Fire-Lite MS-9050UD Manual

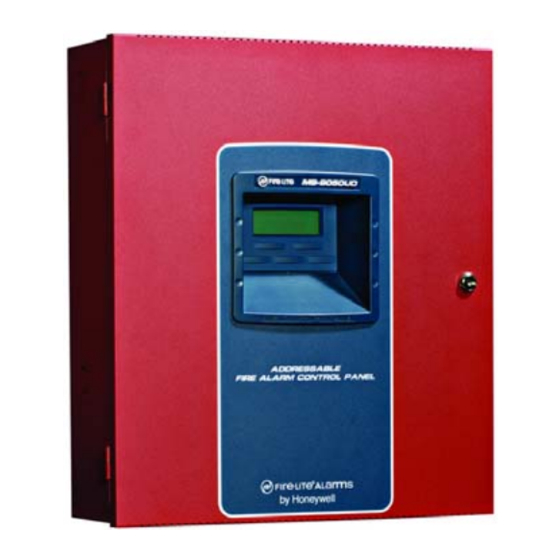

Addressable fire alarm control panel

Hide thumbs

Also See for MS-9050UD:

- Operating instructions (1 page) ,

- Wiring diagram (1 page) ,

- User manual (216 pages)

Summary of Contents for Fire-Lite MS-9050UD

- Page 1 Addressable Fire Alarm Control Panel MS-9050UD MS-9050UDC Document 52413 10/22/2010 Rev: P/N 52413:F ECN 10-564...

-

Page 2: Fire Alarm System Limitations

Fire Alarm System Limitations While a fire alarm system may lower insurance rates, it is not a substitute for fire insurance! An automatic fire alarm system—typically made up of Heat detectors do not sense particles of combustion and smoke detectors, heat detectors, manual pull stations, audible alarm only when heat on their sensors increases at a predeter- warning devices, and a fire alarm control panel with remote mined rate or reaches a predetermined level. -

Page 3: Installation Precautions

Installation Precautions Adherence to the following will aid in problem-free installation with long-term reliability: WARNING - Several different sources of power can be Like all solid state electronic devices, this system may connected to the fire alarm control panel. Disconnect all operate erratically or can be damaged when subjected to light- sources of power before servicing. - Page 4 Software Downloads In order to supply the latest features and functionality in fire alarm and life safety technology to our customers, we make frequent upgrades to the embedded software in our products. To ensure that you are installing and programming the latest features, we strongly recommend that you download the most current version of software for each product prior to commissioning any system.

-

Page 5: Table Of Contents

Table of Contents Section 1: Product Description ..................... 12 1.1: Features and Options ...........................12 1.2: Specifications...............................14 1.3: Controls and Indicators..........................15 1.4: Circuits.................................16 1.5: Digital Alarm Communicator/Transmitter ....................17 1.6: Components ..............................17 1.6.1: Intelligent Addressable Detectors: Newer Series ................18 1.6.2: Intelligent Addressable Modules: Newer Series ................18 1.6.3: 300 Series Intelligent Addressable Devices ..................18 1.6.4: Device Accessories..........................18 1.7: Optional Modules and Accessories ......................19... - Page 6 Table of Contents 2.9.6: ANN-LED Annunciator Module .......................48 Specifications............................48 Mounting and Installation........................48 ANN-LED Board Layout and Connection to FACP ................49 2.9.7: ANN-RLY Relay Module........................49 Specifications............................49 Mounting and Installation........................50 ANN-RLY Board Layout and Connection to FACP................51 Section 3: Programming ......................52 3.1: Programming Data Entry ..........................52 3.2: User Programming ............................53 3.3: Initial Power-up............................54...

- Page 7 Table of Contents 3.7.5: System .............................144 3.7.6: Zone Setup............................145 Section 4: Operating Instructions ..................148 4.1: Panel Control Buttons..........................148 4.1.1: Acknowledge/Step...........................148 4.1.2: Alarm Silence ..........................148 4.1.3: Drill/Hold 2 Sec..........................148 4.1.4: Reset ..............................148 4.2: Status Indicators and LEDs........................148 4.3: Normal Operation ............................149 4.4: Trouble Operation............................150 4.5: Alarm Operation ............................151 4.6: Supervisory Operation ..........................152...

- Page 8 Table of Contents Section 7: Power Supply Calculations ................180 7.1: Overview..............................180 7.2: Calculating the AC Branch Circuit ......................180 7.3: Calculating the System Current Draw .......................181 7.3.1: Overview............................181 7.3.2: How to Use Table 7.3 on page 182 to Calculate System Current Draw .........181 7.4: Calculating the Battery Size........................183 7.4.1: NFPA Battery Requirements ......................183 7.4.2: Selecting and Locating Batteries .....................183...

- Page 9 NEC Article 300 Wiring Methods NEC Article 760 Fire Protective Signaling Systems Applicable Local and State Building Codes Requirements of the Local Authority Having Jurisdiction (LAHJ) Fire-Lite Documents: Fire-Lite Device Compatibility Document #15384 SLC Wiring Manual Document #51309 CHG-120F Battery Charger...

- Page 10 9050udlayout.wmf SECONDARY PRIMARY MS-9050 Series Manual — P/N 52413:F 10/22/2010...

- Page 11 Peripheral Devices ANN-RLY ANN-(R)LED 10 Form-C Relay Card LED Display Doc. #53033 Doc. #53032 1 2 3 4 5 6 7 8 Alarm NAC 1 NAC2 NAC 3 NAC 4 Silenced Fault Fault Fault Fault Earth Battery Charger Disabled Fault Fault Fault ZONE 1...

-

Page 12: Section 1: Product Description

Communicator/Transmitter) all on one circuit board. This compact, cost effective, intelligent addressable control panel has an extensive list of powerful features. The combination of Fire-Lite’s newer series devices and legacy 300 Series devices, along with the MS-9050UD FACP, offer the latest in fire protection technology. - Page 13 SLC operates up to 10,000 ft. (3,000 m) with twisted, unshielded fire wire • Compatible with Fire-Lite addressable devices (refer to the SLC Wiring Manual) • Compatible with legacy Fire-Lite 300 Series addressable devices (refer to the SLC Wiring Manual) • Optional 4XTMF module (conventional reverse polarity/city box transmitter) •...

-

Page 14: Specifications

End-of-Line Resistor: 4.7 K, ½ watt (P/N 71252 UL listed) for Style Y (Class B) NAC Refer to the Fire-Lite Device Compatibility Document for listed compatible devices A circuit programmed for door holders or auxiliary power does not support notification appli- ances. -

Page 15: Controls And Indicators

Controls and Indicators Product Description Special Application Primary ANN-BUS Power - TB3 Nominal Operating Voltage: 24 VDC Maximum Current (Terminals 1 & 2): 500 mA Power-limited, supervised Special Application Secondary ANN-BUS Power - ANN-SEC - TB1 Nominal Operating Voltage: 24 VDC Maximum Current (Terminals 1 &... -

Page 16: Circuits

Product Description Circuits LED Indicators LED indicators are provided to annunciate the following conditions: • AC Power (green) • Fire Alarm (red) • Supervisory (yellow) • Trouble (yellow) • Alarm Silenced signals (yellow) Key Panel Mounted on the main circuit board, the key panel includes a window for the LCD display and LED indicators as listed above. -

Page 17: Digital Alarm Communicator/Transmitter

Digital Alarm Communicator/Transmitter Product Description Relays One fixed and two fully programmable Form-C dry contact relays are provided. The fixed fail-safe relay monitors system trouble and the two programmable relays are factory default programmed for system alarm and system supervisory. Contacts are rated 2.0 amps @ 30 VDC (resistive) and 0.5 amps @ 30 VAC (resistive). -

Page 18: 1: Intelligent Addressable Detectors: Newer Series

SLC address that is set in the detector head using built-in rotary decimal switches. Note that a blinking LED on an intelligent detector indicates communication between the detector and the control panel. Refer to the Fire-Lite Device Compatibility Document for a list of approved conventional detectors. -

Page 19: Optional Modules And Accessories

Optional Modules and Accessories Product Description EOL-C(R/W) Mounting Plate The EOL-CR (red) and EOL-CW (white) are single End-of-Line resistor plates which are required for use in Canada. An ELR, which is supplied with each module and fire alarm control panel, is mounted to the EOL-C(R/W) plate. - Page 20 Product Description Optional Modules and Accessories Battery Boxes BB-26 The BB-26 battery box may be used to house up to two 26 AH batteries and the CHG-75 Battery Charger. The battery box, which is red and is provided with knockouts, was designed specifically to compliment mounting below the FACP.

-

Page 21: Getting Started

Before connecting the control panel to the public switched telephone network, the installation of two RJ31X jacks is necessary. If trouble is experienced with this equipment, for repair or warranty information, please contact: Manufacturer: Fire•Lite Alarms, Inc. One Fire-Lite Place Northford, CT 06472 (203) 484-7161 Product Model Number: MS-9050UD FCC Registration Number: US:1W6AL03B9050UD AC Ringer Equivalence: 0.3B... -

Page 22: 3: Telephone Company Rights And Warnings

Product Description Telephone Requirements and Warnings instructions, consult the telephone company or a qualified installer about installing the RJ31X jack and alarm dialing equipment. Refer to“Digital Communicator” on page 31 for an illustration of the proper installation of this equipment. Important! The DACT must not be used to dial a phone number that is call-forwarded. - Page 23 Telephone Requirements and Warnings Product Description “The Ringer Equivalence Number (REN) assigned to each terminal device provides an indication of the maximum number of terminals allowed to be connected to a telephone interface. the termi- nation of an interface may consist of any combination of devices subject only to the requirement that the sum of the REN of all devices does not exceed 5.”...

