Festo CP Factory Manual

Mr buffer and palletizing robot

Hide thumbs

Also See for CP Factory:

- Manual (126 pages) ,

- Original operating instructions (90 pages) ,

- Manual (115 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Manual

Advertisement

Table of Contents

Summary of Contents for Festo CP Factory

- Page 1 CP Factory / CP Lab ® Manual MR Buffer and palletizing robot Festo Didactic CP Factory / CP Lab 02/2018...

- Page 2 Festo Didactic accepts no liability for injury or harm to trainees, the training company and/or any third parties which may occur when the installation is used beyond a genuine training situation, except Festo Didactic has caused such injury or harm intentionally or by grossly negligence.

-

Page 3: Table Of Contents

3.6.3 Proximity switch (Indexing units) ____________________________________________________ 34 3.6.4 Proximity switch (transfer unit) ______________________________________________________ 36 3.7 Adjusting the one-way flow control valves _________________________________________________ 37 3.8 Visual inspection _____________________________________________________________________ 39 3.9 Commissioning _______________________________________________________________________ 39 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 4 5.3.3 Scalance Ethernet Switch ___________________________________________________________ 87 5.4 RFID ________________________________________________________________________________ 90 5.4.1 24 V Terminal Block _______________________________________________________________ 91 5.4.2 SYS link Interface _________________________________________________________________ 93 5.5 I/O terminal __________________________________________________________________________ 94 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 5 Content 5.6 Mechanic Components_________________________________________________________________ 96 5.6.1 Conveyor Motor ___________________________________________________________________ 96 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 6: General Safety Instructions

(before voltage) and must only be separated last (after voltage separation). • If not specified differently in the technical data, the device does not have an integrated fuse. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 7: Pictographs

Disregarding this symbol may lead to malfunctions at the machine or in its surrounding area. Information This means that you obtain tips for the use and especially useful information. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 8: Safety Terminal Sockets

(green-yellow) signal input/signal output (black) The specified protection categories and the safety can only been guaranteed when using Festo Didactic safety laboratory cables. Any damaged or faulty safety laboratory cables have to be blocked instantly and to be removed from the training area. -

Page 9: Handling The System

Please check that all screw connections which have been loosened during the maintenance, servicing or repair works are firmly seated. 1.4.6 Organizational measures All existing safety equipment has to be checked regularly. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 10: Staff

Before they start work, all persons in charge of works at the system commit themselves to: • read the safety chapter and the warnings in this manual, • observe the basic principles about work safety and accident prevention. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 11: Introduction

Festo Didactic herewith rules out any legal responsibility for damages of the trainee, the training company and/or a third party which might occur when using the system beyond a genuine training situation, unless the damage has been caused by Festo Didactic intentionally or due to gross negligence. -

Page 12: Resources

The following resources are available: Pallet carrier These pallet carriers are available for transporting the pallets. Pallet These pallets are available for receiving always one workpiece. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 13 Box with retainer for 15 raw turning pieces – Box Partnumber 26 Box with retainer for 10 PCB´s – Box Partnumber 27 Box with retainer for 10 front/backcovers or assembled workpieces – Box Partnumber 28 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 14 CP part fuse on the right no 213 no 1213 CP fuses both CP part both fuses no 214 no 1214 CP part customer no 1210 freely selectable © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 15: Design And Function

You have to see for an appropriate distance between the system and the wall. Keep away any dust from the station resulting from construction works (covering). © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

