Perkins 400 Series Operation And Maintenance Manual

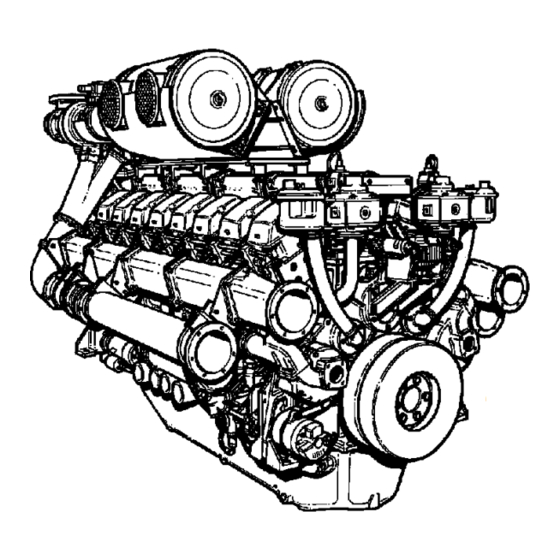

Industrial engine

Hide thumbs

Also See for 400 Series:

- User handbook manual (76 pages) ,

- Operation and maintenance manual (80 pages) ,

- Operation and maintenance manual (100 pages)

Need help?

Do you have a question about the 400 Series and is the answer not in the manual?

Questions and answers