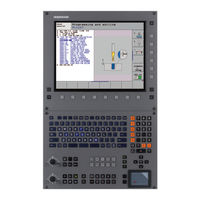

HEIDENHAIN iTNC 530 E Manuals

Manuals and User Guides for HEIDENHAIN iTNC 530 E. We have 2 HEIDENHAIN iTNC 530 E manuals available for free PDF download: User Manual

HEIDENHAIN iTNC 530 E User Manual (689 pages)

Conversational Programming

Brand: HEIDENHAIN

|

Category: Control Panel

|

Size: 25 MB

Table of Contents

-

-

Introduction37

-

The Itnc38

-

-

-

-

-

Data Backup96

-

-

-

Deleting a File106

-

Tagging Files107

-

Renaming a File108

-

-

Adding Comments133

-

-

Display Help141

-

Show Error List142

-

Window Contents143

-

-

-

-

Feed Rate F162

-

Spindle Speed S163

-

-

Tool Data164

-

Tool Length L164

-

Tool Radius R165

-

Tool Change176

-

-

-

-

Path Functions200

-

Tool Movements200

-

Straight Line L214

-

Circle Center CC217

-

Straight Line Lp227

-

Auxiliary Points242

-

Relative Data243

-

Basic Settings253

-

Layer Settings254

-

Datum Specifying255

-

Zoom Function258

-

-

-

-

Point Tables298

-

Drilling (Cycle)307

-

Reaming (Cycle)309

-

Boring (Cycle)311

-

Sl Cycles397

-

-

D Data (Cycle)442

-

-

Special Cycles476

-

Position Display484

-

Label Lbl518

-

Nesting Depth521

-

Types of Nesting521

-

-

-

Test Run593

-

Program Run596

-

MOD Functions607

-

Mod Function608

-

Code Numbers611

-

Introduction617

-

-

Network Settings675

-

Overview Tables685

-

Status Displays687

-

Example689

-

Advertisement

HEIDENHAIN iTNC 530 E User Manual (514 pages)

Cycle Programming

Brand: HEIDENHAIN

|

Category: Control Panel

|

Size: 10 MB

Table of Contents

-

-

Application58

-

Function66

-

Point Tables66

-

-

-

Cycle Run75

-

Drilling75

-

Reaming77

-

Boring79

-

Back Boring87

-

Bore Milling95

-

Tapping New107

-

Rigid Tapping109

-

Prerequisites115

-

Thread Milling117

-

Circular Pocket146

-

Slot Milling150

-

Circular Slot155

-

Rectangular Stud160

-

Circular Stud164

-

Circular Pattern173

-

Linear Pattern176

-

SL Cycles182

-

Contour Geometry185

-

Contour Data190

-

Pilot Drilling192

-

Rough-Out194

-

Floor Finishing198

-

Side Finishing199

-

Contour Train201

-

Trochoidal Slot205

-

Cylinder Surface221

-

Run 3-D Data255

-

Ruled Surface259

-

Face Milling263

-

Datum Shift274

-

Datum Setting281

-

Mirror Image282

-

Rotation284

-

Scaling Factor286

-

Working Plane290

-

Dwell Time303

-

Program Call304

-

Cycle Function306

-

Tolerance307

-

Cycle Parameters310

-

-

Basic Rotation322

-

Basic Rotation331

-

Tool Monitoring400

-

Ref. Plane402

-

Measure Angle405

-

Measure Hole408

-

Measure Plane437

-

Calibrate Ts447

-

Measuring449

-

-

Cycle Run451

-

Measuring in 3-D451

-

Cycle Parameters452

-

Log Function465

-

-

Backlash473

-

Error Outputs480

-

Fixed Cycles509

Advertisement

Related Products

- HEIDENHAIN ITNC 530 - PILOT SMART NC

- HEIDENHAIN ITNC 530 - CYCLE PROGRAMMING

- HEIDENHAIN ITNC 530 - CONVERSATIONAL PROGRAMMING

- HEIDENHAIN iTNC 530 HSCI

- HEIDENHAIN IK 5000 QUADRA-CHEK

- HEIDENHAIN QUADRA-CHEK IK 559 Series

- HEIDENHAIN ID 344980-01

- HEIDENHAIN ID 344980-02

- HEIDENHAIN ID 331143-04

- HEIDENHAIN IOB 49