Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Nanoptix PayCheck NextGEN

- Page 1 PayCheck NextGEN ™ Technicians Manual October 18, 2017 Document # 720009-0000R...

- Page 2 Legal Notices Disclaimer Information in this document is subject to change without notice. Consult your Nanoptix Inc. sales representative for information that is applicable and current. Nanoptix Inc. reserves the right to improve products as new technology, components, software and firmware become available.

- Page 3 AC line filtering, over-current and short-circuit protection. Use of this product with a power supply other than the Nanoptix Inc. power supply will require you to test the power supply and Nanoptix Inc. printer for FCC and CE mark certification.

-

Page 4: Table Of Contents

4 Spare parts replacement instructions ............. 23 5 Printer Maintenance Instructions ............. 29 6 Service & Support ..................32 Returning printers back to Nanoptix for repairs (RMA) ......32 Technical Support Contact Information ............32 Document # 720009-0000 October 18, 2017... - Page 5 Technicians Manual Figures 1: N ™ N ......1 IGURE ANOPTIX HECK RINTER 2: T ............3 IGURE ICKET TACK RIENTATION 3: L ................ 4 IGURE OADING APER 4: I – ..............5 IGURE NTERFACE LEFT ...

- Page 6 Technicians Manual Tables 1: S ................2 ABLE PECIFICATIONS 2: I ................ 5 ABLE NTERFACE LEFT 3: I ..............6 ABLE NTERFACE RIGHT 4: I – ..............6 ABLE NTERFACE FRONT 5: LED I ..............9 ABLE NFORMATION ...

-

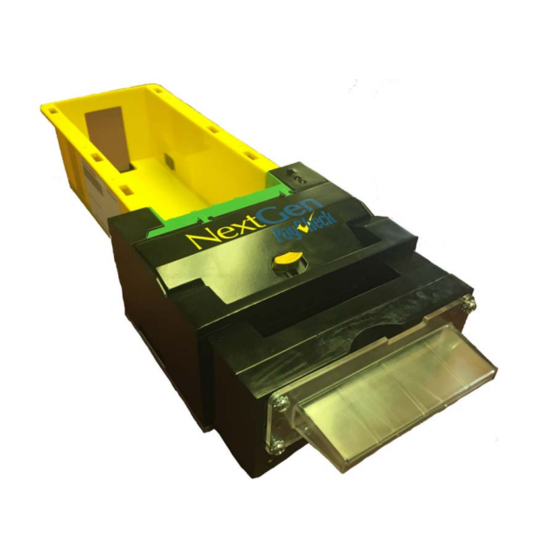

Page 7: About The Printer

About the Printer 1.1 Description of Printer The Nanoptix PayCheck™ NextGen, is extremely fast, quiet, and very reliable. With thermal printing technology, there is no ribbon cassette to change, and paper loading is extremely simple. The printer is small enough to fit almost anywhere and is easy to use with the ticket exiting from the front. -

Page 8: General Specifications

Technicians Manual 1.2 General specifications Print Method Direct Thermal Resolution 8 dot/mm (203 dpi) Print Width 64mm Paper Width 65mm Cartridge Size 400, 600, 800 Operating Temperature 0° to 60° C Storage Temperature -20° C to 75° C Operating Relative Humidity 5% to 90% RH at 50C (non-condensing) Communication Interface Options 2 Bidirectional RS-232C... -

Page 9: Paper Loading

Technicians Manual 1.3 Paper Loading The paper stack should be changed when it is low or out. Caution: The printer will not operate without paper, but it may continue to accept data from the host computer. Since the printer cannot print any transactions, the data may be lost. The maximum stack that will fit in the ticket cartridge is 400, 600 or 800 tickets depending on the cartridge option that was purchased with the printer. -

Page 10: Figure 3: Loading Paper

Technicians Manual Open drawer. Drop ticket stack into ticket (if necessary) cartridge. Feed ticket into printer mechanism Once paper has been aligned until resistance is felt. ticket is ready to print. Figure 3: Loading Paper Document # 720009-0000 October 18, 2017... -

Page 11: Printer Interface

Technicians Manual 1.4 Printer Interface Identifier Type Function USB type B USB communication 14 pin “Molex mini fit” Power & dual serial communication Left jumper Connects pin 5 to Pin 7 & 10 on port B Right jumper Bezel control connected to pin 9 of port B Switch left position Port B Aux port Netplex Switch right position... -

