Table of Contents

Advertisement

1.

2.

3.

4.

5.

6.

7.

8.

9.

24. Laddomat 21

Instruction manual - GB

Contents

www.atmos.cz

3

3

4

4

5

6

7

7

8

9

9

10

10

12

12

12

13

14

14

14

15

16

16

17

17

18

18

19

20

20

21

21

22

23

23

24

24

24

24

25

25

25

26

26

27

28

28

28

29

29

29

30

31

32

32

32

33

34

34

34

35

35

36

37

38

39

GB-1

Advertisement

Table of Contents

Summary of Contents for Atmos C15E

-

Page 1: Table Of Contents

24. Laddomat 21 25. Thermoregulatory valve ESBE 26. Operating a system with accumulation tanks The standard ATMOS accumulation tanks provided Tank insulation Advantages 27. Connection of overheat protecting cooling loop with a safety valve Honeywell TS 130 - 3/4 A or WATTS STS20 28. - Page 2 24 to 36 months. The guarantee period for other parts remains unaffected. In non-compliance with these instructions the drum’s and the heatproof pipes’ serv- ice life may dramatically decrease. The boiler drum may corrode in as little time as 2 years. www.atmos.cz 2-GB...

-

Page 3: Intended Use

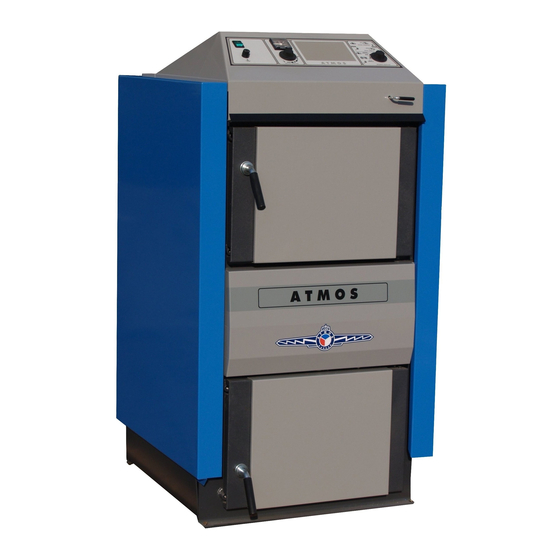

Instruction manual - GB 1. Intended use The environmentally friendly boilers ATMOS DC 15/18/20/22/25/30/32/40/50/70/75 are designed for heating family houses, cottages, holiday houses and other similar objects. Boilers are suitable for buildings with heat loss ranging between 15 - 75 kW, depending on type. The boilers are constructed mainly for burning log food. -

Page 4: Control Panel For Boilers With Ventilator

1. Thermometer 6. Ignition valve pulling rod 2. Main switch 7. Area for electronic regulation of the heating 3. Waste gas thermostat system (92x138 mm) 4. Control thermostat (boiler) 8. Pump thermostat (only DC 15EPL) 5. Safety irreversible thermostat www.atmos.cz 4-GB... -

Page 5: Advantages Of Boilers

DC15E excluded). Large fuel hopper allows burning of the log pieces with the maximum length 330 - 1,000 mm, depending on the boiler type. Large pieces of waste wood can also be burned. All boilers are equipped with cooling loop for overheating protection. www.atmos.cz GB-5... -

Page 6: Technical Data

Instruction manual - GB 3. Technical data www.atmos.cz 6-GB... -

Page 7: Boiler Drawings Key

970 1170 1170 1140 1470 946 1092 1046 1046 946 1100 1153 930 1000 930 930 1000 1000 1000 1000 1137 1100 1100 1000 1230 1100 6/4” 6/4” 6/4” 6/4” 6/4” 6/4” 6/4” 6/4” 6/4” 6/4” 2” 2” 2” 2” 2” 2” www.atmos.cz GB-7... -

Page 8: Drawings Of Boilers

Instruction manual - GB Drawings of boilers www.atmos.cz 8-GB... -

Page 9: Cut Away View - Dc15E

Cut away view - DC15E Cut away view – DC70S Combustion chamber 3. Ash-pan door 5. Heatproof shaped piece - nozzle 31. Heatproof shaped piece – half moon 32. Heatproof shaped piece – combus- tion area plate. 34. Cleaning aperture www.atmos.cz GB-9... -

Page 10: Extraction Ventilator Schematics

(DC22S, DC25S, DC25S DC30SX, DC32S, DC40SE, DC30SX DC40SX) length 500 mm; DC32S DC50S boilers (DC50S, DC40SE DC50SE) length 700 mm. DC40SX DC50SE Roof of the lower combustion area must always be fully pressed against the boiler rear wall. www.atmos.cz 10-GB... - Page 11 CAUTION – do not turn the rear face when handling 4. For type 39. Combustion area lining (2 x 2 piece) 38. Spherical area Spherical area /14/ must be DC15E pushed to the rear of combus- tion area www.atmos.cz GB-11...

