Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Maico ER 60 E

- Page 1 ИНСТРУКЦИЯ Maico ER 100 EH...

- Page 2 Recess-mounted exhaust air system according to DIN 18017-3 ER-UP/GH ER 60 E ER 100 E w w w . m a i c o - v e n t i l a t o r e n . c o m...

-

Page 4: Table Of Contents

11. Mounting preparations ........13 Fan insert 11.1 Installation specifications for Electronic circuit boards ER-UP/GH with ER 60 E or ER 100 E Housing floor seal single room/second room ......13 Sensor (H model) 11.2 Preparations for wall installation ..14 Cover 11.3 Ceiling installation preparations .. -

Page 5: Fan Insert

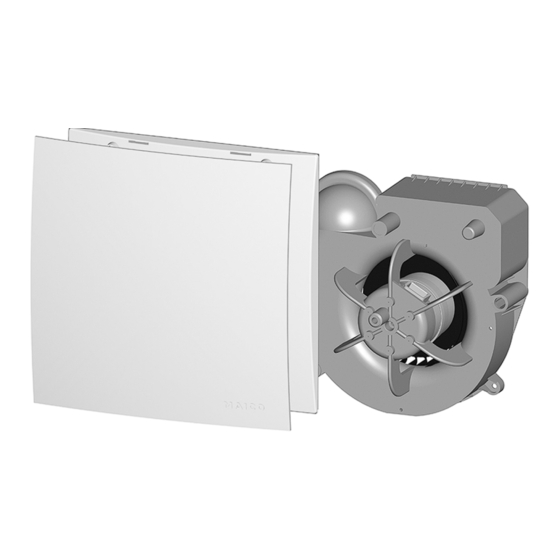

● Replacement air filter for fan insert ER 60/ER 100 and filter change indicator (time strip) Fan inserts (final assembly) Fan insert ER 60 E / ER 100 E Filter mats ZRF Article no. internet or catalogue. Article no. 0093.0923 ●... -

Page 7: General Notes

1. General notes 1. General notes 4. Non-intended use Please read these instructions These fans must not be used in the following carefully. Follow the instructions. situations under any circumstances. Read Pass these instructions onto the all the safety instructions. owner. -

Page 8: Safety Instructions

4. Non-intended use 5. Safety instructions NOTICE: Damage to the unit ● During the build phase, damage to unit WARNING caused by soiling of the fan and air channels. Risks for children and people Fan operation is not permitted during the build phase. - Page 9 5. Safety instructions WARNING DANGER Risk of injury when working at heights. Risks from parts which may affect the Use appropriate, certified climbing aids ventilation system which are added or modified at a later date. Parts (range (ladders). Stability should be ensured, if necessary have the ladders steadied by hood, air-ventilated fireplace etc.) which a 2nd person.

- Page 10 5. Safety instructions DANGER DANGER of fire spreading Danger of electric shock. Before In the event of a fire, there is a risk removing the housing cover and before of the fire spreading installing the electrics, switch off all supply ●...

-

Page 11: Operating The Fan

(using a switch), depending on unit are specified for ER recess-mounted versions variant and connection variant. with ER 60 E or ER 100 E fan inserts. Barrier-free units work as per the automatic Other ER-UP housing types are not permitted function. -

Page 13: Permitted Exhaust Air Systems

7.3.2 ER 60 E or ER 100 E fan insert ● Fan insert with cover and exhaust air filter 7.3 Possible combinations for installation in ER-UP/GH housing. The ER recess-mounted exhaust air systems ●... - Page 14 Can be Power type time controlled cable [min] by speed [mm²] ER 60 E Standard board 3 x 1.5 ER 100 E Standard board 3 x 1.5 ER 60 EVZ, ER 100 EVZ VZ board 5 x 1.5 ER 60 EG, ER 100 EG G board 5 x 1.5...

