Siemens SIMATIC ET 200SP Manual

Hide thumbs

Also See for SIMATIC ET 200SP:

- System manual (409 pages) ,

- Manual (270 pages) ,

- Operating instructions manual (166 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Siemens SIMATIC ET 200SP

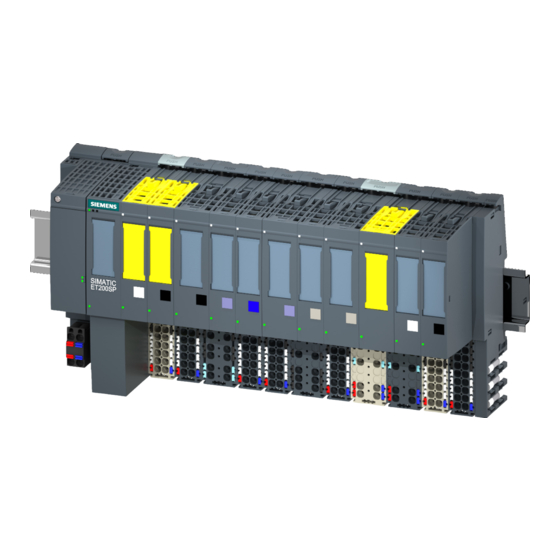

- Page 2 ___________________ Preface ___________________ Documentation guide ___________________ SIMATIC Product overview ___________________ Wiring ET 200SP Technology Module TM Count ___________________ 1x24V (6ES7138-6AA00-0BA0) Configuring/address space ___________________ Interrupts/diagnostic messages Manual ___________________ Technical specifications ___________________ Parameter data record 02/2017 A5E33002339-AB...

- Page 3 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 4: Preface

In order to protect plants, systems, machines and networks against cyber threats, it is necessary to implement – and continuously maintain – a holistic, state-of-the-art industrial security concept. Siemens’ products and solutions only form one element of such a concept. Customer is responsible to prevent unauthorized access to its plants, systems, machines and networks. - Page 5 Siemens accepts no liability for the use of the open source software over and above the intended program sequence, or for any faults caused by modifications to the software.

-

Page 6: Table Of Contents

Table of contents Preface ..............................4 Documentation guide ..........................7 Product overview ............................. 11 Properties ..........................11 Functions ..........................14 2.2.1 Detection of counting signals ....................14 2.2.2 Measured value determination ....................16 2.2.3 Switching the outputs at comparison values ................17 2.2.4 Position input for Motion Control .................... -

Page 7: Documentation Guide

Documentation guide The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three areas. This arrangement enables you to access the specific content you require. Basic information The system manual describes in detail the configuration, installation, wiring and commissioning of the SIMATIC ET 200SP. - Page 8 You can download the product information free of charge from the Internet (https://support.industry.siemens.com/cs/us/en/view/73021864). Manual Collection ET 200SP The Manual Collection contains the complete documentation on the SIMATIC ET 200SP distributed I/O system gathered together in one file. You can find the Manual Collection on the Internet (https://support.industry.siemens.com/cs/ww/en/view/84133942).

- Page 9 ● Manuals, characteristics, operating manuals, certificates ● Product master data You can find "mySupport" - CAx Data in the Internet (http://support.industry.siemens.com/my/ww/en/CAxOnline). Application examples The application examples support you with various tools and examples for solving your automation tasks. Solutions are shown in interplay with multiple components in the system - separated from the focus in individual products.

- Page 10 You can find the SIMATIC Automation Tool on the Internet (https://support.industry.siemens.com/cs/ww/en/view/98161300). PRONETA With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network during commissioning. PRONETA features two core functions: ● The topology overview independently scans PROFINET and all connected components.

-

Page 11: Product Overview

Product overview Properties Article number 6ES7138-6AA00-0BA0 View of the module ① ⑥ Module type and designa- LED for encoder supply tion ② ⑦ LED for diagnostics LED for supply voltage ③ ⑧ 2D matrix code Function class ④ ⑨ Terminal connection dia- Module type color coding gram ⑤... - Page 12 Product overview 2.1 Properties Properties The TM Count 1x24V technology module has the following properties: ● Technical properties – One channel – Interfaces: 24 V encoder signals A, B and N from sourcing, sinking or push pull encoders and sensors 24 V encoder supply output, short-circuit proof DI0, DI1 and DI2 digital input signals DQ0 and DQ1 digital output signals...

