Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Spectrum Controls SLC 500

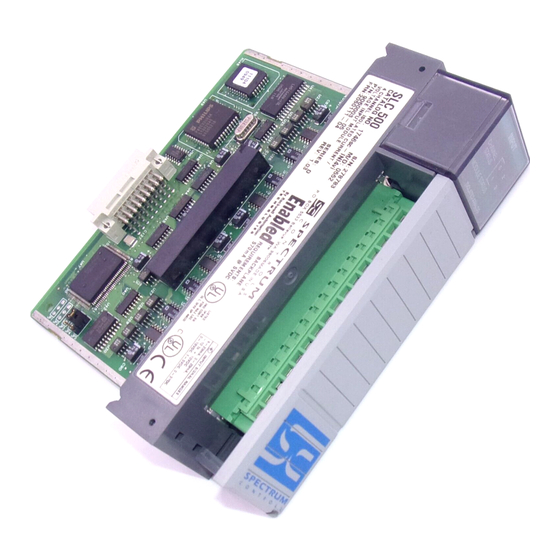

- Page 1 User’s Manual Pub. 0300181-07 Rev. A...

-

Page 2: Important Notes

No patent liability is assumed by Spectrum Controls, Inc. with respect to the use of any of the information, products, circuits, programming, or services referenced herein. -

Page 3: Table Of Contents

SLC 500™ 50 kHz Counter/Flowmeter Input Module Table of Contents IMPORTANT NOTES ............................... II MODULE OVERVIEW ......................... 1-1 1.1 G ......................1-1 ECTION ENERAL EATURES ENEFITS 1.2 I ....................... 1-2 ECTION NCREASED CCURACY AND ELIABILITY 1.3 R ........................... 1-2 ECTION... - Page 4 SLC 500™ 50 kHz Counter/Flowmeter Input Module ......................6-1 ISCONNECTING RIME OVERS ........................... 6-2 OWERING LED I ...................... 6-2 NTERPRETING NDICATORS .............................. 6-3 ODES ............................6-4 IGNAL ..........................6-4 ROUBLESHOOTING CHAPTER 7 MAINTAINING YOUR MODULE AND ENSURING SAFETY ..............7-1 ........................

- Page 5 Use this guide if you design, install, program, or maintain a control system that uses Allen-Bradley Small Logic Controllers. You should have a basic understanding of SLC 500 products. You should also understand electronic process control, and the ladder program instructions required to generate the electronic signals that control your application.

- Page 6 SLC 500™ 50 kHz Counter/Flowmeter Input Module Allen-Bradley Refer to this Document Pub. No. Allen-Bradley Advanced Programming 1747-6.11 Software (APS) Reference Manual Getting Started Guide for Advanced 1747-6.3 Programming Software (APS) SLC 500 Software Programmers’ Quick ABT-1747-TSG001 Reference Guide Allen-Bradley HHT (Hand-Held...

- Page 7 SLC 500™ 50 kHz Counter/Flowmeter Input Module Actions ou situations risquant d’entraîner des blessures pouvant être ATTENTION mortelles, des dégâts matériels ou des pertes financières. Les messages « Attention » vous aident à identifier un danger, à éviter ce danger et en discerner les conséquences.

- Page 8 SLC 500™ 50 kHz Counter/Flowmeter Input Module User’s Manual Pub. 0300181-07 Rev. A...

-

Page 9: Module Overview

Module Overview The 1746sc-CTR4 and the 1746sc-CTR8 are 4 and 8 channel Counter/ Flow Meter modules. The modules are suitable for general purpose counter and flow meter applications that require a large number of input channels and high accuracy. The module supports both AC and DC input signal types. The counter functions include programmable control of the counter including start, stop, reset, preset control and user defined flags. -

Page 10: Section 1.2 Increased Accuracy And Reliability

Chapter 1: Module Overview • Input voltage ranges: AC (50mv–75V peak), 5 Vdc, 12 Vdc, 24 Vdc. • Input frequency: AC 50 kHz Max, DC 50 kHz Max. • Maximum count value: ±32 K or ±8 M. • Programmable Scaling, K, M, R Factor. •... -