-

Page 24: Section 2: Installation

Section 2: Installation The cabinet may be either semi-flush or surface mounted. The cabinet mounts using two key slots and two 0.250” (6.35 mm) diameter holes located in the backbox. The key slots are located at the top of the backbox and the two securing holes at the bottom. Carefully unpack the system and check for shipping damage. -

Page 25: Mounting Chassis/Transformer/Main Circuit Board

Mounting Chassis/Transformer/Main Circuit Board Installation 2.2 Mounting Chassis/Transformer/Main Circuit Board One transformer is supplied standard with the control panel. Install the transformer and chassis in the location indicated in the following illustration. When the location is dry and free of construction dust, install the chassis/transformer/circuit board assembly. - Page 26 Installation Mounting Chassis/Transformer/Main Circuit Board Semi-Flush Mounting Do not recess box more Hinge Slot for than 3.875” into wall to optional Dress Panel avoid covering venting holes on top of box. Mounting slots for optional Trim Ring Semi-Flush mounting hole Hinge Slot for optional Dress Panel Figure 2.3 FACP Cabinet Mounting...

- Page 27 Mounting Chassis/Transformer/Main Circuit Board Installation Depth Depth = Door Backbox Door Backbox Left Side Right Side Bottom Figure 2.4 FACP Cabinet Dimensions MS-9050 Series Manual — P/N 52413:F 10/22/2010...

-

Page 28: Power

Installation Power 2.3 Power WARNING: RISK OF DAMAGE AND ELECTRICAL SHOCK SEVERAL DIFFERENT SOURCES OF POWER CAN BE CONNECTED TO THIS PANEL. DISCONNECT ALL SOURCES OF POWER BEFORE SERVICING. THE PANEL AND ASSOCIATED EQUIPMENT MAY BE DAMAGED BY REMOVING AND/OR INSERTING CARDS, MODULES OR INTERCONNECTING CABLES WHILE THIS UNIT IS ENERGIZED. -

Page 29: Relays

Relays Installation AC Connection to Transformer leads: NEUTRAL Battery Connection to J1 on FACP Ground Stud 2.4 Relays The FACP provides two programmable Form-C relays and one fixed fail-safe Form-C trouble relay, all with contacts rated for 2.0 amps @ 30 VDC (resistive) or 0.5 amps @ 30 VAC (resistive). Note that relay connections must be nonpower-limited. -

Page 30: Notification Appliance Circuits

Use UL listed 24 VDC notification appliances only. Circuits are supervised and power-limited. Refer to the Fire-Lite Device Compatibility Document for a listing of compatible notification appli- ances. The NACs, which are located on the main circuit board, may be expanded via the Fire-Lite- FCPS Series field charger/power supplies. -

Page 31: Ul Power-Limited Wiring Requirements

UL Power-limited Wiring Requirements Installation 2.6 UL Power-limited Wiring Requirements Power-limited and nonpower-limited circuit wiring must remain separated in the cabinet. All power-limited circuit wiring must remain at least 0.25” (6.35 mm) away from any nonpower-lim- ited circuit wiring and nonpower-limited circuit wiring must enter and exit the cabinet through dif- ferent knockouts and/or conduits. - Page 32 Installation Digital Communicator Important! The DACT must not be used to dial a phone number that is call-forwarded per require- ments of UL 864 9th Edition. Customer Premises Equipment and Wiring Network Computer RJ31X Service Jack Provider’s Unused Facilities RJ-11 Jack MS-9050UD Telephone Line...

-

Page 33: Optional Modules/Accessories Installation

Optional Modules/Accessories Installation Installation 2.8 Optional Modules/Accessories Installation WARNING: RISK OF ELECTRIC SHOCK DISCONNECT ALL SOURCES OF POWER (AC AND DC) BEFORE INSTALLING OR REMOVING ANY MODULES OR WIRING. 2.8.1 4XTMF Transmitter Module Installation The 4XTMF provides a supervised output for a local energy municipal box transmitter in addition to alarm and trouble reverse polarity. - Page 34 Installation Optional Modules/Accessories Installation Before installing the module, place the disconnect switch to the right (disconnect) position to pre- vent accidental activation of the municipal box. Note that a Disconnect LED will illuminate after the module is installed in the MS-9050UD. In addition, the System Trouble LED will turn on to indicate the Disconnect condition.

-

Page 35: 2: Ann-Sec Option Card

Optional Modules/Accessories Installation Installation Test system for proper operation. Standoff Standoff Jumper JP2 Jumper JP28 J8 & J9 Connectors 4XTMF MS-9050UD Figure 2.11 4XTMF Connectors to MS-9050UD Connectors NOTE: Jumper JP2 on the FACP main circuit board can be used to configure the FACP supervisory relay for operation with the 4XTMF module. -

Page 36: Ann-Bus Devices

Installation ANN-BUS Devices Secure the ANN-SEC to the circuit board with the supplied screw. standoff and screw ANN-SEC connector to J13 on main circuit board FACP Circuit Board Figure 2.12 Installing the ANN-SEC Option Card 2.9 ANN-BUS Devices WARNING: RISK OF ELECTRICAL SHOCK DISCONNECT ALL SOURCES OF POWER (AC AND DC) BEFORE INSTALLING OR REMOVING ANY MODULES OR WIRING. -

Page 37: Calculating Wiring Distance For Ann-Bus Modules

ANN-BUS Devices Installation Calculating Wiring Distance for ANN-BUS Modules The following instructions will guide the installer in determining the type of wire and the maximum wiring distance that can be used with FACP ANN-BUS accessory modules. To calculate the wire gauge that must be used to connect ANN-BUS modules to the FACP, it is nec- essary to calculate the total worst case current draw for all modules on a single 4-conductor bus. -

Page 38: Wiring Distance Calculation Example

Installation ANN-BUS Devices 4.02 2.54 Exception: When using the ANN-RLY module, the installer must ensure that the maximum 24VDC power line drop does not exceed 0.3 volts. This results in the following wiring limitations: Wire Gauge Maximum Wire Length 312 feet 497 feet 787 feet 1,250 feet... -

Page 39: Wiring Configuration

ANN-BUS Devices Installation Wiring Configuration Figure 2.13 illustrates the wiring between the FACP and ANN-BUS devices. ANN-BUS and power wiring are supervised and power-limited ANN-BUS Device Primary ANN-BUS MS-9050UD Figure 2.13 FACP wiring to ANN-BUS Device Powering ANN-BUS Devices from Auxiliary Power Supply Figure 2.14 illustrates the powering of ANN-BUS devices from an auxiliary power supply such as the FCPS-24FS6/8, when the maximum number of ANN-BUS devices exceeds the ANN-BUS power requirements. -

Page 40: 2: Ann-Bus Device Addressing

Installation ANN-BUS Devices 2.9.2 ANN-BUS Device Addressing Each ANN-BUS device requires a unique address (ID Number) in order to communicate with the FACP. A 5-position DIP switch on each device is used to set this address. The address set for these devices must also be programmed at the FACP for the specific device (refer to the programming section titled “ANN-BUS”... -

Page 41: Mounting

ANN-BUS Devices Installation To close the cover, make certain the key switch is in the ON (Unlocked) position. Swing the cover closed, snapping it shut Turn the key switch to the OFF (Locked) position by turning clockwise and remove the key Annunciator backplate Annunciator cover with LCD display... - Page 42 Installation ANN-BUS Devices Route wires from hole in backplate, through wiring channel and then to ANN-80 terminal block TB1. wiring channel wires Remove appropriate amount of wire insulation. Connect the wiring from the FACP ANN-BUS to annunciator TB1 terminals 3 (A) & 4 (B). Make certain to connect A to A and B to B.

-

Page 43: 4: Ann-S/Pg Serial/Parallel Interface Module

ANN-BUS Devices Installation The following table shows the ANN-80 connections to the MS-9050UD. MS-9050UD (TB3) ANN-80 (TB1) Terminal 1 GND (-) Terminal 1 (-) Terminal 2 PWR (+) Terminal 2 (+) Terminal 3 A (ANN-BUS) Terminal 3 (A) Terminal 4 B (ANN-BUS) Terminal 4 (B) Programming Following installation and wiring of the ANN-80 LCD annunciator to the FACP, the annunciator... -

Page 44: Specifications

Installation ANN-BUS Devices Specifications • Operating Voltage: 24 VDC • Current (Alarm and Standby): 45 mA • Ambient Temperature: 32 F to 120 F (0 C to 49 • Max. Wiring Distance from FACP: 6,000 ft. (1,800 m) • Mounting: Surface •... -

Page 45: 5: Ann-I/O Led Driver Module

ANN-BUS Devices Installation 2.9.5 ANN-I/O LED Driver Module The ANN-I/O is an LED driver module that can be used in a wide variety of applications, including as an interface with most customized graphic annunciators. The ANN-I/O can drive up to 40 LEDs. -

Page 46: Ann-I/O Connection To Facp

Installation ANN-BUS Devices ANN-I/O Connection to FACP The ANN-I/O connects to the FACP via the ANN-BUS as illustrated in Figure 2.18. After the ANN-I/O is connected to the panel, it must be added to the system via FACP programming. Refer to the section titled “Modules Installed”... - Page 47 ANN-BUS Devices Installation The LEDs are wired as illustrated in Figure 2.19. Note that the illustration depicts only connectors P1 and P2. Wiring is identical for P3 (LEDs 21-30) and P4 (LEDs 31-40). Figure 2.19 ANN-I/O LED Wiring MS-9050 Series Manual — P/N 52413:F 10/22/2010...

