Table of Contents

Advertisement

Quick Links

- 1 Configuration

- 2 Fas-230 Linear Transfer Module: Transport System

- 3 Troub-200 Fault Simulation System

- 4 Fas-201 Base F Eeding /Verification Module

- 5 Fas-202 Base Rejecting / Transfering Module

- 6 Fas-203 Bearing F Eeding /Transfering Module

- 7 Fas-204 Bearing Measuring/Transfering Module

- 8 Fas-220 Pallet Transfer Module

- Download this manual

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SMC Networks FAS-200

- Page 2 FAS-200 USER MANUAL...

- Page 3 Equipment for training in flexible integrated assembling systems Technical Description...

- Page 4 TEN REASONS FOR CHOOSING THE FAS200 SYSTEM The FAS200 is manufactured entirely from industrial grade materials of maximum strength and quality. 2. It complies with European safety directives in respect of both low voltage and machine safety. 3. It may include pallet transfer integrate several modules allowing. 4.

- Page 5 The system allow the development of skills such as: ANALYSIS, INSTALLATION/ ASSEMBLY/ IMPLEMENTATION, MAINTENANCE/ DIAGNOSIS/ FAULT REPAIR, START-UP/ SET-UP, DESIGN/LAYOUT, PROGRAMMING, PREPARATION DOCUMENTATION, DEFINITION OF PROCEDURES, MEASURING, ETC., integrating different technologies including: Pneumatics/Electro-pneumatics, Hydraulics/Electro- hydraulics, Electrical Actuators, Robotics/Manipulation, Industrial Communications, Control Systems, Electric Automatisms, Safety Devices, Basic Mechanical Systems, Artificial Vision Systems and so on.

-

Page 6: Table Of Contents

FLEXIBLE ASSEMBLY SYSTEM FAS200 INDEX INDEX ................................. 4 CONFIGURATION .......................... 5 GENERAL OVERVIEW: ........................ 9 FAS-230 MODULE: TRANSPORT SYSTEM ............13 LINEAR TRANSFER TROUB-200 FAULT SIMULATION SYSTEM ................... 17 FAS-201 BASE F /VERIFICATION ................18 EEDING MODULE FAS-202 BASE ................23 REJECTING TRANSFERING MODULE FAS-203 BEARING F... -

Page 7: Configuration

FLEXIBLE ASSEMBLY SYSTEM FAS200 1. CONFIGURATION The FAS-200 system is the ideal answer to integral training in industrial automation. It is fully modular and flexible equipment and in keeping with industrial reality. The technologies included in its different assembly modules, as well as the assembly process with several variants, allow the user to develop the professional skills required by today’s automated industry. - Page 8 Robotized screwing module FAS-214 Transfering and vision inspection module FAS-215 After visual inspection rejecting module FAS-216 Warehouse module FAS-220 Pallet transfer module FAS-230 Linear transfer for 4 modules FAS-200 Empty module for future projects User Manual for FAS200 - 6 -...

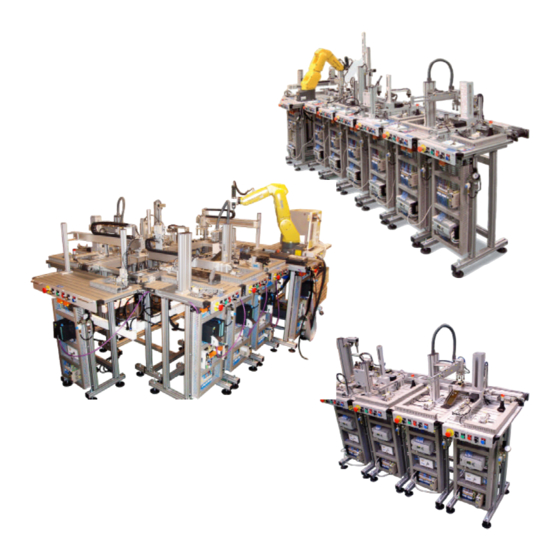

- Page 9 FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS200 CONFIGURATION: The modules that make up the configuration of this system FAS200 are: Figure 2: Example of system FAS200 with configuration of 8 modules. STATION Qty. FAS-201 Base Feeding/Verification module FAS-202 Base Rejecting/Transfering module FAS-203 Bearing Feeding/Transfering module FAS-204 Bearing Measuring/Transfering module...

