Johnson Controls IFC-3030 Installation Manual

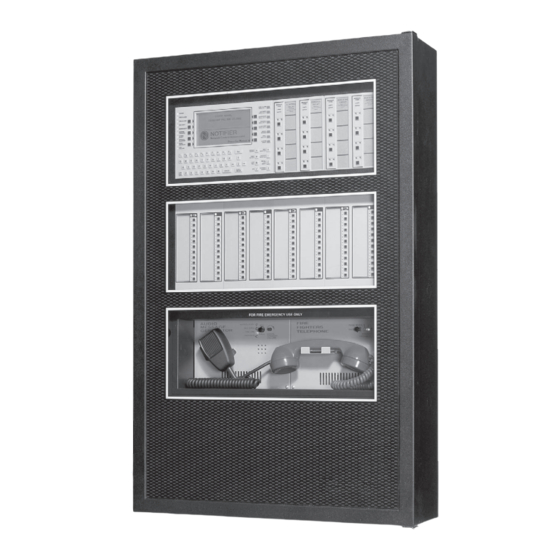

Fire alarm control panel

Hide thumbs

Also See for IFC-3030:

- Operation manual (76 pages) ,

- Wiring manual (72 pages) ,

- Programming manual (156 pages)

Summary of Contents for Johnson Controls IFC-3030

- Page 1 Fire Alarm Control Panel IFC-3030 Installation Manual Document 52024 08/05/2005 P/N 52024:C • ECN 05-126...

- Page 2 (especially in bedrooms), smoking in bed, and violent explosions (caused by escaping gas, improper storage of flammable materials, etc.). Precau-L-1-2005.fm IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 3: Installation Precautions

Microsoft Corporation. LEXAN® is a registered trademark of GE Plastics, a subsidiary of General Electric Company. ©2005 by Honeywell International Inc. All rights reserved. Unauthorized use of this document is strictly prohibited. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 4 • Your suggestion for how to correct/improve documentation Send email messages to: FireSystems.TechPubs@honeywell.com Please note this email address is for documentation feedback only. If you have any technical issues, please contact Technical Services. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 5: Table Of Contents

3.14.2: Loop Control Module, Loop Expander Module................37 Mounting Instructions ..........................37 Setting SLC Loop Number........................38 Enabling External Power Supervision....................38 3.15: Connecting Power Sources and Outputs....................41 3.15.1: Overview ............................41 3.15.2: Connecting the Power Supply ......................42 3.15.3: Checking AC Power ........................42 IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 6 A.4: Wire Requirements............................63 Appendix B: Canadian Applications..................65 B.1: Standalone Application ..........................65 B.2: Local Network Application .........................65 B.3: Automatic Alarm Signal Silence.........................65 B.4: Annunciator Applications ...........................65 B.5: Releasing Devices ............................65 Index ............................69 IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 7: Section 1: About This Manual

EIA-485 and EIA-232 Serial Interface Standards NEC Article 300 Wiring Methods NEC Article 760 Fire Protective Signaling Systems Applicable Local and State Building Codes Requirements of the Local Authority Having Jurisdiction Canadian Electrical Code, Part 1 IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 8: Supplemental Documentation

SCS Smoke Control Manual (Smoke and HVAC Control Station) Manual 15712 DPI-232 Manual 51499 TM-4 Installation Document (Reverse Polarity Transmitter) 51490 UDACT Manual (Universal Digital Alarm Communicator/Transmitter) 50050 Table 1.1 Related Documentation (1 of 2) IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 9: Cautions And Warnings

Information about procedures that could cause programming errors, runtime errors, or equipment damage. WARNING: Summary in bold Indicates information about procedures that could cause irreversible damage to the control panel, irreversible loss of programming data or personal injury. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 10 Notes IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 11: Section 2: System Overview

2.1.3 System Limitations System expansion must take into consideration the following: The physical limitations of the cabinet configuration. The electrical limitations of the system power supply. The capacity of the secondary power source (standby batteries). IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 12: System Components

