Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Atmos DC 18 S

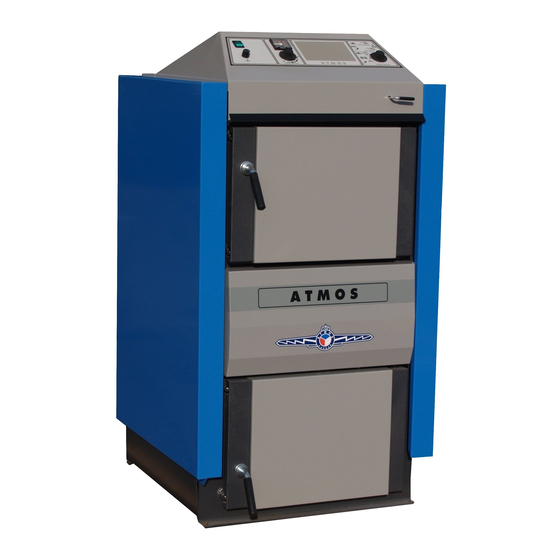

- Page 1 DC 25 S DC 50 SE DC 25 GS DC 32 S DC 75 SE DC 32 GS DC 50 S DC 40 GS 11/2002 Producer: Jaroslav CANKAŘ - ATMOS Bělá pod Bezdězem Tel.: +420 326 / 701 404, 701 414 www.atmos.cz...

- Page 2 WE WISH YOU ARE SATISFIED WITH OUR PRODUCT AND THEREFORE WE RECOMMEND YOU TO KEEP THE BELOW MENTIONED PRINCIPLES THAT ARE IMPORTANT FOR THE LONG LIFE AND CORRECT FUNCTION OF THE BOILER. 1. The used wood must be dry – max. 12 - 20 % of moisture – 2 years old. 2.

-

Page 3: Purpose

1. Purpose The ecological warm water boiler ATMOS is determined for heating in the one-family houses and other similar buildings. The boiler types are used according to the required power output from 20 up to 75 kW. The boilers are constructed especially for combustion of lump wood. All kind of dry wood can be used, especially wood billets with the max. -

Page 6: Operating Instructions

WASTE GAS EXHAUST VENTILATOR = COMFORTABLE TEMPERATURE The boiler generator is operated with a pre-heated primary and secondary air. The combustion is cha- racterized through a warm constant flame with constant burning quality. The big fuel hopper enables to burn the wood billets of max. length 330 – 1000 mm according to the boiler type. -

Page 7: Firing-Up And Operation

The boiler must be operated in accordance with these instructions to ensure the quality and the secu- re function of the boiler. The boilers are allowed to be attended only by adult persons. During the assembly lay under the rear boiler part to 10 mm. NOTICE During the first firing up a condesation and a condensate outflow appears –... -

Page 8: Operation With Permanent Glowing

Operation with permanent glowing It is possible to operate the boiler with permanent glowing, it means the fire can be kept during the whole night without firing up every day. In the boiler the burning process can continue for more than 12 hours, therefore it is possible after a filling up of the wood and after switching on the ventilator to reach in a short time the full power output of the boiler again. -

Page 9: Maintenance Of The Heating System Incl. Boiler

CERAMICS Maximum amount of ash is up to the level of the roof upper edge! 5. Maintenance of the heating system incl. boiler The water in the heating system must be check and if necessary refilled at least once in 14 days. If the boiler is out of operation during the winter, the water in the system could freeze. -

Page 10: Boiler Accessories

Laddomat. The warranty and after-warranty service is carried out by: ATMOS – Bělá pod Bezdězem Cankař Jaroslav, 294 21 Bělá pod Bezdězem, tel: +420 326/701404 fax: +420 326 70 14 92 and by trade representation companies of ATMOS... -

Page 11: Possible Defects And Trouble Shooting

12. Possible defects and trouble shooting Defect Cause Removal pilot lamp „network“ does - no voltage in the network - to check not burn - the plug is not pushed in the socket properly - to check - faulty switch - to change - faulty cable - to change... - Page 12 The safety distance (200 mm) must be doubled, if the boiler and the flue gas ductings are installed near inflammable materials class C3 (see chart Nr. 1). The safety distance is also to double if the inflam- mability class of the materials is not determined. The safety distance is reduces to a half (100mm) using the thermal insulation plates (asbestos plates) that are incombustible and min.