- Page 10 FLEXIBLE ASSEMBLY SYSTEM FAS200 System FAS200 Number of modules: 8 modules Number of modular conveyors: 2 units of linear transfer (for 4 modules) Control: SIEMENS PLC of CPU 1214C serie. Field and control network: ETHERNET. Figure 3: Communication of the system FAS200 with configuration of 8 modules. User Manual for FAS200 - 8 -...

-

Page 11: General Overview

FLEXIBLE ASSEMBLY SYSTEM FAS200 2. GENERAL OVERVIEW: The flexible assembly system has been specially conceived for persons to acquire professional capabilities in connection with the Occupational Groupings of Electricity/ Electronics and Maintenance, such as: - Installation, Electromechanical Maintenance and Line Transport. - Industrial Equipment Maintenance. - Page 12 FLEXIBLE ASSEMBLY SYSTEM FAS200 The system comprises a flexible automation cell which carries out an assembly process involving a number of predetermined parts with a total of 24 different possibilities. Figure 5: Turning mechanism Figure 6: Turning mechanism components Parts are transported between the different modules by an automated linear transfer with corresponding stoppers and precision lifters-positioners.

- Page 13 FLEXIBLE ASSEMBLY SYSTEM FAS200 The process modules function either independently of the transport system, in in single or couple modes, or integrated into it, in cell mode. The modules are located in a side of the linear transfer, and may be withdrawn for re-positioning in a different order (the repositioning of different modules of the system can mean repositioning of stoppers, lifters-positioners and reprogramming of the controllers of the system),...

- Page 14 FLEXIBLE ASSEMBLY SYSTEM FAS200 front each station incorporates start, stop, step-by- step/continuous cycle and reset pushbuttons. In addition, the control pushbuttons incorporate a main switch on/off and emergency pushbuttons for emergency stops. Figure 12: Control pushbuttons of a module. The system is modular and may be extended, allowing future incorporation of other process modules according to user needs.

-

Page 15: Fas-230 Linear Transfer Module: Transport System

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-230 LINEAR TRANSFER MODULE: TRANSPORT SYSTEM Figure 13: FAS230 Linear Transfer Module. The transport system is composed by 2 meters long lines admitting up to four modules each (2`9 meters long lines admitting up to six modules each for special case) which links the modules to facilitate the envisaged assembly process. - Page 16 FLEXIBLE ASSEMBLY SYSTEM FAS200 Different layouts can be defined for future expansions. The transfer follows a rectangular path or linear path. The master PLC controls and coordinates the rest of the PLCs connected to the network and it is located in the “body feeding and checking”...

- Page 17 Both the pallet retention point and the relative position of the module within the system FAS200 may be varied, making it simple to modify the distribution of the component bases of the FAS-200. Although not recommended such modifications as the system FAS200 is sent mechanically adjusted and programmed to the specific distribution and any variation of the distribution would also reprogram the control of the system.

- Page 18 FLEXIBLE ASSEMBLY SYSTEM FAS200 Actuators (some modules): - 1 Compact double-acting cylinders with guide Ø16, Stroke: 30mm (MGPM16- 30Z), with flow regulators. Controlled by 5/2 way monostable solenoid valve. - 1 Two-directions rotary table ?max: 90º (MSUB3-90S), with flow regulators. Controlled by 5/2 way monostable solenoid valve.

-

Page 19: Troub-200 Fault Simulation System

FLEXIBLE ASSEMBLY SYSTEM FAS200 TROUB-200 FAULT SIMULATION SYSTEM Most of the modules incorporate a Fault Simulation System TROUB-200 fitted to the side of each module or in the electrical panel, depending of the configuration. Figure 18: TROUB-200 in the Figure 19: TROUB-200 in a side of electrical panel. -

Page 20: Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-201 BASE FEEDING/VERIFICATION MODULE Figure 20: FAS201 Base Feeding/Verification Module. FUNCTION OF THE MODULE: This first module feeds the body or base which is the support for the turning mechanism, verifies orientation and moves it to the final position (loading position) located in the transfer system of the next module. -

Page 21: Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 microswitch which sends the appropriate signal to the PLC of the second module which in turn sends the signal “start cycle” to the PLC of this first module. The confirmation of the body is in correct orientation is got by a pneumatic cylinder like a checker turning on an internal flag of the PLC, signal used by this PLC to send the signal “body OK”... - Page 22 FLEXIBLE ASSEMBLY SYSTEM FAS200 • Verification of position: The body contains a housing in which the other components are fitted. This housing must always be facing upwards when the base is placed on the pallet (in the next module). To check correct body...

