Table of Contents

Advertisement

M0087369-08 (en-us)

April 2021

Operation and

Maintenance

Manual

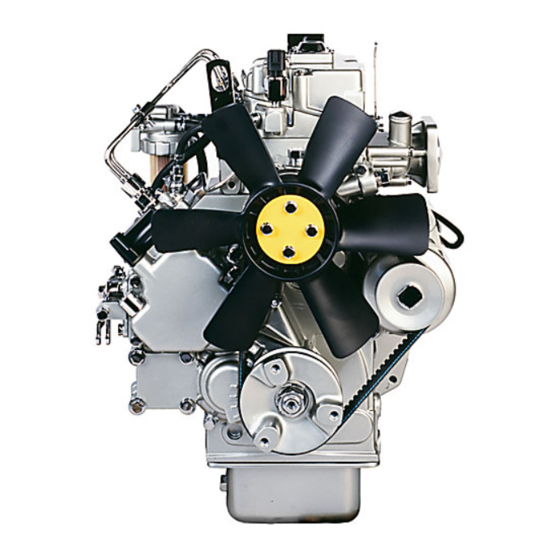

402J-05, 403J-07, 403J-11, 403J-11T,

403J-15, 403J-17, 403J-17T and 404J-

22 Industrial Engines

IH (Engine)

IF (Engine)

IG (Engine)

IZ (Engine)

IS (Engine)

IK (Engine)

IJ (Engine)

IN (Engine)

Copyright of Perkins Engine Company Limited. NOT FOR REPRINTING OR RESALE

Advertisement

Table of Contents

Need help?

Do you have a question about the 402J-05 and is the answer not in the manual?

Questions and answers