-

Page 48: 6: Ann-Led Annunciator Module

Installation ANN-BUS Devices 2.9.6 ANN-LED Annunciator Module The ANN-LED and ANN-RLED annunciator modules provide LED annunciation of general sys- tem faults and input zones/points when used with a compatible FACP. The ANN-LED module pro- vides alarm (red), trouble (yellow) and supervisory (yellow) indication for up to ten input zones or addressable points. -

Page 49: Ann-Led Board Layout And Connection To Facp

ANN-BUS Devices Installation ANN-LED Board Layout and Connection to FACP Figure 2.22 illustrates the ANN-LED board showing locations of screw terminals for connection to the FACP and the DIP switches for selecting the ANN-BUS ID number. ANN-BUS (ID#) Address DIP switch Ground wire from mounting screw to FACP Earth Ground stud is required for some Canadian applications. -

Page 50: Mounting And Installation

Installation ANN-BUS Devices Mounting and Installation The ANN-RLY relay module can be mounted inside the FACP main circuit board chassis or inside the ROME Series enclosure. Refer to the ANN-RLY Installation Document #53033 for instructions on chassis mounting or to the ROME Series Installation Document #53530 for mounting in the sep- arate backbox. -

Page 51: Ann-Rly Board Layout And Connection To Facp

ANN-BUS Devices Installation ANN-RLY Board Layout and Connection to FACP Figure 2.24 illustrates the ANN-RLY board showing locations of screw terminals for connection to the FACP and the DIP switches for selecting the ANN-BUS ID number. ANN-BUS (ID#) Address DIP switch ANN-RLY ANN-BUS and power wiring are +24 VDC... -

Page 52: Section 3: Programming

Section 3: Programming NOTICE TO USERS, INSTALLERS, AUTHORITIES HAVING JURISDICTION AND OTHER INVOLVED PARTIES This product incorporates field-programmable software. In order for the product to comply with the requirements in the Standard for Control Units and Accessories for Fire Alarm Systems, UL 864, certain programming features or options must be limited to specific values or not used at all as indicated below: Program feature Permitted in... -

Page 53: User Programming

User Programming Programming 3.2 User Programming The MS-9050UD is completely field programmable and requires no special software skills. While programming the MS-9050UD, the fire protection capabilities of the control panel are enabled. Site-specific programming may be accomplished in three ways: •... -

Page 54: Initial Power-Up

Programming Initial Power-up User Programming Levels There are two user programming levels: • User Master Program Level 1 is used for programming panel specific data relating to device types, zoning, messages, control panel functions, etc. • User Maintenance Program Level 2 is used by a qualified operator to access features such as Disable/Enable, View and Clear History, Walktest and System Time Change. - Page 55 Programming and Passwords Programming To access user Programming mode, press the Enter or Mode key. The LCD will display the follow- ing: 1=READ STATUS MODE 2=PROGRAMMING MODE 3=MANUAL DIAL MODE 4=REMOTE DOWNLOAD To enter the user Programming mode, press 2. The display will read as follows: PROGRAMMING ENTER PASSWORD *****...

-

Page 56: Master Programming Level

Programming Master Programming Level 3.6 Master Programming Level When the Master Program Level password is entered, the control panel will enter user Program- ming mode. In this mode, the piezo sounder remains off, the trouble relay is activated and the sys- tem Trouble LED flashes until Programming mode is exited. -

Page 57: 1=Autoprogram

Master Programming Level Programming 3.6.1 Autoprogram Pressing 1 while viewing Programming Screen #1, will select the Autoprogram option, which prompts the control panel to poll all devices installed on the SLC loop. The primary purpose of autoprogramming is to allow the installer a fast and easy way to bring the system on-line as quickly as possible. -

Page 58: Detector Programming

Programming Master Programming Level Detector Programming Pressing 1, while viewing the Point Program Screen, will allow the programmer to add, delete or change the programming of an addressable detector. The following screen will be displayed by the control panel: DETECTOR 1=ADD 2=DELETE 3=EDIT... -

Page 59: Delete Detector

Master Programming Level Programming Delete Detector Pressing 2 in the Detector Screen will display the Delete Detector Screen which allows the pro- DETECTOR grammer to delete a specific detector: 1=ADD 2=DELETE 3=EDIT DELETE DETECTOR Detector Screen ENTER DETECTOR# Delete Detector Screen A flashing cursor will appear in the position of the first asterisk to the left. - Page 60 Programming Master Programming Level If the selected address has been added to programming, device summary screens will be displayed. These screens allow the programmer to view all device settings at a single glance. Pressing the left or right arrow keys will allow the programmer to rapidly view the devices at the previous or next address (if installed).

- Page 61 Master Programming Level Programming The following examples show the editing of a photoelectric smoke detector with address 017, located on the SLC loop: EDIT DETECTOR 1D017 1=ENABLED 2=TYPE SMOKE(PHOTO) 3=VERIFICATION Edit Detector Screen #2 EDIT DETECTOR 1D017 1=WALKTEST 2=PAS 3=PRE-SIGNAL Edit Detector Screen #3 EDIT DETECTOR 1D017 1=ZONE ASSIGNMENT...

- Page 62 Programming Master Programming Level Type To select the type of detector being programmed, press the 2 key while viewing the Edit Detector Screen #2. This will cause the control panel to display the following Detector Type Screen: DETECTOR TYPE 1=SMOKE(PHOTO) 2=USER-DEFINED-1 EDIT DETECTOR 3=SMOKE (ION)

- Page 63 Master Programming Level Programming Walktest The Walktest feature allows one person to test the system devices without the necessity of manually EDIT DETECTOR resetting the control panel after each device activation. To enable a device for the Walktest feature, 1=WALKTEST 2=PAS press 1 while viewing the Edit Detector Screen #3 until the display reads Walktest Yes.

- Page 64 Programming Master Programming Level With the preceding program settings, when the detector with address 005 is activated, zone Z18 will cause its associated control module to activate immediately, sounding the connected signaling device to indicate the Pre-signal condition. Following the Pre-signal delay time, zone Z001 will cause its associated control module to activate and the control panel will initiate an alarm condition.

- Page 65 Master Programming Level Programming Pressing 1 while viewing the Adjective/Noun Screen will cause the following screen(s) to be dis- 1=STANDARD ADJECTIVE played. Note that the keyboard down arrow key must be pressed to see all the Adjective screens. 2=STANDARD NOUN Press the number corresponding to the adjective that is to be used as a descriptor for the location of 3=CUSTOM ADJECTIVE the detector currently being programmed.

- Page 66 Programming Master Programming Level Pressing 2 while viewing the Adjective/Noun Screen will cause the following screen(s) to be dis- 1=STANDARD ADJECTIVE played. Note that the keyboard down arrow key must be pressed to see all the Noun screens. Press 2=STANDARD NOUN the number corresponding to the noun that is to be used as a descriptor for the location of the detec- 3=CUSTOM ADJECTIVE tor currently being programmed.

- Page 67 Master Programming Level Programming Pressing 3 or 4 while viewing the Adjective/Noun Screen will display screens similar to the previ- 1=STANDARD ADJECTIVE ous Adjective and Noun Screens. The new screens will list custom Adjectives and Nouns which 2=STANDARD NOUN have been programmed into the control panel by the user utilizing the PK-CD programming kit. 3=CUSTOM ADJECTIVE These descriptors are selected as described in the previous sections.

-

Page 68: Module Programming

Programming Master Programming Level With the cursor on the last letter of the Noun field, press the zero key again to increment the room number to 305. Press the Enter key to store the information. Module Programming Pressing 2, while viewing Point Program Screen #2, will allow the programmer to add, delete or POINT PROGRAM change the programming of an addressable module. -

Page 69: Add Module

Master Programming Level Programming Pressing 1 for Control Module or 2 for Monitor Module will cause the following screen to be dis- played: ADD MODULE MODULE# IS ADDED Add Module Screen #3 The programmer can continue adding modules by pressing the ESC or left arrow key which will return the display to the Add Module Screen #1. - Page 70 Programming Master Programming Level When the last digit is keyed-in, if the selected address has not been added to programming, a screen showing information about a device that is installed with a lower address, closest to the selected address, will be displayed. If no modules are installed on the loop, the following screen will be dis- played: NO MODULE INSTALLED...

- Page 71 Master Programming Level Programming If the selected address corresponds to a monitor module, a screen displaying information about the module with the selected address will be displayed as illustrated in the following: NORMAL MONITOR <ADJ><NOUN> ZNNN 1M012 EDIT MONITOR 1M012 1=ENABLED 2=TYPE MONITOR...

- Page 72 Programming Master Programming Level Type Monitor EDIT MONITOR Using the PK-CD Upload/Download utility program, unique user-defined monitor types can be cre- 1=ENABLED 2=TYPE MONITOR ated and loaded into the FACP for later use. The FACP response to the activation of a user-defined type is the same as most previous standard types in the list, thus allowing a variety of user-defined Edit Monitor Screen #2 types and responses.

- Page 73 Style 4 operation and isolator modules must be employed on each non-fire branch of the SLC as per Figure 13 in the Fire-Lite SLC Wiring Manual (document number 51309). Fire and non-fire devices must not be used on the same SLC branch.

- Page 74 Programming Master Programming Level Note that Z** represents the Zone Number(s) corresponding to this device. The factory default for an unprogrammed device is Z00 for general alarm zone. A flashing cursor will appear on the first 0 to the left. Enter the two digit number corresponding to the zone that is to be assigned to this device.

- Page 75 Master Programming Level Programming Pressing 1 while viewing the Adjective/Noun Screen will cause the following screen(s) to be dis- 1=STANDARD ADJECTIVE played. Note that the keyboard down arrow key must be pressed to see all the Adjective screens. 2=STANDARD NOUN Press the number corresponding to the adjective that is to be used as a descriptor for the location of 3=CUSTOM ADJECTIVE 4=CUSTOM NOUN...

