Table of Contents

Advertisement

Quick Links

Print Jet and Extruder Replacement Guide

Introduction

Copyright

© 2014 by 3D Systems, Inc. All rights reserved. This document is subject to change without

notice. This document is copyrighted and contains proprietary information that is the

property of 3D Systems, Inc. Cubify, and the 3D Systems logo are registered trademarks of

3D Systems, Inc. CubePro is a trademark of 3D Systems, Inc. Use of the Cubify.com website

constitutes acceptance of its Terms of Service and Privacy Policy.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

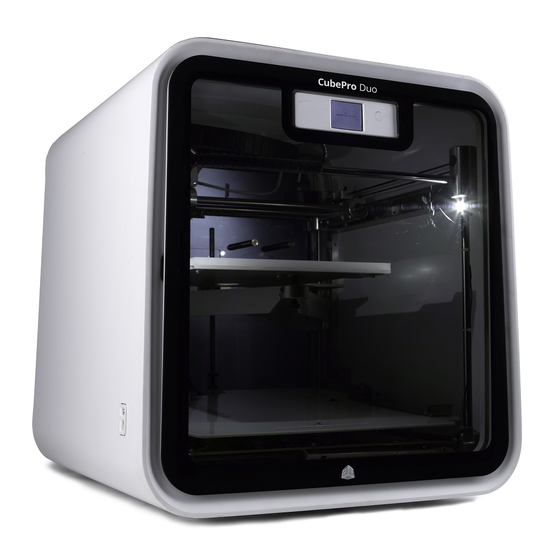

CubePro

Print Jet and Extruder

Replacement Guide

®

Advertisement

Table of Contents

Summary of Contents for 3D Systems CubePro

- Page 1 3D Systems, Inc. Cubify, and the 3D Systems logo are registered trademarks of 3D Systems, Inc. CubePro is a trademark of 3D Systems, Inc. Use of the Cubify.com website constitutes acceptance of its Terms of Service and Privacy Policy.

-

Page 2: Warranty

Warranty 3D Systems warrants that the CubePro 3D Printer will be free from defects in materials and workmanship, during the applicable warranty period, when used under the normal conditions described in the documentation provided to you, including this User Guide. 3D Systems will promptly repair or replace the CubePro 3D Printer, if required, to make it free of defects during the warranty period. - Page 3 CubePro 3D Printer. The warranty period for the CubePro 3D printer is the shorter of (i) 90 days from the date your CubePro 3D printer is activated or (ii) 24 months after the CubePro 3D Printer is shipped from 3D Systems to the end customer or intermediary.

-

Page 4: Important Safety Information

Follow all safety rules in this section and observe all cautions and warnings in this guide. Do not modify any safety features or make modifications to the CubePro. Doing so is prohibited and voids the warranty. Use of print materials other than genuine 3D Systems components may void the warranty. - Page 5 CHAMBER HEATER AND NOTE THAT OTHER COMPONENTS INSIDE THE PRINT CHAMBER MAY BE HOT. To ensure safety, please exercise caution when operating your CubePro. Read and follow all safety precautions as outlined in this user guide. Be careful when operating your CubePro...

- Page 6 At-A-Glance Extruder Carriage Assembly Front Delivery Tube Bracket Extruder Block Delivery Tube Eyelet 1 Extruder 1 Delivery Tube 1 Extruder 2 Delivery Tube Eyelet 2 Extruder 3 Delivery Tube 2 Print Jet Cooling Fan Delivery Tube Eyelet 3 Creation Cooling Fan Delivery Tube 3...

- Page 7 Back Creation Cooling Fan Extruder 2 PCB Carriage Plate Extruder 1 PCB Main Extruder PCB Delivery Tube Bracket Extruder 3 PCB Bottom Fan Harness Cable Clamp Print Jet 2 Print Jet LED Print Jet 3 Print Jet 1...

- Page 8 Main Extruder PCB Extruders - View From Back Extruder 1 Motor Print Jet 2 Print Jet 1 Extruder 3 Motor Extruder 2 Motor Print Jet 3 View From Top...

