Festo CP Lab Manuals

Manuals and User Guides for Festo CP Lab. We have 7 Festo CP Lab manuals available for free PDF download: Manual, Original Operating Instructions

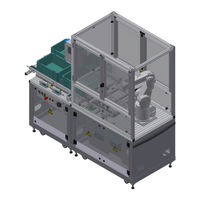

Festo CP Lab Manual (114 pages)

Conveyor

Brand: Festo

|

Category: Industrial Equipment

|

Size: 7 MB

Table of Contents

Advertisement

Festo CP Lab Original Operating Instructions (90 pages)

Brand: Festo

|

Category: Industrial Equipment

|

Size: 1 MB

Table of Contents

Advertisement

Festo CP Lab Manual (57 pages)

Application Modules

Brand: Festo

|

Category: Control Unit

|

Size: 2 MB

Table of Contents

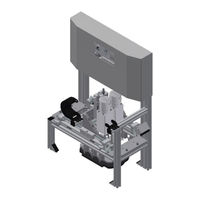

Festo CP Lab Manual (39 pages)

Application module iDrilling

Brand: Festo

|

Category: Industrial Electrical

|

Size: 2 MB