- Page 13 BaseUnits that you can use with the technology module, please refer to the product information on the documentation for the ET 200SP Distributed I/O System (http://support.automation.siemens.com/WW/view/en/73021864). For detailed information on the installation procedure, refer to the ET 200SP Distributed I/O System (http://support.automation.siemens.com/WW/view/en/58649293) system manual. Technology Module TM Count 1x24V (6ES7138-6AA00-0BA0) Manual, 02/2017, A5E33002339-AB...

-

Page 14: Functions

Product overview 2.2 Functions Functions 2.2.1 Detection of counting signals Counting refers to the detection and summation of events. The counters of the technology module detect encoder signals and pulses and evaluate them accordingly. The count direction can be specified using encoder or pulse signals or through the user program. You can control the counting processes with the digital inputs. - Page 15 Product overview 2.2 Functions Capture (Latch) You can configure an external reference signal edge that triggers the saving of the current counter value as Capture value. The following external signals can trigger the Capture function: ● Rising or falling edge of a digital input ●...

-

Page 16: Measured Value Determination

Product overview 2.2 Functions 2.2.2 Measured value determination The following measuring functions are available: Measurement type Description Frequency measurement The mean frequency is calculated at set measuring intervals on the basis of the time profile of the count pulses and returned in hertz as the floating point number. -

Page 17: Switching The Outputs At Comparison Values

"Motion Control"". Additional information A detailed description of the use of Motion Control and its configuration is available in the function manual S7-1500 Motion Control as a download from the Internet (http://support.automation.siemens.com/WW/view/en/59381279). Technology Module TM Count 1x24V (6ES7138-6AA00-0BA0) Manual, 02/2017, A5E33002339-AB... -

Page 18: Fast Mode

Product overview 2.2 Functions 2.2.5 Fast Mode You can use the technology module in Fast Mode for very fast detection of the counter value in case of compressed functionality. In Fast Mode, you have access to a reduced feedback interface but not to a control interface. This means you can use a shorter send clock for the CPU. - Page 19 Product overview 2.2 Functions Gate control Opening and closing the hardware gate (HW gate) defines the period of time during which the counting signals are recorded. The control of the hardware gate takes place externally via the digital inputs of the technology module.

-

Page 20: Additional Functions

Product overview 2.2 Functions 2.2.6 Additional functions Synchronization You can configure the edge of an external reference signal to load the counter with the specified start value. The following external signals can trigger a synchronization: ● Rising or falling edge of a digital input ●... - Page 21 Additional information A detailed description of isochronous mode can be found in the PROFINET with STEP 7 function manual, which is available for download on the Internet (https://support.industry.siemens.com/cs/ww/en/view/49948856). Technology Module TM Count 1x24V (6ES7138-6AA00-0BA0) Manual, 02/2017, A5E33002339-AB...

-

Page 22: Wiring

ET 200SP Distributed I/O System (http://support.automation.siemens.com/WW/view/en/73021864). You can find information about selecting a suitable BaseUnit in the ET 200SP Distributed I/O System (http://support.automation.siemens.com/WW/view/en/58649293) system manual and ET 200SP BaseUnits (http://support.automation.siemens.com/WW/view/en/58532597/133300) device manual. You can find information on wiring the BaseUnit, connecting cable shields, etc. in the Connecting section of the ET 200SP Distributed I/O System (http://support.automation.siemens.com/WW/view/en/58649293) system manual. - Page 23 Wiring 3.1 Pin assignment Terminal assignment of the BaseUnit The table below shows the pin assignment, using the BaseUnit BU15-P16+A0+2B as an example. Table 3- 1 Pin assignment of the BaseUnit BU15-P16+A0+2B View Signal Designation name 24 V incremental encoder 24 V pulse encoder With Without...

- Page 24 Wiring 3.1 Pin assignment Block diagram The figure below shows the block diagram of the technology module. You must ground the shields of the cables between encoder and technology module both through the shield terminal on the BaseUnit (shield bracket and terminal) and also on the encoder.

- Page 25 Wiring 3.1 Pin assignment 24VDC encoder supply To supply the encoder and sensors at the digital inputs, the technology module supplies the DC 24V supply voltage at the 24VDC output with reference to M. Voltage is supplied from the L+/M supply voltage and monitored for short circuits and overload. 24 V encoder signals/count signals The 24 V encoder signals are designated A, B and N.