- Page 23 FLEXIBLE ASSEMBLY SYSTEM FAS200 Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man), no material indicator and error pilot indicator. Composition of module manipulators: Body feeder Magazine capacity: 12 bodies. Actuators: - Double-acting pusher cylinder Ø16, Stroke: 100mm (CD85N16-100-B), with flow regulators and initial-end position detectors.

- Page 24 FLEXIBLE ASSEMBLY SYSTEM FAS200 Electrical control panel: - Mounted on perforated mesh. - Accessible terminal plate with supply connections and coded I/Os. - I/O station: 9 inputs, 5 outputs. - Supply module: 24V/60W. - PLC control: • CPU with digital inputs/outputs. •...

-

Page 25: Fas-202 Base Rejecting / Transfering Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-202 BASE REJECTING/TRANSFERING MODULE Figure 26: FAS202 Base Rejecting/Transfering Module. FUNCTION OF THE MODULE: This second module complementary to previous one. This module rejects of incorrect body or places the body on the pallet, depending of the signal “body OK” from the PLC of the preceding module after verification of the base orientation. - Page 26 FLEXIBLE ASSEMBLY SYSTEM FAS200 This operation begins when the pallet is positioned opposite the module, held in a determined location by a stopper on the linear transfer, and when the PLC of the first module sends the signal “end cycle” to the PLC of this second module. INTEGRAL PARTS: The second module, like the others, may be divided into a series of manipulators.

- Page 27 FLEXIBLE ASSEMBLY SYSTEM FAS200 Suction is generated by a vacuum ejector fitted with a vacuum switch which sends a signal to the PLC indicating that the part has been correctly clamped. Figure 30: Vacuum system. TECHNICAL DATA: Dimensions: Table of slotted aluminium, 450 x 582 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge.

- Page 28 FLEXIBLE ASSEMBLY SYSTEM FAS200 - Vertical axis: Parallel rod cylinder Ø15, Stroke: 50mm (CXSM15-50), with flow regulators and initial-end position detectors. Controlled by 5/2 way monostable solenoid valve. - Vacuum system: 4 telescopic suction cups Ø16 (ZPT16CNK10-B5-A10), with ejector to generate vacuum (ZU07S). Controlled by 3/2 way bistable solenoid valve.

-

Page 29: Fas-203 Bearing F Eeding /Transfering Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-203 BEARING FEEDING/TRANSFERING MODULE Figure 31: FAS203 Bearing Feeding/Transfering Module. FUNCTION OF THE MODULE: This third module feeds the bearing which is going to be placed inside the housing formed in the body by the next module. - Page 30 FLEXIBLE ASSEMBLY SYSTEM FAS200 This operation begins when the pallet is positioned opposite the fourth module, held in a determined location by a stopper and a positioner-lifter on the linear transfer. Confirmation that the pallet is in the correct position is provided by a microswitch which sends the appropriate signal to the PLC of the fourth module which in turn sends the signal “start cycle”...

- Page 31 FLEXIBLE ASSEMBLY SYSTEM FAS200 • Transfer to the measurement position: A manipulator is used to move the bearing from the feeding position (in this third module) to the place where the height measuring operation is to be performed (in next fourth module). The manipulator uses a rack and pinion type rotary actuator which describes an angle of 180º.

- Page 32 FLEXIBLE ASSEMBLY SYSTEM FAS200 Actuators: - Double-acting pusher cylinder Ø16, Stroke: 100mm (CD85N16-50-B), with flow regulators and end position detector. Controlled by 5/2 way monostable solenoid valve. Sensors: - Reed type magnetic detector (D-C73L). - Presence detector: Microswitch OMRON (V-166-1C5). Measurement position transfer manipulator Actuators: - Rotary actuator: Double rack and pinion Ø50, ? max: 180º...

-

Page 33: Fas-204 Bearing Measuring/Transfering Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-204 BEARING MEASURING/TRANSFERING MODULE Figure 36: FAS204 Bearing Measuring/Transfering Module. FUNCTION OF THE MODULE: This fourth module is complementary to previous one. Is in this module where the height is measured to differentiate between the two sizes of bearings. Figure 37: Manipulators of the fourth module. - Page 34 FLEXIBLE ASSEMBLY SYSTEM FAS200 This module rejects the bearing or places it inside the housing of the body on the pallet, depending of the signal “tall bearing” or “short bearing”. The confirmation of the bearing has got the correct height is got by a linear potentiometer like a measurer turning on an internal flag of the PLC, signal “tall bearing”...

