Table of Contents

Advertisement

Contents

MG.28.H2.02 -

.......................................................................................................

General warning .....................................................................................................

Mechanical Installation ...........................................................................................

Electrical Installation, power ...................................................................................

Electrical Installation, control cables ........................................................................

Programming .........................................................................................................

Motor start .............................................................................................................

AKD Lon card ........................................................................................................

Safety regulations ...................................................................................................

Warning against unintended start ...........................................................................

Order form .............................................................................................................

High voltage warning ..............................................................................................

These rules concern your safety .............................................................................

Warning against unintended start ...........................................................................

Control unit ............................................................................................................ 10

Manual initialisation ................................................................................................. 10

Automatic motor tuning .......................................................................................... 11

.................................................................................................... 12

Operation & Display ................................................................................................ 12

Load and Motor ..................................................................................................... 18

References & Limits ................................................................................................ 24

Inputs and outputs ................................................................................................. 28

Special functions .................................................................................................... 34

Serial communication ............................................................................................. 38

Technical functions ................................................................................................. 42

......................................................................................................... 46

Mechanical dimensions .......................................................................................... 46

Mechanical installation ............................................................................................ 47

General information about electrical installation ...................................................... 48

EMC-correct electrical installation ........................................................................... 49

Electrical installation ............................................................................................... 50

Safety clamp .......................................................................................................... 52

Pre-fuses ................................................................................................................ 52

Mains connection ................................................................................................... 52

Motor connection ................................................................................................... 52

RFI switch .............................................................................................................. 53

Direction of motor rotation ...................................................................................... 53

Parallel connection of motors ................................................................................. 53

Motor cables .......................................................................................................... 53

Motor thermal protection ........................................................................................ 54

Earth connection .................................................................................................... 54

Load sharing .......................................................................................................... 54

Tightening Torque, Power Terminals ....................................................................... 54

Access to control terminals .................................................................................... 54

Electrical installation, control cables ........................................................................ 55

Tightening torques, control cables .......................................................................... 56

AKD 2800

...........................................................................

3

3

3

3

3

3

4

4

4

5

7

7

9

9

9

1

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Danfoss AKD 2800

-

Page 1: Table Of Contents

Programming ......................Motor start ......................AKD Lon card ......................Safety regulations ....................Warning against unintended start ................Introduction to AKD 2800 ................Order form ......................High voltage warning ....................These rules concern your safety ................Warning against unintended start ................ - Page 2 AKD 2800 Electrical installation, control terminals ..............56 Relay connection ....................56 Connection examples ..................... 57 All about AKD 2800 ..................58 Display readout ...................... 58 Warnings/alarm messages ..................58 Special conditions ....................62 Aggressive environments ..................62 Galvanic Isolation (PELV) ..................62 EMC emission ......................

-

Page 3: Quick Setup

AKD 2800 Quick Setup General warning Electrical Installation, control cables Using this Quick Setup, you can carry out quick and Remove the front cover underneath the control panel. EMC-correct installation of the frequency converter Place a jumper between terminals 12 and 27. -

Page 4: Motor Start

The card can be ordered as build-in with the AKD5000 Requirements: and comes in an external box for the AKD2800. AKD 2800 must have software version (par 624) 1.32 or higher AKD Lon connections: AKD 5000 must have software version (par The Lon card has two connections. -

Page 5: Warning Against Unintended Start

AKD 2800 3. Correct protective earthing of the unit must be established, the user must be protected against supply voltage, and the motor must be protected against overload in accordance with applicable national and local regulations. 4. The earth leakage current is higher than 3.5 mA. - Page 6 AKD 2800 AKD 2803-2815 200-240 V AKD 2840 200-240 V AKD 2805-2815 380-480 V AKD 2855-2875 380-480 V AKD 2822 200-240 V AKD 2822-2840 380-480 V AKD 2880-2882 380-480 V MG.28.H2.02 -...