- Page 26 Wiring 3.1 Pin assignment Input filter for 24 V encoder signals To suppress interferences, you can configure an input filter for the counting inputs A, B and N. The selected filter frequency is based on a pulse/break ratio of between 40:60 and 60:40. This results in a specific minimum pulse/break time.

- Page 27 Wiring 3.1 Pin assignment ● 12.8 ms ● 20 ms Note If you select the "None" or "0.05 ms" option, you have to use shielded cables for connection of the digital inputs. Digital outputs DQ0 and DQ1 There are two digital outputs. The two digital outputs DQ0 and DQ1 can be activated/switched directly by the specified comparison values or by the user program.

-

Page 28: Configuring/Address Space

Configuring/address space Configuring Introduction The technology module is configured and assigned parameters with the configuration software. The technology module functions are controlled and monitored by the user program. System environment The technology module can be used in the following system environments: Applications Components required Configuration software... - Page 29 Configuring/address space 4.1 Configuring Applications Components required Configuration software In the user program Distributed operation STEP 7 (TIA Portal): High_Speed_Counter in- S7-1500 automation • with an S7-1500 struction system Operating with technology object "Counting and measurement" ET 200SP distributed • I/O system Device configuration with hardware •...

- Page 30 GSD file The respective GSD file for the ET 200SP distributed I/O system is available for download on the Internet: ● GSD file PROFINET IO (http://support.automation.siemens.com/WW/view/en/57138621) ● GSD file PROFIBUS DP (http://support.automation.siemens.com/WW/view/en/73016883) Technology Module TM Count 1x24V (6ES7138-6AA00-0BA0) Manual, 02/2017, A5E33002339-AB...

-

Page 31: Reaction To Cpu Stop

Configuring/address space 4.2 Reaction to CPU STOP Reaction to CPU STOP You set the response of the technology module to CPU STOP for each channel in the basic parameters of the device configuration. Table 4- 1 Response of technology module to CPU STOP Option Meaning Continue opera-... -

Page 32: Address Space

Configuring/address space 4.3 Address space Address space Address space of the technology module Table 4- 2 Range of the input addresses and output addresses of the TM Count 1x24V Inputs Outputs Range 16 bytes 12 bytes Table 4- 3 Range of the input addresses and output addresses of the TM Count 1x24V in "Position input for technology object "Motion Control""... -

Page 33: Parameters

Configuring/address space 4.4 Parameters Parameters 4.4.1 Parameter setting You can use various parameters to define the properties of the technology module. Depending on the settings, not all parameters are available. When parameters are assigned in the user program, the parameters are transferred to the module with the "WRREC" instruction and data record 128 (Page 73). - Page 34 Configuring/address space 4.4 Parameters Parameter setting via ... Basic procedure Hardware configuration in STEP 7 1. Select an appropriate CPU under "Add new device > Controller > SIMATIC (TIA Portal) in "Manual operation S7-1500 / SIMATIC ET 200 CPU"". (without technology object)" operating 2.

- Page 35 Configuring/address space 4.4 Parameters Parameter setting via ... Basic procedure Hardware configuration using GSD 1. Install the latest PROFINET GSD file. file for distributed operation on the You will then find the module in the hardware catalog under "Additional Field PROFINET IO Devices >...

-

Page 36: Parameters For Operating With Technology Object "Counting And Measurement

Configuring/address space 4.4 Parameters 4.4.2 Parameters for operating with technology object "Counting and measurement" Parameters of the TM Count 1x24V The following parameter settings are possible: Table 4- 5 Settable parameters and their default setting in "Operating with technology object "Counting and measure- ment""... - Page 37 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range configura- with tion in RUN configuring soft- ware HSP for STEP 7 (TIA Portal) Filter frequency for counter 200 kHz Channel 100 Hz • inputs 200 Hz • 500 Hz •...

- Page 38 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range configura- with tion in RUN configuring soft- ware HSP for STEP 7 (TIA Portal) Hardware interrupt: New Deactivated Channel Deactivated • Capture value available Activated • Hardware interrupt: Syn- Deactivated Channel Deactivated...

- Page 39 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range configura- with tion in RUN configuring soft- ware HSP for STEP 7 (TIA Portal) Edge selection for DI At rising edge Channel At rising edge • At falling edge •...