-

Page 9: Electrical Connections

Extruder 1 Motor Connector Extruder 2 Motor Connector Extruder 3 Motor Connector Electrical Connections Main Extruder Cable Extruder PCB Connector Component Extruder 1 X1 (A) - 401889-00 Motor: Junction Extruder 2 X2 (A) - 401889-00 Motor: Junction Extruder 3 X3 (A) - 401889-00 Motor: Junction X1 (B) - 401889-00 Extruder 1 PCB: Junction Ex... - Page 10 Main Extruder Cable Extruder PCB Connector Component CubePro LED 401887-00 Wire Harness 2 CubePro Fan 401885-00 Wire Harness 2 (Right Fan) CubePro Fan 401885-00 Wire Harness 2 (Left Fan) CubePro Fan 401884-00 Wire Harness 3 Jet Wiper Assembly...

- Page 11 Left Mounting Post Jet Wiper Assembly Jet Wiper Blade Adjustment Thumbscrew...

- Page 12 Right Mounting Post...

-

Page 13: Tools Needed

Replacing Extruder or Print Jet The material upgrade kit includes a replacement print jet for extruder 2 which has a larger diameter opening. For this upgrade, only print jet 2 should be replaced with the part included in the kit. WARNING: ONCE PRINT JET 2 HAS BEEN UPGRADED, ABS, PLA AND NYLON SHOULD NEVER BE INSTALLED IN CARTRIDGE BAY 2. - Page 14 Select the upper right corner of the triangle on the touchscreen display. NOTE: The printheads will move to the right rear corner of the print pad. Using the designated page from the Setup/Repack instructions, slide the paper between the print jets and the print pad. NOTE: If there is a slight resistance, proceed to step 5.

- Page 15 knob counter-clockwise (from the bottom) until there is a slight resistance. CAUTION: If the print pad is set too high, damage to the print pad or print jets may occur. NOTE: If the paper can not be inserted between the print jets and the print pad, turn the adjustment knob clockwise (from the bottom) until there is a slight resistance on the paper.

- Page 16 NOTE: If the paper can not be inserted between the print jets and the print pad, turn the adjustment knob clockwise (from the bottom) until there is a slight resistance on the paper. Select the upper left corner of the triangle. Once the print jets have moved to the left rear of the print pad, slide the paper between the print jets and the print pad.

- Page 17 Once completed, select the checkmark to exit the utility. Properly remove the material cartridges. NOTE: For more information, refer to the section titled Replacing a Material Cartridge in the user guide. Power off the printer and disconnect it from utility power. CAUTION: The printer must be powered off...

- Page 18 Disconnect the 5-pin jumper cable from junction B-Out of the extruder 2 PCB. Disconnect cable X (B) from junction of the extruder 2 PCB. Using a 2.5 mm hex head driver, loosen and remove the four 2.5 mm hex head bolts securing the delivery tube bracket and block to the extruders.

- Page 19 Move the delivery tube bracket/block aside so that extruder 2 can be removed. Using a 2.5 mm hex head driver, loosen the 2.5 mm hex head screw securing extruder 2 to the carriage plate. NOTE: The screw will remain loose in the extruder housing. NOTE: For clarity, the main extruder PCB was removed from the illustration.

- Page 20 Carefully remove the affected extruder assembly from the carriage plate. NOTE: Do not lose the screw that was loosened in the previous step. CAUTION: Be careful not to damage the print jet cable connected to junction P-Jet of the extruder PCBs. NOTE: For clarity, the main extruder PCB was removed from the illustration.

- Page 21 Disconnect the print jet cable from junction P-Jet of the extruder 2 PCB.

- Page 22 Using the T10 torx driver, loosen but DO NOT remove the T10 torx screw securing the print jet to the extruder assembly.

- Page 23 Rotate the print jet and gently pull upward to remove it from the extruder. NOTE: There is a tab on the print jet that aligns with a channel (A) in the extruder.

