Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Spectrum Controls SLC 500

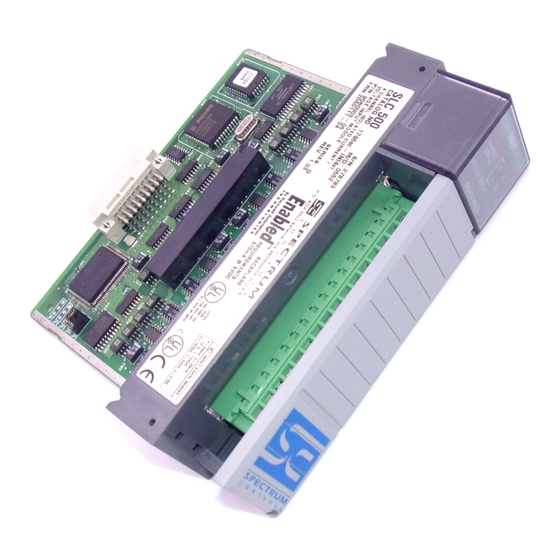

- Page 1 User’s Manual Pub. 0300128-04 Rev. A...

-

Page 2: Important Notes

No patent liability is assumed by Spectrum Controls, Inc. with respect to the use of any of the information, products, circuits, programming, or services referenced herein. -

Page 3: Table Of Contents

Table of Contents IMPORTANT NOTES ............................... II CHAPTER 1 MODULE OVERVIEW ......................... 1-1 1.1 G ......................1-1 ECTION ENERAL EATURES ENEFITS 1.2 D .......................... 1-2 ECTION ETAILED PECIFICATIONS 1.3 R ........................1-5 ECTION EGULATORY EQUIREMENTS CHAPTER 2 INSTALLATION AND WIRING ......................2-1 2.1 P ...................... - Page 4 SLC 500™ Isolated Analog Input Modules 6.1 I ......................... 6-1 ECTION NSPECTING ODULE 6.2 D ......................... 6-1 ISCONNECTING RIME ECTION OVERS 6.3 P ............................6-2 ECTION OWERING 6.4 I LED I ......................6-2 ECTION NTERPRETING THE NDICATORS 6.5 I I/O E .......................

- Page 5 Use this guide if you design, install, program, or maintain a control system that uses Allen-Bradley Small Logic Controllers. You should have a basic understanding of SLC 500 products. You should also understand electronic process control, and the ladder program instructions required to generate the electronic signals that control your application.

- Page 6 SLC 500™ Isolated Analog Input Modules Allen-Bradley Refer to this Document Pub. No. Allen-Bradley Advanced Programming 1747-6.11 Software (APS) Reference Manual Getting Started Guide for Advanced 1747-6.3 Programming Software (APS) SLC 500 Software Programmers’ Quick ABT-1747-TSG001 Reference Guide Allen-Bradley HHT (Hand-Held...

- Page 7 SLC 500™ Isolated Analog Input Modules Actions ou situations risquant d’entraîner des blessures pouvant être ATTENTION mortelles, des dégâts matériels ou des pertes financières. Les messages « Attention » vous aident à identifier un danger, à éviter ce danger et en discerner les conséquences.

- Page 8 SLC 500™ Isolated Analog Input Modules User’s Manual Pub. 0300128-04 Rev. A...

-

Page 9: Chapter 1 Module Overview

Chapter 1 Module Overview The 1746sc-INI4i monitors up to 4 isolated analog current inputs, while the 1746sc-INI4vi monitors up to 4 isolated analog current or voltage inputs (selectable by channel). In both modules, you can select different input ranges (for example, 4–20 mA or 1–5 Vdc) independently, by channel, for optimal use of rack space. -

Page 10: Section 1.2 Detailed Specifications

Chapter 1: Module Overview consuming task. These modules incorporate proprietary Allen-Bradley technology, so they operate and perform like the latest high-performance Allen-Bradley products for full compatibility. Four selectable filter frequencies are provided for signal/noise optimization. For even greater convenience, they are fully configured through software (no DIP switches), can alert the processor to a variety of errors through status bits, and can scale input signals to user-defined ranges without any ladder programming. - Page 11 Chapter 1: Module Overview Table 1-2. Electrical Specifications-Inputs Description Specification Input Current Ranges 4 to 20 mA (selectable for each channel) 0 to 20 mA Input Voltage Ranges‒INI4vi only -10 to +10 VDC (selectable for each channel) 0 to 10 VDC 0 to 5 VDC 1 to 5 VDC SLC Communication Formats...