Page 11: Section 1.5 Detailed Specifications

Chapter 1: Module Overview Section 1.5 Detailed Specifications Table 1-1. Thermocouple Temperature Ranges Specification Description Configuration 4/8 Channel of differential counter inputs 2/4 Channels of quadrature encoding 2/4 Input enable Control lines Input Modes DC counter, AC flow meter Voltage Range AC 0-30 VP 5 VDC 12 VDC... - Page 12 Chapter 1: Module Overview Specification Description Accuracy: Count mode ± 1 Count Rate (Instant) ± 1% at 50 kHz, .001% at 1 Hz Rate (Average) ± 1 Hz Maximum Count Value Low Range -32,768 to +32,767 High Range -8,388,608 to +8,388,607 Fault detection Over and under range status bits, for all modes.

-

Page 13: Section 1.6 Regulatory Requirements

Section 1.7 System Overview The module communicates with the SLC 500 processor and receives +5 VDC and +24 VDC power from the system power supply through the parallel backplane interface. No external power supply is required. You may install as many modules in the system as the power supply can support. -

Page 14: Section 1.9 Module Operation

Chapter 1: Module Overview Section 1.9 Module Operation The module’s input circuitry consists of four or eight single ended inputs. Inputs are expected to be digital, but are built using comparators, so can operate with analog signals. Hysteresis is built into the level detection circuit, so even very slowly varying inputs can be digitized. -

Page 15: Installation And Wiring

Installation and Wiring This chapter will cover: • Avoiding electrostatic damage. • Determining power requirements. • Selecting a rack slot. • Inserting your module into the rack. • Wiring your module. Although your module has a jumper on its printed circuit board, this NOTE jumper is for the manufacturer’s use only. -

Page 16: Section 2.1 Prevent Electrostatic Discharge

Chapter 2: Installation and Wiring Industrial and Commercial Power Systems Noise Reduction Techniques in Electronic Systems, by Henry W. Ott; • published by Wiley-Interscience of New York in 1976 Section 2.1 Prevent Electrostatic Discharge Electrostatic discharge can damage integrated circuits or semiconductors if WARNING you touch analog module card bus connector pins or the terminal block on the module. -

Page 17: Section 2.4 Selecting A Rack Slot

WARNING Before installing or removing your module, always disconnect power from the SLC 500 system and from any other source to the module (in other words, do not “hot swap” your module), and disconnect any devices wired to the module. - Page 18 Chapter 2: Installation and Wiring When inserting your module into the rack, you do not need to remove the supplied terminal block from the module. If, however, you do remove the terminal block, apply the supplied write-on label to the terminal block, and use the write-on label to identify your module’s location and type: To remove the terminal block, unscrew the two retaining screws at the top and bottom of the terminal block, and using a screwdriver or needle-nose pliers,...

-

Page 19: Section 2.7 Wiring Your Module

Chapter 2: Installation and Wiring To insert your module into the rack, follow these steps: 1. Align the circuit board of your module with the card guides at the top and bottom of the chassis. Figure 2-1. Module Insertion into a Rack 2. - Page 20 Peripheral equipment must be suitable for the location in which it is • used. Ensure that the SLC 500 system is installed in a NEMA-rated enclosure • and that the SLC 500 system is properly grounded. • Route the field wiring away from any other wiring and as far as possible from sources of electrical noise, such as motors, transformers, contactors, and AC devices.

-

Page 21: Section 2.8 Preparing And Wiring Cables

Chapter 2: Installation and Wiring Section 2.8 Preparing and Wiring Cables To prepare and connect cable leads and drain wires, follow these steps: 1. Determine the length of cable you need to connect a channel to its field device. Remember to include additional cable to route the drain wire and foil shield to their ground points. - Page 22 Chapter 2: Installation and Wiring Figure 2-2. Ferrite EMI suppressor for CE compliance 9. A system may malfunction due to a change in its operating environment. After installing and wiring your module, check system operation. See the Allen-Bradley system Installation and Operation Manual for more information.

-

Page 23: Block

Chapter 2: Installation and Wiring IMPORTANT: Channels 4-7 are only available on the 1746sc-CTR8 NOTE module. IMPORTANT: A pull-up resistor may be necessary for open collector NOTE inputs. Refer to Chapter 6 for additional information. Section 2.9 Labeling and Re-Installing the Terminal Block The supplied label is mounted on the module door. - Page 24 2-10 Chapter 2: Installation and Wiring User’s Manual Pub. 0300181-07 Rev. A...