- Page 76 Programming Master Programming Level Pressing 2 while viewing the Adjective/Noun Screen will cause the following screen(s) to be dis- 1=STANDARD ADJECTIVE played. Note that the keyboard down arrow key must be pressed to see all the Noun screens. Press 2=STANDARD NOUN the number corresponding to the noun that is to be used as a descriptor for the location of the mon- 3=CUSTOM ADJECTIVE 4=CUSTOM NOUN...

- Page 77 Master Programming Level Programming Description EDIT MONITOR The Description selection allows the programmer to enter additional information about the monitor 1=ADJECTIVE/NOUN module currently being programmed. This information will be displayed as part of the device label 2=DESCRIPTION ***************** on the LCD display. Pressing 2 while viewing Edit Monitor Screen #5 will cause the following Edit Monitor Screen #5 screen to be displayed: DESCRIPTION...

- Page 78 Programming Master Programming Level Edit Module Screen for Control Modules MODULES The programmer can change a module’s existing or factory default programming by pressing 3 in 1=ADD the Modules Screen. The following screen will be displayed: 2=DELETE 3=EDIT Modules Screen EDIT MODULE ENTER MODULE ADDRESS Edit Module Screen...

- Page 79 Master Programming Level Programming To change the programming for the displayed module, press the keyboard down arrow key to view the following Edit Control screens: EDIT CONTROL 1=ENABLED 2=TYPE CONTROL 3=SILENCEABLE Edit Control Screen #2 EDIT CONTROL 1=WALKTEST 2=ZONE ASSIGNMENT 00 ** ** ** ** Edit Control Screen #3 EDIT CONTROL...

- Page 80 Programming Master Programming Level While viewing one of the Control Type screens, select the type of control module being pro- grammed by pressing the corresponding keypad number key. The display will return to the Edit Control Screen #2 and indicate the new type selection. NOTE: A control relay module set to the Resettable Power type will follow the main circuit board 24 VDC resettable power unless the control relay module is disabled.

-

Page 81: Zone Assignment

Master Programming Level Programming Zone Assignment A maximum of five zones can be programmed to each addressable control module. Pressing 2 while viewing Edit Control Screen #3 displays the following screen: ZONE ASSIGNMENT Z00 Z** Z** Z** Z** Zone Assignment Screen Note that Z** represents the Zone Number(s) corresponding to this device. - Page 82 Programming Master Programming Level Pressing 1 while viewing the Adjective/Noun Screen will cause the following screen(s) to be dis- 1=STANDARD ADJECTIVE played. Note that the keyboard down arrow key must be pressed to see all the Adjective screens. 2=STANDARD NOUN Press the number corresponding to the adjective that is to be used as a descriptor for the location of 3=CUSTOM ADJECTIVE 4=CUSTOM NOUN...

- Page 83 Master Programming Level Programming Pressing 2 while viewing the Adjective/Noun Screen will cause the following screen(s) to be dis- 1=STANDARD ADJECTIVE played. Note that the keyboard down arrow key must be pressed to see all the Noun screens. Press 2=STANDARD NOUN 3=CUSTOM ADJECTIVE the number corresponding to the noun that is to be used as a descriptor for the location of the con- 4=CUSTOM NOUN...

- Page 84 Programming Master Programming Level Description The Description selection allows the programmer to enter additional information about the control module currently being programmed. This information will be displayed as part of the device label on the display. Pressing 2 while viewing Edit Control Screen #4 will cause the following screen to be displayed: DESCRIPTION 1M002...

-

Page 85: 3=Zone Setup

Master Programming Level Programming 3.6.3 Zone Setup Pressing 3 while viewing Programming Screen #2 will access the Zone Setup screens as illustrated below: ZONE SETUP 1=ENABLE PROGRAMMING 1=AUTOPROGRAM 2=DISABLE 2=POINT PROGRAM 3=ZONE 17 18 19 3=ZONE SETUP Programming Screen #2 Zone Setup Screen #1 ZONE SETUP 1=ZONES INSTALLED... -

Page 86: Disable

Programming Master Programming Level Disable Pressing 2 for Disable, while viewing Zone Setup Screen #1, displays the following: ZONE TO DISABLE ZONE SETUP 1=ENABLE 2=DISABLE 3=ZONE 17 18 19 Disable Screen Zone Setup Screen #1 This screen allows the programmer to disable zones, one at a time. A flashing cursor appears next to the Z, prompting the programmer to enter a two digit zone number (01 - 19). -

Page 87: Zones Installed

Master Programming Level Programming Zones Installed Pressing 1 for Zones Installed, while viewing Zone Setup Screen #2, will display a screen similar to the following: ZONES INSTALLED 00 01 02 03 04 05 ZONE SETUP 1=ZONES INSTALLED 2=ZONES ENABLED 3=ZONES DISABLED Zone Setup Screen #2 Zones Installed Screen This display will show all of the zones that have been programmed into the control panel. -

Page 88: Zone Type

Programming Master Programming Level Zone Type ZONE SETUP Zone Types must be programmed only if a DACT, programmed for zone reporting, is installed on 1=ZONE TYPES 2=ZONES AVAILABLE the control panel. Pressing 1 for Zone Types, while viewing Zone Setup Screen #3, will display a 3=FUTURE screen similar to the following: Zone Setup Screen #3... -

Page 89: Zones Available

Master Programming Level Programming IMPORTANT! In Zone Type Program Screen #1, selecting WATERFLOW will assign a Waterflow silenceable zone type to the selected zone. Any signaling devices programmed to the same zone can be silenced by pressing the Alarm Silence key or by using the auto-silence feature. To program a waterflow circuit as nonsilenceable, refer to “System Setup”... -

Page 90: Loop Protocol

Programming Master Programming Level Loop Protocol Loop Protocol refers to the SLC loop mode of operation. The only mode available is CLIP (Classic Loop Interface Protocol) which is used for the older legacy addressable devices such as the M300 Series modules and detectors as well as the newer devices. Pressing 2 while viewing the Loop Setup Screen will have no effect on programming. -

Page 91: Trouble Reminder

Master Programming Level Programming Pressing 2 for System Setup, while viewing Programming Screen #2, will cause the following screens to be displayed: SYSTEM SETUP 1=TROUBLE REM PROGRAMMING 2=BANNER 1=LOOP SETUP 3=TIME-DATE 2=SYSTEM SETUP 3=VERIFY LOOP Programming Screen #2 System Setup Screen #1 SYSTEM SETUP 1=TIMERS 2=NAC... - Page 92 Programming Master Programming Level Pressing 1 while viewing the Banner Screen will select the factory default banner setting and dis- BANNER play the following screen: 1=FACTORY 2=USER DEFINED FACTORY BANNER Banner Screen Factory Banner Screen The Factory Banner has now been selected and is stored in nonvolatile memory. Pressing the ESC key will return the display to the Banner Screen.

-

Page 93: Time-Date

Master Programming Level Programming Time-Date SYSTEM SETUP 1=TROUBLE REM The control panel time and date can be changed by pressing 3 while viewing the System Setup 2=BANNER Screen #1. The following screen will be displayed: 3=TIME-DATE System Setup Screen #1 TIME AND DATE 1=TIME 10:00 AM... -

Page 94: Daylight Savings

Programming Master Programming Level digit is entered. After the last year digit is entered, the display will return to the Time-Date Screen which will show the new date entry. If an error is made while entering a digit, press the CLR key to delete the entire entry and begin again. -

Page 95: Timers

Master Programming Level Programming Timers SYSTEM SETUP 1=TIMERS Timer delays for PAS, Pre-signal and waterflow activation can be programmed by pressing 1 while 2=NAC viewing System Setup Screen #2. The following screen will be displayed: 3=RELAYS System Setup Screen #2 TIMERS 1=PAS DELAY 2=PRE SIGNAL... -

Page 96: Presignal Delay

Programming Master Programming Level Pre-signal Delay The factory default setting for Pre-signal delay is 000 for no delay. To select a Pre-signal delay of 001 to 180 seconds for all devices programmed for Pre-signal, press 2 while viewing Timer Screen #1. -

Page 97: Nac (Notification Appliance Circuit)

Master Programming Level Programming AC Loss Delay The reporting of a loss of AC power to a central station can be delayed by programming the length of the desired delay. The factory default setting is 2 hours. Press 1 while viewing Timer Screen #2 to display the following: AC LOSS DELAY 1=NO DELAY... - Page 98 Programming Master Programming Level The following screens will be displayed for each selection: NAC # 1=ENABLED 2=TYPE BELL 3=SILENCEABLE NAC Screen #1 NAC # 1=AUTO SILENCE 2=CODING STEADY NAC Screen #2 NAC # 1=ZONE 00 ** ** ** ** 2=SIL INHIBITED NAC Screen #3 NAC # 1=SYNC TYPE...

- Page 99 Master Programming Level Programming Type The main circuit board NAC type can be programmed by pressing 2 while viewing NAC Screen #1. The following screen will be displayed. Press the down arrow key to view additional screens: NAC TYPE NAC # 1=BELL 1=ENABLED...

-

Page 100: Auto Silence

Programming Master Programming Level Auto Silence The Auto Silence feature, when enabled, automatically silences all main circuit board silenceable notification appliances after a programmed length of time. To enable this feature and program the time delay before Auto Silence activation, press 1 while viewing NAC Screen #2. The following screens will be displayed: AUTO SILENCE NAC #... - Page 101 Master Programming Level Programming Coding (only for NACs not programmed as Sync Strobe Type) The Coding feature allows the programmer to select the type of output that the main circuit board notification appliances will generate when activated. Pressing 2 while viewing NAC Screen #2 will cause the following displays to appear: CODING 1=STEADY...