System Components 2.2 System Components Central Processing Unit (CPU) The central processing unit for the IFC-3030 system can be ordered with a keypad/display (P/N JCPU-3030D) or without a keypad/display (P/N JCPU-3030ND). JCPU-3030D serves as “primary display” version for ULC applications. -

Page 13: Product Diagram

(See Section 3.15 “Connecting Power Sources and Outputs”) J10, J11, J12 Panel circuit module connections (power-limited, supervised) Cable 71088 (See Figure 3.9) Note: Dotted line indicates location of optional keypad & LCD display Figure 2.1 CPU Connections IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 14: 1: Main Power Supply

25 to 200 amp-hours. Refer to the AMPS-24/E Manual for details. Refer to Appendix A, “Electrical Specifications” to determine whether your system requires an auxiliary power supply. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 15: System Cabinets

TM-4 or NCM-W. MP-1B Blank panel for covering panel circuit modules in second, third, or fourth rows of backbox. BP-4 Battery dress panel. DP-1B High-profile battery cover ADP-4B Annunciator dress panel IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 16: Compatible Equipment

CPU is listed below. These are the most common devices at time of publishing; the most complete list of compatible intelligent SLC loop devices is provided in the Johnson Controls SLC Wiring Manual; for conventional non-addressable equipment see the Device Compatibility Document. -

Page 17: System Sensor Compatible Equipment

Security Tamper Switch (Not ULC-listed) STS-1 TM-4 Transmitter Module Universal Digital Alarm Communicator UDACT Transmitter Universal Zone Coder UZC-256 System Sensor Compatible Equipment A2143-00 End of Line Resistor Assembly EOLR-1 End of Line Resistor Assembly IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 18 Notes IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 19: Section 3: Installation

Attach & wire other system components Voice Alarm System components Johnson Controls Voice Alarm System Manual Annunciators and other ACS devices ACS Manual, LCD-80 Manual, etc. Table 3.1 Installation Checklist (1 of 2) IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 20: Mounting A Cabinet

Unless you are familiar with the placement of components within this backbox, only use the knockout locations provided for conduit entry. Follow the instructions below. Mark and pre-drill holes for the top two keyhole mounting bolts. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 21: Laying Out Equipment In Cabinet And Chassis

See Figure 3.3 for possible configurations of these four layers. The BMP-1 Blank Module Plate covers unused positions and also provides a location to door-mount some option boards (see BMP-1 Product Installation Drawing for details). IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 22: Attaching The Cpu & Chassis

Slide circuit-board tabs into slots on chassis as shown in Figure 3.4. Place the board over the stand-offs so that mounting holes line up with those on the chassis. Secure all stand-offs with screws provided. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 23: Mounting Chassis In Backbox

Figure 3.4 Standoffs on Chassis CHS-M3 CAUTION: It is critical that all mounting holes of the IFC-3030 are secured with a screw or stand-off to insure continuity of Earth Ground. Note for JCPU-3030D Due to the difficulty of reaching under the keypad, it may be convenient to remove the insulator from the lithium memory-backup battery at this time. -

Page 24: Attaching Option Boards

If mounting a pair of SLC loop modules, refer to Section 3.14.2 “Loop Control Module, Loop Expander Module” and to Section 3.7.3 “Installing a Multi-layer Module into the Chassis”. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 25: Attaching Panel Circuit Modules

Type your point-programming information onto the slide-in labels provided with your panel circuit module or create custom labels with LabelEase (available from Notifier); insert these labels into the slots at the top of the module. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 26: 2: Mount Expander Boards

Bring the module back down so that the lower board edges slip into the bottom slots. Secure the module to the chassis with the two module screws. Tighten securely. Connect the ribbon cable to the module. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 27 NOTE: Depending on system components, clearance may be tight. Do not force modules! Move the assembly around gently until you find the angle where components and mounting studs pass each other without scraping together. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 28: 4: Connecting Expander Row Ribbon Cables