- Page 40 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range configura- with tion in RUN configuring soft- ware HSP for STEP 7 (TIA Portal) Time base for velocity 60 s/1 min Channel 1 ms • measurement 10 ms • 100 ms •...

-

Page 41: Parameters For Position Input For "Motion Control" Technology Object

Configuring/address space 4.4 Parameters 4.4.3 Parameters for position input for "Motion Control" technology object Parameters of the TM Count 1x24V The following parameter settings are possible: Table 4- 6 Settable parameters and their default setting in "Position input for technology object "Motion Control"" operat- ing mode Parameters Value range... - Page 42 Configuring/address space 4.4 Parameters Parameters Value range Default setting Effective range configura- with tion in RUN configuring soft- ware HSP for STEP 7 (TIA Portal) Sensor type Sourcing output Channel Sourcing output • Sinking output • Push-pull (sinking and sourcing •...

-

Page 43: Parameters For Manual Operation (Without Technology Object)

Configuring/address space 4.4 Parameters 4.4.4 Parameters for manual operation (without technology object) Parameters of the TM Count 1x24V The following parameter settings are possible: Table 4- 7 Settable parameters and their default setting in "Manual operation (without technology object)" operating mode Parameter Value range... - Page 44 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Filter frequency for 200 kHz Channel Channel 100 Hz • counter inputs 200 Hz •...

- Page 45 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Hardware interrupt: Zero Deactivated Channel Channel Deactivated • crossing Activated • Hardware interrupt: New Deactivated Channel...

- Page 46 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Set function of DI Channel Channel Gate start/stop (level-triggered) DI0: Gate •...

- Page 47 Configuring/address space 4.4 Parameters Parameter Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Reaction to violation of a Continue Channel Channel Stop counting • counting limit counting Continue counting...

-

Page 48: Parameters For Operating In Fast Mode

Configuring/address space 4.4 Parameters 4.4.5 Parameters for operating in Fast Mode Parameters of the TM Count 1x24V The following parameter settings are possible: Table 4- 8 Settable parameters and their default setting in "Fast Mode" operating mode Parameters Value range Default setting Effective range with configura-... - Page 49 Configuring/address space 4.4 Parameters Parameters Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Invert direction (counter Deactivated Channel Channel Deactivated • inputs) Activated • Reaction to signal N No reaction to Channel...

- Page 50 Configuring/address space 4.4 Parameters Parameters Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Edge selection for DI At rising edge Channel Channel At rising edge •...

- Page 51 Configuring/address space 4.4 Parameters Parameters Value range Default setting Effective range with configura- configuring software tion in HSP for HSP for STEP 7 STEP 7; (TIA Portal) GSD file Hysteresis 0...255 Channel Channel Potential group Use the poten- Module Module Use the potential group of the •...

-

Page 52: Control And Feedback Interface

A detailed description of the control and feedback bits is available in the Counting, Measurement and Position Detection function manual, which can be downloaded on the Internet (http://support.automation.siemens.com/WW/view/en/59709820). Note Except in "Fast Mode" operating mode, the control and feedback interface is compatible with the control and feedback interface of the TM Count 2x24V technology module of the S7-1500 automation system. -

Page 53: Assignment Of The Control Interface

Configuring/address space 4.5 Control and feedback interface 4.5.1 Assignment of the control interface The user program uses the control interface to influence the behavior of the technology module. Control interface The following table shows control interface assignment: Byte offset from Parameter Meaning start address... - Page 54 Configuring/address space 4.5 Control and feedback interface Byte offset from Parameter Meaning start address EN_CAPTURE Bit 7: Capture function enable EN_SYNC_DN Bit 6: Enable synchronization down EN_SYNC_UP Bit 5: Enable synchronization up SET_DQ1 Bit 4: Set DQ1 SET_DQ0 Bit 3: Set DQ0 TM_CTRL_DQ1 Bit 2: Enable technological function DQ1 TM_CTRL_DQ0...