- Page 102 Programming Master Programming Level If another alarm point is activated and the countdown timer is counting, the alarm point will have no effect on the NACs unless the alarm point’s zones are directly mapped to one of the NACs, in which case it will follow the procedure outlined in step 2. If another alarm point is activated and the countdown timer has stopped counting due to the Acknowledge switch being pressed, the countdown timer will restart and the NACs will respond as outlined in step 2.

-

Page 103: Relays

Master Programming Level Programming The total current draw for each Notification Appliance Circuit cannot exceed 2.5 amps. Refer to the manufacturer’s documentation supplied with the Strobes to determine the maximum current draw for each strobe and ensure that the circuit maximum is not exceeded. To ensure proper strobe and circuit operation, there is also a limit to the number of strobes that can be attached to each circuit. -

Page 104: Canadian Option

Programming Master Programming Level While viewing the selected screen, press the number corresponding to the desired relay type to pro- gram the main circuit board relay. The choice will be stored in memory and the display will return to the Relay Type Screen which will show the programmed type choice. Press the Escape key to return to the Relays Selection Screen and repeat the preceding procedure for the remaining relays. -

Page 105: 6: Verify Loop

Master Programming Level Programming 3.6.6 Verify Loop Pressing 3 while viewing Programming Screen #2, will select the Verify Loop option. During loop verification, the FACP polls each device on the SLC to determine if the device is communicating and whether or not it responds with the proper type identification. The following screen will be dis- played while verification is in progress: PROGRAMMING VERIFYING LOOPS... -

Page 106: Erase History

Programming Master Programming Level Erase History The Erase History option allows a user to erase all events from the history file. This will provide a clean slate in order to use the history file to track future events. Pressing 2 while viewing the His- tory Screen will display the following screen: ERASE HISTORY PROCEED ? - Page 107 Master Programming Level Programming From this screen, it is possible to view the walktest log, untested system points or a summary of the addressable devices tested during the current walktest. The user can select between any of these screens without interrupting the current walktest session. The walktest session will not end until the Unit In Walktest screen is exited by pressing the Escape key.

-

Page 108: 9: Option Modules

Programming Master Programming Level 3.6.9 Option Modules Options available for the MS-9050UD include annunciators, printer connection for acquiring hard- copy printouts of panel data and onboard DACT. Pressing 3 while viewing Programming Screen #3 will display the following screen: PROGRAMMING OPTION MODULES 1=HISTORY 2=WALKTEST... - Page 109 Master Programming Level Programming Modules Installed If an ANN-BUS module is installed, press 2 while viewing ANN-BUS screen #1 to select ANN- BUS addresses for the module(s). The following screen will be displayed. ANN-BUS MODULES 1=ADDR. 1 NONE 2=ADDR. 2 NONE 3=ADDR.

- Page 110 Programming Master Programming Level If ANN-I/O, ANN-LED, or ANN-RLY is the selected module type, the following ANN-BUS Address Screen will be displayed: ANN-BUS MODULES ANN-BUS ADDRESS # 1=TYPE ANN-I/O 2=MODULE OPTIONS ANN-BUS Address Screen Since the options for each of these module types can be individually set, pressing 2 for Module Options, while viewing the ANN-BUS Address Screen will display the available options as described below.

- Page 111 Master Programming Level Programming ANN-I/O Zone Option If Zone is selected as the module option, the first ten LED driver outputs on the ANN-I/O module will display the system status information. The remaining 20 LED driver outputs on the module will display the active/alarm status of each zone.

- Page 112 Programming Master Programming Level points that will be annunciated on a particular ANN-I/O module depend on the programming options selected as far as the device type (detector or module) to be annunciated. The LED assign- ments for each ANN-I/O module will be as follows. ANN-I/O Module #1 ANN-I/O Module #2 Module LED...

- Page 113 Master Programming Level Programming ANN-LED Options Screen Pressing 2 for Module Options while viewing ANN-BUS Address Screen when the ANN-LED option is selected, will display the following screen: ANN-LED ADDR # PROGRAMMING ZONES 00-09 1=ANN-RLY OPTIONS ALARM, TRBL, SUPV 2=ANN-LED OPTIONS ANN-BUS Screen #3 ANN-LED Address Screen #1 ANN-LED ADDR #...

- Page 114 Programming Master Programming Level ANN-RLED Zone Option - Alarm Only If Zone is selected as the module option, and the module is programmed to annunciate alarms only, the first ten LEDs on the ANN-RLED module will display the system status information. The next 20 LEDs on the module will display the active/alarm status of each zone.

- Page 115 Master Programming Level Programming Zone 10 Zone 11 Zone 12 Zone 13 Zone 14 Supervisory Supervisory Supervisory Supervisory Supervisory Zone 15 Zone 16 Zone 17 Zone 18 Zone 19 Active/Alarm Active/Alarm‘ Active/Alarm Active/Alarm Active/Alarm Zone 15 Zone 16 Zone 17 Zone 18 Zone 19 Trouble...

- Page 116 Programming Master Programming Level remaining modules will display the alarm, trouble and supervisory status for each of the ten points in the Point Range programmed for that particular module. The LED assignments for each ANN- LED module will be as follows. First ANN-LED Module (Point Range 01 - 10) Alarm Silenced NAC 1 Fault...

- Page 117 Master Programming Level Programming The ANN-RLY module provides ten Form-C relays which can be programmed for various func- tions. The initial screen displays Relays 1 through 3. Pressing the down arrow key will display the remaining relays for this module. To program any of the ANN-RLY relays, while viewing the appropriate ANN-RLY Option screen, press the number key corresponding to the relay to be programmed.

- Page 118 Programming Master Programming Level ANN-S/PG (Print) Options Screen The Print option allows the programmer to configure the optional printer. Pressing 1 while viewing ANN-BUS screen #2 will display the following screens: ANN-S/PG OPTIONS 1=PORT 2=PRINTER SUPV 3=OFFLINE TIMER ANN-S/PG Options Screen #1 ANN-S/PG OPTIONS 1=BAUD RATE 2=DATA BITS...

- Page 119 Master Programming Level Programming Pressing 1 for Stop Bits while viewing ANN-S/PG Options screen #3 will cause a screen to appear which allows the user to select between 1.0 or 2.0 Stop Bits. ANN-80 Options Screen Pressing 2 while viewing ANN-BUS screen #2 will display the following screen: ANN-80 OPTIONS 1=PIEZO ENABLE 2=LOCK ENABLE...

-

Page 120: Onboard Dact

Programming Master Programming Level ANN-SECONDARY Options Screen Pressing 3 while viewing ANN-BUS screen #2 will display the following screen: ANN-SECONDARY 1=ENABLED The ANN-SECONDARY must be enabled if any modules are connected to the ANN-SEC option card at J13. To enable the Secondary ANN-BUS, press 1 while viewing ANN-SECONDARY screen so that the display reads ANN-SECONDARY Enabled Yes. -

Page 121: On Board Dact

Master Programming Level Programming Primary Phone Press 2 while viewing On Board DACT Screen #1 to program the type of primary phone line being connected to the DACT. The following screen will be displayed: ON BOARD DACT PRIMARY PHONE LINE 1=TYPE TOUCHTONE Primary Phone Line Screen... -

Page 122: Ring Count

Programming Master Programming Level Ring Count ON BOARD DACT The ring count designates the number of rings allowed on the phone line prior to answering an 1=RING COUNT incoming call from a service terminal. The factory default is 0 which means the control panel will 2=CENTRAL STATION not answer any incoming calls. -

Page 123: Backup Reporting

Master Programming Level Programming Backup Reporting The DACT can be programmed to transmit reports to primary and/or secondary central station phone numbers as a backup. Press 2 while viewing Central Station Screen #1 to display the follow- ing screen: BACKUP REPORTING 1=BACKUP ONLY 2=BOTH 3=FIRST AVAILABLE... -

Page 124: Central Station

Programming Master Programming Level Central Station Primary and Secondary Phone Numbers CENTRAL STATION Pressing 1 for Primary or 2 for Secondary will display the following screens. 1=PRIMARY 2=SECONDARY Note that the following information must be entered for both the Primary and Secondary Central 3=REPORT STYLE Station Phone Numbers. -

Page 125: Test Time Interval

Master Programming Level Programming Test Time Interval CENTRAL STATION Pressing 1 while viewing Primary/Secondary Screen #1 will cause the following screens to be dis- 1=TEST TIME INT played: 2=ACCOUNT CODE 3=24HR TST TIME Primary/Secondary Screen #1 TEST TIME INTERVAL 1=24 HOURS 2=12 HOURS 3=8 HOURS Test Time Interval Screen #1... -

Page 126: Hour Test Time

Programming Master Programming Level 24 Hour Test Time CENTRAL STATION Pressing 3 while viewing Primary/Secondary Screen #1 will cause the following screen to be dis- 1=TEST TIME INT 2=ACCOUNT CODE played: 3=24HR TST TIME Primary/Secondary Screen #1 24 HOUR TEST TIME RANGE 0000-2359 24 Hour Test Time Screen Use the 24 Hour Test Time screen to program the time that the DACT will transmit the 24 Hour... - Page 127 Master Programming Level Programming Communication Format CENTRAL STATION Pressing 1 while viewing Primary/Secondary Screen #3 will cause the following screens to be dis- 1=COMM FORMAT played: Primary/Secondary Screen #3 COMM FORMAT 1=ADEMCO EXPRESS 4P1 2=ADEMCO EXPRESS 4P2 3=3P1S C18 A23 Comm Format Screen #1 COMM FORMAT 1=3P1E C18 A23...