-

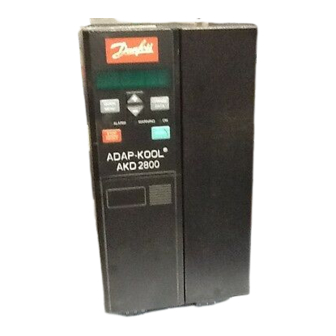

Page 7: Introduction To Akd 2800

Introduction to AKD 2800... - Page 8 AKD 2800 AKD 2800 Operating instructions Software version: 1.3x These operating instructions can be used for all series fre- quency converters with software version 1.3x. The software version number can be seen from parameter 640 Software version no. NB!: Indicates something to be noted by the reader.

-

Page 9: High Voltage Warning

AKD 2800 High voltage warning provide overload protection of the motor, class 20, in accordance with NEC. The voltage of the frequency converter 6. Do not remove the plugs for the motor - and mains is dangerous whenever the converter is supply while the frequency converter is connected connected to mains. -

Page 10: Control Unit

AKD 2800 Control unit These keys are also used in Display mode for selecting On the front of the frequency converter there the display of an operating value. is a control panel. The [QUICK MENU] + [+] keys must be pressed at the same time to give access to all parameters. -

Page 11: Automatic Motor Tuning

AKD 2800 Display readout states Display mode The display shows that in parameter 128 Motor thermal protection the selection made is Thermistor trip [2]. In normal operation, one item of operating data can be displayed continuously at the operator’s own Quick menu choice. -

Page 12: Programming

AKD 2800 Operation & Display is set at Local control and open loop [1] or Local control as parameter 100 [3]. Parameter 200 Output frequency range is set at Both directions. 001 Language 4. parameter 003 Local reference where the reference (LANGUAGE) can be set using the [+] and [-] keys. - Page 13 AKD 2800 Function: Copy to Setup 2 from # The active parameter Setup is selected here. All (COPY TO SETUP 2) parameters can be programmed in four individual Copy to Setup 3 from # parameter Setups. Shifts between Setups can...

- Page 14 AKD 2800 Analog input 60 [mA] NB!: (ANALOG INPUT 60 [MA]) [19] Upload/download can only be performed Pulse reference [Hz] in stop mode. Download can only be (PULSE REF. [HZ] ) [20] performed to a frequency converter with External reference [%] the same software version number, see parameter (EXTERNAL REF.

- Page 15 AKD 2800 Control word [Hex] gives the control word for the Torque [%] denotes the motor’s present load in frequency converter. See Serial communication in relation to the motor’s rated torque. the Design Guide for further information. Power [kW] gives the present power that the Warning word [Hex] gives one or several warnings motor is absorbing in kW.

- Page 16 AKD 2800 Description of choice: Local control as parameter 100 [3] is used when the See parameter 009 Large display readout. motor speed is to be set via parameter 003 Local reference, but without parameter 100 Configuration automatically shifting to Speed regulation, open loop [0].

- Page 17 AKD 2800 Using this function, in parameter 025 Quick Menu NB!: setup the user can select up to 20 parameters If Not active [0] is selected, the motor cannot for the Quick Menu key. be stopped by means of the [STOP]-key.

-

Page 18: Load And Motor

AKD 2800 Load and Motor Function: This parameter enables a choice of principle for adaptation of the U/f ratio of the frequency converter 100 Configuration to the torque characteristic of the load. (CONFIGURATION) Value: Description of choice: Speed control, open loop... - Page 19 AKD 2800 103 Motor voltage U 106 Rated motor speed (MOTOR NOM. SPEED) (MOTOR VOLTAGE) Value: Value: For 200 V units: 50 - 999 V 100 - f x 60 (max. 60000 rpm) 230 V Depends on parameter 102 Motor power, P...

- Page 20 AKD 2800 Description of choice: Complete AMT: AMT is completed by giving a RESET signal. can be set as follows: Parameter 108 Stator resistance, Rs is updated 1. Use the factory settings of R which the with the optimised value.

- Page 21 AKD 2800 Function: ETR warning 2 (ETR WARNING 2) This is where to choose the function of the frequency ETR trip 2 (ETR TRIP 2) converter after the output frequency has become ETR warning 3 (ETR WARNING 3) lower than the value in parameter 123 The min.

- Page 22 AKD 2800 You can also programme the frequency converter to Warning: If the use of start voltage give a warning signal via one of the digital outputs. is exaggerated, this may lead to Select ETR Trip 1-4 if you want a trip when the motor over-energizing and overheating of the is overloaded according to the calculations.