- Page 35 FLEXIBLE ASSEMBLY SYSTEM FAS200 bearing deposited platform, with a centering device operated pneumatic cylinder which locates it at a very precise position, that is needed to perform the measurement of the height correctly. Figure 38: Measuring manipulator. This platform is lifted by a rodless pneumatic cylinder such that the bearing contacts with a touch trigger and gives a height reading.

- Page 36 FLEXIBLE ASSEMBLY SYSTEM FAS200 TECHNICAL DATA: Dimensions: Table of slotted aluminium , 450 x 582 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man) and error pilot indicator.

- Page 37 FLEXIBLE ASSEMBLY SYSTEM FAS200 - Rotary actuator: Double rack and pinion type Ø20, ? max: 180º (MSQXB20A), with flow regulators and two position detectors. Controlled by 5/2 way monostable solenoid valves. - Holding arm: Two-finger parallel-opening gripper (MHK2-16D). Controlled by 5/2 way bistable solenoid valve.

-

Page 38: Fas-205 Hydraulic Pressing Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-205 HYDRAULIC PRESSING MODULE Figure 40: FAS205 Hydraulic Pressing Module. FUNCTION OF THE MODULE: Following the bearing insertion operation performed by the preceding modules, this fifth module carries out the task of pressing the bearing firmly into the body to fix it securely. In actual fact, this pressing operation is not actually carried out;... - Page 39 FLEXIBLE ASSEMBLY SYSTEM FAS200 In spite of this, the components included are all industrial grade and similar to those used in numerous hydraulic applications. They allow the study of systems based on hydraulic technology which incorporate real components integrated in an authentic application. A complete hydraulic unit as required to supply the press cylinder with high pressure oil is installed under the table, avoiding the need for any additional hydraulic installation other than the electrical and pneumatic take-offs from the...

- Page 40 FLEXIBLE ASSEMBLY SYSTEM FAS200 By means of a hydraulic 4/3 way directional control valve, the pressing cylinder now exerts force which may be regulated using the pressure limiting valve incorporated in the hydraulic unit. After pressing, the cylinder returns to its original position, the screen is lifted and the assembly is pushed to the unloading position.

- Page 41 FLEXIBLE ASSEMBLY SYSTEM FAS200 TECHNICAL DATA: Dimensions: Table of slotted aluminium, 450 x 600 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man) and error pilot indicator.

- Page 42 FLEXIBLE ASSEMBLY SYSTEM FAS200 Electrical control panel: - Mounted on perforated mesh. - Accessible terminal plate with supply connections and coded I/Os. - I/O station: 13 inputs, 6 outputs. - Supply module: 24V/60W. - Safety relay with safety switch. - PLC control: •...

-

Page 43: Fas-206 Hydraulic Press Transfering Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-206 HYDRAULIC PRESS TRANSFERING MODULE Figure 44: FAS206 Hydraulic Press Transfering Module. FUNCTION OF THE MODULE: This sixth module is complementary to previous one. Is in this module where the base-bearing assembly is transfered from the pallet of the lineal conveyor to the platform of this module, and then from this platform to the hydraulic press of the previous module. - Page 44 FLEXIBLE ASSEMBLY SYSTEM FAS200 This operation begins when the pallet is positioned opposite the module, held in a determined location by a stopper on the linear transfer, and when the PLC of the fifth module sends the signal “end cycle” to the PLC of this sixth module. INTEGRAL PARTS The sixth module, like the others, may be divided into a series of manipulators.

- Page 45 FLEXIBLE ASSEMBLY SYSTEM FAS200 Figure 47: Feed cylinder to the press. TECHNICAL DATA: Dimensions: Table of slotted aluminium, 450 x 600 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man) and error pilot indicator.

- Page 46 FLEXIBLE ASSEMBLY SYSTEM FAS200 Press feed manipulation Actuators: - Double-acting pusher cylinders Ø12, Stroke: 125mm (CD85N12-125A), with flow regulators and initial-end of stroke position detectors. Controlled by 5/2 way monostable solenoid valves. Sensors: Reed type magnetic detectors (D-A73CL). Electrical control panel: - Mounted on perforated mesh.

-

Page 47: Fas-207 Shaft Classification Module

It is also essential that the module control coordinates part selection operations in accordance with commands supplied by the master responsible for production management in the FAS-200. Figure 49: Manipulators of this module. User Manual for FAS200 - 45 -... - Page 48 FLEXIBLE ASSEMBLY SYSTEM FAS200 Because of this, this module represents an increase in flexibility in that it allows variety in the assemblies put together, in the form of being able to fit shafts of different materials; aluminium or nylon. The existence of these variants means that the extra operations of checking the type of material and extracting ones which are not of the desired material are added to the normal operations of feeding, handling and insertion.

