Table of Contents

Advertisement

Quick Links

WARNING: FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death, or property damage.

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

-

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appliance

and shall be installed for the protection of children

and other at-risk individuals.

This appliance may be installed in an aftermarket, permanently located, manufactured home

(USA only) or mobile home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. A conversion

kit is supplied with the appliance.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Travis Industries, Inc.

Copyright 2015, T.I.

4415 HO ST

(with screen)

Installation Manual

HOT GLASS WILL CAUSE

BURNS

DO NOT TOUCH GLASS

UNTIL COOLED

NEVER ALLOW CHILDREN

TO TOUCH GLASS

12521 Harbour Reach Dr., Mukilteo, WA 98275

$10.00

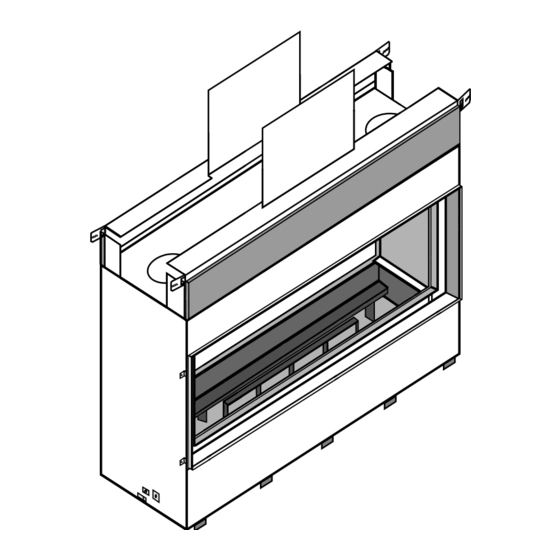

Built-In Direct Vent

Natural Gas or Propane

Residential or Mobile

4150624

Tested and Listed by

Report # 101861882PRT-001

ANSI Z21.88a-2014

CSA 2.33a-2014

Fireplace

Home

www.travisproducts.com

100-01425

Advertisement

Table of Contents

Summary of Contents for Travis Industries 4415 HO ST

- Page 1 4415 HO ST (with screen) Installation Manual WARNING: FIRE OR EXPLOSION HAZARD Failure to follow safety warnings exactly could result in serious injury, death, or property damage. - Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

-

Page 2: Overview

A copy is shown to the right. Massachusetts Approval This manual has been submitted to the Massachusetts Board of State Examiners of Plumbers and Gas Fitters. National Fireplace Institute © Travis Industries 4150624 100-01425... -

Page 3: Table Of Contents

Restrictor Position ............24 Exhaust Restrictor ............24 Intake Restrictor ..............25 Diffuser ................26 Minimum Vent Configuration ........27 Vent Configuration: Vertical Termination ....28 Vent Configuration: Horizontal Termination with Vertical Rise ............29 © Travis Industries 4150624 100-01425... -

Page 4: Safety Warnings

Do not operate if any portion of the heater was submerged in water or if any corrosion occurs. Immediately call a qualified service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water. © Travis Industries 4150624 100-01425... - Page 5 Travis Industries, Inc. grants no warranty, implied or stated, for the installation or maintenance of your heater, and assumes no responsibility of any consequential damage(s).

-

Page 6: Installation Options

34.75 883mm 11.25" 1" 286mm 25mm 15.75" 401mm NOTE: The front is marked "SERVICE SIDE". 10.375" 52.25" * 264mm 1328mm * 16.25" 413mm * Includes the requisite clearance to framing (0.625" 16mm to the sides) © Travis Industries 4150624 100-01425... -

Page 7: Packing List

Secure the fireplace to the framing. Install the drywall. Install the hearth (if applicable). Install the facing (if applicable). Install the mantel (if applicable). Finalize the installation (see page 36). © Travis Industries 4150624 100-01425... -

Page 8: Massachusetts Requirements

See Gas Connection section for additional Commonwealth of Massachusetts requirements. © Travis Industries 4140627 100-01353... -