- Page 12 Chapter 1: Module Overview Description Specification Overall Drift Current Inputs Offset: ±539 nA/°C Gain: ±50.5 ppm/°C Voltage Inputs-INI4vi only Offset: ±352 µV/°C Gain: 34.8 ppm/°C Table 1-3. Physical Specifications Description Specification LED Indicators Four green channel status indicators, one for each channel One green module status indicator Belden 8761 (shielded, twisted-pair) or...

-

Page 13: Section 1.3 Regulatory Requirements

Chapter 1: Module Overview Section 1.3 Regulatory Requirements Compliance Industry Standards Standards UL 61010-2-201 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use - Part 2-201: Particular Requirements for Control Equipment (NRAQ, NRAQ7) UL Safety CAN/CSA C22.2 No. 61010-1-12 (Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use –... - Page 14 Chapter 1: Module Overview User’s Manual Pub. 0300128-04 Rev. A...

-

Page 15: Chapter 2 Installation And Wiring

Chapter 2 Installation and Wiring This chapter will cover: • Avoiding electrostatic damage. • Determining power requirements. • Selecting a rack slot. • Inserting your module into the rack. • Wiring your module. Although your module has a jumper on its printed circuit board, this NOTE jumper is for the manufacturer’s use only. -

Page 16: Section 2.1 Prevent Electrostatic Discharge

Chapter 2: Installation and Wiring Industrial and Commercial Power Systems. Noise Reduction Techniques in Electronic Systems, by Henry W. Ott; • published by Wiley-Interscience of New York in 1976. Section 2.1 Prevent Electrostatic Discharge Electrostatic discharge can damage integrated circuits or semiconductors if WARNING you touch analog module card bus connector pins or the terminal block on the module. -

Page 17: Power Requirements

Chapter 2: Installation and Wiring 201: Particular Requirements for Control Equipment. For specific information required by EN 61010-2-201, see the appropriate sections in this publication, as well as the following Allen-Bradley publications: Industrial Automation Wiring and Grounding Guidelines For Noise •... -

Page 18: Section 2.7 Inserting Your Module Into The Rack

WARNING Before installing or removing your module, always disconnect power from the SLC 500 system and from any other source to the module (in other words, do not “hot swap” your module), and disconnect any devices wired to the module. -

Page 19: Section 2.8 Wiring Your Module

Chapter 2: Installation and Wiring To remove the terminal block, unscrew the two retaining screws at the top and bottom of the terminal block, and using a screwdriver or needle-nose pliers, carefully pry the terminal block loose. To insert your module into the rack, follow these steps: 1. - Page 20 Before wiring the terminal block, take some time to plan your system: • Ensure that the SLC 500 system is installed in a NEMA-rated enclosure and that the SLC 500 system is properly grounded. • Ensure that the load resistance for a current output channel is less than 500 Ω.

- Page 21 Chapter 2: Installation and Wiring the cable and apply shrink wrap. 6. Connect the wires to the terminal block and field device as shown in the following figures and table. The recommended maximum torque is 5 in- lb. (0.565 Nm) for all terminal screws. 7.

- Page 22 Chapter 2: Installation and Wiring Figure 2-2. Wiring Diagrams (Showing Differential Inputs) User’s Manual Pub. 0300128-04 Rev. A...

-

Page 23: Chapter 3 Configuring The 1746Sc-Ini4I

Chapter 3 Configuring the 1746sc- INI4I This chapter covers the following subjects: How the processor communicates with your module. • The difference between channel update time and step response time. • Selecting an input filter frequency. • Auto-calibration time. • Channel enable and disable times. -

Page 24: Output Image-Configuration & User-Defined Scale Limits

Chapter 3: Configuring the 1746sc-INI4I O:4.2. Alternatively, if you want to obtain the status of channel 2, you would check the status word at address I:4.6. The output and input image are described below. Output Image—Configuration & User-Defined Scale Limits The 8-word, output image (defined as the output from the SLC processor to your module) defines how each channel on your module works: The configuration words replace configuration DIP switches on your... -

Page 25: Section 3.3 Selecting A N Input Filter Frequency

Chapter 3: Configuring the 1746sc-INI4I Figure 3-2.. Channel Update Time and Full-scale Step Response Time The actual channel update time and full-scale step response time depend on a number of things, such as the filter frequency selected. Because of this, the number of channel updates than can occur before the channel data word reaches 95% of its expected value can vary. - Page 26 Chapter 3: Configuring the 1746sc-INI4I time, as shown in the following tables. Table 3-1. Cutoff Frequency, Step Response Time, and Effective Resolution (Based on Filter Frequency) Worst-Case Effective Resolution Filter 3dB Cutoff Full-Scale Voltage Current Step Mode Mode Response 50 Hz 13.1 Hz 80 ms 12 bits...