- Page 49 FLEXIBLE ASSEMBLY SYSTEM FAS200 • Index plate: This element is used as a system of alternating rotary movement, in the sense that each turning movement moves the plate round by a number degrees equal circumference divided number of defined positions. In this case, it is a plate of 8 different positions.

- Page 50 FLEXIBLE ASSEMBLY SYSTEM FAS200 Figure 52: Shaft feeder. • Shaft orientation checker: The shaft is not symmetrical and must therefore be mounted on the assembly in a particular position and orientation. The shaft is measured to check whether it has been correctly inserted.

- Page 51 FLEXIBLE ASSEMBLY SYSTEM FAS200 Figure 54: Material detection position. TECHNICAL DATA Dimensions: Table of slotted aluminium section, 450 x 582 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Pushbutton control: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man), no material indicator and error pilot indicator.

- Page 52 FLEXIBLE ASSEMBLY SYSTEM FAS200 Actuators: - 2 Double-acting cylinders Ø10, Stroke: 10mm (C85N10-10). Controlled by 5/2 way monostable solenoid valve. Shaft orientation checker Actuators: - Double-acting cylinder Ø12, Stroke: 50mm (CD85N12-50A), with flow regulators and end position detector. Controlled by 5/2 way monostable solenoid valve.

-

Page 53: Ransfering Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-208 SHAFT REJECTING/TRANSFERING MODULE Figure 55: FAS208 Shaft Rejecting/Transfering Module. FUNCTION OF THE MODULE: This eighth module is complementary to previous one. This module rejects the shaft or places it inside the housing of the body on the pallet, depending of the signal about the shaft material from the PLC of the previous module. - Page 54 FLEXIBLE ASSEMBLY SYSTEM FAS200 The task of placing the shaft is performed on the pallet brought by the belt conveyor and carrying the body-bearing assembly fed and assembled by the previous modules. The shaft fitting operation requires the pallet is stopped and retained by a stopper.

- Page 55 FLEXIBLE ASSEMBLY SYSTEM FAS200 It is this cylinder which turns an arm fitted with a suction cup used to holds the shaft throughout the movement. As in the case of the other manipulators using the vacuum technique, an ejector and vacuum switch are provided for the cylinder.

- Page 56 FLEXIBLE ASSEMBLY SYSTEM FAS200 Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Control panel: Start, stop, reset pushbuttons. Emergency stop button, cutout selector, mode selector (auto-man) and error pilot indicator. Composition of station modules: Shaft insertion in assembly module Actuators: - Compact linear and rotary movement cylinder Ø32, Stroke: 25mm (EMRQBS32-25CB), with flow regulators and initial-end of travel detection for...

- Page 57 FLEXIBLE ASSEMBLY SYSTEM FAS200 Sensors: - Reed type magnetic detectors (D-Z73L). - Vacuum switch PNP output (PS-1100-R06L). Electrical control panel: - Mounted on perforated mesh - Accessible terminal plate with supply connections and coded I/Os. - I/O station: 18 inputs, 11 outputs. - Supply module: 24V/60W - PLC control: •...

-

Page 58: Fas-209 Cover Classification Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-209 COVER CLASSIFICATION MODULE Figure 60: FAS209 Cover Classification Module. FUNCTION OF THE MODULE: The fourth of the components to be assembled in the system FAS200 is a cover which is fitted into a housing formed on the body for this purpose. The cover serves to retain the turning mechanism shaft mounted at the previous modules. - Page 59 It is also essential that the module control coordinates part selection operations in accordance with the commands supplied by the master responsible for production management in the FAS-200. This ninth module feeds the cover which is the closure cap for the turning mechanism, and verifies its material, color and height.

-

Page 60: Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 INTEGRAL PARTS: The ninth module, like the others, may be divided into a series of manipulators. Each sub-division has been made by considering it as a set of components which performs a specific operation within the whole process carried out at the module. - Page 61 FLEXIBLE ASSEMBLY SYSTEM FAS200 Figure 63: Cover feeder. There is a presence sensor in the form of a fiber optic detector which allows the PLC to verify that really there is at least a cover in the feeder to continue the feeding procedure.