- Page 23 AKD 2800 Description of choice: Key in a % value. 137 DC hold voltage (DC HOLD VOLTAGE) Value: 0 - 100% of max. DC hold voltage Function: This parameter is used to keep the motor (holding torque) at start/stop. Description of choice:...

-

Page 24: References & Limits

AKD 2800 References & Limits Par. 100 Configuration Unit Open loop [0] 201 Output frequency low limit, f Process reg, closed loop [1] Par. 416 (MIN OUTPUT FREQ) Value: Description of choice: 0.0 - f 30.0 Hz The minimum reference is preset if the motor... - Page 25 AKD 2800 104 Motor frequency, f ). It is assumed that the reference) is summarized as a percentage of output current will not reach the current limit (set the reference range (Ref - Ref ), added to in parameter 221 Current limit I the other external references.

- Page 26 AKD 2800 224 Warning: High current, I Description of choice: HIGH The output frequency’s upper signal limit f (WARN. CURRENT HI) HIGH must be programmed within the frequency Value: converter’s normal operating range. 0 - I Function: If the output current exceeds the preset limit 227 Warning: Low feedback, FB a warning is given.

- Page 27 AKD 2800 229 Frequence bypass, bandwidth (FREQ BYPASS B.W.) Value: 0 (OFF) - 100 Hz 0 Hz Function: Some systems call for some output frequencies to be avoided because of mechanical resonance problems in the system. In parameters 230-231 Frequency bypass these output frequencies can be programmed.

-

Page 28: Inputs And Outputs

AKD 2800 Inputs and outputs 1 1 1 1 1 1 1 1 D D D D i i i i g g g g i i i i t t t t a a a a l l l l i i i i n n n n p p p p u u u u t t t t s s s s T T T T e e e e r r r r m m m m . - Page 29 AKD 2800 Function: In these parameters 302-307 Digital inputs it is possible to choose between the different enabled functions related to the digital inputs (terminals 18-33). Description of choice: No operation is selected if the frequency converter is not to react to signals transmitted to the terminal.

- Page 30 AKD 2800 Term. Term. Freeze ref/ Function freeze outp. No speed change Speed up Speed down Speed down Freeze reference can be changed even if the frequency converter has stopped. The reference will also be saved if the mains are disconnected.

- Page 31 AKD 2800 308 Terminal 53, analogue input voltage Description of choice: Set the required voltage value. For reasons of (AI [V]53FUNCT.) accuracy, compensation should be made for Value: voltage losses in long signal cables. No function (NO OPERATION) Reference (REFERENCE)

- Page 32 AKD 2800 Terminal 60 Max. scaling - frozen at the present frequency [1] - overruled to stop [2] (AI 60 SCALE HIGH) - overruled to jog frequency [3] Value: - overruled to max. output frequency [4] 0.0 - 20.0 mA 20.0 mA...

- Page 33 AKD 2800 Minimum reference, Ref - Maximum reference, (parameters 204/205). 0 - Temp. 0-20 mA/4-20 mA. An output signal is obtained, which is proportional 0-20 mA/ 4-20 mA. to the present heatsink temperature. 0/4 mA An output signal is obtained, which is proportional to the...

-

Page 34: Special Functions

AKD 2800 Special functions 412 Variable switching frequency (VAR CARRIER FREQ.) 405 Reset function Value: (RESET MODE) Without LC-filter (WITHOUT LC-FILTER) Value: LC-filter connected Manual reset (MANUAL RESET) (LC-FILTER CONNECTED ) Automatic reset x 1 Function: (AUTOMATIC X 1) The parameter must be set to LC-filter connected... - Page 35 AKD 2800 Description of choice: Function: Select among different units to be shown on the display. Set the value to be shown on the display when the The unit is read out if an LCP control unit can be maximum feedback has been obtained on the selected connected, and if Reference [unit] [2] or Feedback [unit] feedback input (parameter 308/314 Analogue inputs).

- Page 36 AKD 2800 Description of choice: 428 F3 frequency Set the output frequency (F1) that is to match the first (F3 FREQUENCY) output voltage (U1), parameter 423 U1 voltage . Value: Par. 426 F2 frequency - 1000 Hz Par. 104 Motor frequency...