Page 9: Fireplace Placement Requirements

The base of the fireplace must be a minimum 64” (1626mm) below the room ceiling. The firebox opening is approximately 10.375” (264mm) above the base of the fireplace. For a typical raised fireplace of 36” (915mm), place the fireplace on a platform 25.625” (651mm) tall. © Travis Industries 4150624 100-01425... -

Page 10: Televisions Placed Above The Fireplace

The homeowner must understand that Travis Industries does not take responsibility for any negative impact to televisions placed near this fireplace. -

Page 11: Using A Buildout Above Fireplace And Television

The homeowner must understand that Travis Industries does not take responsibility for any negative impact to televisions placed near this fireplace. -

Page 12: Using A Buildout Below A Television

The homeowner must understand that Travis Industries does not take responsibility for any negative impact to televisions placed near this fireplace. -

Page 13: Minimum Framing Dimensions

16.25" (413mm) Flush (both sides) * The 15.25" (388mm) dimension is based upon 1/2" (13mm) drywall around the perimeter of the fireplace on both sides. If using thicker drywall (or other facing), you will need to adjust this dimension. © Travis Industries 4150624 100-01425... -

Page 14: Nailing Brackets - Extended (Tile Over) Install

(bend tab down and secure). Secure the fireplace to the framing using the nailing brackets © Travis Industries 4140627 100-01353... -

Page 15: Nailing Brackets - Flush Install

Bend the side nailing brackets as shown below. Rotate the bracket on the rivet 180 degrees. Secure the fireplace to the framing using the nailing brackets and vertical drywall support. © Travis Industries 4150624 100-01425... -

Page 16: Removing The Front Panel

The front cover may be removed to access the components. This is required when relocating the electrical or gas inlet location. To remove the front cover (a) Remove the center nut. (b) Loosen the two outer nuts. (c) Rotate the front panel down. (d) Remove the 11/32" Nutdriver/Wrench front cover. © Travis Industries 4140627 100-01353... -

Page 17: Gas Line Requirements

5/16” i.d. rubber or plastic tubing over the tapered test port. Connect the tubing to the test gauge. WARNING: The brass screw must be tightened after testing to prevent gas leakage. Output pressure Input pressure © Travis Industries 4150624 100-01425... -

Page 18: Gas Line Location

Attach the shutoff valve plate to the bottom of the fireplace. Route the gas line to the bottom and re-attach the gas line to the shutoff valve. Make sure to leak test the entire gas line. © Travis Industries 4140627... -

Page 19: Electrical Connection

(keep the screws). Attach the junction box to the baseplate (make sure all wiring is kept from contacting hot or moving components). Attach the cover plate to the left side. Junction Box Junction Box (from inside fireplace) Baseplate Cover Plate © Travis Industries 4150624 100-01425... -

Page 20: Vent Requirements

Horizontal sections require a 1/4" (6mm) rise every 12" (305mm) of travel. Horizontal sections require non-combustible support every three feet (e.g.: plumbing strap). © Travis Industries 4140627 100-01353... -

Page 21: Vertical Pipe Shield (Both Sides)

Installation (for qualified installers only) Vertical Pipe Shield (both sides) The vertical pipe shields must be bent to a vertical position after the fireplace is in position. © Travis Industries 4150624 100-01425... -

Page 22: Minimum Vent Pipe Shield - Used For Minimum Vent Applications Only

Secure the pipe shield to the vent with the included screws (use the 6 brackets). Make sure the pipe is placed so it protrudes over the elbow as shown below. 12” Section (required) © Travis Industries 4140627 100-01353... -

Page 23: Vent Clearances When Venting Vertically

(1" is required). With a single header, the vent will meet clearances (approx. 2" gap). 6-5/8" Pipe (approx. 6.75" dia.) 8" Pipe (approx. 8.25" dia.) 8.125" 207mm 8.125" 207mm SIDE OF SIDE OF FIREPLACE FIREPLACE © Travis Industries 4150624 100-01425... -

Page 24: Approved Vent Configurations

(see the illustration below). Screw location indicates restrictor position. In this example, the restrictor is set in position # 4. Tighten the screws to secure the restrictor. (open - stock position) # 1 Back of Firebox © Travis Industries 4140627 100-01353... -