-

Page 13: Flue Gas Ducting

14. Flue gas ducting The flue gas ducting must be connected to the chimney. If it is not possible to connect the boiler with the chimney directly, the flue tube should be as short as posiible, not longer than 1 m, without any addi- tional heating surface, and it must raise in the chimney direction. -

Page 14: Spare Parts

Considering the power output of the boiler we recommend to add 10 % for the potencial lower fuel quality and higher moisture. The boiler must be installed in such a way, that in case of a fall-out of electrical energy the boiler is protected against overheating, otherwise the boiler might be damaged. -

Page 15: Door Hinges And Door Closing

• Spruce wood after 1 year of shed storage Max. boiler power output kWh/kg if using this fuel: DC 18 S - 13 kW DC 20 GS - 14 kW DC 25 GS - 19 kW DC 32 GS - 24 kW... -

Page 16: Legend To The Boiler Diagram

ATMOS DC 18 S DC 20 GS DC 32 GS DC 25 GS DC 40 GS DC 40 SE DC 50 SE DC 75 SE DC 22 S DC 25 S DC 32 S DC 50 S 1120 1200 1200... -

Page 17: Boiler With Exhaust Ventilator (S)

BOILER WITH EXHAUST VENTILATOR (S) ATMOS ATMOS GENERATOR DC 18 S, DC 22 S, DC 25 S, DC 32 S, DC 20 GS, DC 25 GS, DC 32 GS, DC 40 GS DC 40 SE, DC 50 S, DC 50 SE, DC 75 SE... -

Page 18: Type And Installation Of Shaped Pieces Into The Combustion Chamber

The roof is composed of two pieces – see the figure. (DC 75SE - 2 x 500 mm) 3. For the type: DC 18 S Shaped piece (spherical space) should be assembled in such a way that the front part of the shaped piece DC 20 GS (10) is 3 cm from the front edge of the boiler frame. -

Page 19: Honeywell Braukmann

– adjustment of the primary and secondary air primary air proportion Setting for the boilers DC 18 S - DC 40 SE (GS) supply optimum: to the stop (5 mm) + 6÷10 mm maximum: to the stop (5 mm) + 10÷12 mm... -

Page 20: Installation Diagram Mechanical Regulation With Exhaust Ventilator - Variant A

Installation Diagram mechanical regulation with exhaust ventilator, Type UCJ 4C52, UCJ 4C82 (DC 18 S - DC 75 SE) (DC 20 GS - DC 40 GS) Variant A The boiler has a combustion products thermostat and a pump thermostat 70 °C. -

Page 21: Installation Diagram Mechanical Regulation With Exhaust Ventilator - Variant B

Installation Diagram mechanical regulation with exhaust ventilator, Type UCJ 4C52, UCJ 4C82 (DC 18 S - DC 75 SE) (DC 20 GS - DC 40 GS) Variant B Process Flue-gas thermostat thermostat Process Cut-out switch thermostat black black Pump Pump thermostat 90 °C... -

Page 22: Installation Diagram With Laddomat 21 And Accumulating Tanks

Installation diagram with LADDOMAT 21 and Accumulating tanks Tubing diameter for Installation with Accumulating tanks Power output of Boiler Part A Part B Copper Steel Copper Steel 18 - 25 kW 28x1 25(1”) 28x1 25(1”) 30 - 40 kW 35x1,5 32(5/4”) 28x1 25(1”) -

Page 23: Boiler Protection Against Overheating

Filter Waste ATMOS The safety valve TS 130 has a sensor placed on the boiler back, protects the boiler against overheating: if the temperature in the boiler exceeds 95 °C, the water is supplied through the water inlet pipe into the cooling loop –... -

Page 24: Laddomat 21

Laddomat 21 Laddomat 21 replaces with its construction Ball valve the normal installation of individual parts. It 1/4“ consists of a cast iron body, a thermoregula- ting valve, a pump, a safety valve, ball valves and thetmometers, when the temperature of water in the boiler is 78 °C, the thermoregula- Ball valve ting valve opens an inlet from a container. -

Page 25: Warranty Certificate

WARRANTY CERTIFICATE for warm water boiler type: ..............series/production year: ..........date of sale: .............. dealer’s stamp: ............Unfilled warranty certificate is invalid Warranty conditions: 1. If observing the purpose of use, operating and maintenance conditions stated in this instructions, we warrant, that the product will keep the qualities complying with the technical standards and conditions for the whole warranty period, it means 12 months since the date of the taking over of the product by the customer and max. -

Page 26: Certification About The Quality And Completeness Of The Product

CERTIFICATION ABOUT THE QUALITY AND COMPLETENESS OF THE PRODUCT The warm water boiler, prod. number:......was checked before shipping. The product complies with the required quality and is complete according to the enclosed product documentation. The product is in conformity with the standard EN 303-5 and LGBL Nr. 33/1992. Prepared for shipping on: Final test: Date:... -

Page 27: Records On Carried Out Guarantee And Post-Guarantee Repairs

Records on carried out guarantee and post-guarantee repairs Repair: ................ -

Page 28: Table Of Contents

CONTENT 1. Purpose ..............2 2. - Page 29 Comments:...

Need help?

Do you have a question about the DC 18 S and is the answer not in the manual?

Questions and answers