-

Page 12: Boiler Accessories

Wood with 20% moisture contents has thermal power of 4 kWh /1 kg of wood Wood with 60% moisture contents has thermal power of 1.5 kWh /1 kg of wood • Example – spruce wood which has been stored for 1 year under shelter – see graph www.atmos.cz 12-GB... -

Page 13: Boiler Bases

Boiler output drops as low as 50% and fuel consumption doubles. 7. Boiler bases We recommend providing a concrete (metal) Boiler type (mm) base under the boiler. DC15E/DC18S/DC22SX DC20GS DC22S/DC25S/DC30SX DC30SE/DC32S/DC25GS/ DC32GS/DC40GS/DC40SX DC40SE 1000 DC50SE 1000 DC50S, DC70S 1000 DC75SE 1300 www.atmos.cz GB-13... -

Page 14: Environment Type And Boiler Placement In A Boiler Room

The flue-gas duct must be connected into the chimney vent stack. If the boiler cannot be connected to the chimney directly, the appropriate flue-gas duct extension must be as short as possible in the given circumstances, but not longer than 1m, it must be without additional heating surface and must incline www.atmos.cz 14-GB... -

Page 15: Fire Prevention During Installation And Use Of Heating Appliances

300 mm (in front of the aperture) and on all the other sides by at least 100 mm. The non-combustible, heat insulating pad can be made from any material of A flam- mability class. www.atmos.cz GB-15... -

Page 16: Connecting Boilers To The Electric Network

(as per ČSN EN 60335—1/1997). Connection may only be carried out by a person qualified in compliance with all valid regulations of the particular country. 13. Wiring diagram of electromechanical regulation with ex- traction ventilátor, type UCJ 4C52 (DC18S – DC40SE) and with pressure ventilátor (DC80, DC7OS, DC22SX – DC40SX) www.atmos.cz 16-GB... -

Page 17: Wiring Diagram Of Electromechanical Regulation With An Ucj 4C52 ( Dc5Ose) Type Extraction Ventilator

14. Wiring diagram of electromechanical regulation with an UCJ 4C52 ( DC5OSE) type extraction ventilator - - - - - Possibility to connect the outlet to a pump with a 95°C safety thermostat 15. Wiring diagram of electromechanical regulation of the DC15E type boiler www.atmos.cz GB-17... -

Page 18: Wiring Diagram For Dc75Se - Electromechanical Regulation With An Ucj 4C52 Type Extraction Ventilator

ČSN EN 442-2 - Heaters – Testing and test analysis CAUTION – the boiler must be installed in compliance with a design prepared in ad- vance. Installation may only be carried out by persons trained by the manufacturer. www.atmos.cz 18-GB... -

Page 19: Choice And Connection Method Of Control And Heating Elements

For the heating system regulation we recommend regulation elements provided by the following companies: a) KOMEXTHERM, Praha Telephone: +420 235 313 284 b) KTR, Uherský Brod Telephone: +420 572 633 985 c) Landis & Staefa Telephone: +420 261 342 382 www.atmos.cz GB-19... -

Page 20: Boiler Corrosion Protection

����� ������ ������ ���� ������ ������ ��������� ���� ����� ������ ��� � ��������� ��� ��� ������ ��� ��� ����� ������ ����� �� � ���� ����� ����� ���������� ���� ������� ����� ����������� ��������� ���� ������ ����� ����� �������� �� www.atmos.cz 20-GB... -

Page 21: Specified Boiler Connection With Laddomat

���� ���������� ��� � ����� ��� �������� ������������� ������ ��� � ����� ���� ���������� ���� ����� ������ ������ ���� ���� ������ ������ ��������� ����� ��������� ����� ������� ������������ ���� ����������� ��������� ���� ������ ����� ����� ����� �������� �� www.atmos.cz GB-21... -

Page 22: Recommended Wiring Diagram With Laddomat 21 And Accumulators

Instruction manual - GB 23. Recommended wiring diagram with Laddomat 21 and ac- cumulators www.atmos.cz 22-GB... -

Page 23: Laddomat

Recommended sizes of the thermoregulatory valve TV 60°C. For boilers: D15E, DC18S, DC20GS, DC22S, DC22SX DC25S, DC25GS, DC30SX ..DN 25 DC32S, DC32GS, DC40GS, DC40SE, DC40SX ........DN 32 DC50S, DC50SE, DC70S, DC75SE ..........DN 40, DN 50 www.atmos.cz GB-23... -

Page 24: Operating A System With Accumulation Tanks

DC30SX DC40SX Output Volume 1000-1500 1500-2000 1500-2000 2000-2500 2500-3000 3000-4000 4000-5000 5000-6000 The standard ATMOS accumulation tanks provided TANK TYPE VOLUME ( l ) DIAMETER (mm) HEIGHT (mm) AN 500 1901 AN 750 1925 AN 1000 1000 2011 Tank insulation A suitable solution is joint mineral wool insulation of the particular number of tanks (of required volume) placed together into a plasterboard structure, or additional filling with granular insulation. -

Page 25: Connection Of Overheat Protecting Cooling Loop With A Safety Valve Honeywell Ts 130 - 3/4 A Or Watts Sts20