- Page 62 FLEXIBLE ASSEMBLY SYSTEM FAS200 The component used consists of a pneumatic cylinder which moves the probe until it touches the cover. An integral linear encoder in the cylinder sends pulses which are counted by a quick counter input at the PLC, making it possible to determine the distance the cylinder advances until it makes contact with the cover.

- Page 63 FLEXIBLE ASSEMBLY SYSTEM FAS200 Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man), no material indicator and error pilot indicator. Composition of module manipulators: Index plate Actuators: - Pusher cylinder: Compact double-acting cylinder Ø25, Stroke: 40mm (CDQ2B25-40D), with flow regulators and initial position detector.

- Page 64 FLEXIBLE ASSEMBLY SYSTEM FAS200 Material detectors Sensors: - Inductive sensor: OMRON (E2A-M12KS04-M1). - Photoelectric sensor: OMRON (E3F2-DS30B4). Electrical control panel: - Mounted on perforated mesh. - Accessible terminal plate with supply connections and coded I/Os. - I/O station: 8 digital inputs, 2 counter inputs, 7 outputs. - Supply module: 24V/60W.

-

Page 65: Fas-210 Cover Rejecting/Transfering Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-210 COVER REJECTING/TRANSFERING MODULE Figure 67: FAS210 Cover Rejecting/Transfering Module. FUNCTION OF THE MODULE: This tenth module is complementary to previous one. This module rejects the cover or places it onside the housing of the body on the pallet, depending of the signal about the cover material from the PLC of the previous module. - Page 66 FLEXIBLE ASSEMBLY SYSTEM FAS200 This operation begins when the pallet is positioned opposite the module, held in a determined location by a stopper on the linear transfer, and when the PLC of the ninth module sends the signal “end cycle” to the PLC of this tenth module. The task of placing the cover is performed on the pallet brought by the belt conveyor and carrying the body-bearing-shaft assembly fed and assembled by the previous modules.

- Page 67 FLEXIBLE ASSEMBLY SYSTEM FAS200 • Cover insertion: Cover insertion, carried out from the last of the index plate position (on the previous module), is performed by a rotary-linear type manipulator. This rotary- linear cylinder makes it possible for a single component to pick up the cover, take it to the unloading point and insert it.

- Page 68 FLEXIBLE ASSEMBLY SYSTEM FAS200 Composition of module manipulators: Incorrect cover rejection manipulator Actuators: - Horizontal axis: Double-acting parallel rod cylinder Ø15, Stroke: 100mm (CXSM15-100), with flow regulators and initial-end position detectors. Controlled by 5/2 way bistable solenoid valve. - Vertical axis: Double-acting parallel rod cylinder Ø10, Stroke: 50mm (CXSM10-50), with flow regulators and initial position detector.

-

Page 69: Fas-211 Screws Dispensing Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-211 SCREWS DISPENSING MODULE Figure 71: FAS211 Screws Dispensing Module. FUNCTION OF THE MODULE: Following insertion operations for the bearing, shaft and cover performed by the preceding modules, this eleventh module carries out the task of feeding the screws that the next module is going to insert them in the four holes of the base (or body) for this purpose. - Page 70 FLEXIBLE ASSEMBLY SYSTEM FAS200 This operation begins when the pallet is positioned opposite the twelfth module, held in a determined location by a stopper (with lifter and rotary actuator) on the linear transfer. Confirmation that the pallet is in the correct position is provided by a microswitch which sends the appropriate signal to the PLC of the twelfth module which in turn sends the signal “start cycle”...

- Page 71 FLEXIBLE ASSEMBLY SYSTEM FAS200 This cylinder is used to transfer the screws from point at which they are fed in to the point where the following module picks them up for fitting to the assembly. In this case, there is a screws sensor in the form of a photoelectric cell with fiber optic which allows the PLC to verify that a screw really has been extracted following the feeding procedure.

- Page 72 FLEXIBLE ASSEMBLY SYSTEM FAS200 Transfer manipulation Actuators: Double-acting parallel rod cylinder Ø15, Stroke:100mm (CXSM15-100), with flow regulators and initial-end of stroke position detectors. Controlled by 5/2 way bistable solenoid valve. Sensors: Reed type magnetic detectors (D-Z73L). Photoelectric cell OMRON (E3X-NA41). Fiber optic OMRON (E32-DC200).