- Page 37 AKD 2800 Description of choice: Description of choice: The factory setting is Enable [1], which means that Quick regulation is obtained by a high gain, but the integration link is initialised in relation to the if the gain is too high, the process may become actual output frequency if either the current limit, the unstable due to overshoot.

-

Page 38: Serial Communication

AKD 2800 Serial communication Serial communication [1] Setup msb Setup lsb Function 500 Address Setup 1 (BUS ADDRESS) Value: Setup 2 0 - 126 Setup 3 Function: Setup 4 This parameter allows the allocation of an address to each frequency converter in a serial Logic and [2] communication network. - Page 39 AKD 2800 Jogging (JOGGING) Logic or [3] Max. speed (MAX SPEED) Dig. Dig. Setup Stop and trip (STOP AND TRIP) Setup Setup Setup Setup Function: In this parameter you can select the required reaction for the frequency converter when the preset time in parameter 513 Bus time interval has been exceeded.

- Page 40 AKD 2800 5 5 5 5 1 1 1 1 5 5 5 5 - - - - 5 5 5 5 4 4 4 4 1 1 1 1 D D D D a a a a t t t t a a a a r r r r e e e e a a a a d d d d o o o o u u u u t t t t V V V V a a a a l l l l u u u u e e e e : : : : Par.

- Page 41 Status word, parameter 534: Gives the present status word for the frequency converter in Hex. See Serial communication for the AKD 2800. Inverter temperature, parameter 537: Gives the present inverter temperature on the frequency converter. The cut-out limit is 90-100 °C, with cut back in at 70 ±...

-

Page 42: Technical Functions

AKD 2800 Technical functions 6 6 6 6 0 0 0 0 0 0 0 0 - - - - 6 6 6 6 0 0 0 0 5 5 5 5 O O O O p p p p e e e e r r r r a a a a t t t t i i i i n n n n g g g g D D D D a a a a t t t t a a a a V V V V a a a a l l l l u u u u e e e e : : : : Par. - Page 43 AKD 2800 617 Fault log: Value 620 Operation Mode (OPERATION MODE) (F.LOG: VALUE) Value: Value: [Index 1 - 10] Value: 0 - 9999 Normal operation (NORMAL OPERATION) Control card test (CONTROL CARD TEST) Function: Initialise (INITIALIZE) In this parameter it is possible to see at which value a trip occurred.

- Page 44 AKD 2800 5. The frequency converter automatically undertakes a test of the control card. If the frequency converter displays a fault code from 37-45, the control card test has failed. Change the control card to start up the frequency converter.

- Page 45 AKD 2800 6 6 6 6 2 2 2 2 1 1 1 1 - - - - 6 6 6 6 4 4 4 4 2 2 2 2 N N N N a a a a m m m m e e e e p p p p l l l l a a a a t t t t e e e e V V V V a a a a l l l l u u u u e e e e : : : : Par.

-

Page 46: Installation

AKD 2800 Mechanical dimensions The drawings below give the mechanical dimensions. AKD 2840 200-240 Volt All dimensions are in mm. AKD 2855-2875 380-480 Volt AKD 2803-2815 200-240 Volt AKD 2805-2815 380-480 Volt AKD 2880-2882 380-480 V AKD 2822 200-240 Volt AKD 2822-2840 380-480 Volt MG.28.H2.02 -... -

Page 47: Mechanical Installation

AKD 2800 Mechanical installation Please pay attention to the requirements that apply to installation. The frequency converter is cooled by means of air circulation. For the unit to be able to release its cooling air, the minimum free distance above and below the unit must be minimum 100 mm . -

Page 48: General Information About Electrical Installation

AKD 2800 General information about electrical installation High voltage warning The voltage of the frequency converter is dangerous whenever the equipment is connected to mains. Incorrect installation of the motor or frequency converter may cause damage to the equipment, serious injury or death. Comply with the instructions in this manual, as well as national and local rules and safety regulations. -

Page 49: Emc-Correct Electrical Installation

AKD 2800 EMC-correct electrical installation General points to be observed to ensure - It is important to ensure good electrical contact from EMC-correct electrical installation. the installation plate through the installation screws to the metal cabinet of the frequency converter. -

Page 50: Electrical Installation

AKD 2800 Electrical installation AKD 2822 200-240 V, 2822-2840 380-480 V AKD 2803-2815 200-240 V, 2805-2815 380-480 V MG.28.H2.02 -... - Page 51 AKD 2800 AKD 2840 200-240 V, 2855-2875 380-480 V AKD 2880-2882 380-480 V Please note, that the units will be supplied with two bottom plates; one for metric glands and one for conduits. MG.28.H2.02 -...