-

Page 55: Assignment Of The Feedback Interface

Configuring/address space 4.5 Control and feedback interface 4.5.2 Assignment of the feedback interface The user program receives current values and status information from the technology module by means of the feedback interface. Feedback interface The following table shows the assignment of the feedback interface: Byte offset from Parameter Meaning... -

Page 56: Assignment Of The Feedback Interface In Fast Mode

Configuring/address space 4.5 Control and feedback interface 4.5.3 Assignment of the feedback interface in Fast Mode The user program receives current values and status information from the technology module by means of the feedback interface. Feedback interface The following table shows the assignment of the feedback interface in Fast Mode: Byte offset from Parameter Meaning... -

Page 57: Interrupts/Diagnostic Messages

Interrupts/diagnostic messages Status and error displays LEDs The figure below shows you the LED displays (status and error displays) of TM Count 1x24V. ① ⑧ DIAG (green/red) Status of DI1 (green) ② ⑨ Status A (green) Status of DI2 (green) ③... - Page 58 Interrupts/diagnostic messages 5.1 Status and error displays Meaning of the LED displays The following tables explain the meaning of the status and error displays. Remedial measures for diagnostic messages can be found in the section Diagnostic messages (Page 60). Table 5- 1 Status and error displays DIAG LED DIAG Meaning...

- Page 59 Interrupts/diagnostic messages 5.1 Status and error displays ChannelLEDs The A, B, N and DIm LEDs indicate the current level of the associated signals. The LEDs of the digital outputs DQm indicate the desired state. The LEDs UP and DN indicate the logical counting direction. The flashing frequency of the channel LEDs is limited to ca.

-

Page 60: Diagnostic Messages

Interrupts/diagnostic messages 5.2 Diagnostic messages Diagnostic messages Enabling the diagnostic interrupts You enable the diagnostic interrupts in the basic parameters of the device configuration. The technology module can trigger the following diagnostic interrupts: Table 5- 5 Possible diagnostic interrupts Diagnostic interrupt Monitoring Monitoring is always active. - Page 61 RD_REC instruction using data record 0 and 1. For the structure of the data records, refer to the product manual for the IM 155-5 DP ST interface module, which is available for download on the Internet (https://support.industry.siemens.com/cs/ww/en/view/78324181). Diagnostic messages The diagnostics are displayed as plain text in STEP 7 (TIA Portal) in the online and diagnostics view.

- Page 62 Interrupts/diagnostic messages 5.2 Diagnostic messages Diagnostic alarm Error Meaning Remedy code Hardware interrupt Module cannot send an interrupt because a Change interrupt processing in the • • lost previous interrupt has not been processed CPU and re-assign technology module parameters correspondingly Possible cause: Too many hardware inter- •...

- Page 63 Interrupts/diagnostic messages 5.2 Diagnostic messages Diagnostic alarm Error Meaning Remedy code Wire break at Channel not connected Connect the channel digital input A, B Resistance of encoder circuit too high Use a different encoder type or modify • or N the wiring, for example, use shorter cables with larger cross-sections Check encoders...

-

Page 64: Hardware Interrupts

Interrupts/diagnostic messages 5.3 Hardware interrupts Hardware interrupts Introduction For the technology module, you can configure which events are to trigger a hardware interrupt during operation. What is a Hardware Interrupt? The technology module will trigger a hardware interrupt as configured in response to specific events/states. - Page 65 Interrupts/diagnostic messages 5.3 Hardware interrupts Hardware interrupt EventType number Synchronization of the counter by an external signal Direction reversal Can only be configured in Counting mode The feedback bit STS_DIR has the default value "0". A hardware interrupt is not triggered when the first counter value is changed immediately after switching on the technology module in the down direction You can activate any combination of events to trigger hardware interrupts.

-

Page 66: Technical Specifications

Technical specifications 6ES7138-6AA00-0BA0 Product type designation TM Count 1x24V General information BaseUnits that can be used BU type A0 Product function I&M data Yes; I&M0 to I&M3 Engineering with STEP 7 TIA Portal can be configured/integrated V13 / ‒ as of version STEP 7 can be configured/integrated as of version V5.5 SP3 / ‒... - Page 67 Technical specifications 6ES7138-6AA00-0BA0 Digital inputs Number of inputs Digital inputs, configurable Input characteristics to IEC 61131, Type 3 Digital input functions, configurable Gate start/stop Capture Yes; not available with Fast Mode Synchronization Freely assignable digital input Input voltage Rated value, DC 24 V For signal "0"...

- Page 68 Technical specifications 6ES7138-6AA00-0BA0 Load resistance range Low limit 48 Ω High limit 12 kΩ Output voltage for signal "1", min. 23.2 V; L+ (-0.8 V) Output current for signal "1" rated value 0.5 A; per digital output for signal "1" permissible range, max. 0.6 A;...