-

Page 128: Event Codes

Programming Master Programming Level The Communication Format is determined by the type of receiver that the DACT is transmitting to. Consult your Central Station for proper selection or consult our factory representatives. For any format chosen, the control panel automatically programs all of the event codes. Select the Communication Format by pressing the corresponding number key while viewing the appropriate Comm Format screen. - Page 129 Master Programming Level Programming 3+1, 4+1 Express, and 4+1 Standard The information shown in Table 3.3 is automatically programmed for the Central Station phone number Event Codes when any of these Formats are selected. Enter 0 for an Event Code Setting to disable the report.

- Page 130 Programming Master Programming Level POINT_FAULT POINT_DISABLE AC_FAIL DRILL SLC 1 OPEN FAULT SLC 1 SHORT FAULT GROUND FAULT LOW BATTERY NO_BATTERY TELCO LINE 1 TELCO LINE 2 COMM FAULT 1 COMM FAULT 2 TOTAL COMM FLT PRINTER FAULT NAC 1 FAULT NAC 2 FAULT 27V SYS PWR FAULT NAC 1 DISABLE...

- Page 131 Master Programming Level Programming 4+2 Standard, 4+2 Express, 3 + 1, 4 + 1, and 4+2 Expanded Formats The information shown in Table 3.4 is automatically programmed for the Central Station phone number Event Codes when any of these Formats are selected. Enter 00 for an Event Code Setting to disable the report.

- Page 132 Programming Master Programming Level MON-USER-DEF-17 POINT_FAULT POINT_DISABLE AC_FAIL DRILL SLC 1 OPEN FAULT SLC 1 SHORT FAULT GROUND FAULT LOW BATTERY NO_BATTERY TELCO LINE 1 TELCO LINE 2 COMM FAULT 1 COMM FAULT 2 TOTAL COMM FLT PRINTER FAULT NAC 1 FAULT NAC 2 FAULT 27V SYS PWR FAULT NAC 1 DISABLE...

- Page 133 Master Programming Level Programming Ademco Contact ID Format The information shown in Table 3.5 is automatically programmed for the Central Station phone number Event Codes when Ademco Contact ID Format is selected. Enter 000 for an Event Code Setting to disable the report. Event Code Settings Event Description Zone...

- Page 134 Programming Master Programming Level MON-USER-DEF-17 POINT_FAULT Zone Point POINT_DISABLE Zone Point AC_FAIL DRILL SLC 1 OPEN FAULT SLC 1 SHORT FAULT GROUND FAULT LOW BATTERY NO_BATTERY TELCO LINE 1 TELCO LINE 2 COMM FAULT 1 COMM FAULT 2 TOTAL COMM FLT PRINTER FAULT NAC 1 FAULT NAC 2 FAULT...

-

Page 135: Manual Dial Mode

Master Programming Level Programming Report Style CENTRAL STATION Pressing 3 while viewing Central Station Screen #2 will cause the Report Style display to toggle 1=PRIMARY 2=SECONDARY between Point and Zone. Setting the Report Style to Point will program the DACT to report indi- 3=REPORT STYLE POINT vidual point status to the Central Station. -

Page 136: 10: Password Change

Programming Master Programming Level Phone Line Supervision ON BOARD DACT Pressing 1 while viewing On Board DACT Screen #3 will cause the following screen to be dis- 1=SUPERV PHONE LINE played: SUPERVISE PHONE LINE On Board DACT Screen #3 1=PHONE LINE 2 The Phone Line 2 option allows the programmer to select whether the second phone line is super- vised. -

Page 137: 11: Clear Program

Master Programming Level Programming The new five digit password must be re-entered to accept the change. The display will then return to the initial Password Change Screen. 3.6.11 Clear Program Pressing 2 while viewing Programming Screen #4, will select the Clear Program option. This will PROGRAMMING cause the LCD to display the following screen: 1=PASSWORD CHANGE... -

Page 138: 12: Program Check

Programming Master Programming Level 3.6.12 Program Check The Program Check feature allows the programmer to view the zones which have been pro- PROGRAMMING grammed to the Notification Appliance Circuits on the control panel but have not been pro- 1=PASSWORD CHANGE 2=CLEAR PROGRAM grammed to Initiating Devices as well as other circuits with no input or output correlations. -

Page 139: Maintenance Programming Level

Maintenance Programming Level Programming Pressing 3 while viewing Program Check screen will cause a screen similar to the following to be displayed: ZONES NO OUTPUT 05 07 09 10 11 1D001 The Zone No Output feature allows the programmer to view the zones which have not been pro- grammed to at least one output device (not including general alarm Zone 00). -

Page 140: 1: Disable Point

Programming Maintenance Programming Level Note that in the preceding screens, an arrow appears to inform the programmer that additional options can be viewed by pressing the keypad down arrow key, as shown in the following screen. PROGRAMMING 1=WALKTEST 2=SYSTEM 3=ZONE SETUP 3.7.1 Disable Point Pressing 1 for Point Program, while viewing Maintenance Screen #1 will cause the following PROGRAMMING... -

Page 141: 2=History

Maintenance Programming Level Programming 3.7.2 History Pressing 2 while viewing Maintenance Screen #1 will cause the following screen to be displayed: PROGRAMMING 1=POINT PROGRAM 2=HISTORY HISTORY 3=PROGRAM CHECK 1=VIEW EVENTS Maintenance Screen #1 2=ERASE HISTORY History Screen The History feature allows the operator to view control panel events which have been stored in a history file in memory and erase the contents of the history file Pressing 1 while viewing the History screen will cause the following screen to be displayed: HISTORY... -

Page 142: 3=Program Check

Programming Maintenance Programming Level 3.7.3 Program Check PROGRAMMING Pressing 3 while viewing Maintenance Screen #1 will cause the following screen to be displayed: 1=POINT PROGRAM 2=HISTORY 3=PROGRAM CHECK PROGRAM CHECK 1=NACS NO INPUT Maintenance Screen #1 2=ZONES NO INPUT 3=ZONE NO OUTPUT Program Check Screen The Program Check feature allows the programmer to view the zones which have been pro- grammed to the Notification Appliance Circuits on the control panel but have not been pro-... -

Page 143: 4: Walktest

Maintenance Programming Level Programming Pressing 3 while viewing Program Check screen will cause a screen similar to the following to be displayed: ZONES NO OUTPUT 05 07 09 10 11 1D001 The Zone No Output feature allows the programmer to view the zones which have not been pro- grammed to at least one output device (not including general alarm Zone 00). -

Page 144: 5: System

Programming Maintenance Programming Level Pressing 1 for View Walktest Log while viewing the Unit In Walktest screen will cause a screen sim- ilar to one of the following two screens to be displayed: ALARM: MONITOR NO EVENTS IN NORTH CLASSROOM WALKTEST LOG Z001 10*15A 012310 1M006... -

Page 145: 6: Zone Setup

Maintenance Programming Level Programming To change the time, press 1 to display the following screen: ENTER TIME 01:00 AM 1=AM 2=PM Time Screen A flashing cursor will appear on the left side of the display. Enter the four digit number corre- sponding to the time (0000 - 1259). - Page 146 Programming Maintenance Programming Level Pressing 1 while viewing Zone Setup screen will display the following screen: ZONE TO ENABLE Enable Screen A flashing cursor appears to the right of the Z. To enable a zone, enter the two digit zone number (00 - 19).

- Page 147 Maintenance Programming Level Programming Pressing 2 will cause the display to change to Pre-signal 18 On. Each press of the 2 key will cause the display to toggle between Pre-signal 18 On and Pre-signal 18 Off. When Zone 18 is pro- grammed On, a Pre-signal activation of any device will cause Zone 18 to activate.

-

Page 148: Section 4: Operating Instructions

Section 4: Operating Instructions 4.1 Panel Control Buttons 4.1.1 Acknowledge/Step The first press of the Acknowledge/Step button silences the piezo sounder, changes flashing indica- tors/LEDs to steady and also changes the status field on the LCD display from capital letters to small letters. -

Page 149: Normal Operation

Normal Operation Operating Instructions Fire Alarm Fire Alarm indicator flashes red when one or more alarms occur. It illuminates steady when the Acknowledge/Step or Alarm Silence button is pressed. The Fire Alarm indicator turns off when the Reset button is pressed. The indicator will remain off if all alarms have been cleared. Supervisory Supervisory indicator flashes yellow when one or more supervisory conditions occur, such as a sprinkler valve tamper condition. -

Page 150: Trouble Operation

Operating Instructions Trouble Operation Performs autotest for all SLC devices Tests memory Updates and reads all communications busses (EIA-485, EIA-232, etc.) 4.4 Trouble Operation With no alarms in the system, the detection of a trouble will cause the following: •... -

Page 151: Alarm Operation

Alarm Operation Operating Instructions DIRTY2 - maintenance alert indicating that a detector needs immediate maintenance since it has been within 80% of its alarm threshold for 24 hours INVREP - maintenance alert indicating a hardware problem in the detector ... -

Page 152: Supervisory Operation

Operating Instructions Supervisory Operation A typical alarm display would be as illustrated below: ALARM PULL STATION <ADJ> <NOUN> Z000 10:00A 012110 1M001 Note that the device type, which in this example is PULL STATION, can be any other programma- ble alarm type. The information displayed in the above example provides the following information: •... -

Page 153: Process Monitor Operation

Process Monitor Operation Operating Instructions A typical Supervisory event would be displayed as illustrated in the following: ACTIVE SUPERVISORY <ADJ> <NOUN> Z000 10:00A 012110 1M001 Note that, like alarms, supervisory signals latch (except when programmed for supervisory autore- settable) and can be assigned to software zones. Supervisory alarms do not cause resound as do other alarm conditions. -

