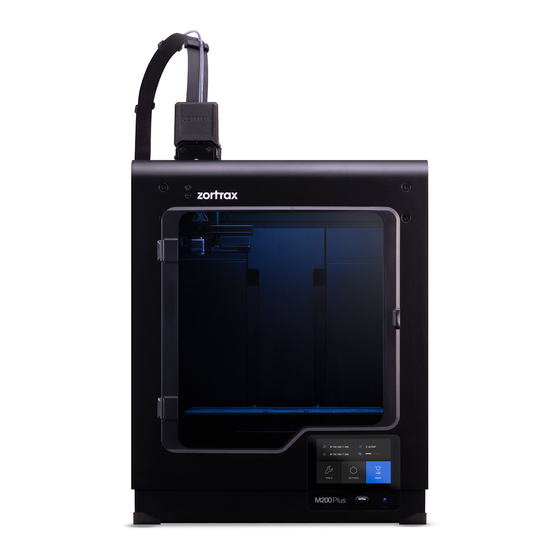

Summary of Contents for zortrax M200

- Page 1 Extruder Bearing Replacement SOURCE: https://support.zortrax.com/extruder-bearing-replacement/ page 1 / 24...

- Page 2 Table Of Content Unplugging the Power Cable Material Guide Removal Unplugging the Extruder Cable Unplugging all Cables from the Extruder PCB Unscrewing the Extruder PCB Extruder Lower Printed Cover Removal Unscrewing the Extruder Aluminum Cover Unscrewing the Extruder Motor Extruder Motor Removal Unscrewing the Extruder Bearing Extruder Bearing Removal Extruder Bearing Assembly...

- Page 3 If the material is loaded into the extruder, unload the material using the “Material” -> “Unload material” option in the printer menu. The following manual shows the M200 repair work. For the M300, these procedures are the same. page 3 / 24...

- Page 4 Unplugging the Power Cable Turn off the printer and unplug the power cable and wait a few minutes for all the capacitors to discharge. page 4 / 24...

- Page 5 Material Guide Removal Detach the material guide from the extruder cover. Next, separate the guide from the extruder cable. page 5 / 24...

- Page 6 Unplugging the Extruder Cable Detach the extruder upper printed cover and unplug the extruder cable. page 6 / 24...

- Page 7 Unplugging all Cables from the Extruder PCB Unplug all the cables from the extruder PCB. page 7 / 24...

- Page 8 Unscrewing the Extruder PCB Unscrew the two screws that secure the extruder PCB using a 2mm Allen key. Remove the PCB from the extruder. page 8 / 24...

- Page 9 Extruder Lower Printed Cover Removal Remove the extruder lower printed cover. page 9 / 24...

- Page 10 Unscrewing the Extruder Aluminum Cover Unscrew the screws that secure the extruder aluminum cover on both sides of the extruder. Separate the cover from the extruder motor. page 10 / 24...

- Page 11 Unscrewing the Extruder Motor Unscrew the four screws that secure the extruder motor. page 11 / 24...

- Page 12 Extruder Motor Removal Separate the extruder motor from the extruder block. page 12 / 24...

- Page 13 Unscrewing the Extruder Bearing Unscrew one screw that secures the extruder bearing. page 13 / 24...

- Page 14 Extruder Bearing Removal Remove the extruder bearing using tweezers. page 14 / 24...

- Page 15 Extruder Bearing Assembly Insert the new bearing into the extruder block and secure it with the screw. page 15 / 24...

- Page 16 Extruder Motor Assembly, part 1 Reattach the extruder motor to the extruder block. page 16 / 24...

- Page 17 Extruder Motor Assembly, part 2 Secure the motor with the screws. Press the motor to the right side so that the bearing rack is as close to the bearing as possible. Tighten the screws crosswise in the following order: 1-4, 2-3. page 17 / 24...

- Page 18 Extruder Aluminum Cover Assembly Reattach the extruder aluminum cover to the extruder and secure it with the screws. Remember to screw the aluminum cover evenly on both sides to avoid deformation. page 18 / 24...

- Page 19 Extruder Lower Printed Cover Assembly Attach the new extruder lower printed cover to the extruder. page 19 / 24...

- Page 20 Extruder PCB Assembly Place the extruder PCB in its place and secure it with the two screws. page 20 / 24...

- Page 21 Plugging all Cables into the Extruder PCB Plug all the cables in. Remember to arrange the cables so that they don’t get damaged, e.g. by wrapping against each other. page 21 / 24...

- Page 22 Plugging the Extruder Cable Plug the extruder cable in, and then attach the extruder upper cover to the lower cover. MAKE SURE THE EXTRUDER CABLE IS PROPERLY PLUGGED IN. page 22 / 24...

- Page 23 Material Guide Installation Attach the material guide to the extruder cover. Next, secure the guide to the extruder cable with the material guide clamps. MAKE SURE THE MATERIAL GUIDE IS PROPERLY INSTALLED IN THE COVER. page 23 / 24...

- Page 24 Plugging the Power Cable Plug the power cable in. page 24 / 24...

Need help?

Do you have a question about the M200 and is the answer not in the manual?

Questions and answers