- Page 69 Technical specifications 6ES7138-6AA00-0BA0 24 V encoder signal -30 V Permitted voltage at input, min. • 30 V Permitted voltage at input, max. • Interface hardware Input characteristics to IEC 61131, Type 3 Sinking/sourcing input Isochronous mode Isochronous mode (application synchronized until terminal) Bus cycle time (TDP), min.

- Page 70 Technical specifications 6ES7138-6AA00-0BA0 Position detection Suitable for S7-1500 Motion Control Measuring functions Measuring time, configurable Dyn. measuring time adjustment Number of threshold values, configurable Measuring range 0.04 Hz Frequency measurement, min. • 800 kHz Frequency measurement, max. • 1.25 µs Period measurement, min.

- Page 71 Technical specifications Derating information for total current of outputs If the digital outputs of the TM Count 1x24V are operated with resistive or inductive loads, you should derate the total current of the loads at the digital outputs of the technology module.

- Page 72 If the switching frequency is greater than 0.5 Hz or there is greater inductance at the digital outputs, the total current must be reduced further. Dimensional drawing See ET 200SP BaseUnits (http://support.automation.siemens.com/WW/view/en/58532597/133300) manual Technology Module TM Count 1x24V (6ES7138-6AA00-0BA0) Manual, 02/2017, A5E33002339-AB...

-

Page 73: Parameter Data Record

Parameter data record Parameter assignment and structure of the parameter data record You have the option of reassigning module parameters with the user program while the CPU is in RUN. The parameters are transferred to the module using data record 128, for example with the WRREC instruction. - Page 74 Parameter data record A.1 Parameter assignment and structure of the parameter data record Bit → Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Byte ↓ 4...51 Counting channel Operating mode Reserved Operating mode: 0000 : Reserved 0001...

- Page 75 Parameter data record A.1 Parameter assignment and structure of the parameter data record Bit → Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Byte ↓ 8...9 Hardware interrupts Reserved Change of Underflow Overflow Gate stop Gate start...

- Page 76 Parameter data record A.1 Parameter assignment and structure of the parameter data record Bit → Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Byte ↓ Behavior of DI0 Behavior of Edge selection (DI0): Select level Reserved Set function of DI (DI0):...

- Page 77 Parameter data record A.1 Parameter assignment and structure of the parameter data record Bit → Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Byte ↓ Counter behavior at limits and gate start Reaction to gate start: Reaction to violation of a counting limit: Reset when counting limit is violated:...

- Page 78 Parameter data record A.1 Parameter assignment and structure of the parameter data record Structure of data record 128 in Fast Mode The following table shows you the structure of data record 128 for TM Count 1x24V for "Fast Mode" operating mode. The values in byte 0 to byte 3 are fixed and must not be changed. Table A- 2 Parameter data record 128: "Fast Mode"...

- Page 79 Parameter data record A.1 Parameter assignment and structure of the parameter data record Bit → Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Byte ↓ 10...15 Behavior of a DQ Set output (DQ1): Set output (DQ0): 0000 : Digital output without function...

- Page 80 Parameter data record A.1 Parameter assignment and structure of the parameter data record Bit → Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Byte ↓ 20...43 Values 20...23 High counting limit: DWORD: Value range: 1 to 33554431 or 1 to 01FFFFFF 24...27 Comparison value 0:...

-

Page 81: Parameter Validation Error

Parameter data record A.2 Parameter validation error Parameter validation error If you make the parameter settings in STEP 7 (TIA Portal) or in STEP 7 , the parameter values are checked before they are transferred to the technology module. This process prevents parameter errors. - Page 82 Parameter data record A.2 Parameter validation error Error codes The following table shows the module-specific error codes and their meaning for parameter data record 128. Table A- 3 Error codes for parameter validation Error code in STATUS parame- Meaning Remedy ter (hexadecimal) Byte 0 Byte 1 Byte 2 Byte 3 Data record number unknown...

- Page 83 Parameter data record A.2 Parameter validation error Error code in STATUS parame- Meaning Remedy ter (hexadecimal) Byte 0 Byte 1 Byte 2 Byte 3 Low counting limit > comparison value 0 Low counting limit < comparison value 0 • • Low counting limit >...

Need help?

Do you have a question about the SIMATIC ET 200SP and is the answer not in the manual?

Questions and answers