Page 12: Figure 5: Interface - Right

Technicians Manual Identifier Type Function USB type A USB communication (expansion) RJ45 802.3 Network interface Micro HDMI Video, etc. Table 3: Interface - right Figure 5: Interface – right Identifier Type Function SD media card interface MicroSD Molex microfit 3.0 Bezel illumination Mini USB type B maintenance... -

Page 13: Printer Controls

Technicians Manual 1.5 Printer Controls 1.5.1 Printer Reset (Service use only) The printer is reset by disconnecting and reconnecting the power/communication cable. Once connected, the printer goes through a startup routine and resets itself. Figure 7: Printer Reset 1.5.2 Paper Feed Button The paper feed button is used to advance the paper. -

Page 14: Dip Switches

Technicians Manual 1.5.3 DIP switches DIP switch is available through the access hole of the bottom plate. Figure 9: DIP Switch Identifier Position Function Recovery mode OFF (default) Run mode ON or OFF (default) Spare ON or OFF (default) Spare ON (default) Watchdog enabled Watchdog disabled... -

Page 15: Led

Technicians Manual 1.5.4 LED Two LEDs provide visual feedback of the operation of the printer. Figure 11: LED Positions Error LED Status LED Condition (Red) (Green) Printer Ready Paper Out MED BLINK Temperature Error Voltage Error (Over 26.2 SLOW BLINK VDC) FAST BLINK Print Head Error... -

Page 16: Paper Low

Technicians Manual 1.5.5 Paper Low There are 4 paper low detection options. Paper low sensor 1 is only used when paper low sensor 2 is in the off position. Detection quantity (sheets) Paper low 2 position HIGH MEDIUM Table 6: Paper low To change the paper low detection quantity. -

Page 17: Testing The Printer

To print the test ticket, the printer must be powered “ON” while holding the paper feed button for approximately 5 seconds. A status ticket similar to below will be printed. Pressing the button again will result in blank tickets. Model: PAYCHECK NextGen Firmware: NPG-9.99Z (0x6D00) Printer Driver Ver: 1.0.1.1... -

Page 18: Printer Performance Metrics

“ON” and operating in normal “Run Mode”. Press and hold the paper feed button for approximately 5 seconds. A performance ticket similar to below will be printed. (B8D52E31) Performance Report (B8D52E31) Nanoptix Paycheck USB printer Statistics Printer ID: P4B3671... -

Page 19: Clearing Jams

Technicians Manual 1.7 Clearing Jams The Nanoptix PayCheck NextGen printer’s paper guide and printing mechanism roller are easily removed, giving full access to the paper path. Figure 15: Clearing Jams Document # 720009-0000 October 18, 2017... -

Page 20: Troubleshooting The Printer

2 Troubleshooting the Printer 2.1 Basic Printer Operation Although the Nanoptix PayCheck™ printer is a complex device, its operation is fairly simple. The printer requires two consumables to operate, (1) a regulated 24 VDC power source and (2) approved thermal paper. The printer is equipped with eight communication interface ports The printer is mounted using a slidding baseplate. -

Page 21: Communication Cables Pin-Out

Technicians Manual 2.2 Communication Cables Pin-Out 2.2.1 Universal Communication interface The table below describes the connection pin-out for the Universal Interface (14-pin “Molex” type) Signal Name Printer I/O Host I/O Printer Function Reset Input Output Resets Printer PRT_AUX_RXD Input Output Auxiliary Receive VAUX Input... -

Page 22: Printing Problems

2.3 Printing Problems The table below can be used to determine the cause and resolution of the most common problems that may occur. If the information in this section does not correct the problem, contact a Nanoptix service representative. Problem Possible Causes... -

Page 23: Main Controller Pcb Connector Layout

Technicians Manual 2.3.1 Main Controller PCB Connector Layout J301 TPH groudning tab Future J401 Feeder motor J500 Future J600B Index (Top Of Form) J300A Thermal print head J800 Paper-in chute sensor & cover closed J701 Paper low – one sheet J702 Paper low –... -

Page 24: Media And Supplies Guide

Technicians Manual 3 Media and Supplies Guide 3.1 Thermal Paper Specifications NOTE: Qualified thermal paper with the following specifications is required for proper operation. Width 65 mm +/-1 (2.56 IN) Length 156 mm +/- 1 (6.14 IN) Thickness 4.5 +0.1 -0.3 mil Brightness Smoothness 2000 sec Avg. -

