Table of Contents

Advertisement

ILUUIII,

I lllllm

I,IllLILll, I II

IL

Save This Manual For

Future Reference

A/RS

owners

manual

MODEL NO.

113.239392

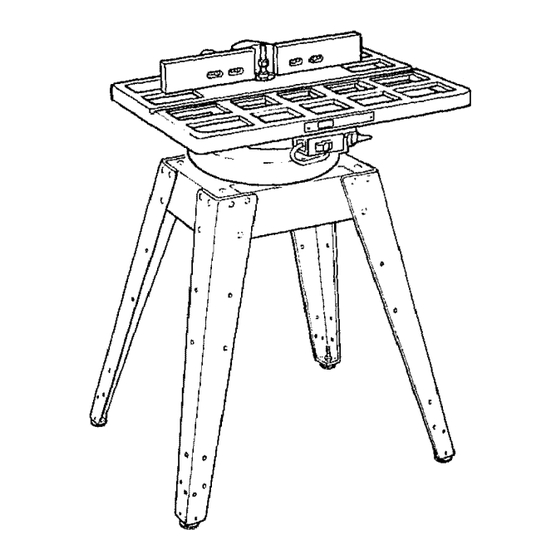

SHAPER WITH STEEL

LEGS AND I/2H.P.

MOTOR

113.239400

SHAPER

WITH STEEL

LEGS AND 3/4 H.P. MOTOR

113.239420

SHAPER

WITH

STEEL

LEGS

AND

1 H,P.

MOTOR

Serial

Number

Model and serial numbermaybe

found

on the tront of the table.

You should record both model and

serial numberin a safe place for future

use,

FOR YOUR

SAFETY:

Read ALL

INSTRUCTIONS

carefully.

Part No. SP5427

/I:RRFTSMRN

WOOD SHA

• assembly

• operating

, repair parts

Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

Printed in U.S,A.

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.239420

- Page 1 ILUUIII, I lllllm I,IllLILll, I II Save This Manual For Future Reference A/RS owners manual MODEL NO. 113.239392 SHAPER WITH STEEL LEGS AND I/2H.P. MOTOR 113.239400 SHAPER WITH STEEL LEGS AND 3/4 H.P. MOTOR 113.239420 SHAPER WITH STEEL LEGS 1 H,P. MOTOR Serial /I:RRFTSMRN...

- Page 2 WOOD SHAPER If within one year from the date of purchase, this Craftsman Wood Shaper Saw fails due to a defect in material or workmanship, Sears will repair it, free of charge. WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

- Page 3 Additional Safety Instructions for Wood Shaper 14.Rubbish, shavings, stock, or other objects or material Safety Signal Words should not be allowed on the floor where they may be iDANGER: means if the safety information is not followed a tripping hazard. someone will be seriously injured or killed.

- Page 4 31.Note and follow Safety tnslructions that appear on the WARNING: The 4-3/8"flat motor pulley and th-_ 2"spindle pulley furnished, will the cutterl Shaper Switch asse.mbly. ' ..approximately 9000 R.P.M. when used with a 34_0 t DANGER motor. Never substitute these pulleys to increase l -'OR YOUR OWK SAFETY: READ ,t_tD LIN0 EFI _TM'I00_=_lE...

- Page 5 UNPACKING AND CHECKING CONTENTS Mod el 113.239392and t 13.239400 Wood Shapers are shipped complete in one carton and include steel legs and motor. CONTENTS Separate all parts from packing materials and check each one WARRANTY ........with the illustration and the list of Loose Parts to make certain General Safety Instruction for Power Tools ..

- Page 6 LIST OF LOOSE PARTS Item Part Name Qty. Leg ..............' Screw, Truss Hd. 1t4-20 x 5t8 ..... 28 * Nut, Hex 1./4-20 ..........* Lockwasher, 1/4 External ......28 Channel, Support .......... Stiffener ............Stiffener, Side ..........Stitloner, End ..........* Screw, Pan Hd.

