HEIDENHAIN TNC 320 Programming Station Manuals

Manuals and User Guides for HEIDENHAIN TNC 320 Programming Station. We have 3 HEIDENHAIN TNC 320 Programming Station manuals available for free PDF download: User Manual, User's Manual For Cycle Programming

HEIDENHAIN TNC 320 Programming Station User's Manual For Cycle Programming (465 pages)

Brand: HEIDENHAIN

|

Category: Control Unit

|

Size: 8 MB

Table of Contents

-

-

Overview50

-

Application54

-

Point Tables60

-

Application60

-

-

-

Fundamentals94

-

Overview94

-

Cycle Run95

-

Cycle Run97

-

Cycle Run100

-

Cycle Parameters102

-

Prerequisites104

-

Cycle Run106

-

Cycle Parameters108

-

Cycle Run110

-

Cycle Parameters112

-

Cycle Run114

-

Cycle Parameters116

-

Cycle Run118

-

Cycle Parameters120

-

Cycle Run122

-

Cycle Parameters124

-

-

-

Fundamentals130

-

Overview130

-

Cycle Run131

-

Cycle Parameters133

-

Cycle Run136

-

Cycle Parameters139

-

Cycle Run141

-

Cycle Parameters143

-

Cycle Run146

-

Cycle Parameters148

-

Cycle Run151

-

Cycle Parameters153

-

Cycle Run155

-

Cycle Parameters157

-

Cycle Run159

-

Cycle Parameters161

-

Cycle Run164

-

Cycle Parameters168

-

-

-

Fundamentals176

-

Overview176

-

Cycle Run177

-

Cycle Parameters178

-

Cycle Run180

-

Cycle Parameters181

-

-

-

SL Cycles186

-

Fundamentals186

-

Overview187

-

Cycle Parameters188

-

Fundamentals189

-

Cycle Parameters193

-

Cycle Run194

-

Cycle Parameters195

-

Cycle Run196

-

Cycle Parameters198

-

Cycle Run200

-

Cycle Parameters201

-

Cycle Run202

-

Cycle Parameters204

-

Cycle Run205

-

Cycle Parameters206

-

Cycle Parameters207

-

Cycle Run208

-

Cycle Parameters210

-

-

-

Fundamentals218

-

Cycle Run219

-

Cycle Parameters221

-

Cycle Run222

-

Cycle Parameters224

-

Cycle Run225

-

Cycle Parameters227

-

Cycle Run228

-

Cycle Parameters230

-

-

-

Fundamentals236

-

Fundamentals246

-

-

Fundamentals250

-

Overview250

-

Effect251

-

Cycle Parameters251

-

Effect252

-

Cycle Parameters253

-

Status Displays256

-

Effect257

-

Cycle Parameters257

-

Status Displays257

-

Effect258

-

Cycle Parameters259

-

Effect260

-

Cycle Parameters261

-

Scaling262

-

Effect262

-

Cycle Parameters262

-

Effect263

-

Cycle Parameters264

-

Effect265

-

Cycle Parameters266

-

Resetting266

-

-

-

Fundamentals274

-

Overview274

-

Function275

-

Cycle Parameters275

-

Cycle Function276

-

Cycle Parameters277

-

Cycle Function278

-

Cycle Parameters278

-

Cycle Function279

-

Cycle Parameters281

-

Cycle Run282

-

Cycle Parameters283

-

Cycle Run287

-

Cycle Parameters290

-

-

-

Touch Probe Data301

-

-

Fundamentals304

-

Overview304

-