- Page 27 Chapter 3: Configuring the 1746sc-INI4I Figure 3-3. Signal Attenuation with 50 Hz Input Filter Figure 3-4. Signal Attenuation with 60 Hz Input Filter User’s Manual Pub. 0300266-04 Rev. A...

-

Page 28: Section 3.4 Auto-Calibration Time

Chapter 3: Configuring the 1746sc-INI4I Figure 3-5. Signal Attenuation with 250 Hz Input Filter Figure 3-6. Signal Attenuation with 500 Hz Input Filter Section 3.4 Auto-Calibration Time Your module requires some time to auto-calibrate a channel. During this time, your module cannot sample and convert input signals. The following table shows the time required for auto-calibration. -

Page 29: Section 3.5 Channel Enable And Disable Times

Chapter 3: Configuring the 1746sc-INI4I Table 3-3. Auto-calibration Time Per Channel (Based on Filter Frequency) Filter Frequency 50 Hz 60 Hz 250 Hz 500 Hz Current 182 ms 152 ms 39 ms 19.6 ms Input Voltage 508 ms 430 ms 108 ms 56 ms Input (-... - Page 30 Chapter 3: Configuring the 1746sc-INI4I User’s Manual Pub. 0300128-04 Rev. A...

-

Page 31: Chapter 4 Using Your Input Module

Chapter 4 Using Your Input Module This chapter provides information about: • Entering your input module’s ID code. • Configuring each input channel. • Setting the user-defined scale limits (optional). • Monitoring each input channel. • Checking each input channel’s configuration and status. To use your module, you need: Programming equipment, such as an Allen-Bradley Hand-Held Terminal •... - Page 32 Chapter 4: Using Your Input Module Important - After reconfiguring a channel, you must toggle the channel NOTE enable bit (configuration bit 0) in order for your module to use the new configuration. User’s Manual Pub. 0300128-04 Rev. A...

-

Page 33: Input Channel Enable (Configuration Bit 0)

Chapter 5: Programming Examples A detailed explanation appears in the following table: Table 4-1. Input Channel Configuration Word (O:e.0 through O:e.3) Input Channel Enable (configuration bit 0) Use this bit to enable or disable a channel. To minimize update times, disable any unused channels. -

Page 34: Input Range (Configuration Bits 1-3)

Chapter 4: Using Your Input Module Input Range (configuration bits 1–3) Use this bit field to configure the channel for the type of input device you want to connect to your module. Data Format (configuration bits 4–6) Use this bit field to select one of the following formats: Engineering units (mV or nA). -

Page 35: Open Input Circuit Response (Configuration Bits 7 And 8)

Chapter 5: Programming Examples Selected Actual Signal Limits Count Limits Data Format Input Min. Max. Min. Max. Range 0–20 mA 0 mA +20 mA +16384 4–20 mA +4 mA +20 mA +3277 +16384 See note ➁. User-defined ±10 V -10.25 V +10.25 V scale A (and 0–10 V... -

Page 36: Auto-Calibration Enable (Configuration Bit 11)

Chapter 4: Using Your Input Module • A higher filter frequency decreases the update time, but it also decreases the noise rejection and effective resolution. Refer to Chapter 3, Items To Consider Before Using Your Module, for more information on selecting a filter frequency. Auto-Calibration Enable (configuration bit 11) Use this bit to enable or disable auto-calibration. - Page 37 Chapter 5: Programming Examples Important - The following equations show you how to convert user-defined scale units (or any type of units) to engineering units, and vice versa: S = {(U – U ) × (∆S) ÷ (∆U)} + S D = {(S - S (∆U) ÷...

-

Page 38: Section 4.4 Monitoring Each Input Channel

Chapter 4: Using Your Input Module Section 4.4 Monitoring Each Input Channel The input signal data resides in words 0 through 3 of the input image file (addresses I:e.0 through I:e.3). The values present depend on the input types and data formats selected. - Page 39 Chapter 5: Programming Examples Table 4-3. Input channel status word (I:e.4 through I:e.7) These bit settings in the status word 15 14 13 12 11 10 9 Indicate this Input channel disabled Input channel enabled ±10 Vdc input range 1–5 Vdc input range 0–5 Vdc input range 0–10 Vdc input range 0–20 mA input range...