Before putting boilers into operation, it is necessary to ensure that the system has been filled with wa- ter, and air-bled. Wood boilers must be operated in compliance with the instructions stipulated in this manual so that satisfactory and safe functioning is achieved. They can only be operated by adults. www.atmos.cz GB-25... -

Page 26: Ignition And Operation

The regulation is based on the pre-set outgoing temperature value. The temperature set on the thermostat should be 5°C lower than the temperature set on the FR 124 draught regulator. (Indicated by dots on the thermostat scale). www.atmos.cz 26-GB... -

Page 27: Draught Regulator - Honeywell Braukmann Fr 124 - Assembly Instructions

95°C, the control flap valve must be fully closed (only providing the setscrew gap). It is always necessary to fine-tune the specified operating temperature (80-90°C) uti- lising the mixing valves behind the boiler either manually or by electronic regulation with electric actuator. www.atmos.cz GB-27... -

Page 28: Boiler Output And Combustion Setting

Maximum setting: fully closed (5 mm) + 10÷20 mm Boiler with compressive ventilator DC70S Basic setting of primary-secondary air ratio (70kW) Optimum setting: fully closed (5 mm) + 5÷10 mm Maximum setting: fully closed (5 mm) + 15÷20 mm www.atmos.cz 28-GB... -

Page 29: Setting The Servo-Drive Controlled Valve With In-Built Spring For Boilers Dc50Se

CAUTION – during operation, the ignition valve pulling rod must be retracted, other- wise damage to the ventilator (S) will occur. Otherwise, the ventilator (S) will sustain damage. 31.Steady heat operation It is possible to use boilers for slow-burning operation, i.e. keeping the fire up overnight without the www.atmos.cz GB-29... -

Page 30: Boiler Cleaning

7 to 14 days. Boilers DC70S must be checked at least 2x a year and the compressive ventilator and the air duct may need cleaning. If necessary, clean the area behind the heating area rear screen from tars and ash /41/, /19/. www.atmos.cz 30-GB... -

Page 31: Ceramic Ash Areas

Maximum ash quantity ! NOTE –regular and thorough cleaning is important for permanent stabilised output and a long service life of your boiler. If not cleaned properly, damage to the boiler may occur –the manufacturer’s guarantee is rendered invalid www.atmos.cz GB-31... -

Page 32: Heating System Maintenance - Including Boilers

- design issue set water temperatures heating system - use dry firewood and split logs into halves - low quality fuel (high mois- - repair ture content, over sized logs) - ignition valve leaking www.atmos.cz 32-GB... -

Page 33: Spares

/28/ Breaker /37/ CAUTION – for boilers DC18S, DC22S, DC25S, DC20GS, DC22SX, DC25GS, DC30SE, DC30SX use the draught ventilator UCJ4C52 with rotation wheel around Ø150 mm; for boilers DC32GS, DC40GS, DC32S, DC50S, DC40SE, DC40SX use the draught ventila- www.atmos.cz GB-33... -

Page 34: Heatproof Shaped Piece (Nozzle) Replacement

If you want to adjust the hinge settings, first take off the upper hood (control panel) and remove both pins. Then remove the door and slightly turn the screw with a right- www.atmos.cz 34-GB... -

Page 35: Environmental Protection

37. Environmental protection The ATMOS gasifying boilers comply with the most demanding environmental requirements and were awarded the “Environmentally friendly product” mark, in compliance with directive No. 13/ 2002 of the Ministry of Environment of the Czech Republic. The boilers are certified in compliance with the European standard EN 303-5 and they fall within class 3. -

Page 36: Guarantee Conditions

- company representing ATMOS in the particular country for the particular region - installation company that carried out the installation - Jaroslav Cankař a syn ATMOS, Velenského 487, 294 21 Bělá pod Bezdězem, Czech Republic, Telephone. +420 326 701 404 www.atmos.cz... -

Page 37: Boiler Installation Report

Boiler functions and all regulations and safety Size: ............elements were inspected during the operation Moisture content: .........* start-up. Person responsible for the inspection: ..........Dne: ......Stamp : ..........Customer’s signature: ........(Responsible person’s signature) * measured values www.atmos.cz GB-37... -

Page 38: Annual Inspections Records

Date Date Date Date stamp and signature stamp and signature stamp and signature stamp and signature Date Date Date Date stamp and signature stamp and signature stamp and signature stamp and signature www.atmos.cz 38-GB... -

Page 39: Records Of Guarantee Period And Post-Guarantee Period Repairs

Repair: ..............................Repair: ..............................Repair: ..............................Repair: ..............................Repair: ..............................Repair: ........................................repair carried out by, date Repair: ..............................Repair: ..............................Repair: ..............................Repair: ..............................Repair: ..............................Repair: ..............................Repair: ........................................repair carried out by, date www.atmos.cz GB-39... - Page 40 Coll. N.V.č.71/2000 Coll., N.V.č.102/2001 Coll. N.V.č.205/2002 Coll. The product is safe providing the aforementioned conditions are followed The manufacturer Jaroslav Cankař a syn ATMOS has taken measures to ensure the compliance of the products launched on the market with technical documentation and essential requirements.

Need help?

Do you have a question about the C15E and is the answer not in the manual?

Questions and answers