Page 154: Medical Alert Condition Operation

Operating Instructions Medical Alert Condition Operation • Activate appropriate LED on the ANN-LED annunciator (required for this application) • Each ANN-LED can support up to 10 zones. Hazard conditions latch. They can be assigned to software zones. 4.9 Medical Alert Condition Operation Medical alert operation is: •... -

Page 155: Disable/Enable Operation

Disable/Enable Operation Operating Instructions 4.12 Disable/Enable Operation Input points which are disabled do not cause an alarm or any zone activation. Disabled output points are held in the off state. All disabled points are treated as if they were in trouble, with the exception being the status label that will be displayed is DISABL. -

Page 156: Coded Operation

Operating Instructions Coded Operation Important: When a Notification Appliance Circuit with a mix of audible and visual devices is programmed for silenceable and the synchronization feature is selected, only the audible devices will be turned off if the Silence key is pressed. The visual devices (strobes, etc.) will continue to operate. -

Page 157: Special System Timers

Special System Timers Operating Instructions When a detector triggers an alarm, the onboard piezo sounds immediately, but the NACs are pre- vented from activating for 15 seconds. This inhibit time is factory set and cannot be changed. Pressing the Alarm Silence or Acknowledge/Step key during the 15 second inhibit time will silence the piezo sounder and start a timer which prevents activation of NACs for an additional time dura- tion which can be user programmed for up to three minutes. -

Page 158: 4: Waterflow Retard Timer

Operating Instructions Walktest 4.20.4 Waterflow Retard Timer If selected, this option will delay the activation of a waterflow type alarm for a programmable time duration from 1 to 90 seconds. This delay is in addition to any time delay inherent in the waterflow device. -

Page 159: Read Status

Read Status Operating Instructions While in Walktest, the trouble relay is activated and the system Trouble LED flashes (as in all of the Program and status change operations). The alarm relay is not activated. 4.22 Read Status Read Status functions do not require a password. The control panel will continue to provide fire protection while in Read Status mode. -

Page 160: 1=System Point

Operating Instructions Read Status The following screens will be displayed: READ STATUS READ STATUS 1=SYSTEM POINT 1=TROUBLE REMINDER 2=TIMERS 2=ZONES 3=NACS 3=POWER Read Status Screen #1 Read Status Screen #2 READ STATUS READ STATUS 1=RELAYS 1=ANN-BUS 2=PROGRAM CHECK 2=PHONE LINE 3=HISTORY 3=CENTRAL STATION Read Status Screen #3... - Page 161 Read Status Operating Instructions The operator selects the type of device which is to be viewed by pressing 1 for Detector or 2 for Module. If 1 is pressed, the display will change to the following screen: READ SYSTEM POINT ENTER DETECTOR# Entering the three digit detector address will cause the control panel to display the current status of the selected device.

-

Page 162: 2=Zones

Operating Instructions Read Status 4.22.2 Zones Pressing 2 while viewing Read Status Screen #1 will cause the following screens to be displayed: READ STATUS ZONES 1=SYSTEM POINT 2=ZONES 1=ZONES INSTALLED 3=POWER 2=ZONES ENABLED Read Status Screen #1 3=ZONES DISABLED Zones Screen #1 ZONES 1=SPECIAL PURPOSE 2=ZONE TYPE... -

Page 163: 4: Trouble Reminder

Read Status Operating Instructions The following table lists the circuit being measured, possible conditions and their respective volt- age ranges: Circuit Condition Voltage Range Normal Battery (nominal) 27.05 to 28.15 VDC Battery Low Battery 17.7 to 20.4 VDC No Battery 0 to 17.6 VDC ANN-BUS Power Normal... -

Page 164: 6: Nac

Operating Instructions Read Status These screens will indicate the delay time, in seconds, for each of the first three possible delay options. The AC Loss Delay time is displayed in hours. 4.22.6 NAC Pressing 3 while viewing Read Status Screen #2 will display the following screen: 1=NAC 1 2=NAC 2 The operator can press 1 to view the programmed options for NAC 1 or 2 to view the programmed... -

Page 165: 8: Program Check

Read Status Operating Instructions 4.22.8 Program Check Pressing 2 while viewing Read Status Screen #3 will cause a screen similar to the following to be displayed: PROGRAM CHECK 1=NACS NO INPUT 2=ZONES NO INPUT 3=ZONES NO OUTPUT Pressing 1 while viewing the Program Check screen will display a screen which will indicate if any input zones have not been programmed to one of the Notification Appliance Circuits. -

Page 166: 10: Ann-Bus

Operating Instructions Read Status 4.22.10 ANN-BUS Pressing 1 while viewing Read Status Screen #4 will display the following screens: ANN-BUS ENABLED 2=MODULES INSTALLED 3=ANN-S/PG OPTIONS ANN-BUS Screen #1 ANN-BUS 1=ANN-80 OPTIONS 2=ANN-SECONDARY ANN-BUS Screen #2 Pressing 2 for Modules Installed, while viewing ANN-BUS Screen #1 will display screens with ANN-BUS Addresses 1 through 8. -

Page 167: 11: Phone Line

Read Status Operating Instructions 4.22.11 Phone Line Pressing 2 while viewing Read Status Screen #4 will display the following screen: PHONE LINE PRIMARY TOUCHTONE SECONDARY TOUCHTONE This screen indicates the both the Primary and Secondary phone lines have been configured for touchtone dialing operation. -

Page 168: 13: Service Terminal

Operating Instructions Read Status 4.22.13 Service Terminal Pressing 1 for Ring Count, while viewing Read Status Screen #5 will display the following screens: READ STATUS 1=RING COUNT 2=PRINT SERVICE TERMINAL 3=TIME-DATE RING COUNT Read Status Screen #5 Service Terminal Screen 4.22.14 Print To print program data or control panel status, press 2 while viewing Read Status Screen #5. - Page 169 Read Status Operating Instructions DEVICE # DEVICE TYPE % DRIFT COMP CHAMBER TIME/DATE 1D001 SMOKE (PHOTO) 1281 12:01AM 01-08-2010 1D002 SMOKE (PHOTO) 1281 12:01AM 01-08-2010 1D003 SMOKE (PHOTO) 1259 12:01AM 01-08-2010 1D004 SMOKE (PHOTO) 1309 12:02AM 01-08-2010 1D005 SMOKE (PHOTO) 1281 12:02AM 01-08-2010 1D006...

-

Page 170: 15: Time-Date

Operating Instructions Read Status Figure 4.1 illustrates a graphic representation of the maintenance levels: DIRTY Maintenance Urgent Maintenance Alert Acceptable Range Low Chamber Reading VALUE Figure 4.1 Diagram of Maintenance Levels Pressing 2 while viewing Print Screen #2 allows the user to print the DACT summary which will detail all of the onboard DACT settings. - Page 171 Notes MS-9050 Series Manual — P/N 52413:F 10/22/2010...

-

Page 172: Section 5: Central Station Communications

Section 5: Central Station Communications The control panel transmits zone and system status reports to Central Stations via the public switched telephone network. Two supervised telephone line connections are made to interface the control panel to the telephone lines. Two optional 7 foot telephone cords are available for this pur- pose and can be purchased separately. - Page 173 Central Station Communications The control panel is capable of reporting detailed messages depending upon the format in use. Table 5.1 shows the reporting structure for all formats. Format Format Format Format Report 3+1/4+1/Standard 3+1/4+1/Expanded 4+2/Standard 4+2/Expanded 4+1 Express 4+2 Express Alarm SSS(S) A SSS(S) A...

- Page 174 Central Station Communications Where SSS or SSSS Subscriber ID Alarm (1st digit) Alarm (2nd digit) Zone Number Alarm Restore (1st digit) Alarm Restore (2nd digit) Zone Trouble (1st digit) Zone Trouble (2nd digit) Zone Trouble Restore (1st digit) RTZ2 Zone Trouble Restore (2nd digit) System Trouble (1st digit) System Trouble (2nd digit) System Trouble Restore (1st digit)

-

Page 175: Transmittal Priorities

Transmittal Priorities Central Station Communications 5.1 Transmittal Priorities The integral communicator transmits highest priority events first. Events, in terms of priority, are listed below in descending order: Alarms (highest priority level) Pull stations Waterflow Smoke detector Other alarm types ... - Page 176 Central Station Communications Transmittal Priorities The table below shows UL listed receivers which are compatible with the MS-9050UD. Format 4+1 Ademco Express 4+2 Ademco Express ...

-

Page 177: Section 6: Local/Remote Site Upload/Download

® XP or greater, with a 2400 baud compatible modem and Fire-Lite Upload/Download software kit P/N PK-CD, may serve as a Service Terminal. This allows download of the entire program or upload of the entire program, history file, walktest data, current status, time and date. -

Page 178: Transferring A Program

Local/Remote Site Upload/Download Transferring a Program The Remote Download password (default 00000) must be entered to access the Remote Download feature. Note that the default password can be changed using the Password Change option (refer to “Password Change” on page 136). Entering the correct password will cause the following screen to be displayed: REMOTE DOWNLOAD 1=PROPRIETARY... -

Page 179: Security Features

Security Features Local/Remote Site Upload/Download 6.3 Security Features Upload and download with the control panel have been carefully designed to include key security features to ensure proper functionality. Any time a transfer is initiated, the control panel and the Service Terminal will communicate and transfer data before contacting a Central Station. When the data transfers are completed and the control panel disconnects from the Service Terminal, the control panel will call the Central Station and report one of the following conditions: •... -

Page 180: Section 7: Power Supply Calculations

Section 7: Power Supply Calculations 7.1 Overview This section contains instructions and tables for calculating power supply currents in alarm and standby conditions. This is a four-step process, consisting of the following: Calculating the total amount of AC branch circuit current required to operate the system Calculating the power supply load current for non-fire and fire alarm conditions and calculating the secondary (battery) load Calculating the size of batteries required to support the system if an AC power loss occurs... -

Page 181: Calculating The System Current Draw

Use Table 7.3 on page 182 to calculate current draws as follows: Enter the quantity of devices in all three columns. Enter the current draw where required. Refer to the Fire-Lite Device Compatibility Document for compatible devices and their current draw. - Page 182 Power Supply Calculations Calculating the System Current Draw Table 7.3 contains columns for calculating current draws. For each column, calculate the current and enter the total (in amperes) in the bottom row. When finished, copy the totals from Calculation Column 2 and Calculation Column 3 to Table 7.4 on page 183. Calculation Column 1 Calculation Column 2 Calculation Column 3...