-

Page 25: Configuring The 1746Sc-Ctr4/Ctr8

Configuring the 1746sc- CTR4/CTR8 This chapter explains how the module and the SLC processor communicate through the processor’s I/O image tables. It also describes the module’s input filter characteristics. Topics discussed include: Module ID code. • Module addressing. • Operating modes. •... - Page 26 Chapter 3: Configuring the 1746sc-CTR4/CTR8 Figure 3-1. Image Table Output Image - Configuration Words Thirty-two (CTR-8) or sixteen (CTR-4) words of the SLC processor’s output image table are reserved for the module. For the CTR8, output image words 0-31 are used to configure input channels 0-7. For the CTR4, output image words 0-15 User’s Manual Pub.

-

Page 27: Section 3.3 Operating Modes

Chapter 3: Configuring the 1746sc- CTR4/CTR8 are used to configure input channels 0-4. Each output image word configures a single channel, sets the preset, limit and scale factors and can be referred to as a configuration word. Each word has a unique address based on the slot number assigned to the module. - Page 28 Chapter 3: Configuring the 1746sc-CTR4/CTR8 Uni-Directional With this configuration, the input increments in an upward direction. All 8 channels may be configured in the unidirectional mode. Every clock pulse will increment the counter on the rising edge. The direction of the counter may be inverted by setting the Count NOTE Direction bit described in the Configuration chapter.

-

Page 29: Section 3.5 Modes

Chapter 3: Configuring the 1746sc- CTR4/CTR8 In the X4 Quadrature mode, invalid signals are not detected. A broken NOTE input wire, jitter or noise on the input can cause additional counts to be registered. The modules response to four possible error conditions are listed below: •... -

Page 30: Section 3.6 Channel Turn-On, Turn-Off, And Reconfiguration Times

Chapter 3: Configuring the 1746sc-CTR4/CTR8 The module’s Channel LEDs only indicate the state of the counters NOTE start/stop bit. They do not indicate that state of the external hardware gate. Counter Start / Stop Bit This bit allows the counter to continue to count up or down from its present value. -

Page 31: Channel Configuration, Data, And Status

Channel Configuration, Data, and Status Read this chapter to: Configure each input channel. • Set user-defined scale limits. • Monitor each input channel. • Check each output channel’s configuration and status. • Section 4.1 Configuring Each Input Channel The Data Register format uses Class 3 operation. Class 3 mode allows the module to use 32 input words and 32 output words of data, as listed below. - Page 32 Chapter 4: Channel Configuration, Data, and Status Figure 4-1. Configuration Word User’s Manual Pub. 0300181-07 Rev. A...

- Page 33 Chapter 4: Channel Configuration, Data, and Status Figure 4-2. Configuration Word Settings Counter Start/Stop: (Configuration Bit 0) This bit allows the counter to continue to count up or down from its present value. Starting or enabling the counter with this bit will not override the external NOTE counter enable input.

- Page 34 Chapter 4: Channel Configuration, Data, and Status Reset Flags: (Configuration Bit 2) The reset flags command is performed when this bit is set. Reset flags affects the counter zero, counter limit and counter maximum flags (Status word bits 8, 6, and 5, respectively.) These particular flags remain high, regardless of the counter behavior, until a reset is performed.

- Page 35 Chapter 4: Channel Configuration, Data, and Status Figure 4-3. One Period Rate Measurement The accuracy while operating in the average mode is ±1 count. When using the Instant mode, the accuracy is ±1% at 50 kHz and improves to ±0.002% at 100 Hz.

- Page 36 Chapter 4: Channel Configuration, Data, and Status Count Mode: (Configuration Bits 6-7) The Count Mode bit selects 1 of 4 types of counter operation. The Unidirectional counter mode is configured as an Up or Down counter. The module will support 8 unidirectional input channels. Every clock pulse increments the counter.

- Page 37 Chapter 4: Channel Configuration, Data, and Status Stop on Limit: (Configuration Bit 9) This bit, when set, will hold the counter output at its limit value. When the counter counts to the limit value it will either rollover to zero, or hold its output at the limit value, until the Limit Flag is cleared.

