SGND DOUT1 SGND Copley Controls Page 70 of 139... - Page 71 J4 P ESCRIPTIONS EZ Boards EZ Boards Enc2 /A Enc2 /X Enc2 A Enc2 X Enc2 /B +5V ENC Enc3 B SGND J4 P IGNALS Signal Signal /ENCA2 /ENCX2 ENCA2 ENCX2 /ENCB2 +5VENC ENCB2 SGND Copley Controls Page 71 of 139...

- Page 72 IN6 & IN7 available as logic inputs. IN7 SLI-MISO 15, 17, Signal Ground SGND 5 AEV, APV EZ 2 AEV, APV I N 1 7 IN1 7 100p SGN D SGND VC3G1 Copley Controls Page 72 of 139...

- Page 73 0 100 I N 3 Direc tion SGN D EZ Boards Signal J5 Pins PWM 50% Single-Ended N.C. PWM 50% 5 AEV, APV EZ Duty 0 100 I N 3 Direc tion SGN D Copley Controls Page 73 of 139...

- Page 74 I N 5 D I ( ) EZ Boards Signal J5 Pins I N 6 D I ( ) PWM 50% SGND N.C. PWM 50% 5 AEZ, APZ Duty I N 3 P M ( ) M ( ) SGND Copley Controls Page 74 of 139...

- Page 75 EZ Board Signals J4 Pins Pulse(+) Count-Up(+) Quad A Enc2 A ENCA2 Pulse(-) Count-Up(-) /Quad A Enc2 /A /ENCA2 Dir(+) Count-Down(+) Quad B Enc2 B ENCB2 Dir(-) Count-Down(-) /Quad B Enc2 /B /ENCB2 Sgnd Copley Controls Page 75 of 139...

- Page 76 D I ( ) D I ( ) SGND SGND AEZ, APZ Input Type J4 EZ Signals J4 Pins PWM(+) Enc2 A ENCA2 PWM(-) Enc2 /A /ENCA2 Dir(+) Enc2 B ENCB2 Dir(-) Enc2 /B /ENCB2 Signal Ground Copley Controls Page 76 of 139...

- Page 77 M ulti Port ENC 2 O utput M ulti Port I nput ENC 2 M ulti Port ENC 2 O utput M ulti Port I nput 5 V output 5 0 0 mA Signal G round Copley Controls Page 77 of 139...

- Page 78 Enc /X /ENCX2 Signal Ground M ulti Port I nput ENC 2 M ulti Port ENC 2 O utput M ulti Port I nput 5 V output 5 0 0 mA Signal G round Copley Controls Page 78 of 139...

- Page 79 ATCHING AULTS EFAULT PTIONAL AULTS Short circuit (Internal or external) Over-current (Latched, I Drive over-temperature Over-voltage Motor over-temperature Under-voltage Feedback Error Motor Phasing Error Following Error Command Input Lost Motor Wiring Disconnected STO Active Copley Controls Page 79 of 139...

- Page 80 = Warning limit reached; an error counter of the CAN controller has reached or exceeded the warning level. Double Flash = Error control event. A guard event or heartbeat event has occurred = Bus off. The CAN controller is bus off. Copley Controls Page 80 of 139...

-

Page 81: Ez Board Indicators

Latching Faults (* Default) Optional Faults Short circuit (Internal or external) Over-current (Latched, I Drive over-temperature Over-voltage Motor over-temperature Under-voltage Feedback Error Motor Phasing Error Following Error Command Input Lost Motor Wiring Disconnected STO Active Copley Controls Page 81 of 139... - Page 82 = Warning limit reached; an error counter of the CAN controller has reached or exceeded the warning level. Double Flash = Error control event. A guard event or heartbeat event has occurred = Bus off. The CAN controller is bus off. Copley Controls Page 82 of 139...

- Page 83 EVELOPMENT OARD ONNECTOR OCATIONS When using the STO feature, VLOGIC must be produced by power supplies with transformer isolation from the mains, PELV or SELV ratings, and a maximum output voltage of 60 Vdc. Copley Controls Page 83 of 139...