-

Page 40: Over-Range Error (Status Bit 12)

You may be able to recover from this type of error by resetting the SLC 500 processor or cycling power to your module. User’s Manual Pub. 0300128-04 Rev. A... -

Page 41: Chapter 5 Programming Examples

Chapter 5 Programming Examples Read this chapter to familiarize yourself with how to use the advanced features of your module for: PID control • User-defined scaling • For information on how to use the Allen-Bradley Advanced Programming Software (APS) to create ladder programs, see the Getting Started Guide For APS. - Page 42 Chapter 5: Programming Examples Figure 5-2. Programming for PID Control Example Figure 5-2. Data Table for PID Control IMPORTANT: When using your module’s Scaled For PID data format NOTE with the SLC PID function, ensure that the Maximum Scaled S (word7) and Minimum Scaled S (word 8) PID instruction parameters match your module’s maximum and minimum scaled range in...

-

Page 43: Section 5.2 User -Defined Scaling

Chapter 5: Programming Examples Section 5.2 User-Defined Scaling Your input module was designed to work directly with applications requiring special data scaling—without an intermediate scaling operation. Example. Suppose your input module is in slot 3, and you have a pressure sensor with a 4–20 mA range connected to channel 0. - Page 44 Chapter 5: Programming Examples User’s Manual Pub. 0300128-04 Rev. A...

-

Page 45: Chapter 6 Testing Your Module

• Interpreting I/O error codes. • • Troubleshooting. Before testing your module, test your SLC 500 system using the procedures described in your Allen-Bradley system Installation & Operation Manual. Section 6.1 Inspecting Your Module You can prevent many potential problems by simply inspecting your analog module: 1. -

Page 46: Section 6.4 Interpreting The Led Indicators

Discontinue testing until you can get the LED to illuminate. The most probable reasons for the LED not illuminating are: The SLC 500 system is not receiving power from its power supply. • The rest of the SLC 500 system is not receiving power. -

Page 47: Section 6.5 Interpreting I/O Error Codes

Either the power is off, the module is powering up, or a module fault occurred. Cycle power. If the condition persists, call your local distributor or Spectrum Controls for assistance. Section 6.5 Interpreting I/O Error Codes I/O error codes appear in word S:6 of the SLC processor status file. The first two digits of the error code identify the slot (in hexadecimal) with the error. -

Page 48: Section 6.6 Troubleshooting

Chapter 6: Testing Your Module Section 6.6 Troubleshooting Figure 6-2. Problem Resolution Flowchart User’s Manual Pub. 0300128-04 Rev. A... -

Page 49: Chapter 7 Maintaining Your Module And Ensuring Safety

The printed circuit boards of your module must be protected from dirt, oil, moisture, and other airborne contaminants. To protect these boards, install the SLC 500 system in an enclosure suitable for its operating environment. Keep the interior of the enclosure clean, and whenever possible, keep the enclosure door closed. -

Page 50: Section 7.3 Getting Technical Assistance

Controls Inc., please ensure that the unit is enclosed in approved ESD packaging (such as static-shielding/metallized bag or black conductive container). Spectrum Controls, Inc. reserves the right to void the warranty on any unit that is improperly packaged for shipment. - Page 51 Chapter 8 Verifying Calibration Read this chapter to verify your module’s calibration. To verify your module’s calibration, you need: A precision input source whose accuracy is better than or equal to ±1 mV • on a 10 V scale and 0.5 A on a 20 mA scale (such as an Electronic Development Corporation Programmable IEEE 488 GP-IB DC Calibrator, Model 521).

-

Page 52: Chapter 8 Verifying Calibration

5. Repeat steps 3 and 4 for each remaining channel. Section 8.4 Service If the input data is out of range, call the Spectrum Controls Technical Services to make arrangements for returning your module for factory calibration. User’s Manual Pub. 0300128-04 Rev. A... -

Page 53: Index

Index Input Type · 1-1 Add-On-Profile · 3-8 LED · 1-4 Low Voltage Directive · 2-1 block diagram · 1-6 Module Configuration · 3-10 Mounting · 2-4 Conventions used in the manual · v Noise · 2-3, 2-8 EMC Directive · 2-1 Power Requirements ·... - Page 54 User’s Manual Pub. 0300128-04 Rev. A...

- Page 55 User’s Manual Pub. 0300266-04 Rev. A...

- Page 56 ©1997-2021, Spectrum Controls, Inc. All rights reserved. Specifications subject to change without notice. The Encompass logo and SLC 500 are trademarks of Rockwell Automation. Corporate Headquarters Spectrum Controls Inc. 1705 132nd Avenue NE, Bellevue, WA 98005 USA Fax: 425-641-9473 Tel: 425-746-9481 Web Site: www.spectrumcontrols.com...

Need help?

Do you have a question about the SLC 500 and is the answer not in the manual?

Questions and answers