- Page 7 JAM NUT (3/8-24) SPINDLE LOCK TABLE SUPPORT INSTALLING ELEVATING KNOB AND TABLE SUPPORT SCRE_M (DOG POINT) Position table upside down on 2 x 4's on edge for support and clearance for Spindle assembly. Install (3/8-24) on short threaded elevating rod and screw the rod into the threads in the...

- Page 8 4. Place Belt Guard under Motor [between Motor Support Bracket and Motor Mount) and make certain 5/8" shaft is centered in Belt Guard hole. Install nuts finger tight. 5!16 IN. HEX NUTS INSTALLING MOTOR PULLEY install motor pulley (flat-faced pulley) on motor shaft, 5_21N,...

- Page 9 MOUNTING MOTOR SUPPORT ASSEMBLY MOTOR TO SHAPER MOTOR MOUNT PLATE Place V-belt on motor pulley and attach motor mount BASE SPINDLE plate to shaper base with bolts 13/8-18 x t-inch} PU LL EY EL EVATI NG and washers, Leave bolts finger tight.

- Page 10 item Part Name Qty. Leg ..............* Screw, Truss Hd. 1/4-20 x 5/8 ..... 28 * Nut, Hex 1/4-20 ..........* Lockwasher, 1/4 External ......28 Channel, Support .......... Stiffener ............Stiffenol, Side ..........Stilfener, End .........."ii ,'21 * Screw, Pan Hd. Ty A N8 x lj2 ...... 4 * Nut, Hex Hd, 3/8-16 ........

- Page 11 5/16-18 X 2 IN. HEX HD, SCREWS WASHERS FENCE INSTALLING SHAPER FENCE - FOR STRAIGHT EDGE SHAPING ONLY Install the fence with two 5/16-18 x 2 inch hex head screws and two plain washers. These screws thread into tapped holes in the table. Adjust the fence as outlined on page 13, _UA_D I/4-2B LOCKNUT...

- Page 12 GETTING TO KNOW YOUR WOOD SHAPER CUTTER GUARD FENCE LOCK KNOB FENCE FACE INSERT TABLE SLOT MITER GAUGE TABLE FE NCE ADJUSTING KNOB 8 FENCE LOCK KNOB FENCE FACE ELEVATING CONI_OL LEVER SPINDLE LOCK KNOB ON-OFF SWITCH MOTOR (NOT FURNISHED) MOTOR MOUNT PLATE MOTOR...

- Page 13 Provides added protection for irregular shaping, Guard TO lock switch in OFF position.,, hold switch is adjustable for various thickness of material, with one hand.,. REMOVE key with other hand. ALWAYS LOCK SWITCH "OFF" WHEN CAUTION: A_ways rotate the spindle by hand before SHAPER IS NOT IN USE,,.

- Page 14 ADJUSTMENTS FENCE FACE WARNING: For your own safety, turn switch "off" and removeplugfrom power source outletbeforemaking any adjustments. ADJUSTABLE SHAPER FENCE Move both fence faces out 3/4" by turning the two fence adjusting knobs, FENCE FACE FENCE ADJUSTING KNOBS STRAIGHT EDGE FENCE FACE...

- Page 15 BASIC SHAPING OPERATIONS NOTE: This shaper is designed for use with maximum 1/2 inch diameter cutters having a 1/2 inch diameter bore. 1. For those operators prefer to use a motor that rotates clockwise (facing pulley end} which would drive the spindle in a clockwise direction...

- Page 16 AUXILIARY FENCEPWORK SUPPORT WORKPIECE STRAIGHT EDGE SHAPING CAUTION: The Shaper fence must be used in all straight 27 IN. edgeshapingoperations. 1. When shaping stock 3 inches wide or less, an auxiliary fence/work support must be used as shown, 2, Make the push stick asshown. SLIGHTLY THICKER THAN...

- Page 17 SPeNDS'AUnT IRREGULAR OR CURVED SHAPING "_ DIRECTION A variety of shapes may be produced w_th the shaper by DIRECT ,KEYED WASHER FEED changing height cutter relation ROTATION SPACER workpiece, by using various combinations of cutters successive passes, and/or by inverting cutter and changing direction...