-

Page 84: Motor Feedback

Hall U Enc B Cos(-) Hall V Enc /A Cos(+) Hall W Enc A Signal Gnd Enc /S +5Vout Enc S Motemp Signal Gnd Signal Gnd Enc /X +5Vout Signal Gnd Enc X Sin(-) Copley Controls Page 84 of 139... - Page 85 M A 3 3 6 2 1 2 1 ENC A M A 3 2 1 1 2 1 5 V E N C 1 (2 ) SG N D I N 6 M A 3 0 7 Copley Controls Page 85 of 139...

- Page 86 2 AEV, APV SDATA M A 3 3 6 2 1 2 1 SDATA M A 3 3 6 2 1 3 0 5 V E N C 1 (2 ) SG N D Copley Controls Page 86 of 139...

- Page 87 5 0 0 mA SG N D BiSS EnDat Abs-A Signal P1 Pins SDATA Data ENCA1 /SDATA /Clk /Data /ENCA1 SCLK Data ENCX1 /SCLK /Data /ENCX1 Sin(+) SIN1+ Sin(-) SIN1- Cos(+) COS1+ Cos(-) COS1- +5VENC 6, 17 Copley Controls Page 87 of 139...

- Page 88 The Absolute A interface is a serial, half-duplex type that is electrically the same as RS-485 Absolute A Encoder P1 AEZ, APZ 2 AEV, APV 1.2k D ata C m d D ata 1.2k C m d M A 3 3 6 2 SG N D Copley Controls Page 88 of 139...

- Page 89 P1 Pins Motemp [IN5] Motemp VC3G17 5,16,25, SGND SGND 100 p SGND BS 4999 Thermistor/Posistor Property Ohms Resistance in the temperature range 20°C to +70°C 60~750 Resistance at 85°C ≤1650 Resistance at 95°C ≥3 Copley Controls Page 89 of 139...

-

Page 90: Ez Development Board Pins Heatsink Mounting

Mount the heatsink onto the drive taking care to see that the holes in the heatsink, interface pad, and drive all line up. Torque the M2.5 mm mounting screws to 4 in-lb, 64 in-oz, 0.45 Nm. Copley Controls Page 90 of 139... -

Page 91: Safe Torque Off (Sto) - Use, Connections And Wiring

The equipment manufacturer must take into account all the aspects of the system in which the AEV & APV drives are components. Copley Controls does not accept any liability for direct or indirect injury or damage caused by the use of information in this document. The equipment manufacturer is always responsible for the safety of its product and its suitability under applicable laws. - Page 92 De-Energize – This term refers to the application of voltage less than or equal to the maximum rated de-energize threshold voltage to an individual STO input. Note that de-energizing an STO input results in the STO function being activated AEV-APV UserBoard External STO Muting AEV-APV UserBoard External STO Muting Copley Controls Page 92 of 139...

-

Page 93: Sto Reference Standards

Part 5-2: Safety requirements – Functional IEC 60664-1 Product Safety Considerations for Insulation Coordination of Low-Voltage Equipment Table F.2 Clearances to Withstand Transient Overvoltages IEC 62061 Functional safety of safety-related electrical, electronic and programmable electronic control systems Copley Controls Page 93 of 139... -

Page 94: Sto Architecture And Function

+60 Vdc in a fault condition. Therefore a constraint on the larger system is that the power supply used to energize the STO inputs must be an SELV or PELV type. Copley Controls Page 94 of 139... -

Page 95: Sto Channel Operation

1 = Voltage applied to the STO input is greater than or equal to the rated minimum energize level. A motion control system design for Cat. 3 PL e, and/or SIL 3 rating must use 2 channels for the STO function. Copley Controls Page 95 of 139... -