J12 - Panel P7.1–P7.8 P5.1–P5.8 P6.1–P6.8 P8.1–P8.8 Circuit #3 Connects third group of panel modules in backbox. P11.1–P11.8 P9.1–P9.8 P10.1–P10.8 P12.1–P12.8 Figure 3.9 Expander Row Ribbon Cable Setup IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 29: Initiating Device Circuits With Izm-8Rk/Ize-A

Wire initiating devices according to the manufacturer's instructions packaged with each device. For Canada, model N-ELR End-of-Line Resistor Assembly required. Maximum line resistance due to wiring is 100 ohms. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 30: 2: Style D Field Wiring

Wire initiating devices according to the manufacturer's instructions packaged with each device. Maximum line resistance due to wiring is 100 ohms. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 31: Nacs With Icm-4Rk⁄Ice-4

For zone coded applications, see the UZC-256 Universal Zone Coder manual. For power wiring see Figure 3.14. The ICM-4RK is California Code programmable (microprocessor P/N 34077 Rev. B or higher). To program for California Code, cut diode D35 as shown in Figure 3.13. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 32: 1: Power Supply Connections

Auxiliary power supply connections to ICM-4RK/ICE-4 must come from a power supply whose battery terminals are tied back to those on the main power supply. Failure to do so will cause panel circuit trouble at the control panel and possible equipment damage. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 33: Form-C Relays On The Cpu

SW1 and SW2 away from the factory default positions shown in Figure 3.16. SW1 set to Security SW2 set to Supervisory Move switch to opposite position to convert to Alarm relays. Figure 3.16 Form-C Relay Connections IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 34: Form-C Relays With Crm-4Rk/Cre-4

Notification Appliance Circuits (NACs), see Section 3.13 “Notification Appliance Circuit Current Limitations” on page 36, as well as the manual for your system’s power supply. Figure 3.17 Field-Wiring a CRM-4RK or CRE-4 Module IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 35: Form-C Relays With Auxiliary Relay Module (Arm-4)

K2 K3 K4 NC NO – These 3 holes for These 2 holes for support stand-offs. mounting stand-offs. NC NO NC NO Connection for Cable P/N 71092 Figure 3.17 ARM-4 Stand-off & Terminal Locations IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 36: 3: Field Wiring An Auxiliary Relay Module

JP2 located above J5 and J6. Figure 3.18 Typical Supply/Notification Circuit Configurations icejump.cdr NOTE: The term “total” in these figures assumes that no Notification Appliance power is drawn for any other purpose. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 37: Connecting Specific Option Boards

99. These and other capacity restrictions for CLIP mode loops are discussed in Section 3.19 “Wiring a Signaling Line Circuit (SLC)”. Refer to the Johnson Controls SLC Wiring Manual for wiring requirements and specific details. -

Page 38: Setting Slc Loop Number

D28 LCM-320 Ground Fault J2 LEM-320 Connection LCM-320 Connection SW1 Set to assign a unique SLC loop number LCM-320 LEM-320 Note: Do not cut any jumpers on LCM-320 or LEM-320 Figure 3.19 LCM-320 & LEM-320 Diagram IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 39 Figure 3.20 Connecting LCM-320 with LEM-320 Angle tab on LCM-320 Use a slimline screwdriver (3/32") into slot on CHS-4L to fasten down LEM-320 through the hole in the LCM-320 board. Figure 3.21 Inserting LCM-320/LEM-320 into CHS-4L IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

- Page 40 LCM (in front) LEM (in back) Figure 3.22 SLC Loop Connections on LCM-320 and LEM-320 J7 on CPU J1 on LCM-320 J3 on LCM-320 “Data in” “Data out” Figure 3.23 Connecting Multiple LCM-320/LEM-320 Pairs IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 41: Connecting Power Sources And Outputs

Auxiliary power supply connections to ICM-4RK/ICE-4 must come from a power supply whose battery terminals are tied back to those on the main power supply. Failure to do so will cause panel circuit trouble at the control panel and possible equipment damage. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 42: 2: Connecting The Power Supply