- Page 18 The starting pin must be used as a pivot to support the Workpiece MUST contact the FRONT of the cutter and work until it has been fed into the shaper collar. collar - toward the miter gauge slot. Starting Pin may be located in either of the two threaded In addition,11he following operations are some which can holes near the table insert opening, depending upon the...

- Page 19 MAINTENANCE WARNING: For your own safety, turn switch "OFF" and remove plug from power source outlet beforemaintaining or lubricating your saw. NOTE: Alter a few hoursof operation,tighten both pulleyset screws securely withthe Hex wrenchesprovided. Frequently clean your culting toots with Craflsman Gum and Pitch Remover.

- Page 20 TROUBLE SHOOTING WARNING: For your own safety, turn switch "off" and remove plug from power source outlet before trouble shooting your shaper. REMEDY TROUBLE PROBABLE CAUSE Set screwengaging slot Spindle Tighten screw then back it off 1/4 turn, Adjust until in spindle assembly Assembly actuates action is smooth without end play.

- Page 21 TROUBLE SHOOTING -- MOTOR NOTE: Motors used on wood-working tools are particularly susceptib{e 1othe accumulation of sawdust and wood chtps and should be blown out or "vacuumed" frequently to prevent interference with normal motor ventilation. TROUBLE PROBABLE CAUSE REMEDY 1. Motor. Excessive noise.

- Page 22 REPAIR PARTS PARTS LiST CRAFTSMAN WOOD SHAPER MODEL 113.239392, 113.239400 113.239420...

- Page 23 PARTS LIST CRAFTSMAN WOOD SHAPER MODEL 113.239392, 113.239400 113.239420 Always Order by Part No. - Not by Key Number FIGURE 1 Part Part Description Description ,, ,,, 72008 72003 Fence Assembly (See Figure 2) Guard, Pulley 60167 Washer, .343 x 1.062 x 1/8...

- Page 24 PARTS LIST FOR CRAFTSMAN WOOD SHAPER MODEL 113.2393921 113.239400 113.239420 FIGURE 2 - FENCE ASSEMBLY 72008 Part Description 72008 Fence Assembly Complete STD 511005 *Screw, Pan Hd., 10-24 x 1/2 38711 Bracket, Retaining 38612 Knob, Adjusting 18451 Washer, Spring 38413...

- Page 25 PARTS LIST CRAFTSMAN WOOD SHAPER MODEL 113.239392, 113.239400 113.239420 FIGURE 3 - LEGS Part DescrlptTon 820040 60314 * Screw, Truss Hd. 1/4-20 x 5/8 STD541025 Nut, Hex 1/4-20 STD551225 Lockwasher, 1/4 External 66060 Channel, Support 72030 Stiffener 68059 Stiffener, Side...

- Page 26 PARTS LIST FOR CRAFTSMAN WOOD SHAPER MODEL NO. 113.239392, 113.239400 113.239420 FIGURE 4 - ON/OFF POWER OUTLET 60382 AND MOUNTING BRACKET Description • On/Off Power Outlet 60382 508984 Cord, Molded Housing, Switch 822206 60256 Key, Switch 60374 Switch, Locking Cover, Switch 822205 Screw, Pan Hd.

- Page 27 PARTS LIST CRAFTSMAN WOOD SHAPER MODEL 113.239392, 113.239400 113.239420 FIGURE 6 - MOTOR PARTS LIST ANY ATTEMPT TO REPAIR THIS MOTOR MAY CREATE A HAZARD UNLESS REPAIR IS DONE BY QUALIFIED SERVICE TECHNICIAN, REPAIR SERVICE IS AVAILABLE AT YOUR NEAREST...

- Page 28 ... SEAIRS owners WOOD SHAPER manual SERVICE Now that you have purchased your wood shaper, should a need ever exist for repair parts or service, simply contact any Sears Service Center and most Sears, Roebuck and Co. stores. Be sure to provide all pertinent facts when you call or visit.

Need help?

Do you have a question about the 113.239420 and is the answer not in the manual?

Questions and answers