Page 96: Sto Function Specifications

(AEZ,APZ) Response Time rom Vin ≤ 2.0 Vdc or open to P M outputs disabled (off): ≤ 1.5 ms Type Opto-isolators, +5 VDC compatible Maximum cable length 30 m (98.4 ft) Copley Controls Page 96 of 139... -

Page 97: Environmental Specifications

ISO 13849-2, IEC 61800-5-2. Electrical Safety Directive 2014/35/EU – Low Voltage, UL 61800-5-1:2016 Machinery Directive 2006/42/EC Directive 2014/30/EU IEC 61800-3:2017, Category C3 Markings Label is visible on PC board Hazardous Lead free and RoHS compliant Substances Copley Controls Page 97 of 139... -

Page 98: Limitations And Necessary Risk Reductions

AC mains that meets the requirements for reinforced or double insulation. If the drive +HV can be 60 Vdc or less, then the VLOGIC and +HV can be driven from a single SELV or PELV type source. Copley Controls Page 98 of 139... - Page 99 Connections to the STO inputs must provide spacing that is greater than the minimum creepage and clearance of 1.24 mm. that is required for fault exclusion when considering the FMEDA (Failure Modes, Effects, and Diagnostic Analysis) of the system. Copley Controls Page 99 of 139...

- Page 100 5 seconds until the test passes on STO1 and STO2 input channels. The following figure is intended as a visualization of the internal diagnostics testing. Copley Controls Page 100 of 139...

-

Page 101: Pc Board Design For Sto

Creepage and clearance based on standard IEC 60664-1 • Dominant requirement: Fault Exclusion against short circuits. Creepage & Description Clearance Between adjacent STO circuits 0.200 mm Between STO circuits and control circuits 0.500 mm Between STO circuits and chassis 0.200 mm Copley Controls Page 101 of 139... -

Page 102: Installation Overview

This graphic shows the elements of a complete AEV & APV drive installation. The STO feature and interface to the machine-level functional safety equipment are highlighted in red to emphasize the aspects of the installation that are addressed in this manual. Copley Controls Page 102 of 139... - Page 103 STO-IN1 OR STO-IN2 Open STO Status A digital output can be programmed to be active when the drive is disabled by the STO function. The active level of the output is programmable to be HI or LO. Copley Controls Page 103 of 139...

-

Page 104: Sto: Installation For Aev & Apv Modules

Driving the STO inputs in series would require a higher voltage than the nominal +24 Vdc, and if one of the STO inputs or its wiring were to fail as a short-circuit, it would apply the full DC power to a single input. Copley Controls Page 104 of 139... - Page 105 Resistor, 2.2 k, 2 W, 1% RHC2512FT2K20 Stackpole Electronics Important: The locations of the Zener diodes for the IN1 channel are different than the locations of the diodes for the STO-IN1 and STO-IN2 channels. Copley Controls Page 105 of 139...

- Page 106 Stop button is pressed in, this is the time delay to the K3~K4 contact opening which will activate the STO (3). STO response time. This is the time between the de-energizing of the drive STO inputs (K3~K4 contacts open) and the entry into the safe-state. Copley Controls Page 106 of 139...

- Page 107 [ ] That the motor and associated load is free to move. [ ] That any other safety measures or warnings needed to ensure safe execution of periodic tests are in place Copley Controls Page 107 of 139...

- Page 108 (these depend on the drive’s control mode settings). Try to start the drive. Ensure that the motor stays at a standstill. Then, energize the STO-IN2 circuit Restart the drive and ensure that the drive and motor operate normally. Copley Controls Page 108 of 139...

- Page 109 The drive cannot be hardware-enabled until all inputs programmed as Enable inputs are true AND the bits 0 AND bit 1 in the STO function status parameter (0x219D) are zero. Copley Controls Page 109 of 139...

-

Page 110: Sto: Installation For Aez & Apz Models

STO IN1( ) STO IN1( ) Circuits 12. k STO IN2( ) 2 V 5.1V Channel 2 STO IN2 STO IN2( ) 2.2k 6.2V STO TN2 STO IN2( ) unctional Safety Circuit oundary Copley Controls Page 110 of 139... - Page 111 There are no user-replaceable parts in the AEV & APV. The warranty will be void if the user attempts any repairs. For safety and to assure compliance with documented system data, only Copley Controls shall perform repairs to the AEV & APV.

