HEIDENHAIN TNC 620 Manuals

Manuals and User Guides for HEIDENHAIN TNC 620. We have 8 HEIDENHAIN TNC 620 manuals available for free PDF download: User Manual, Operating Instructions Manual, Replacing Instructions

HEIDENHAIN TNC 620 User Manual (546 pages)

Brand: HEIDENHAIN

|

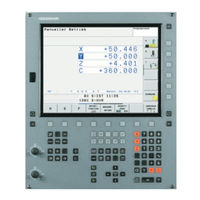

Category: Control Panel

|

Size: 7 MB

Table of Contents

Advertisement

HEIDENHAIN TNC 620 User Manual (616 pages)

Brand: HEIDENHAIN

|

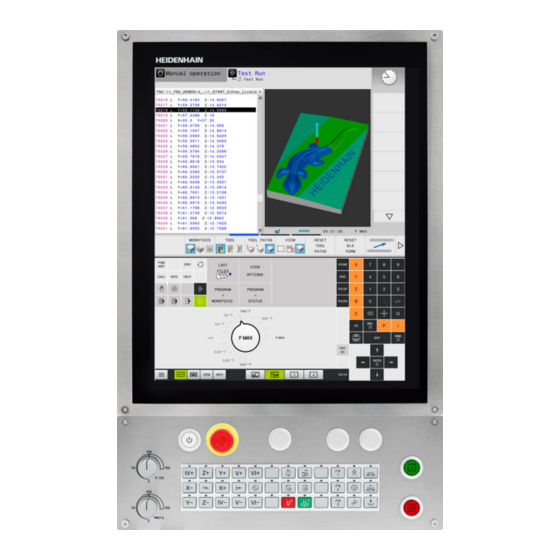

Category: Control Systems

|

Size: 16 MB

Table of Contents

HEIDENHAIN TNC 620 User Manual (598 pages)

Klartext Programming

Brand: HEIDENHAIN

|

Category: Control Systems

|

Size: 11 MB

Table of Contents

Advertisement

HEIDENHAIN TNC 620 User Manual (539 pages)

Brand: HEIDENHAIN

|

Category: Industrial Equipment

|

Size: 11 MB

Table of Contents

HEIDENHAIN TNC 620 User Manual (499 pages)

Setup, Testing and Running NC Programs

Brand: HEIDENHAIN

|

Category: Control Panel

|

Size: 12 MB

Table of Contents

HEIDENHAIN TNC 620 User Manual (521 pages)

Setup, Testing and Running NC Programs

Brand: HEIDENHAIN

|

Category: Control Systems

|

Size: 14 MB

Table of Contents

HEIDENHAIN TNC 620 Operating Instructions Manual (64 pages)

Programming Station

Brand: HEIDENHAIN

|

Category: Controller

|

Size: 3 MB

Table of Contents

HEIDENHAIN TNC 620 Replacing Instructions (12 pages)

Brand: HEIDENHAIN

|

Category: Control Systems

|

Size: 0 MB