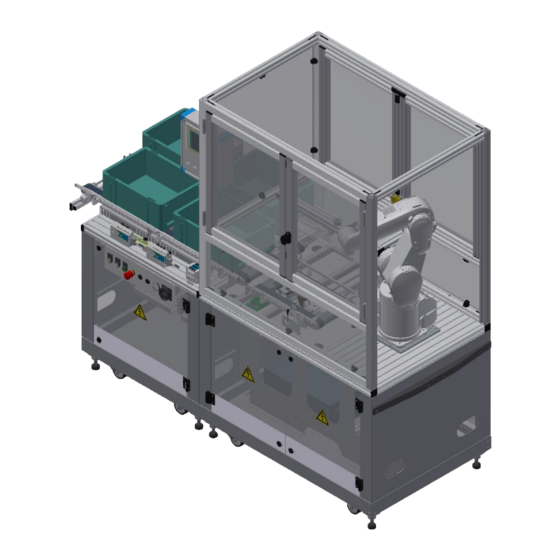

Page 16: Mr Buffer Module With Palletizing Robot

Any boxes requested before are first equipped with these workpieces and then output at the buffer. Pos. Description Touch panel Conveyor output Conveyor input I/O module Operating panel Valve terminal I/O terminal robot RV-4FL RFID sensor shift unit © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 17: Interface To Basic Module Bypass

MR Buffer. The sensors are designed for checking if there is a front or a back cover on the carrier. Pos. Description sensor BG5 – front cover sensor BG6 – back cover © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 18: Supply Of The Mr Buffer With Palletizing Robot

3.3.3 Supply of the MR Buffer with palletizing robot power supply Position Station power supply 110V / 230V / 400V power supply to another station (optional) power supply to another station (optional) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 19: Electrical Installation

The station MR Buffer with palletizing robot has got three electric boards. Electric boards Position Station I/O board ET200SP 32IN/32OUT / +K1 board for power supply / +T1 board for power supply / +K4 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 20 Siemens Sirius / 3SK1111-2AB30 Switchboard 24V Emergency stop board Start-up current limiters Kaleja M-MZS-4-30 / 06.05.020 Start-up current limiters Kaleja M-MZS-4-30 / 06.05.020 Clamps I/O terminal XD11 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 21 Siemens ET200SP / CPU 1512SP F-1PN I/O terminal XD11 I/O terminal XD12 I/O terminal XD13 I/O terminal XD14 clamps connecting plug 24V distributor UMSTBVK 2,5 / 5 GF-5, 08 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 22 230 V Hager SN01 / 2055242 protective contact socket 230 V Hager SN01 / 2055242 connecting plug 24V terminal block UMSTBVK 2,5 / 5 GF-5, 08 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 23: Rfid Connections

Design and function 3.4.1 RFID connections Position Station Siemens PLC Turk Gateway Profinet IO / BL20-GW-EN-PN RFID Sensor (G2 –TF1) / TN-CK40-H11147 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 24: Emergency-Stop Structure

Design and function 3.4.2 Emergency-Stop structure Example emergency-stop connections with emergency-stop terminal block © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 25 IN1 clamp emergency-stop button – distributor from another station OUT1 clamp emergency-stop button - distributor from another station OUT2 clamp emergency-stop button -distributor from another station 24 V clamp emergency-stop button © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 26 F2-XZ2-X4 Terminal clips for control panel, power supply, Emergency-stop relay. Example for Emergency-stop linking with 3 modules © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 27 4. If the module has been connected with other modules, the emergency-stop is effective at all stations and must therefore be acknowledged at every station by pressing the illuminated push-button “Adjusting” and acknowledging the error at the HMi © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 28: Emergency-Stop With Central Control

At this module, you can click on the message line at the top at the HMI, where the error message will be displayed in the main window. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 29: Commissioning

Now the module must be supplied with electric voltage (400 V). The voltage has to be provided by the customer. Furthermore, an expert installation must be guaranteed. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 30: Adjusting The Sensors

© Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 31 5. Please check the setting by inserting a box. Remark The recognition of all boxes must be guaranteed. Documents • Data sheets / operating instructions fibre optic unit SOEG_L and fibre optics SOEZ-SE © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 32: Proximity Switch (Transfer Unit)

© Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 33 5. Please check the setting by inserting a box. Remark The recognition of all boxes must be guaranteed. Documents • Data sheets / operating instructions fibre optic unit SOEG_L and fibre optics SOEZ-SE © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 34: Proximity Switch (Indexing Units)