-

Page 183: Calculating The Battery Size

Calculating the Battery Size Power Supply Calculations 7.4 Calculating the Battery Size Use Table 7.4 to calculate the total Standby and Alarm load in ampere hours (AH). This total load determines the battery size (in AH), required to support the control panel under the loss of AC power. -

Page 184: Appendix A: Software Zones

Appendix A: Software Zones A.1 Correlations Setup and configuration of an addressable system is different than a conventional system. In a con- ventional system, assignment of input devices (smoke detectors, pull stations, heat detectors, etc.) to zones is accomplished through wiring. The wiring is direct from clearly marked panel terminals to any device assigned to a particular zone. - Page 185 Correlations Software Zones Correlation of Input and Output Zones Input Devices Zones Output Devices SD355 CMF-300 SD355 CMF-300 ZONE MMF-300 CMF-300 MMF-302 CMF-300 CMF-300 MMF-302 CMF-300 CP355 ZONE CMF-300 CP355 SD355 CMF-300 SD355 ZONE SD355 CMF-300 MMF-302 The zone correlations which are shown graphically above are also presented in Table A.1 on page 186.

- Page 186 Software Zones Correlations ADDRESSABLE DEVICE ZONE ASSIGNMENT Address Device Type Zone Number ADJ/NOUN SD355 FIRST HALL SD355 ELEV. LOBBY MMF-300 MMF-302 1, 2 MMF-300 1, 2 CMF-300 CMF-300 CMF-300 CMF-300 1, 2, 3 CMF-300 CP355 2ND FLOOR CP355 ROOM 210 CMF-300 CMF-300 SD355...

- Page 187 Correlations Software Zones ADDRESSABLE DEVICE ZONE ASSIGNMENTS Address Device Type Zone Number ADJ/NOUN Table A.2 Blank Programming Sheet MS-9050 Series Manual — P/N 52413:F 10/22/2010...

- Page 188 Software Zones Correlations ADDRESSABLE DEVICE ZONE ASSIGNMENTS Address Device Type Zone Number ADJ/NOUN Table A.3 Blank Programming Sheet MS-9050 Series Manual — P/N 52413:F 10/22/2010...

-

Page 189: Appendix B: Default Programming

Appendix B: Default Programming The following table provides a list of the programming options and their factory default settings. Program Option Factory Default Program Option Factory Default Master Password 00000 NAC 1 & 2 Enable Enabled Maintenance Password 11111 NAC 1 & 2 Silenceable Detector Programming Not Installed NAC 1 &... - Page 190 Default Programming Month Start Daylight Savings March ANN-I/O Range 00-19 Week Start Daylight Savings Week 2 ANN-I/O Active LEDs Only Month End Daylight Savings November ANN-RLY Relay 1 Zone 1 Week End Daylight Week 1 ....through........Verification ANN-RLY Relay 10 Zone 10 Waterflow Silenceable ANN-LED Point/Zone...

-

Page 191: Appendix C: Nfpa Standard-Specific Requirements

Central Station DACR or Protected Premises Receiving Unit. This unit must be installed as outlined in “Digital Alarm Communicator/Transmitter” on page 17. 4XTMF Transmitter Module for connection to the Fire-Lite RS82 Remote Station Receiver. See Figure C.2, “Remote Station Connection Using 4XTMF Module,” on page 193, for installation instructions for this unit. - Page 192 NFPA Standard-Specific Requirements NFPA 72 Auxiliary Fire Alarm System All connections are power-limited and supervised. This application is not suitable for separate transmission of sprinkler supervisory or trouble conditions. Notes: 3 ohms maximum loop resistance allowed for wiring from control panel to Municipal Box. Cut JP28 on the MS-9050UD main circuit board to supervise placement of 4XTMF module and circuit.

- Page 193 NFPA Standard-Specific Requirements Cut Jumper JP28 on the MS-9050UD main circuit board to supervise placement of the 4XTMF module. Refer to “4XTMF Transmitter Module Installation” on page 33 for detailed information. RS82 Remote Station Receiver UL listed. Refer to Instruction Manual for Remote Station Receiver Model RS82. Polarity Shown is Normal Standby Power-limited...

- Page 194 NFPA Standard-Specific Requirements NFPA 72 Proprietary Protective Signaling Systems MS-9050UD Addressable Fire Control Panel MS-9050UD Main Board Form-C Alarm contact programmed to activate on General Alarm. Form-C Trouble contact which will automatically activate on any Trouble condition. Form-C relay contact programmed to activate on Supervisory condition.

-

Page 195: C.1: Central Station/Remote Station Transmitter: Connection To Facp Dry Contacts

Central Station/Remote Station Transmitter: Connection to FACP Dry Contacts NFPA Standard-Specific Requirements C.1 Central Station/Remote Station Transmitter: Connection to FACP Dry Contacts The dry contacts of the FACP programmable relays can be used to trip a UL-864 Listed Central Station/Remote Station Transmitter. The FACP contacts must be supervised by the Central Sta- tion/Remote Station Transmitter module using End-of-Line Resistors (ELRs) with a value deter- mined by the Transmitter manufacturer. -

Page 196: C.2: Mbt-1 Municipal Box Trip - Silenceable

NFPA Standard-Specific Requirements MBT-1 Municipal Box Trip - Silenceable C.2 MBT-1 Municipal Box Trip - Silenceable The following figure illustrates the connection of the MBT-1 (Municipal Box Trip) between the FACP and a Local Energy Municipal Box. The use of an addressable control module programmed for General Alarm and Silenceable allows silencing of the Municipal Box without resetting the panel or box. - Page 197 Notes MS-9050 Series Manual — P/N 52413:F 10/22/2010...

-

Page 198: Appendix D: Facp With Keltron

Appendix D: FACP with Keltron The following figure illustrates the connections between the FACP and Keltron Receiver/Transmit- ter. CAUTION: POSSIBLE EQUIPMENT DAMAGE FOR REASONS OF WIRING DIAGRAM CLARITY, TERMINAL DESIGNATIONS OF KELTRON MODULES ARE NOT SHOWN IN ACTUAL ORDER. FOLLOW KELTRON MANUAL AND MODULE MARKINGS FOR EXACT TERMINAL LOCATIONS TO PREVENT SEVERE MODULE DAMAGE! IMPORTANT! All connections between the FACP and Keltron modules must be made within 20 feet and enclosed within conduit or equivalently protected against mechanical injury. -

Page 199: Appendix E: Wire Requirements

Appendix E: Wire Requirements T-tapping of the SLC loop wiring is allowed for 2-wire (Style 4) configurations. The total resis- tance of any branch cannot exceed 40 ohms. The total wire length of all branches cannot exceed 10,000 feet (3,000 m). Connecting external system accessories to the MS-9050UD main circuits must be carefully consid- ered to ensure proper operation. -

Page 200: E.1: Nac Wiring

Wire Requirements NAC Wiring E.1 NAC Wiring The following table lists NAC wiring requirements for the FACP. CLASS-B CLASS-A Max. Max. allowable wire pair lenth Max. allowable wire pair length allowable NAC Load (feet) (feet) total loop (Amps) resistance AWG 12 AWG 14 AWG 16 AWG 18... -

Page 201: Appendix F: Hvac Control

Appendix F: HVAC Control The FACP can be programmed to shut down a building’s HVAC fans in the event of a fire. The fans cannot be restarted until the fire alarm condition has been cleared and the FACP has been reset to a normal (non-alarm) condition. -

Page 202: F.2.2: Hvac Ovrride

HVAC Control Monitor Module Operation F.2.2 HVAC OVRRIDE The HVAC OVRRIDE type code can be assigned to any addressable monitor module for the pur- pose of overriding or preventing the HVAC SHUTDN control relay modules from activating. The HVAC OVRRIDE monitor module acts globally throughout the FACP system and therefore is not programmed to a particular software zone. -

Page 203: Appendix G: Ademco Contact Id Format Event Code Descriptions

Appendix G: Ademco Contact ID Format Event Code Descriptions This appendix describes the various Event Codes and their messages which are available for the Ademco Contact ID Format. G.1 Transmission Format Between DACT and Receiver The transmission string for the Ademco Contact ID Format is as follows: SSSS 18 QXYZ GG CCC where SSSS = Four digit Subscriber ID Account Code... - Page 204 Ademco Contact ID Format Event Code Descriptions Ademco Contact ID Typical Printout EVENT CODE CLASSIFICATIONS ALARMS OPEN/CLOSE DISABLES/ SUPERVISORY TROUBLES TEST/MISC. REMOTE ACCESS BYPASSES Medical Fire System Open/Close System Test Fire Sounder/Relay Remote Access Sounder/Relay Panic System Peripheral Access Control System Peripheral Burglary Communication...

- Page 205 Ademco Contact ID Typical Printout Ademco Contact ID Format Event Code Descriptions EVENT MESSAGE 142 Polling loop short ALARM - Polling Loop Short - # 143 Expansion module failure ALARM - Exp. Module Fail - # 144 Sensor tamper ALARM - Sensor Tamper - # 145 Expansion module tamper ALARM - Exp.