Table 3.3 AC Power Checklist 3.15.4 Auxiliary Power Supply Connections If an optional auxiliary power supply is installed in the cabinet, connect it at this time. Follow the connection procedures specified in your auxiliary power supply manual. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 43: Ul Power-Limited Wiring Requirements

Disconnecting TM-4 for Annual Testing Follow standard installation procedures as described in the TM-4 installation documentation. To disable reporting, slide SW4 Disable All Output switch from “Enable” to “Disable.” Refer to TM-4 documentation for product drawing. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 44: Installing Printers

UL fire and security requirements for an ancillary device; it is not ULC-listed. For more information on the Keltron printer, contact the manufacturer (Keltron Corp., Waltham, MA). Installation and configuration instructions follow. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 45: 1: Printer Installation Sequence

Uninterruptable Power Supply (UPS) that is UL-listed for Fire Protective Signaling. Plug the DB-25 connector end of the custom cable into the EIA-232 port of your printer. Tighten securely. Configure the printer as described in Section 3.18.2 “Configuring the Printer”. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 46: 2: Configuring The Printer

Programming Manual for instructions.) • Data bits: 8 • Parity: None • Stop bits: 1 Table 3.5 Keltron DIP Switch Settings Set the printer DIP switches SP1 and SP2 according to settings in Table 3.5. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 47: Wiring A Signaling Line Circuit (Slc)

Section 5.3 “Operational Checks”. 3.19.2 Capacity The IFC-3030 supports up to five pairs of loop control and expander modules, providing from one to ten SLC loops. Each loop has a total capacity of 318 intelligent/addressable devices: •... -

Page 48: 3: Installation

Loop Expander Module”. Note that the unique SLC loop number assigned to a module does not need to match the module’s location in the cabinet. For details on designing, installing and configuring SLC loops, see the Johnson Controls SLC Wiring Manual. B+ A+ B- A-... -

Page 49: Section 4: Applications

• Installing a Security Tamper Switch into the cabinet • Circuit Wiring NOTE: IFC-3030 is not listed for Canadian security application. Municipal Box (Auxiliary) Municipal Box applications require a TM-4 Transmitter module. Refer to the Transmitter Module TM-4 installation document for installation details. -

Page 50: Nfpa 72 Central Or Remote Station Fire Alarm System (Protected Premises Unit)

The figure below shows typical wiring diagram for a NFPA 72-1999 Central Station Fire Alarm System (Protected Premises Unit) or a Remote Station Fire Alarm System (Protected Premises Unit) using the Universal Digital Alarm Communicator/Transmitter (UDACT) and IFC-3030. Connect and program the UDACT according to the directions given in The UDACT Instruction Manual. -

Page 51: Nfpa 72 Proprietary Fire Alarm Systems

IFC-3030 will automatically transmit General Alarm, General Trouble, General Supervisory, and Security signals to a listed compatible Protected Premises Receiving Unit. A simplified drawing of connections between the receiving unit and the IFC-3030 protected premises unit is shown in Figure 4.3. -

Page 52: Fire/Security Applications

Security Module I/O Circuit Shielding — terminate the shield at earth ground at the junction box containing the module. • When employed as a Protected Premises Unit, the IFC-3030 cabinet door must be wired with an STS-1 Tamper Switch that is monitored by the control panel •... -

Page 53: 3: Installing A Security Tamper Switch

Select the address of the module(s) to be used for security. Select one of the type codes described in Section 4.5.2 “General Security Requirements”. For detailed instruction on programming Type Codes, refer to the Programming Manual. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 54: 6: Wiring For Proprietary Security Alarm Applications

A or B UL-listed, normally-closed security switch End-of-Line SW101 SW 201 Resistor SW202 SW302 SW402 UL-listed, normally-open security switch UL-listed, normally-closed security switch XP5-M Figure 4.5 Wiring Diagram for Proprietary Security Alarm Applications IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 55: 7: Connecting An Rks-S Remote Key Switch