Cycle Run306

-

Cycle Parameters307

-

Cycle Run309

-

Cycle Parameters310

-

Cycle Run312

-

Cycle Parameters313

-

Cycle Run315

-

Cycle Parameters316

-

Cycle Run318

-

Cycle Parameters318

-

Cycle Run319

-

Cycle Parameters320

-

-

-

Overview324

-

Cycle Run328

-

Cycle Parameters330

-

Cycle Run332

-

Cycle Parameters333

-

Cycle Run335

-

Cycle Parameters337

-

Cycle Run339

-

Cycle Parameters340

-

Cycle Run342

-

Cycle Parameters344

-

Cycle Run347

-

Cycle Parameters348

-

Cycle Run351

-

Cycle Parameters353

-

Cycle Run356

-

Cycle Parameters358

-

Cycle Run360

-

Cycle Parameters361

-

Cycle Run363

-

Cycle Parameters364

-

Cycle Run365

-

Cycle Parameters367

-

Cycle Run369

-

Cycle Parameters370

-

-

Fundamentals376

-

Overview376

-

Tool Monitoring380

-

Cycle Run382

-

Cycle Parameters382

-

Cycle Run383

-

Cycle Parameters383

-

Cycle Run384

-

Cycle Parameters385

-

Cycle Run387

-

Cycle Parameters388

-

Cycle Run391

-

Cycle Parameters392

-

Cycle Run395

-

Cycle Parameters396

-

Cycle Run398

-

Cycle Parameters399

-

Cycle Run401

-

Cycle Parameters402

-

Cycle Run404

-

Cycle Parameters405

-

Cycle Run407

-

Cycle Parameters408

-

Cycle Run410

-

Cycle Parameters411

-

Cycle Run413

-

Cycle Parameters414

-

-

-

Overview420

-

Cycle Run421

-

Cycle Parameters422

-

Cycle Run423

-

Cycle Parameters424

-

Cycle Run425

-

Cycle Parameters427

-

-

Fundamentals444

-

Overview444

-

Cycle Run450

-

Cycle Parameters450

-

Fundamentals451

-

Cycle Run451

-

Cycle Parameters452

-

Cycle Run453

-

Cycle Parameters454

-

Cycle Run455

-

Cycle Parameters456

-

Cycle Run457

-

Cycle Parameters458

-

-

Tables of Cycles459

Advertisement

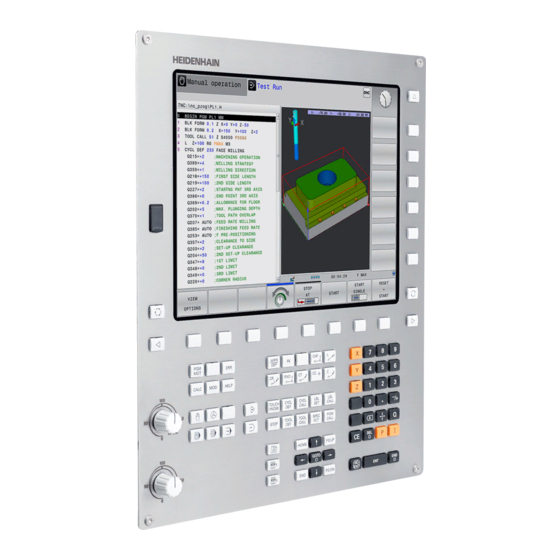

HEIDENHAIN TNC 320 Programming Station User Manual (670 pages)

Compact Contouring Control

Brand: HEIDENHAIN

|

Category: Control Unit

|

Size: 27 MB

Table of Contents

-

Overview54

-

Introduction73

-

The TNC 32074

-

Programming78

-

Test Run78

-

Portscan91

-

Vnc95

-

Fundamentals102

-

Files129

-

Data Backup131

-

Programming Aids157

-

Tool183

-

MOD Functions577

HEIDENHAIN TNC 320 Programming Station User Manual (439 pages)

Cycle Programming

Brand: HEIDENHAIN

|

Category: Control Unit

|

Size: 9 MB

Table of Contents

-

-

Contents6

-

-

Centering61

-

Drilling63

-

Reaming65

-

Boring67

-

Back Boring75

-

Bore Milling83

-

Drilling88

-

-

5.1 Fundamentals

128-

Circular Pocket134

-

Slot Milling138

-

Circular Slot143

-

Rectangular Stud148

-

Circular Stud152

-

-

Datum Shift245

-

Datum Setting251

-

Mirror Image252

-

Rotation254

-

Scaling256

-

Working Plane260

-

Advertisement