-

Page 15: Environmental Conditions And Operating Limits

Ambient temperature - 10 °C ensured during operation with air-ventilated to + 60 °C. fireplaces. The maximum permitted pressure Maico accepts no liability for corrosion difference per living unit is 4 Pa. damage caused by improper storage, e.g. storage in damp surroundings. -

Page 16: Mounting Preparations

11. Mounting preparations Suitable mounting material is to be supplied by the customer. 11.1 Installation specifications for ER-UP/GH with ER 60 E or ER 100 E single room/second room Number of units per floor, living unit Max. 3 fans or 3 connections... -

Page 17: Preparations For Wall Installation

11. Mounting preparations Preparing the shaft 11.2 Preparations for wall installation 1. Produce opening in shaft or alternatively 15 Suction duct for second room connection produce a wall facing. Ensure a suitable, on ER-UP/GH: flexible aluminium duct flat surface for the ER-UP housing so that AFR 75/AFR 80 the fan insert can be safely inserted in the 18 Main duct: Steel folded spiral-seams duct... -

Page 19: Ceiling Installation Preparations

11. Mounting preparations Cut connection duct to a length 11.3 Ceiling installation preparations which allows it to be fitted on the Suction duct for second room connection exhaust socket and also sealed for on ER-UP/GH: flexible aluminium duct ventilation at the unit end. AFR 75/AFR 80 7. - Page 20 11. Mounting preparations Main duct (steel folded spiral-seams Duct attachment with duct clamp, alterna- duct) tively duct attachment with clamping band Connection duct ER-UP/GH: Flexible aluminium duct Floor ceiling Steel threaded rod / stair bolt Duct attachment Fig. 5 Duct clamp / clamping band Ceiling compound Shaft wall...

-

Page 21: Preparations For The Electrical Connection

11. Mounting preparations 6. Fit duct attachments to ceiling ( Fig. 5). 1. Switch off mains fuse, secure against Only use permitted attachment material. being accidentally switched back on and position a visible warning sign. DANGER 2. Lay power cable to the installation location. -

Page 22: Housing Installation

11. Mounting preparations The ER-UP/GH housing must be inserted 2. Check shutter seal (visual check). This without any warping. Failure to do so will must fit tightly. mean that the fan insert cannot engage 3. Insert shutter [2] into exhaust socket as correctly in the ER-UP/GH housing and the shown in Fig. - Page 23 12. Installation ‒ ER-UP/GH - single room 2. Cut the mounting support [37] to the Exhaust socket with plastic shutter required length, bend it into shape and 18 Main duct, steel folded spiral-seams duct fix it to the ER-UP/GH housing with the 19 Connection duct, flexible aluminium duct supplied fixing screws.

- Page 25 12. Installation ‒ ER-UP/GH - single room DANGER DANGER Fire may spread if connection duct [19] Risk of short-circuits and damage to is incorrectly installed. unit. If the cable grommet [39] is not installed correctly, water may penetrate Only use permitted cable sheathing the ER-UP/GH housing.

- Page 26 12. Installation ‒ ER-UP/GH ‒ second room Housing floor seal 2. Place installation socket [11] in ER-UP/GH housing. The edge of the socket must click Installation socket for second room into place on the wall of the housing. extraction Ø 75 / Ø 80 Adapter 3.

- Page 27 12. Installation ‒ ER-UP/GH ‒ second room Installation socket for second room 12.1.7 Ceiling installation ER-UP/GH ‒ extraction Ø 75 / Ø 80 second room Adapter Observe mounting information in chapter Filter mat, filter class G2 12.1.2. Protective grille 1. Mount ER-UP/GH housing on ceiling as Suction duct, second room connection: described in chapter 12.1.5.

-

Page 28: Electrical Connection

13. Electrical connection 13. Electrical connection DANGER Danger to life from electric shock/The 20 Power cable unit will be damaged if installed 39 Cable grommet incorrectly with too long a power cable. 41 Terminal box If the cable feed is too long inside the housing, the fan insert cannot be in- To prevent the fan and/or electric stalled correctly. - Page 29 13. Electrical connection 13.1.1 Connect the unit electrically NOTICE 1. Switch off mains fuse, secure and fit Unit damage caused by EVZ and EH warning sign. units touching ESD sensitive components on the electronic circuit 2. Remove plaster protective cover. board.