Page 25: Intake Restrictor

Position # 3 Loosen the three screws shown above (1/4” nutdriver). Slide the restrictor down all the way down and re-tighten the screws. © Travis Industries 4150624 100-01425... -

Page 26: Diffuser

Remove the diffuser. 1/4" Nutdriver Bend the round portion of the diffuser so it is flat (open). DIFFUSER SIDE VIEW Secure the flattened diffuser plate with the Before (Closed - Stock) screws removed earlier. After (Open) © Travis Industries 4140627 100-01353... -

Page 27: Minimum Vent Configuration

The termination must fall within the shaded area shown in the chart. Use the indicated restrictor positions. One 45° elbow may be used on the horizontal run. HINT: Use minimum vent kit “H” from Travis Industries (additional vent will be required). NG (Natural Gas) Exhaust Restrictor # 1 (stock) -

Page 28: Vent Configuration: Vertical Termination

(it does not matter both lengths of horizontal run whether it turns right or left). (Horizontal Length = H1 + H2). It may be a 90° or 45° elbow. This is considered a vertical elbow © Travis Industries 4140627 100-01353... -

Page 29: Vent Configuration: Horizontal Termination With Vertical Rise

(it does not matter both lengths of horizontal run whether it turns right or left). (Horizontal Length = H1 + H2). It may be a 90° or 45° elbow. This is considered a vertical elbow © Travis Industries 4150624 100-01425... -

Page 30: Vent Configuration: Horizontal Termination With Vertical Rise - 8" Vent

(it does not matter both lengths of horizontal run whether it turns right or left). (Horizontal Length = H1 + H2). It may be a 90° or 45° elbow. This is considered a vertical elbow © Travis Industries 4140627 100-01425... -

Page 31: Termination Requirements

Minimum 12” (305mm) above the roof line (for vertical terminations) Minimum 24” (610mm) horizontal clearance to any surface (such as an exterior wall) – for vertical terminations NOTE: Measure clearances to the nearest edge of the exhaust hood. © Travis Industries 4150624 100-01425... -

Page 32: Hearth Requirements

Drywall Supports Attach the drywall supports (see page 15 for details on modifying the supports for flush installations). © Travis Industries 4140627 100-01353... -

Page 33: Facing Requirements - Flush Install

4415 = 45.5" 1156mm 261mm 6015 = 61.5" 1563mm below the glass opening (do not place seams on corners of glass, especially the upper corners). Base of Fireplace Do not drill zone © Travis Industries 4150624 100-01425... -

Page 34: Facing Requirements - Extended (Tile Over) Install

NOTE: Screws may be used to secure cement board or tile backer to the fireplace. Do not penetrate the fireplace more than 1/2” (13mm). (a) Fiber Board (included with fireplace) (b) Drywall (or other 11-1/4" combustible) 286mm (c) Tile (or other non- 15-3/4" combustible) 401mm 10-3/8" 45-1/4" 264mm 1150mm © Travis Industries 4140627 100-01353... -

Page 35: Do Not Drill Or Screw Zone

Make sure screws penetrate no more than ½” (13mm) into the fireplace. Maximum Screw Penetration = 1/2" (long screws will hinder component access) Do not drill screws into this shaded area. Fireplace components are located in this area. © Travis Industries 4150624 100-01425... -

Page 36: Mantel Requirements

Combustible mantel columns (legs) that protrude ¾” (19mm) or less from the glass frame must meet the facing clearances (minimum 0” (0mm) from the side of the fireplace). Non-combustible mantel columns do not have a minimum clearance. © Travis Industries 4140627 100-01353... -

Page 37: Steps For Finalizing The Installation

5. Make sure the accent light bulbs are in place and work correctly. NOTE: Take care to not touch the bulb with your fingers (use a cloth or paper towel). 6. Install the crushed glass (see page 44). 7. Replace the glass frame. © Travis Industries 4150624 100-01425... -