Page 25: Figure 19: Ticket Specifications

Technicians Manual Figure 19: Ticket Specifications Document # 720009-0000 October 18, 2017... -

Page 26: Ordering Thermal Paper

3.2 Ordering Thermal Paper The following paper grade produced by Appleton and Kanzaki Specialty Papers are recommended by Nanoptix. There are a number of paper converters qualified to supply this Table 13 paper, provided they use the recommended grades listed in Paper qualification services are offered by Nanoptix for additional grades not listed below. -

Page 27: Parts List

Technicians Manual 3.4 Parts List Figure 20: Part List Document # 720009-0000 October 18, 2017... -

Page 28: Figure 21: Mechanical Dimensions - Right

Technicians Manual Mechanical Drawings Figure 21: Mechanical Dimensions - Right Figure 22: Mechanical Dimensions - Front Figure 23: Mechanical Dimensions - Top Document # 720009-0000 October 18, 2017... -

Page 29: Spare Parts Replacement Instructions

Technicians Manual 4 Spare parts replacement instructions Use ESD protection (such as a wrist strap) anytime a PCB is exposed Instruction A: Removal of printer from mounting bracket 1. Pull printer forward until resistance is felt, then move green lever all the way to the left 2. -

Page 30: Figure 26: Base Plate

Technicians Manual Instruction C: Removal of the base plate 1. Remove 4 screws then lift up to remove baseplate Figure 26: Base Plate Instruction D: Removal of the circuit boards 1. Disconnect the 2 paper low harnesses 2. Lift board and disconnect the remaining harnesses 3. -

Page 31: Figure 28: Ticket Inlet & Index Sensor

Technicians Manual Instruction E: Removal of ticket inlet & Index mark (TOF) sensor 1. Remove 2 mounting screws and lift ticket inlet 2. Remove sensor by pushing out the sensor holder Figure 28: Ticket Inlet & Index sensor Instruction F: Removal of ticket tray 1. -

Page 32: Figure 30: Front Bar

Technicians Manual Instruction G: Removal of front bar 1. Remove 2 mounting screws and lift bar Figure 30: Front bar Instruction H: Removal of printing mechnism assembly 1. Lift assembly up while guiding harnesses through their coresponding access holes Figure 31: Printing Mech Document # 720009-0000 October 18, 2017... -

Page 33: Figure 32: Paper Guide

Technicians Manual Instruction I: Removal of paper guide assembly 1. Remove the mounting screw then slide the guide assembly up and away from printing mechanism Figure 32: Paper guide Instruction J: Removal of top paper guide from assembly 1. Push out on both lower paper guide tabs at the same time while slidding the top paper guide forward. -

Page 34: Figure 34: Chute Sensor

Technicians Manual Instruction K: Removal of chute sensor 1. Push front sensor mounting clip then lift sensor up. Figure 34: Chute sensor Instruction L: Removal of paper guide switch assembly 1. Remove mounting screw and lift up the assembly up Figure 35: Guide switch Document # 720009-0000 October 18, 2017... -

Page 35: Printer Maintenance Instructions

5 Printer Maintenance Instructions Note: Under normal operating conditions, the minimum interval for cleaning the Nanoptix PayCheck™NextGen printer is 3 months or 5 km of paper printed, which ever comes first. 1. Remove excess dust using a portable vacuum cleaner or wipe clean with a damp... -

Page 36: Figure 38: Remove Roller

Technicians Manual 3. Remove roller by pressing down and rolling towards front of printer Figure 38: Remove Roller 4. Clean the roller with a cotton swab and a mild soap solution. Figure 39: Clean Roller 5. Clean paper guide sensor using cotton swab Figure 40: Clean paper guide sensor using cotton swab Document # 720009-0000 October 18, 2017... -

Page 37: Figure 41: Clear Dust Off Gears Using Compressed Air

Technicians Manual 6. Clear dust off gears using compressed air Figure 41: Clear dust off gears using compressed air Clean the print line (black line on the print head) with a cotton swab and isopropyl alcohol. Figure 42: Clean Print Line Document # 720009-0000 October 18, 2017... -

Page 38: Service & Support

Technicians Manual 6 Service & Support 6.1 Returning printers back to Nanoptix for repairs (RMA) • Send repair approval request to Nanoptix Inc. which should include: Printer model # Serial # Brief problem description • Ship defective products to Nanoptix Inc.

Need help?

Do you have a question about the PayCheck NextGEN and is the answer not in the manual?

Questions and answers