-

Page 52: Safety Clamp

AKD 2800 Safety clamp 400-Volt units with RFI-filters may not be connected to mains supplies in which the voltage between phase and earth is more than 300 Volts. Please note that for the IT mains and the delta earth the mains voltage can exceed 300 Volts between phase and earth. -

Page 53: Rfi Switch

AKD 2800 Terminal 96 connected to U-phase. Terminal 97 connected to V-phase. Terminal 98 connected to W-phase. The direction of rotation can be changed by switching two phases on the motor terminals. RFI switch Parallel connection of motors Mains supply isolated from earth:... -

Page 54: Motor Cables

Load sharing [5]. Use 6.3 mm Faston Plugs for DC (Load Sharing). NB!: Contact Danfoss or see instructions no. MI.50.NX.02 If an unscreened/unarmoured cable is used, for further information. some EMC requirements are not complied with. -

Page 55: Electrical Installation, Control Cables

AKD 2800 Electrical installation, control cables Control cables must be screened/armoured. The screen must be connected to the frequency converter chassis by means of a clamp. Normally, the screen must also be connected to the chassis of the controlling unit (use the instructions for the unit in question). -

Page 56: Tightening Torques, Control Cables

AKD 2800 Tightening torques, control cables Control wires must be connected with a tightening Relay connection torque of 0.22-0.25 Nm. See parameter 323 Relay output for programming of relay output. Nr. 01 - 02 1 - 2 make (normally open) -

Page 57: Connection Examples

AKD 2800 Connection examples Potentiometer reference Voltage reference via a potentiometer. Start/stop Start/stop using terminal 18 and coasting stop using terminal 27. Par. 308 Analog input = Reference [1] Par. 309 Terminal 53, min. scaling = 0 Volt Par. 310 Terminal 53, max. scaling = 10 Volt Par. -

Page 58: All About Akd 2800

AKD 2800 Display readout Warnings/alarm messages The frequency converter shows the present A warning or an alarm will appear in the display output frequency in Hertz [Hz]. as a numerical code Err. xx. A warning will be shown on the display until the fault has... - Page 59 AKD 2800 LED indication WARNING/ALARM 8: Undervoltage Warning yellow If the intermediate circuit voltage (UDC) is lower than Alarm the inverter’s Undervoltage limit the inverter will be Trip locked yellow and red switched off until the UDC once more goes above the undervoltage limit.

- Page 60 ALARM 37-45: Internal fault and the motor, or in the motor. Turn off the frequency If one of these failures occurs, please contact Danfoss. converter and remove the earth fault. Alarm 37, internal fault number 0: Communication ALARM 15: Switch mode fault fault between control card and BMC.

- Page 61 AKD 2800 Calculations are taking too long, possibly due A frequency converter warning is given while to noise on the motor cables. AMT is being performed. ALARM 56: AMT warning during AMT WARNING 99: Locked See parameter 18. Alarm/warning limits:...

-

Page 62: Special Conditions

AKD 2800 Special conditions aggressive gases in the air are copper rails and cable ends that are black on existing electrical installations. Aggressive environments As all other electronic equipment, a frequency converter contains a number of mechanical and Derating for ambient temperature... - Page 63 AKD 2800 1. Transformer and optical separation in voltage supply. 2. Optical insulation between Basic Motor Control and control card. 3. Insulation between the control card and the power part. 4. Relay contacts and terminals relating to other circuits on the control card.