-

Page 73: Fas-212 Screws Insertion Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-212 SCREWS INSERTION MODULE Figure 75: FAS212 Screws Insertion Module. This module carries out the final operation to fit components to the assembly under construction, and involves the insertion of four screws in four threaded holes in the base body of the turning mechanism. The technology used to effect the movements at this module, based on different pneumatic cylinders, means it is only possible to unload the screws at a single point. - Page 74 FLEXIBLE ASSEMBLY SYSTEM FAS200 In contrast with preceding modules, where communication between the slave modules and the master was limited to sending start messages and end of cycle indications, here there is a greater need for coordination between the units. As a result, more use is made of the possibilities offered by the PLC network for information exchange between the different modules.

- Page 75 FLEXIBLE ASSEMBLY SYSTEM FAS200 • Screws insertion manipulator: Once the previous module have deposited a screw and transferred it to the pick-up point, this pneumatic manipulator fits the screw into one of the holes in the turning mechanism body retained on the transfer. Constructed using two parallel rod cylinders, this manipulator degrees...

- Page 76 FLEXIBLE ASSEMBLY SYSTEM FAS200 - Vertical axis: Double-acting parallel rod cylinder Ø15, Stroke: 50mm (CXSM15-50), with flow regulators and initial-end of stroke position detectors. Controlled by 5/2 way monostable solenoid valve. - Holding: Two-finger parallel opening pneumatic gripper (MHK2-16D) and open-closed position detectors.

-

Page 77: Fas-213 Robotized Screwing Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-213 ROBOTIZED SCREWING MODULE All the preceding modules were of a design which actuators based fluid technology predominated (pneumatics and hydraulics). These were primarily electropneumatic components, although the study of electrohydraulic technology was facilitated at the bearing pressing module. With a view to matching the system to all most widely... - Page 78 FLEXIBLE ASSEMBLY SYSTEM FAS200 INTEGRAL PARTS Given the flexibility and numerous possibilities offered by the use of robots in automating operations, at this module it is regarded as enough to use the element for the operations needed to drive in the four screws. Control of the robot’s movements between the different points can be carried out by a controller (different depending on the type of robot).

- Page 79 FLEXIBLE ASSEMBLY SYSTEM FAS200 Figure 82: Programming pendant for YASKAWA MOTOMAN robot. The operations of the robot begin when the pallet is positioned opposite the module, held in a determined location by a stopper and lifter (which incorporates a four centering pins for a suitable positioning) on the linear transfer.

- Page 80 FLEXIBLE ASSEMBLY SYSTEM FAS200 Control panel: Start, stop, reset pushbuttons. Emergency stop button, cutout selector, mode selector (auto-man) and error pilot indicator. Composition of station modules: - Robot YASKAWA MOTOMAN 6 axes (MHJ). - Compact Controller FS100 YASKAWA MOTOMAN . - Programming pendant YASKAWA MOTOMAN (JZRCR-YPP03-1), software and cable (depending of the configuration) - Electrical Screwdriver Hitachi (DB 3DL), 3`6V y 180 rpm.

-

Page 81: Fas-214 T Ransfering And Vision Inspection Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-214 TRANSFERING AND VISION INSPECTION MODULE With a view to matching the system to all the most widely used sensor techniques in industrial automation, this module introduces a new though widespread advanced sensor technology, that of vision system. For this, a very used process... - Page 82 FLEXIBLE ASSEMBLY SYSTEM FAS200 INTEGRAL PARTS The vision module, like the others, may be divided into a series of manipulators. Each sub-division has been made by considering it as a set of components which performs a specific operation within the whole process carried out at the module.

- Page 83 FLEXIBLE ASSEMBLY SYSTEM FAS200 Rotary movement and movement regulation is effected by step motor (servo/ direct current), with a phase A/B incremental encoder to provide instantaneous reading of motor rotation. Control is via driver which set up a closed loop force-position-speed regulation system.

- Page 84 FLEXIBLE ASSEMBLY SYSTEM FAS200 TECHNICAL DATA: Dimensions: Table of slotted aluminium, 450 x 600 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man) and error pilot indicator.

- Page 85 FLEXIBLE ASSEMBLY SYSTEM FAS200 Electrical control panel: - Mounted on perforated mesh. - Accessible terminal plate with supply connections and coded I/Os. - I/O station: 15 digital inputs, 15 outputs. - Supply module: 24V/60W. - PLC control: • CPU with digital inputs/outputs. •...

-

Page 86: Fas-215 After Visual Inspection Rejecting Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-215 AFTER VISUAL INSPECTION REJECTING MODULE Figure 88: FAS215 After Visual Inspection Rejecting Module. FUNCTION OF THE MODULE: This module is complementary to previous one. This module rejects the turning mechanism or places it on the pallet that is waiting on the transfer system, depending of the signal about the vision inspection system from the PLC of the previous module. - Page 87 FLEXIBLE ASSEMBLY SYSTEM FAS200 INTEGRAL PARTS The module, like the others, may be divided into a series of manipulators. Each sub-division has been made by considering it as a set of components which performs a specific operation within the whole process carried out at the module.