Figure 4.6 Connecting the M301MJ Module to the RKS-S SLC Out TENS ONES ADDRESS LOOP Wire an R-47K M300MJ End-of-Line Resistor into the circuit RKS-S rear Figure 4.7 Connecting the M300MJ Module to the RKS-S IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 56: 8: Single Tenant Security System With Entry/Exit Delay

Programming Notes for Figure 4.8 Programming of Key Switch, Access Points, and Motion Detection RKS Remote Key Switch with Monitor Module Address: LXXMYYY (arbitrary) Type ID: ACCESS MONITOR Zone Map: (none) Custom Label: Arming Switch IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 57 Type ID: RELAY Zone Map: Custom Label: Security Group Output Signal Silence: No Walk Test: Yes/No (Installer Specified) Switch Inhibit: Yes B. MM Programming Address: LXXMYYY (arbitrary) Type ID: SECURITY-L Zone Map: (none) IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 58: 9: Security Annunciation

Power-limited wiring • Supervised for open circuit only • Supervised for open circuit and shorts • Supervised for power loss • Supervised for power loss For more information, refer to the IFC-3030 Programming Manual. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 59: 3: Wiring

For NFPA 13 and 15 applications, disable the Soak Timer (Soak=0000); for NFPA 16 applications, set the Soak Timer (0600-0900 seconds). Refer to the IFC-3030 Programming Manual for instructions on setting the Soak Timer. For applications using power-limited circuits: a) Use an End-of-Line device (P/N REL-47K) with the M300CJ module. -

Page 60: 1: Connecting An Nbg-12Lra Agent Release-Abort Station

NOTE: See Circuit Requirements for Section 4.7 “Connecting a Releasing Device to a M300CJ Module” on page 59. NOTE: Devices for use in releasing applications must be programmed as type code RELEASE CIRCUIT or REL CKT ULC. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 61: Section 5: Testing The System

For instructions on how to measure the total DC resistance of a populated SLC pair, refer to the “Measuring Loop Resistance” section of the Johnson Controls SLC Wiring Manual (P/N 51870)The minimum DC resistance between conductors of an unpopulated SLC pair cannot be less than 1 K ohms. -

Page 62: Battery Checks And Maintenance

Take care to avoid accidental shorting of the leads from uninsulated work benches, tools, bracelets, rings, and coins. CAUTION: Shorting the battery leads can damage the battery, equipment, and could cause injury to personnel. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... -

Page 63: Appendix A: Electrical Specifications

Use Table A.1 on page 64 to determine the specific wiring requirements for each circuit. Compliance with the Federal Communications Commission (FCC) and Canadian Department of Communication regulations on electrical energy radiation requires the following: Use twisted-pair IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 64 CHG-120 External battery 12 AWG in conduit 20 ft (6.1 m) 12 AWG charger maximum (3.25mm Table A.1 Wire Requirements Notifier brand cable is recommended; see the product catalog available from Paige Electric. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 65: Appendix B: Canadian Applications

– Green must be used to indicate the presence of power or an activated output. B.5 Releasing Devices Supervision for shorts is required; use REL-47K and type code R ULC. Refer to Section 4.6 “Releasing Applications”. IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 66 Notes IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

- Page 67 Notes IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

- Page 68 Notes IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

-

Page 69: Index

26 CPU 22 compatible equipment 16 expander module 26 control panel circuit board, see CPU installation steps 25 ribbon cables 28 Keltron printer, see printers 46 CPU 13 see also ICM-4RK, ICE-4, IFC-3030 Installation Manual — P/N 52024:C 08/05/2005... - Page 70 61 XP5-M 54 sharing NAC current 36 Signalling Line Circuit, see SLC see also SLC Wiring Manual 47 see also SLC Wiring Manual 47 specifications 63 SLC loop number for LCM-320/ LEM-320 38 IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

- Page 71 IFC-3030 Installation Manual — P/N 52024:C 08/05/2005...

- Page 72 Controls Group www.johnsoncontrols.com 507 E. Michigan Street P.O. Box 423 Release C Milwaukee, WI 53201 Printed in U.S.A.

Need help?

Do you have a question about the IFC-3030 and is the answer not in the manual?

Questions and answers