Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for zortrax M200

- Page 1 MANUAL ENTER AN ENVIRONMENT OF PROFESSIONAL 3D PRINTING...

-

Page 3: Table Of Contents

CONTENTS INTRODUCTION Cleaning the platform Thank you for choosing Zortrax M200® Straightening perforated plate SAFETY Drive belts maintenance Before you start working with Zortrax M200® Drive pulleys maintenance read safety tips Lubricating ZORTRAX M200 Extruder maintenance In the box TROUBLESHOOTING... -

Page 4: Introduction

Zortrax M200® manual allow you to easily and securely install and media (electronic, mechanical, photocopying, recording or other) configure our product. -

Page 5: Safety

SAFETY Before you start working with Zortrax M200® read safety tips: SAFETY SIGNS USED IN THIS TEXT: • Never touch the model, hotend or platform during printing Caution – these actions may harm you if you won’t follow the instruction. -

Page 6: Zortrax M200

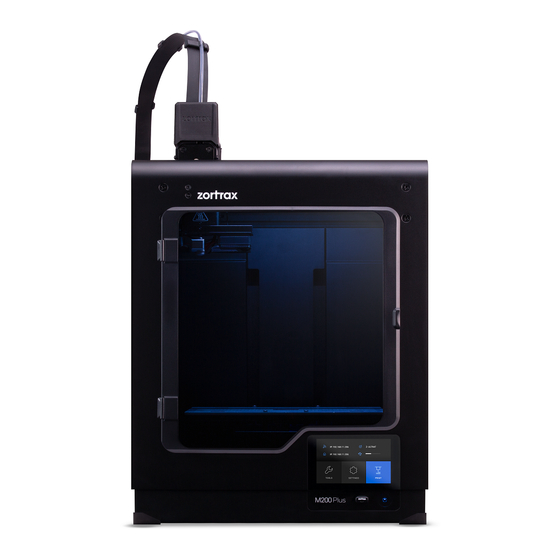

ZORTRAX M200 3D printing is a technology for industry and design. Using 3D printer in technical and design studios lowers the costs of prototyping. The integration of key elements of the printer - dedicated Z-Suite® software and composition of the Z-Filaments™ let us create new 3D printing technology –... -

Page 7: In The Box

IN THE BOX SD Card Z-Suite®* Zortrax M200® Filament Spool Filament Build Filament Guide Power Cable & & 3D Printer Holder Spool Platform SD Card Reader Quick Start Guide Cutting Knife Nozzle Key Spatula Safety & Allen Keys & Pliers &... -

Page 8: Filaments

OVERVIEW Extruder Extruder Cable Filament Filament Guide Hotend Build Platform Display Filament Mount Power Connector Z Axis Screw Control and Switch Knob... - Page 9 PRINTING MATERIALS OVERVIEW For Zortrax M200® we use high quality thermoplastic material – filaments. All our materials have carefully selected composition and properties. We advise you to print with dedicated filaments only. Only Z-Filaments™ guarantee safe and high quality prints.

- Page 10 PRINTING MATERIALS OVERVIEW MATERIAL PROPERTIES Suitable for mechanical Available in a wide range of Z-ABS™ High printing precision Suitable for utility models treatment colors Suitable for mechanical Z-ULTRAT™ Durable High quality prints Suitable for large prints treatment Suitable for mechanical Z-FLEX™* Elastic Models are flexible and elastic...

-

Page 11: Preparation For First Use

PREPARATION FOR FIRST USE PREPARE YOUR PRINTER TO WORK Place the platform inside M200® and match magnets (you can see them in the picture). Carefully connect both connectors to the platform. Place the cables using fastening clamps. Attach clamps to the cables and cables to the printer housing. -

Page 12: Prepare Your Printer To Work

PREPARATION FOR FIRST USE PREPARE YOUR PRINTER TO WORK Attach power supply cable. Mount filament guide. Mount filament spool holder. Mount spool of the Z-ABS™ on the spool holder. Spool should rotate anti-clockwise. Lead the filament through the filament guide to the printer. CAUTION! Always connect the power cable into a grounded outlet. -