The proximity switches are used for checking the end position of the cylinder for the indexing unit. The proximity switches react to a permanent magnet on the piston of the cylinder. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 35 6. Check the positioning of the proximity switch by repeated test runs of the cylinder. Documents • Data sheets / operating instructions proximity switch 574334 (SMT-8M-A-PS-24V-E-0,3-M8D) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 36: Proximity Switch (Transfer Unit)

They do not require any settings but are integrated within the stop of the axis. Documents • Data sheets / operating instructions Proximity switch 150362 (SEIN-4B-PS-K-L) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 37: Adjusting The One-Way Flow Control Valves

3.7 Adjusting the one-way flow control valves One-way flow control valves Position Description one-way flow control valves GRLA for indexing unit 1 one-way flow control valves GRLA for indexing unit 2 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 38 3. Turn on the one-way flow control valves slowly until you reach the desired speed of the piston. Documents • Data sheets One-way flow control valve (193138) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 39: Visual Inspection

2. The module is supplied with about 6 bar compressed air. At a first commissioning, you have to see for slowly increasing the pressure (thus unpredictable events are prevented). 3. Now you can work with the module. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 40: Operation

• Operation has to be effected according to the manual. • Any uncontrolled pressing of the various switches/buttons of all control units has to be prevented. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 41: The Operation Panel Of The Station

Control system ON S1-SF1 Light on Announce power available Manometer Announce air pressure Emergency stop S1-FQ1 Emergency stop function Main Switch S1-QB1 Main switch power supply © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 42: Touch Panel

Current consumption 0.5 A Starting current I²t 0.5 A²·s Power Power consumption 12 W Processor Type of processor Memory Flash Memory available for user data 12 Mbyte © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 43 Operation Festo CDPX panel © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 44 UL us - Listed (OL) Ethernet PLC interface RS485 USB interface Ethernet interface RJ45 10/100 MBd Mounting type Front panel installation Material information conform to RoHS Programming software Designer Studio © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 45: Process Description

Operation 4.3 Process description Position Description Box Stopper 3 Box Stopper 4 Box Stopper 1 Box Stopper 2 Transfer Unit © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 46: Process Description Box Stopper 1-4

Operation 4.3.1 Process description box Stopper 1-4 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 47 Operation © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 48: Process Description Transfer Unit

Operation 4.3.2 Process description transfer unit © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 49 Operation © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 50: Switching On The Mr Buffer With Palletizing Robot

3. The module/application module will execute the run until cycle end. During this time, the button Cycle End has got a red background. 4. The stoppers are extended. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 51: Operating Modes

Operating the basic modules is always the same procedure. A basic module with the application module drilling serves as an example here. Any additional operating possibilities are described separately in the corresponding manuals. The operation is not depending on the type of the operating panel, Festo and Siemens Panels have got the same functions. -

Page 52: Menu Structure Of The Operating Panel

Changing contents depending on the main menu or the sub menu Display of the operation mode automatic or setting Display if Default or MES operating mode has been selected (Default Mode not available) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 53: Menu Navigation In General

If you open the door, the robot will stop. If you close the door again, the robot will continue to execute its present task. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 54 If you click on the blue marked field (no matter where you are in the menu), the following window will open (Pos 2) Operating window – the operating window is always the same and allows a fast operating of the station © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 55: Operation Mode Home

Cycle End Button: Here you can stop the presently active operating mode. Selection of the mode: Default –not available – can not be selected MES – automatic run is completely controlled by MES software © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 56 Sub Menu Overview The inputs/outputs of the station are displayed here. Button send out box – in an indefinable status the box can be given out manually here. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 57 With a click on the button User Dialogue, the following window will open: If you click into the user or password fields, the entry window will open and you can enter the user data. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 58 Operation Here you can enter the user data. With the return button, the entry is acknowledged. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 59: Operation Mode Setup