-

Page 64: Emc Emission

AKD 2800 EMC emission screened/armoured control cable, control box with The following system results are achieved on a potentiometer, screened/armoured motor cable system consisting of a AKD Series 2800 with and screened/armoured brake. AKD 2803-2875 Emission Industrial environment Residential, commercial and light industry... -

Page 65: General Technical Data

AKD 2800 General technical data Mains supply (L1, L2, L3): Supply voltage AKD 2803-2815 220-240 V (N, L1) ............1 x 220/230/240 V ±10% Supply voltage AKD 2803-2840 200-240 V ............3 x 200/208/220/230/240 V ±10% Supply voltage AKD 2805-2882 380-480 V ............3 x 380/400/415/440/480 V ±10% Supply frequency ............................. - Page 66 AKD 2800 Control card, analog inputs: Number of analog voltage inputs ........................1 pcs. Terminal number ..............................53 Voltage level ........................0 - 10 V DC (scaleable) Input resistance, R ........................approx. 10 k Max. voltage ..............................20 V Number of analog current inputs ........................1 pcs.

- Page 67 AKD 2800 Control card, analog output: Number of programmable analog outputs ......................1 Terminal number ..............................42 Current range at analog output ......................0/4 - 20 mA Max. load to common at analog output ....................... 500 Accuracy on analog output ..................Max. error: 1.5 % of full scale Resolution on analog output ..........................

- Page 68 AKD 2800 Control characteristics: Frequency range ......................0.2 - 132 Hz, 1 - 1000 Hz Resolution of output frequency ..................0.013 Hz, 0.2 - 1000 Hz Repeat accuracy of Precise start/stop(terminals 18, 19) ..............≤ ± 0.5 msec System response time (terminals 18, 19, 27, 29, 33) ................≤ 26.6 msec Speed control range (open loop) ..................

-

Page 69: Technical Data, Mains Supply 1 X 220 - 240 V/3 X 200-240 V

AKD 2800 Technical data, mains supply 1 x 220 - 240 V/3 x 200-240 V According to . international Type 2 2 2 2 8 8 8 8 0 0 0 0 3 3 3 3 2 2 2 2 8 8 8 8 0 0 0 0 5 5 5 5... -

Page 70: Technical Data, Mains Supply 3 X 380 - 480 V

AKD 2800 Technical data, mains supply 3 x 380 - 480 V According to international standards Type 2 2 2 2 8 8 8 8 0 0 0 0 5 5 5 5 2 2 2 2 8 8 8 8 0 0 0 0 7 7 7 7... -

Page 71: Factory Settings

AKD 2800 Factory Settings Parameter Factory setting 4-setup Conv. Data description index type Language English Local/remote operation Remote-controlled Local reference 000,000.000 Active Setup Setup 1 Programming Setup Active Setup Setup copying No copying LCP copy No copying Display scaling 1.00... - Page 72 AKD 2800 Parameter- Factory setting 4-setup Conv. Data- description index type Configuration Speed reg., open loop Torque characteristics Constant torque Motor power P depends on unit Motor voltage U depends on unit Motor frequency f 50 Hz Motor current I...

- Page 73 AKD 2800 Parameter Factory setting 4-setup Conv. Data description index type Output frequency, 30 Hz low limit f Output frequency, 60 Hz high limit f Minimum ref Ref 30 Hz Maximum ref Ref 60 Hz Ramp-up time 1 0.70 sec.

- Page 74 AKD 2800 Parameter Factory setting 4-setup Conv. Data description index type Reset function Manual reset Aut. restart time 5 sec. Var. carrier frequency No LC-filter Min. feedback 0.000 Max. feedback 1500.000 Process units ´ U1 voltage par. 103 F1 frequency Par.

- Page 75 AKD 2800 Parameter Factory setting 4-setup Conv. Data description index type Operating hours Hours run kWh counter Number of cut ins Number of overtemperatures Number of overvoltages Fault log: Error code Fault log: Time Fault log: Value Reset of kWh counter...

- Page 76 AKD 2800 ............................Address Initialise ........................Aggressive environments Integration ............Analogue input ............Analogue output ..........Automatic motor tuning 11, 19 ..............Language ............Load compensation ..............Load sharing ........................Bus time interval Local reference ............................

- Page 77 AKD 2800 ............................RCD relays ..............Reference ............Reference function ..............Relative ............Relay connection .............. Reset function ..............RFI switch ............Slip compensation ............Special motor mode ..........Speed control, open loop ..............Start voltage ..............Start/stop ............

Need help?

Do you have a question about the AKD 2800 and is the answer not in the manual?

Questions and answers