Page 13: Loading Filament

Zortrax M200® is heating the extruder. When the display shows the message “Please insert filament”, insert the end of the filament into the extruder. When Zortrax M200® finishes loading filament, printer is ready to print. Remove filament remains using tweezers. -

Page 14: Auto-Calibration

Tighten 3 pcs screws on the bottom of the platform. Zortrax M200® is checking level of the back part of the platform. Zortrax M200® is showing information which screw should be tighten and which should be loosen. Follow the instruction on the display. - Page 15 Zortrax M200® displays the message which way to tighten the front screw. If the level is incorrect, Zortrax M200® will check the level of the front part of the platform and displays information in which way the screw should be tighten.

-

Page 16: Software&Firmware

Z-SUITE® SOFTWARE INSTALLATION Use .stl, .obj or .dxf format files to work with your Zortrax M200®. Most CAD and 3D modeling software allows you to convert 3D files to this format. To prepare a file for 3D printing (in the .zcode format) install Z-Suite™... -

Page 17: Printing

Select the model in the a .zcode™ format file. Now the printing procedure will run automatically. The display shows information about extruder and platform heating level. After heating elements, M200® starts printing. Progress bar shows the percentage of print advancement. -

Page 18: Removing Print

PRINTING REMOVING PRINT When the printing process ends, turn off your Zortrax M200®. Disconnect the cables from the platform. Remove the platform. Remove the models using spatula. Wear safety glasses and gloves. Place the platform inside the M200® and plug the connectors. -

Page 19: Removing Support

PRINTING REMOVING SUPPORT Models printed on Zortrax M200® composed of bottom part (raft), support and the print. Remove raft and support. Remember to wear safety gloves and glasses. Removing raft is easy – simply detach it from the model with your hands. -

Page 20: Support & Maintenance

SUPPORT & MAINTENANCE Keep your M200® efficient and safe – run maintenance regularly. CAUTION! Turn off the power and unplug connec- tors when carrying maintenance tasks. CAUTION! Never use compressed air to clean your printer. It can damage bearings and guides. - Page 21 SUPPORT & MAINTENANCE MIEJSCE CZYNNOŚCI CZĘSTOTLIWOŚĆ Main Cleaning the machine and its environment, especially bottom plate of the Before each printing printer Head Check if the head is not clogged with the filament remains Before each printing Remove the filament remains Before each printing Build plate Cleaning perforated platform...

-

Page 22: Changing The Filament

CHANGING THE FILAMENT To change the filament, from the “Filament” menu select “Unload filament” option. Zortrax M200® is heating the extruder. The display shows the message “Withdrawing filament”. Filament begins to withdraw from the extruder. When the process is complete –remove the filament. To load new filament, follow the instruction on page 13. -

Page 23: Cleaning The Platform

SUPPORT & MAINTENANCE CLEANING THE PLATFORM Turn off the printer and detach the platform connectors. Carefully remove the platform. Clean the perforated platform using spatula. Unscrew screws mounting platform. Use allen key Clean the bottom part of the perforated platform using Remove remains from the aluminum plate. -

Page 24: Straightening Perforated Plate

SUPPORT & MAINTENANCE STRAIGHTENING PERFORATED PLATE If between the center of the perforated plate and aluminum heated plate you can sense space, it means platform has deformed. This is a result of normal use. To straighten the platform, please bend it as you can see in the photo. -

Page 25: Drive Belts Maintenance

Properly tensioned belts guarantee correct work of your machine. Provided machine has properly tensioned belts. Check if none of them is loose. To check, gently tug. Properly tensioned belt vibrates making sounds. If belts are loose please visit our Support Centre at www.zortrax.com/support-center... - Page 26 SUPPORT & MAINTENANCE DRIVE BELTS MAINTENANCE Loosen 4 pcs screws mounting motor (pic. 3). Press the motor down, make sure that the belt is tighten (pic.4). Tighten the screws mounting motor, keep the belts tighten. Attach motor connectors.