ST2: display stopper ST2 G1_BG6: sensor BG6 indicates when stopper is up (flashing green when active) Up: move up stopper ST2 (G1_MB4 is activated – flashing blue when active) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 60 ST4: display stopper ST4 G1_BG16: sensor BG16 indicates when stopper up (flashing green when active) Up: move up stopper ST4 (G1_MB14 is activated – flashing blue when active) © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 61 – not directly on the RFID (for an easier entry) area display of the active sensors (flashing green when active) and activators (flashing orange when active) at the stopper display of the RFID reading status © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 62 - the robot is busy 10 – display of step number xConnected – connection Drive Unit is established Retry – try it again Exit Cycle – finishing the present cycle © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 63: Parameter

Display of the MES IP address, and additionally, the IP of the MES can be set here (password protected, User: festo, PW: festo) Entry fields for individual resource numbers, query port and status port of the MES connection © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 64: Starting The Automatic Mode

A grey button with blue colour indicates that this function is selectable. 1. Switch on the station and wait until HMI has been booted. The following screen appears: 2. Press the Setup button © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 65 3. Select the Default or MES mode, for this example the Default Mode has been selected. 4. Press the Automatic button. 5. Automatic mode is active © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 66: Terminating The Automatic Mode

Operation 4.7.3 Terminating the Automatic Mode 1. Press the Cycle end button, the automatic process is stopped instantly © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 67: Writing On The Rfid Tag Manually

BoxPNo – Here, the part number of the box and the retainer for the workpieces to be picked up are displayed or entered. 7. Press the „write“ button in order to write the performed modifications on the tag. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 68: Mr Buffer And Palletizing Robot Parameters

15 ( conveyor position), constant a box Target position [-] limitation: none, value: 0, at runtime Workpiece number [-] limitation: none, value: 0, at runtime © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 69: Components

The maximum reach of the robot arm is 648,7 mm. RV-4FL Performance Inputs 32 Inputs for communication Outputs 32 Outputs for communication Max. reservation 1 work piece/pallet © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 70: Drive Unit Cr750-D

Interface cover for USB and battery Plug for teach pendant Servo on button Servo off button Start button Up button Main switch END button RESET button Stop button © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 71 CNUSER 11 CNUSER 12 CNUSER 13 Slot 1 / for connector 1 (in/output 0-15) Slot 2 / for connector 2 (in/output 16-31) CNUSER 2 LAN1 for Ethernet © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 72: Teach Pendant R32Tb

Auto position (OP) for the stand alone mode • Auto position (EXT) for the communication with other controls • Teach position for the Teach mode. Teach pendant © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 73: Teach Pendant R56Tb

• Position Auto (OP) for standalone mode. • Position Auto (EXT) for communication with other controller. • Position Teach for teach mode. Teach pendant © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 74: Set Up

50 Pin cable from Ria-Box to slot 1 / there is a special cable necessary, this cable is plugged at the Drive Unit and then connected to the 50 PIN cable RIA Box © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 75 Komponenten Robot RV4-FL set up example for standalone mode Position Description Cable to Drive Unit Programming PC Drive Unit CR750D Cable to Ethernet interface © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 76 Komponenten Robot RV4-FL set up example for standalone mode Position Description Cable to Drive Unit Programming PC Drive Unit CR750D Cable to Ethernet interface © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 77: Drive Unit Interface

2033 DI_ExitCurrCycle programme cycle 104,1 input 2034 - Reserve_RobState1 2039 reserved for extension input 2040 - Reserve_RobState2 2047 Byte reserved for extension © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 78 2152 - 2159 box is completely driven in 118.1 input 2160 - 2167 pallet available at bypass 118.2 workpiece available at input 2168 - 2175 bypass 118.3 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 79 2120 - 2127 Byte reserved Byte 7 ReserveByte8 output 2128 - 2135 Byte reserved Byte 8 ReserveByte9 output 2136 - 2143 Byte reserved Byte 9 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 80: Parameter