- Page 112 Evaluate the impact of decommissioning on adjacent operating units and facilities or other field services. Conduct a proper review and obtain required authorization. Ensure that the safety functions remain appropriate during decommissioning activities. Implement appropriate change management procedures for all decommissioning activities. Copley Controls Page 112 of 139...

-

Page 113: Operational Theory

60 Vdc. +HV P OWER The +HV input drives the high-voltage PWM outputs. When this is not connected to the VLOGIC input, the full range of rated voltages can be used. Copley Controls Page 113 of 139... -

Page 114: Commutation Modes

Over CANopen, one drive produces a Sync message that carries a high-resolution time-stamp. The other drives on the network receive the Sync message and adjust their internal clocks so that all of the drives on the network have their PWM frequencies synchronized. Copley Controls Page 114 of 139... -

Page 115: Input Command Types

For instance, with a dead band of 100 mV, the drive ignores signals between –100 mV and +100 mV, and treats 101 mV as 1 mV, 200 mV as 100 mV, and so on. Dead Band -100 -200 -200 -100 Input Copley Controls Page 115 of 139... - Page 116 To use the analog position command as an absolute position command, the drive must be homed every time it is enabled. The Homing sequence may be initiated by CAN, ASCII serial, CVM or CPL Indexer program commands. Copley Controls Page 116 of 139...

- Page 117 This prevents the 0% or 100% commands that would result from a controller failure or a cable break which could result in the input pulled up to +5V or pulled-down to Signal Ground (0V). Copley Controls Page 117 of 139...

- Page 118 Pulse Input Direction Input Velocity Command The drive can be set to increment position on the rising or falling edge of the signal. Stepping resolution can be programmed for electronic gearing. Copley Controls Page 118 of 139...

- Page 119 In quadrature format, A/B quadrature commands from a master encoder (via two inputs) provide velocity and direction commands, as shown below. A Input B Input Velocity Command The ratio can be programmed for electronic gearing. Copley Controls Page 119 of 139...

-

Page 120: Communications

CANopen network. CAN communications are described in the next section. RS-232 Serial The RS-232 port is a three-wire, DTE, full-duplex port. Control commands can be sent over the RS-232 port using Copley Controls ASCII interface commands. In addition, CME software communicates with the drive (using a binary protocol) over this link for drive commissioning, adjustments, and diagnostics. - Page 121 The fixed address and station alias are always available. If the switch-based station alias is used, it is the responsibility of the user to ensure that each drive has a unique station alias. Copley Controls Page 121 of 139...

- Page 122 The drive then uses cubic polynomial interpolation to “connect the dots” so that the motor reaches each point at the specified velocity at the programmed time. Copley Controls Page 122 of 139...

- Page 123 Programmed value in Program the address into flash only. flash memory For more information on CAN addressing, see the CME User Guide. For more information on CANopen operations, see the following Copley Controls documents: • CANopen Programmer’s Manual • CML Reference Manual •...

-

Page 124: Brake Operation

PWM Delay Brake/Stop Response Time count begins. hen response time has passed, the drive’s output stages are disabled. This delay ensures the brake has time to lock in before disabling the power section. Copley Controls Page 124 of 139... - Page 125 When the value is negative, the brake is released immediately when the drive is enabled and the PWM outputs are enabled after the programmable delay expires. The graphic below is not part of CME, but shows the timings in the same colors as the Brake setting screen. Copley Controls Page 125 of 139...

-

Page 126: Protection

When using non- DANGER latched faults, be sure to safeguard against unexpected motion. Failure to heed this warning can cause equipment damage, injury, or death. Copley Controls Page 126 of 139... - Page 127 If current is not detected, it is a fault. released to stop the motor. Over Current Optional: The I2T current-limit for the drive Reduce drive current (Latched) has been reached * Configured as latching by default. Programmable to be non-latching. Copley Controls Page 127 of 139...