- Page 88 FLEXIBLE ASSEMBLY SYSTEM FAS200 Composition of module manipulators: Body rejection module Actuators: - Horizontal axis: Parallel rod cylinder Ø20 Stroke: 100mm (MGPM20-100Z) with flow regulators and initial-end position detector. Controlled by 5/2 way biestable solenoid valve. - Vertical axis: Parallel rod cylinder Ø15 Stroke: 50mm (CXSM15-50) with flow regulators and initial-end position detector.

-

Page 89: Fas-216 W Arehouse Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-216 WAREHOUSE MODULE Figure 90: FAS216 Warehouse Module. FUNCTION OF THE MODULE: Once the final assembly is completed, it must be removed from the transport system. This storage uses a system based on two coordinate axes, so that the bodies (with bearings, shafts, covers and screws) picked off the conveyor belt may be allocated at any point on the... - Page 90 FLEXIBLE ASSEMBLY SYSTEM FAS200 INTEGRAL PARTS The storage module, like the others, may be divided into a series of manipulators. Each sub-division has been made by considering it as a set of components which performs a specific operation within the whole process carried out at the module.

- Page 91 FLEXIBLE ASSEMBLY SYSTEM FAS200 TECHNICAL DATA: Dimensions: Table of slotted aluminium, 450 x 582 mm. Height 900 mm. Air treatment unit: Filter to 5 µm, pressure regulator and pressure gauge. Control panel: Start, stop, reset pushbuttons. Emergency stop button, main switch on/off, mode selector (auto-man) and error pilot indicator.

- Page 92 FLEXIBLE ASSEMBLY SYSTEM FAS200 Drivers: - Servodriver serie LEC (LECA6P-LEFS25AA-500).. Electrical control panel: - Mounted on perforated mesh. - Accessible terminal plate with supply connections and coded I/Os. - I/O station: 17 inputs, 13 outputs. - Supply module: 24V/240W. - Servodriver serie LEC. - PLC control: •...

-

Page 93: Fas-220 Pallet Transfer Module

FLEXIBLE ASSEMBLY SYSTEM FAS200 FAS-220 PALLET TRANSFER MODULE Figure 94: FAS220 Pallet Transfer Module. FUNCTION OF THE MODULE: This modules allow transfer the pallets from one row of the system (conveyor belts) to the next one so when the layout of the system can be a closed loop or opened, but never in line. - Page 94 FLEXIBLE ASSEMBLY SYSTEM FAS200 Can be more than one module FAS220 per configuration of the system FAS200: If the layout is opened in U-shaped, there must be only one module FAS220 to transfer the pallets between the two linear transfers FAS230: Figure 96: System FAS200 in opened layout.

- Page 95 FLEXIBLE ASSEMBLY SYSTEM FAS200 If the layout is opened in line, any module FAS220 is necessary to transfer the pallets because the linear transfer itself FAS230 is moving the pallets between the modules of the system FAS200: Figure 98: System FAS200 with layout in line. The manipulator of this module is designed with two cartesian axes in U- shaped.

- Page 96 FLEXIBLE ASSEMBLY SYSTEM FAS200 The vacuum system is formed with a ejector, element to generate a vacuum; a vacuum switch, sensor to detect the correct level of vacuum, enough hand safety assembly; and four suction cups, final elements act with the vacuum. Figure 100: Ejector and vacuum switch.

- Page 97 FLEXIBLE ASSEMBLY SYSTEM FAS200 The assembly is stopped al the end of belts of the linear transfer by a metal piece, not allowing it to continue on its way and falll to the floor, waiting in this position to be picked up and taken to the next belts of next linear transfer.

- Page 98 FLEXIBLE ASSEMBLY SYSTEM FAS200 Horizontal axis Actuators: - Double-acting rodless cylinder Ø25, Stroke: 600mm (MY1C25G-600), with flow regulators and initial-end position detectors. Controlled by 5/2 way biestable solenoid valve. Sensors: - Reed type magnetic detectors (D-Z73L). - Capacitive sensor: OMRON (E2K-X4MF1). Electrical control panel: - Mounted on perforated mesh.

Need help?

Do you have a question about the FAS-200 and is the answer not in the manual?

Questions and answers