- Page 24 Carefully remove the print jet from the extruder. NOTE: There is a tab (A) on the end of the print jet that aligns with the channel (B) in the extruder.

- Page 25 Insert the new print jet into the extruder.

- Page 26 Rotate the print jet counter-clockwise so the cable from the print jet is facing the same direction as the extruder PCB.

- Page 27 Vertically center print jet 2 in the pinch clamp of the extruder housing and tighten the T10 torx screw (A) enough that the print jet is securely held. NOTE: For printers with 2 or 3 print jets, the height for print jets 1 and 3 will be adjusted to the height of print jet 2 after the extruder assembly has been reinstalled.

- Page 28 Connect the print jet cable to junction P-Jet on the extruder 2 PCB.

- Page 29 Carefully insert extruder assembly 2 into the carriage plate. CAUTION: Be careful not to damage the print jet cable connected to junction P-Jet of the extruder PCBs. NOTE: If necessary, carefully adjust the cable alignment if the extruder assembly is difficult to install. NOTE: For clarity, the main extruder PCB was removed from the illustration.

- Page 30 Using a 2.5 mm hex head driver, tighten the 2.5 mm hex head screw securing the extruder 2 assembly to the carriage plate. NOTE: For clarity, the main extruder PCB was removed from the illustration. It does not need to be removed for this procedure.

- Page 31 Insert the original 2.5 mm hex head screws into the extruder block and secure it to the extruders using a 2.5 mm hex head driver. NOTE: For clarity, the main extruder PCB was removed from the illustration. It does not need to be removed for this procedure. Connect cable X2 (B) to junction...

- Page 32 Connect cable X2 (A) to the junction on the extruder 2 motor. Connect the 5-pin jumper cable to junction B-Out of the extruder 2 PCB. For printers with two (2) or three (3) print jets, loosen the T10 torx screws on...

- Page 33 extruders 1 and 3. CAUTION: There should be enough access to reach the torx screws using an insulated torx driver. Exercise caution when working around the PCBs. NOTE: Print jet 2 should not need further adjustment. Connect the printer to utility power, turn on the main power switch and then turn on the display.

- Page 34 Press the X and Y adjustment arrows until print jet 2 is closely aligned above the front print pad adjustment knob. NOTE: The red line in the illustration demonstrates an approximate alignment of print jet 2 and the front print pad adjustment knob. Press the Z: up arrow until the nozzle of print jet 2 lightly touches the print pad.

- Page 35 Verify that the nozzles of print jet 1 and print jet 3 are also touching the printpad. When all of the print jet nozzles lightly touch the print pad, power off the printer and disconnect it from utility power. Tighten the left and right print jet T10 torx screws using a T10 torx driver. Connect the printer to utility power and power on the printer.

- Page 36 If the wiper blade is too high, remove the jet wiper assembly and turn the adjustment thumbscrew (A) clockwise. Reinstall the jet wiper and return to step 48. If the wiper tip is too low, remove the jet wiper assembly and turn the adjustment thumbscrew (A) counter-clockwise.

- Page 37 the printer. If necessary, repeat steps 1 - 11 to calibrate the print pad. Proceed to the Z-Gap and Level Gap procedure in section 5 of this guide. Once the Z- Gap and Level Gap are correct, refer to section 6 of this guide and calibrate the offset jets.

- Page 38 Calibrating the Level Gap Leveling the print pad is very important to ensure quality prints. Checking the Z-Gap and Level Gap becomes necessary after replacing a print jet, an extruder assembly, or the print pad. The Level Gap calibration file is always printed with print jet 1. There are two independent files for checking Level Gap: one for ABS printing and one for PLA printing.

- Page 39 print jet nozzles. The Level Gap should be checked and adjusted once the Z-Gap is correct (B).