-

Page 27: Drive Pulleys Maintenance

SUPPORT & MAINTENANCE DRIVE PULLEYS MAINTENANCE Check if the XY axes pulleys working with short motor belt are tighten. To check if pulleys are tighten, remove XY axes motor. Unplug motor connector (pic. 1) and unscrew 4 pcs screws mounting motor (pic. - Page 28 SUPPORT & MAINTENANCE DRIVE PULLEYS MAINTENANCE Remove the motor and spacer (pic. 3). Tighten screws mounting pulley (pic. 4).

- Page 29 SUPPORT & MAINTENANCE DRIVE PULLEYS MAINTENANCE Mount the motor, spacer and tighten the screws (partly). Motor should move vertically on screws (pic. 5). Press the motor down, so that the belt is tightened (pic. 6). Keep tense, tighten screws mounting motor and attach connector.

- Page 30 DRIVE PULLEYS MAINTENANCE Please check if blocking pulleys are tighten when maintaining your M200®. There are 2 screws on each pulley. First check the tightness of the rack on the X axis and the Y axis which cooperates with a short drive belt on the motor X or Y (pic.

-

Page 31: Lubricating

SUPPORT & MAINTENANCE LUBRICATING Use service grease to lubricate the linear guide on XY axes (pic. 1 and pic. 2) – you can find grease in the set that came with the printer (white tube). Apply a thin layer on each guide. You can also use silicone grease. - Page 32 (white tube). You can also use silicone grease*. you can find trapezoidal screw in HX2 version of Zortrax M200®. Version HW1 and HW3 do not require smearing of Z axis screw.

-

Page 33: Extruder Maintenance

Extruder maintenance allows you to print high quality models. To start, please withdraw filament from the extruder (pic. 1). Turn on your M200® and select “Filament” -> “Unload filament” option from main menu. Zortrax M200® is withdrawing the filament and the LCD display shows “Withdrawing filament”... - Page 34 SUPPORT & MAINTENANCE EXTRUDER MAINTENANCE Remove top part of the plastic cover - cover is mounted on latches (pic. 3). Unscrew 2 pcs screws mounting platform (pic. 4).

- Page 35 SUPPORT & MAINTENANCE EXTRUDER MAINTENANCE Disconnect motor plug (pic. 5) and remove the motor – unscrew 4 pcs screws from the front of the extruder (pic. 6).

- Page 36 SUPPORT & MAINTENANCE EXTRUDER MAINTENANCE Clean the pulley on the motor shaft. Remove filament remains (pic. 7). Assemble everything following the steps in a reverse order.

-

Page 37: Troubleshooting

• if the filament is not finished; • if the nozzle is not blocked Please go to support.zortrax.com Nozzle does not provide filament or provides it discontinuously Please go to support.zortrax.com Printed models are deformed Increase speed fan. If that won’t help,... -

Page 38: Dictionary

Support is made of the same filament as the model. Hotend – The set of heating block, nozzle and filament supply slot. This is the most important part of M200® - here the material is heated to the required temperature, plasticized and applied layer after layer to the platform. - Page 39 DICTIONARY Support – Supporting material generated with model which let you print difficult models. Zortrax M200® is using SES™ technology which means that support is removable. Z axis screw – Screw which allows the platform to move up and down. It requires maintenance.

-

Page 40: Specifications

SPECIFICATIONS PHYSICAL DIMENSIONS PRINTING Without Spool 345 x 360 x 430 mm [13.6 x 14 x 17 in] Print technology LPD™ - Layer Plastic Deposition With Spool 345 x 430 x 430 mm [13.6 x 17 x 17 in] Build volume 200 x 200 x 185 mm [7.87 L x 7.87 W x 7.28 H in] Shipping Box... - Page 42 CONTACT Technical Support: zortrax.com/support-center www.zortrax.com...

Need help?

Do you have a question about the M200 and is the answer not in the manual?

Questions and answers