Table of Contents

Advertisement

Quick Links

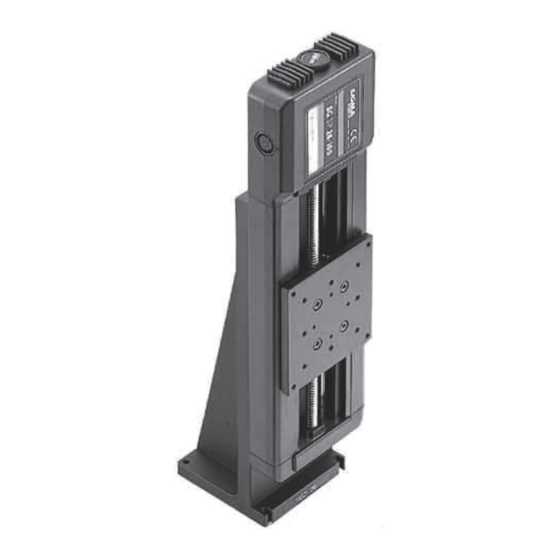

Motorized Stages and Actuator

SGSP/SGMV/TSDM/KST

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

Ⅰ. Installation

1-1. Mounting・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1-2. Connecting to Stage Controller・・・・・・・・・・・・

1-3. Connection Cables・ ・・・・・・・・・・・・・・・・・・・・・・

1-4.

2-1. Operating Conditions・・・・・・・・・・・・・・・・・・・・

2-2. Direct Action/ZF-Axis Stages・・・・・・・・・・・・・

2-3. Rotation/Gonio Stages・・・・・・・・・・・・・・・・・・

Miniature Actuator・ ・・・・・・・・

Installation Manual

CONTENTS

3

5

8

9

・ ・ ・・・・・・・

10

11

11

11

12

3-1. About Check and Maintenance ・・・・・・・

3-2. Lubrication・・・・・・・・・・・・・・・・・・・・・・・・・

3-3. About Life・・・・・・・・・・・・・・・・・・・・・・・・・・

3-4. Store・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4-1. Instruments・ ・・・・・・・・・・・・・・・・・・・・・・・

4-2. Items to Check・ ・ ・・・・・・・・・・・・・・・・・・・・

4-3.

4-4. Typical Measurement・・・・・・・・・・・・・・・・

Series

13

14

15

15

16

16

・・・・・

16

16

Advertisement

Table of Contents

Summary of Contents for OptoSigma SGSP Series

-

Page 1: Table Of Contents

Motorized Stages and Actuator SGSP/SGMV/TSDM/KST Series Installation Manual CONTENTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ For Your Safety Ⅰ. Installation Ⅲ. Check and Maintenance 1-1. Mounting・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3-1. About Check and Maintenance ・・・・・・・ 1-2. Connecting to Stage Controller・・・・・・・・・・・・ 3-2. Lubrication・・・・・・・・・・・・・・・・・・・・・・・・・ 1-3. Connection Cables・ ・・・・・・・・・・・・・・・・・・・・・・ 3-3. About Life・・・・・・・・・・・・・・・・・・・・・・・・・・ ・... - Page 2 Notes regarding these materials ・ These materials are intended as a reference to assist our customers in the use of the SIGMAKOKI CO., LTD. Product best suited to the customer’s application; they do not convey any license under any intellectual property rights, or any other rights, belonging to SIGMAKOKI CO., LTD.

-

Page 3: For Your Safety

For Your Safety ◦ Before using this product, read this manual and all warnings or cautions in the documentation provided. ◦ Only Factory Authorized Personnel should be changes and/or adjust the parts of controller. The Symbols Used in This Manual WARNING CAUTION This symbol marks warnings that should be read and used to... -

Page 4: Disclaimer Of Liability

Disclaimer of Liability ① SIGMAKOKI CO., LTD. does not accept liability for damages resulting from the use of this product or the inability to use this product. ② SIGMAKOKI CO., LTD. does not accept liability for damages resulting from the use of this product that deviates from that described in the manual. -

Page 5: Mounting

Installation �.Installation 1-1.Mounting 【Before Installation】 (1) Please see our latest catalog for outer dimensions or sizes of fixing holes. (2) Check that your package includes the stage and accessories. (3) Try an experimental connection of the stage and the stage controller to see if the stage can be driven by the controller correctly. - Page 6 Notes on Attaching on Slide Table Check the length of fixing screws in fixing a product onto the upper table. If the length of a screw exceeds the specified table depth, it will adversely affect the internal parts, resulting in poor accuracy or in the extreme case, leading to giving damage to the body of the stage.

- Page 7 Installation stages Motorized rotary Stages High-rigidity, high-precision motorized Please tighten with 3 cap screws. Tighten Tighten Base of stage Base of stage High-precision motorized gonio stages High-precision ZF axis motorized stages Please tighten with 3 cap screws. Tighten Tighten Base of stage Base of stage TSDM stages Motorized miniature actuator...