-

Page 40: Calibrating The Offset Jets

(1) print jet installed. Calibration files can be downloaded from www.3dsystems.com/shop/cubepro/downloads. These files are printed like any other .cubepro file. There are four files available. The files are specific for the model printer (CubePro Duo or CubePro Trio) and for the material type (ABS or PLA) currently installed in the printer. -

Page 41: Reading The Offset Jets Scale

Y-Axis Scale X-Axis Scale Print Jet 3 Y-Axis Scale Print Jet 2 X-Axis Scale Print Jet 1 Y-Axis Scale Print Jet 1 X-Axis Scale Print Jet 2 Y-Axis Scale Print Jet 3 X-Axis Scale In the print scale illustration, the X+ scale (left-to-right) contains three (3) rows of printed lines. -

Page 42: Offset Jets Calibration Procedure

Note the white arrow printed from print jet 2 and compare it to the positioning of the blue arrow printed by print jet 1. Note that the white arrow is slightly left of the blue arrow meaning that print jet 2 is misaligned. Print jet 2 must be moved in a positive direction (right) to align with print jet 1. - Page 43 (CubePro Duo or CubePro Trio) and for the material type (ABS or PLA) currently installed in the printer. Insert the mass storage device into the CubePro USB inlet port and select PRINT. Navigate to the calibration file and select PRINT.

- Page 44 Once the printer has finished printing, remove the print pad from the printer and inspect the scales. If adjustments are required, proceed to the next step. If the scales are aligned properly, no further action is required. Navigate to the Print Jet Calibration screen and select OFFSET JETS.

- Page 45 Press the up arrow three times to increase the value to 22.30 mm. NOTE: Pressing the up arrow increases (+) the value. Pressing the down arrow decreases (-) the value. Pressing the value repeatedly will scroll through the digits left-to-right. NOTE: You can also select the Y-axis settings and adjust those settings the same way.

-

Page 46: Printing The Level Gap Calibration File

Printing The Level Gap Calibration File NOTE: Ensure the print pad is completely clean from glue and printed parts before beginning this procedure. Download the CALIBRATION FILES and extract them to your computer’s hard drive. Navigate to the file location and copy the appropriate file to your USB mass storage device. -

Page 47: Adjustment Knob Measurement

NOTE: For more information, refer to the section titled Applying Cube Glue. NOTE: It may take several minutes to print the file. When finished, remove the print pad and verify the Level Gap. NOTE: Refer to the sections titled Reading The Z-Gap Calibration Print and Reading The Print Pad Level Calibration Print. - Page 48 Correct Closed Z-Gap Referring to the illustration, the Closed Z-Gap bars (B) should touch the baseline (A). Incorrect Closed Z-Gap If there is a gap (B) between the Closed Z-Gap bars and the baseline (A), turn all three print pad adjustment knobs counter-clockwise (left) 1-step and then print the file again to verify the lines touch.

- Page 49 Correct Open Z-Gap If there is a gap (B) between the Open Z-Gap bars (C) and the baseline (A) and there is no gap between the Closed Z-Gap bars and the baseline, the Z-Gap is correct. Incorrect Open Z-Gap If there is no gap (B) between the Open Z-Gap bars (C) and the baseline (A), turn all three (3) print pad adjustment knobs clockwise (right) 1-step and print the file again to verify that the lines do not touch.

-

Page 50: Reading The Print Pad Level Calibration Print

Reading the Print Pad Level Calibration Print Correct Print Pad Level The Print Pad Level is correct when each of the four (4) corner calibration points have no gaps between the Print Pad Level calibration lines and the baselines. NOTE: Before making any adjustments to the Print Pad Level, the Z-Gap must be correct. - Page 51 Acceptable Print Pattern The Print Pad Level calibration file should print with no gap between the Print Pad Level calibration lines and the baselines. The illustration indicates an acceptable print pattern from a profile view. Unacceptable Print Patterns If the gap between the print pad and the print jet nozzles is too small, the Print Pad Level calibration lines will press in and scrape the baseline.

Need help?

Do you have a question about the CubePro and is the answer not in the manual?

Questions and answers