-

Page 38: Section 4.2 Output Register - Scale And Limit Data Values

Chapter 4: Channel Configuration, Data, and Status numbers, or it can start at the user defined preset value. When this bit is set to 0 the counter will continue to count down through • zero into negative numbers. When set to 1 the counter will roll under to the preset value. •... - Page 39 Chapter 4: Channel Configuration, Data, and Status In extended count mode (counts up to ±8M) the preset will be multiplied NOTE by 256 internally such that a user preset of 1000 will result in a preset of 25600. This allows the preset value to cover the whole ±8 million count range.

-

Page 40: Section 4.3 Input Registers - Channel Data

4-10 Chapter 4: Channel Configuration, Data, and Status counter is the counter value divided by the K Factor. A value of zero must be written to the K Factor to disable this feature. Figure 4-6. Preset/K Factor Word Rate Limit/R Factor: The rate limit function is used in the Normal operation mode. - Page 41 Chapter 4: Channel Configuration, Data, and Status 4-11 CTR8 CTR4 Scale/Limit Value 7 Channel MSW, LSW, I:e.28 to I:e.31 (N/A) Rate Data, Status Reg Figure 4-8. Data Words Counter Data, High word: This input data register contains the upper word of the counter’s accumulator. This register is a 16 bit word in binary 2’s complement format.

- Page 42 4-12 Chapter 4: Channel Configuration, Data, and Status This input data register contains the rate value while operating in rate mode. This register is a 16 bit word in binary 2’s complement format and represents the input value. Note that if the R Factor is present the output date value is represented as the Rate / R Factor.

- Page 43 Chapter 4: Channel Configuration, Data, and Status 4-13 Counter Start/Stop Echo: (Status Bit 0) This bit echoes the setting of the Counter Enable bit set in the channels control register. The counter enable bit allows the counter to continue to count up or down from its present value.

- Page 44 4-14 Chapter 4: Channel Configuration, Data, and Status operation. Max Rate Flag: (Configuration Bit 9) The max rate flag is set when the input rate exceeds its maximum range of 32,767 kHz. This flag indicates that the input counter rate is over the valid range of the module and that the value indicated in the rate data register may not be correct.

-

Page 45: Programming Examples

Programming Examples Learning to configure your counter to meet your application requirements will require knowledge of counter configuration, ladder logic programming and data management. Read this chapter to familiarize yourself with how to use the advanced features of your module. The following examples show simple counter configurations. -

Page 46: Section 5.2 Ring Counter Sample

Chapter 5: Programming Examples Configuration Word O:e.2 Counter Limit 10,000 We have set the limit to 10,000. If you change Configuration Bit 9 to 1, the counter will reach the limit and NOTE then hold its value until the Limit Flag is cleared. Then it will roll to 0 and continue counting to 10,000. -

Page 47: Section 5.4 Using Preset Values With Extended Mode

Chapter 5: Programming Examples Channel 0 Output Register Configuration (O:e.0) Config. Bit Description Bit Setting Description Normal Normal Mode Roll Under Preset Roll Over Roll to Zero Direction 0 (Default) No Inversion Count Size 0 (Default) ±32K Freq. Filter 0 (Default) 50kHz Stop on Limit No Stop... -

Page 48: Section 5.5 Using Scaling With Count And Rate Outputs

Chapter 5: Programming Examples Limit are multiplied by 256. The resolution of the Preset and Limit values in the standard mode is one count. The resolution in the extended mode is 256 counts. Count Size ±32 K ±8 M Description Preset Value 1000 256,000... - Page 49 Chapter 5: Programming Examples external gate enable, and the associated pulses that the module will accumulate: Given the above wave form, the module will begin counting the first positive going input pulse after the external enable input goes low. The module will accumulate 4 counts in the channel count register and stop when the external enable input goes high.

- Page 50 Chapter 5: Programming Examples Channel Register I:e.23 I:e.27 I:e.31 Clearing Loaded Factor Data In order to clear the factored data 0 must be loaded into the Preset / K Factor, Limit / M Factor and Limit / R Factor registers. After entering 0 into these registers bit 15 of the module Configuration register must be toggled from 0 to 1 and then back to 0.