-

Page 128: Position And Velocity Errors

If the drive is receiving position commands from the digital or differential inputs, then the drive must be disabled and then re-enabled using the drive’s enable input or though software commands. After re-enabling, the drive will operate normally. Copley Controls Page 128 of 139... - Page 129 The bit is not reset until the error remains within the tracking window for the programmed tracking time. ELOCITY RACKING LLUSTRATION The following diagram illustrates the use of tracking window and time settings in velocity mode. Actual Velocity Limited Velocity ± Tracking Window Tracking Time Tracking Window Output Copley Controls Page 129 of 139...

-

Page 130: Digital Inputs

CAUTION: If the drive is switched back to current or velocity mode with this option selected, the limit switches will no longer function. For more information on *Hold position when limit switch is active, see the CME User Guide. Copley Controls Page 130 of 139... -

Page 131: Analog Inputs

Brake connector. A flyback diode is connected between the drain of the MOSFET and +24V Input pin of the Brake connector. This provides an internal flyback diode for motor brakes. The brake output (OUT3) is described in Brake Operation Copley Controls Page 131 of 139... -

Page 132: Appendix

Continuous Current Limit if the commanded current is greater than the Continuous Current Limit. If instead the commanded current is less than or equal to the Continuous Current Limit, the output current will be equal to the commanded current. Copley Controls Page 132 of 139... - Page 133 The actual output current follows the current command until the I T Accumulator Variable value reaches the I setpoint and current limiting is invoked. Copley Controls Page 133 of 139...

-

Page 134: A: Connecting Aez/Apz For Serial Control

RS-232 CAN Network Cable UTP CAT.5E Gigabit Ethernet RJ45 RJ45 RJ45 RJ45 CAN Port CAN Port CAN Port ADDR ADDR ADDR RJ45 RJ45 ADDRESSES MUST BE 120 Ohm SET BEFORE POWER-UP Terminator OR RESET. Copley Controls Page 134 of 139... -

Page 135: B: Ordering Guide And Accessories

AEV-THK Heatsink kit (Tall Pins heatsink, thermal pad, and hardware) SER-CK Serial Cable Kit: 9-Pin Dsub receptacle to 6-pin modular adapter, plus modular cable for EZ board SER-USB-RJ11 Serial Interface Cable: USB to RJ11 Copley Controls Page 135 of 139... - Page 136 APV-THK Heatsink kit (Tall Pins heatsink, thermal pad, and hardware) SER-CK Serial Cable Kit: 9-Pin Dsub receptacle to 6-pin modular adapter, plus modular cable for EZ board SER-USB-RJ11 Serial Interface Cable: USB to RJ11 Copley Controls Page 136 of 139...

- Page 137 AEV-THK Heatsink kit (Tall Pins heatsink, thermal pad, and hardware) SER-CK Serial cable kit: 9-Pin Dsub receptacle to 6-pin modular adapter, plus modular cable for EZ board SER-USB-RJ11 Serial Interface Cable: USB to RJ11 Copley Controls Page 137 of 139...

- Page 138 Model Description Screw, M2.5 x 40 mm Philips head screw Nut, M2.5-0.45 DIN Zinc Plated Nylon Insert Lock Nut AEV-THK Thermal material APV-THK Copley non-threaded spacers, 20.5 mm Tall Pins Heatsink, 2 inch tall Copley Controls Page 138 of 139...

- Page 139 Accelnet Plus Micro Modules User Guide 16-01687 Rev 03 Accelnet Plus Micro Modules User Guide P/N: 16-01687 Revision 03 October 21, 2020 Copley Controls Analogic Motion Controls 20 Dan Road Canton, MA 02021 USA All rights reserved © 2020 Copley Controls...

Need help?

Do you have a question about the Accelnet Plus AEV-090-14 and is the answer not in the manual?

Questions and answers