-

Page 8: Connecting To Stage Controller

High-precision motorized stage Tighten Base of stage Example of Fixing Product onto Slide Table Fixing cap Model Tight depth (mm) [mm] Size SGSP15 3≦a≦5、(2≦a≦3) M3、(M2) Product SGSP・SGMV20/26 4≦a≦6 M3、M4 Slide Table SGSP33 4≦a≦8 SGSP46/65 6≦a≦12、(4≦a≦8) M6、(M4) 2<a≦4 M2、M3 SGSP40-*ZF SGSP60-*ZF 4≦a≦6、(3≦a≦4) M4、(M3) SGSP80-*ZF... -

Page 9: Connection Cables

Installation (2) Connection with Controllers or Drivers from Other Vendors Use the connectors that can correctly match with ones used for the motorized stage. Make connections as described in the wiring diagrams (see the descriptions in the catalog for checking your stage). The motorized stage has the internal limit sensors to detect the ends of the strokes. -

Page 10: Resonance And Hunting Of The Stages

1-4.Resonance and Hunting of the Stages A motorized stage will suddenly generate large vibration (noises) at a certain speed (frequency) range, which can result in missing steps or halting of stage movement in the extreme case. The cause of this problem is the resonance which is generated by the coincidence of a driving speed and a characteristic frequency of the mechanical structure, happened when vibration the pulse-driven motor rotation can produce affects the body of the motorized stage. -

Page 11: Ⅱ. Notes On Use 2-1. Operating Conditions

Notes on Use �.Notes on Use 2-1.Operating Conditions The stage shall be used under the following conditions: ◦ Temperature: 5-40 °C 5-40 [ Humidity: 30-80% (without condensation) 30-80[%] (without condensation) 2-2.Direct Action/ ZF-Axis Stages An SGSP or TSDM or KST series stage has a knurled knob at the motor shaft, which •... -

Page 12: Stepping Motor-Driven Miniature Actuator

2-4.Stepping Motor-driven Miniature Actuator The ACT series stage has a knurled knob at the motor shaft, which allows you to rotate • the spindle head manually. Do not fix actuators so tightly that the body of the stage becomes distorted. ●... -

Page 13: Ⅲ. Check And Maintenance

Check and Maintenance ��Check and Maintenance 3-1.About Check and Maintenance Constant checks and maintenance are essential to operate the stage without failure. Please see the Check and Maintenance List and perform daily checks and maintenance. (1) General Checks Check Before Operation Before you operate (move) the motorized stage, or if the stage has been left unused for a considerable period of time, make sure that there are no abnormality or foreign substances in the moving parts as well as they are adequately greased to... -

Page 14: Lubrication

Note 1) Checking frequencies are listed as guides. Actually, they may vary depending on how often you use stages. 3-2.Lubrication See our latest catalog for details How you lubricate will affect the life and smooth movement of the motorized stage. Check for the lubrication in daily maintenance. -

Page 15: About Life

Check and Maintenance 3-3.About Life The life of the high-rigidity, high-precision stages depend on such parts as the precision guide blocks, bearings, ball screws, couplings, motors, etc. Though the life of a ball screw always sliding to drive the stage is generally said to be 10 to 15 thousand hours (depends on cases and purposes), its smooth movement is greatly affected by lubrication. -

Page 16: Ⅳ. Accuracy Verification

�.Accuracy Verification Principally the accuracy of our motorized stages shall randomly inspected based on JIS B 6191 and 6192 ( both concerning general rules of test method for machine tool) and international standards (ISO230-1, 230-2, etc.) with instruments calibrated by a standard gauge traceable to the national standards. 4-1.Instruments Dynamic Calibrator (HP5529A) (Agilent Technologies) ... - Page 17 Accuracy Verification ・Repeatable Positioning Accuracy Perform positioning to a point in the same direction seven time in each area of the stage (both ends and center of the stage). Find the maximum deviation in each target (positioning) point. Determine the repeatable positioning accuracy as the maximum deviation from among the three testing areas.

- Page 18 ・Straightness Vertical/horizontal deviation from the axis in a traveling direction. Perform positioning sequentially in a (single) direction from the reference point (home) throughout the movable range with constant intervals. Measure the deviation from the axis in the traveling direction in each positioning target, and determine the straightness as the maximum deviation from among the measured.

- Page 19 Accuracy Verification (2) Rotating Gonio Stage ・ Repeatable Positioning Accuracy Perform point Perform positioning at twelve points with intervals from the reference point sequentially. Note that positioning for a position is repeated five times in reciprocating motions. Calculate the difference between the measured value (acual position traveled from the reference point) and the target (commanded traveled position from the reference point) for each point.

- Page 20 2021.8 10th edition...

Need help?

Do you have a question about the SGSP Series and is the answer not in the manual?

Questions and answers