.168.0.7","192.168.0.8","192.168.0.9","192.168.0.10"; • NETPORT=10000, 10001, 10002, Camera_Port, 10004, 10005, 10006, 10007, 10008, 10009 • NETMODE=Ud,1,1,0,1,1,1,1,1,1; Slot Parameter: • SLT1=Us,"3","CYC","START","1"; • SLT2=Us,"MONITORHOME","REP","ALWAYS","1"; • SLT3=Us,"ENRGSAVEVACU","REP","ALWAYS","1"; • SLT4=Us,"PCBTRAYCNTRL","REP","ALWAYS","1"; • SLT5=Us,"MONITORPALWS","REP","ALWAYS","1"; © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 81: Main Tasks/Programmes

5.1.9 More information on the robot Please refer to the robot manual in order to obtain the operating information. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 82: Robot Positions

Tool 1 – Master Product XY direction of the box Tool 1 – Master Product gripper position of the workpiece on the P_ByPasPlacePose basic module bypass © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 83: Electrical Components

TR.1 • connection for limit switch for stop • short circuit-proof and temperature-protected • start-up current limitation © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 84 No /Yes housing plastic housing light grey dimensions 59x77x50 weight about 100 temperature protection/short circuit protection Yes / Yes connection type single 4mm², stranded. 2.5mm² screw connection © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 85 -5K2 / Q0.6:29 X1:st conveyor drive stop conveyor motor DC / -X3M1:4 X2:M1 conveyor motor connection conveyor motor DC / -X3M2:3 X2:M2 conveyor motor connection © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 86: Siemens Control

Komponenten 5.3.2 Siemens Control Siemens ET 200 SP / CPU 1512SP F-1PN You will find detailed information about the control in the circuit diagram © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 87: Scalance Ethernet Switch

Komponenten 5.3.3 Scalance Ethernet Switch Siemens Scalence Ethernet switch The SCALANCE X208 has got eight RJ45 sockets for the terminal device connection or further network segments. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 88 If the auto negotiation function has been switched off, the function MDI/MDI-X auto crossover is also not active. Therefore, you might have to use a crossover cable. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 89 Polarity inversion (Auto Polarity Exchange) If the reception cable pair has been connected incorrectly (RD+ and RD- mixed up), the inversion of the polarity is effected automatically. © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 90: Rfid

Komponenten 5.4 RFID Turck RFID control slot module name comments control BL20-GW-EN-PN Profinet interface RFID card BL20-2RFID-A for 2 RFID sensors © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 91: Terminal Block

Komponenten 5.4.1 24 V Terminal Block Murr Mico 4.6 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 92 Switch-on capacity max. 20 mF (per channel) Sum messages output potential-free 30 V AC/DC, 100 mA Switch-on remotely (ON) 10...30 V DC Pulse length minimum 20 ms © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

-

Page 93: Sys Link Interface

EX.5 output AX.6 input EX.6 output AX.7 input EX.7 power supply power supply power supply power supply power supply power supply power supply power supply © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... -

Page 94: I/O Terminal

IEEE 488 24-pin inputs 8 (4 of them are connected) outputs 8 (4 of them are connected) current consumption maximum 1A per PIN supply voltage 24 VDC © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot... - Page 95 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 96 Ott Conveyor motor XDP037007-01 name power supply UN /Volt 24 V idling speed n0 [min-1] nominal current <800 nominal torque MN [Nm] transmission ratio i 1/100 © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

- Page 97 Komponenten Festo Didactic SE Rechbergstraße 3 73770 Denkendorf Germany Internet: www.festo-didactic.com E-mail: did@de.festo.com © Festo Didactic CP Factory / CP Lab ° MR Buffer and palletizing robot...

Need help?

Do you have a question about the CP Factory and is the answer not in the manual?

Questions and answers