-

Page 51: Testing Your Module

Interpreting I/O error codes • Troubleshooting • Before testing your module, test your SLC 500 system using the procedures described in your system’s Installation & Operation Manual. Inspecting Your Module You can prevent many potential problems by simply inspecting your analog module: 1. -

Page 52: Powering Up

Discontinue testing until you can get the LED to illuminate. The most probable reasons for the LED not illuminating are: The SLC 500 system is not receiving power from its power supply. • The rack slot where your module is located is defective. -

Page 53: Codes

Chapter 6: Testing Your Module Operation The module has 9 (5-CTR4) LED’s that indicate the following: Module Status LED: 1 Green LED: Indicates that the module has completed its self-test and is ready. Module and self-test errors are reported by an error blink code. -

Page 54: No Signal

Chapter 6: Testing Your Module Programming Software (APS) Reference Manual, Allen-Bradley publication 1746-6.11. No Signal After reviewing your configuration and LEDs for errors you may want to check the input register Rate word for any indication of signal. If status bit 1 (Counter Input State) is high and status bit 11 (Rate Zero) is high you may require a 1 to kΩ... - Page 55 Chapter 6: Testing Your Module User’s Manual Pub. 0300181-07 Rev. A...

- Page 56 Chapter 6: Testing Your Module User’s Manual Pub. 0300181-07 Rev. A...

-

Page 57: Chapter 7 Maintaining Your Module And Ensuring Safety

The printed circuit boards of your module must be protected from dirt, oil, moisture, and other airborne contaminants. To protect these boards, install the SLC 500 system in an enclosure suitable for its operating environment. Keep the interior of the enclosure clean, and whenever possible, keep the enclosure door closed. -

Page 58: Section 7.3 Getting Technical Assistance

When in hazardous locations, turn off power before replacing or wiring modules. This device is intended to be used only with the Allen-Bradley SLC 500 Systems. Refer to your system’s Installation & Operation Manual for more information. -

Page 59: Section 7.4 Declaration Of Conformity

Chapter 7: Maintaining your Module and Ensuring Safety For further information or assistance, please contact your local distributor, or call the Spectrum Controls Technical Support at: For Rockwell Automation Compatible I/O Products: 1-440-646-6900 • United Kingdom 01-908-635-230 • Australia 1-800-809-929 •... - Page 60 Chapter 7: Maintaining your Module and Ensuring Safety User’s Manual Pub. 0300181-07 Rev. A...

-

Page 61: Appendix A Floating Point Rate Mode

Appendix A Floating Point Rate Mode Read this appendix to: Configure rate for floating point mode. • Read input words to get data. • Use ladder logic to create floating point value. • Overview The floating point rate mode allows the user to monitor rate to a higher degree of accuracy. -

Page 62: Input Registers: Channel Data

Appendix A: Floating Point Rate Mode Table A-1. Data Word Addresses CTR8 CTR4 Scale/Limit Value I:e.0 to I:e.3 I:e.0 to I:e.3 0 Channel LSW, Rate Data High, Rate Data Low, Status Reg 1 Channel LSW, Rate Data High, Rate I:e.4 to I:e.7 I:e.4 to I:e.7 Data Low, Status Reg I:e.8 to I:e.11... -

Page 63: Ladder Logic

Appendix A: Floating Point Rate Mode upper output word when in the extended count mode. Bit 15 represents the sign for each word. Note: Extended count mode is not a valid configuration when using the floating point rate mode. Figure A-3. Counter Low Word Rate Register words: These two input data registers contain the rate value while operating in floating point rate mode. - Page 64 Appendix A: Floating Point Rate Mode User’s Manual Pub. 0300181-07 Rev. A...

- Page 65 User’s Manual Pub. 0300181-07 Rev. A...

- Page 66 ©1997-2021, Spectrum Controls, Inc. All rights reserved. Specifications subject to change without notice. The Encompass logo and SLC 500 are trademarks of Rockwell Automation. Corporate Headquarters Spectrum Controls Inc. 1705 132nd Avenue NE, Bellevue, WA 98005 USA Fax: 425-641-9473 Tel: 425-746-9481 Web Site: www.spectrumcontrols.com...

Need help?

Do you have a question about the SLC 500 and is the answer not in the manual?

Questions and answers