Page 38: Air Shutter Adjustment

ACID WASH WARNING: Make sure any masonry that has been treated with acid wash has been properly neutralized (this is used primarily with brick faces). Acid wash (muriatic acid) is used to remove excess mortar. © Travis Industries 4140627 100-01353... -

Page 39: Convection Air Diverter (Front Vs. Back)

--To adjust the air to the rear, adjust the right side diverter counter-clockwise (approximately ¼ turn) and the left side diverter clockwise. --NOTE: You can adjust the diverter to any combination to obtain the desired heat distribution. Cutaway of Air Diverter © Travis Industries 4150624 100-01425... -

Page 40: Glass Frame Removal And Installation

The glass frame tool is shipped inside the fireplace, under the concealment cover. The first time it is used you may need to loosen the screw (1/4” wrench). The tool is accessed after removing the screen. NOTE: Replace the tool in this location after use. © Travis Industries 4140627 100-01353... - Page 41 1. Remove the concealment cover and place aside. It has two holes that aid in removal. 2. Remove the three screws holding the screen in place (1/4” nutdriver- magnetic driver recommended). Then pivot the screen down slightly until the clips on the bottom disengage from the glass frame. © Travis Industries 4150624 100-01425...

- Page 42 3. Use the glass tool to unlatch the glass frame. Remove the glass frame. The glass frame is held in place with four tabs inserted into four slots at the bottom of the firebox opening. © Travis Industries 4140627 100-01353...

-

Page 43: Fireback Installation

Install the firebacks as shown below. Remove the fireback clips on both sides. These clips have key-holes, allowing removal without removing the screw. 5/16" Nutdriver Place the side firebacks in place then secure using the clips removed earlier. © Travis Industries 4150624 100-01425... -

Page 44: Crushed Glass Installation

Disperse the crushed glass evenly along the glass tray. Make sure the two air channels are free of crushed glass. Use the glass frame tool (or screwdriver) to clear this area. Make sure the glass is only 1 layer deep on the burner. © Travis Industries 4140627 100-01353... -

Page 45: Lp Conversion Instructions

(regulator), torx wrench, and pilot orifice. The burner orifices and burner gaskets are shipped with the appliance. 1. Access the firebox. 2. Remove the glass tray. Remove the 4 screws holding it in place (1/4” nutdriver). © Travis Industries 4150624 100-01425... - Page 46 4. Remove the burner support as shown below. It is held in place with 10 screws (1/4” nutdriver). 5. Remove and discard the NG (stock) manifold cover and orifice gasket (1/4” nutdriver). Install the LP manifold cover included in the owner’s pack. LP Manifold Cover © Travis Industries 4140627 100-01353...

- Page 47 (a) Use a 7/16” open-end wrench to remove the pilot hood. (b) Remove and discard the Natural Gas (NG) orifice. Place the LP orifice in the pilot assembly then replace the pilot hood, tightening the pilot hood until it is snug (do not over-tighten). © Travis Industries 4150624 100-01425...

- Page 48 10. Replace the remaining firebox components. 11. Replace the glass. 12. Make the gas line connection, bleed the gas line (if applicable), start the heater and thoroughly leak-test all gas connections and the gas control valve. © Travis Industries 4140627 100-01353...

-

Page 49: Wiring Diagram

Power 3 Amp Fuse 3 Amp Fuse Appliance Ground 3.15A FUSE Integrated Pilot Sensor Fireplace Flame Control Detect (IFC) Spark System Jumper Appliance Ground IPI/CPI JUMPER WIRE Black (4) AA Batteries Battery Box (Manual On/Off) © Travis Industries 4150624 100-01425... - Page 50 Vertical Termination ........28 Heating Specifications ........6 Vent Firestop ............ 20 Installation Options ..........6 Vent Installation ..........20 Intake Restrictor ..........25 Vent Requirements .......... 20 Listing Details ............. 2 Wiring Diagram ..........49 © Travis Industries 4140627 100-01353...

Need help?

Do you have a question about the 4415 HO ST and is the answer not in the manual?

Questions and answers