-

Page 31: Installation Of Fan Insert And Cover

14. Installation of fan insert and cover If there are no further increases, the unit 14. Installation of fan insert and continues to run at nominal load level 1 until cover the humidity again falls below the saved reference value. 14.1 Settings on electronic circuit If the humidity falls below the saved reference boards... - Page 32 14. Installation of fan insert and cover Fan insert Note wiring diagrams in box base. Electronic circuit board (control) Cables must not prevent the fan from Housing floor seal being slid in. 38 Plaster protective cover Lever [43] and stud 41 Terminal box [44] 42 Optional fixing with screws...

-

Page 33: Installing The Cover

4. Switch off unit. vide compensation if housing is inserted at too much of an angle). If installing on a wall, ensure that the Maico name is in the bottom right. ● If the housing edge is flush with the plas- ter, use central screw [7.1], M6 x 16 mm,... -

Page 34: Cleaning, Maintenance

10 Filter mat, filter class G2 1. Only use a dry cloth to clean the cover [7] In case of questions, please contact: of the fan. Maico Elektroapparate-Fabrik GmbH 2. If the cover is very dirty, remove it and Steinbeisstraße 20 clean with water. -

Page 35: Filter Change, Second Room

Degree of protection according to Filter-Shop: rating plate only guaranteed if www.ventilatorshop24.com installed as stipulated (fan insert engaged, internal cover closed). In case of questions, please contact: Maico Elektroapparate-Fabrik GmbH Steinbeisstraße 20 78056 Villingen-Schwenningen Germany Tel. +49 7720 694 445 +49 7720 694 175 Internet: www.ventilatorshop24.com... -

Page 37: Extraction Socket Er-As For Wc Odour Extraction

17. Extraction socket ER-AS for WC odour extraction ER-UP/GH housing units can be connected 17. Extraction socket ER-AS for to the WC flushing pipe using the ER-AS WC odour extraction extraction socket. A Ø 70 duct cross section facilitates low air speeds in the connecting duct and an effective, draft-free extraction of odours. -

Page 38: Fault Rectification

18. Fault rectification 18. Fault rectification Fault Cause, measure Fan is too loud. ● Dirty filter. ● Call on the services of a trained electrician Replace filter. any time there is a fault. ● Fan insert incorrectly ● Repairs should only be carried out by a installed. -

Page 39: Spare Parts

G2 according to you are. EN 779 Dispose of the air filter in an Maico Elektroapparate-Fabrik GmbH environmentally-friendly way, in compliance Steinbeisstraße 20 with the regulations valid in the country where 78056 Villingen-Schwenningen you are. -

Page 40: Wiring Diagrams

Tolerances for the times stated below = nominal value + 20 %. ER 60 E, ER 100 E ER 60 E and ER 100 E The fan starts up after switching on the room lighting (with switch S1). The fan also switches off after the room lighting has been turned off. - Page 41 22. Wiring diagrams ER 60 EH, ER 100 EH ER 60 EH, ER 100 EH Standard switching: For function of the humidity control chapter 14.1. The humidity variant must not be deactivated using a switch on terminal 1 and/or terminal N. Standard switching: Permanent base load operation The fan is running in base load operation,...

- Page 43 22. Wiring diagrams ER 60 EH, Switching option 2: Manual base load operation ER 100 EH The fan is switched manually to base load Switching option 2 operation with switch "S1". Humidity control is active, see Standard Switching. If, after being manually switched with switch "S1", the fan is in: ●...

- Page 44 Maico Elektroapparate-Fabrik GmbH • Steinbeisstr. 20 • 78056 Villingen-Schwenningen • Germany • Service +49 7720 6940 • technik@maico.de...

- Page 45 СМОТРИТЕ ТАКЖЕ Канальные Реверсивные Комплектующие Вытяжные вентиляторы вентиляторы вентиляторы вентиляции Установка Проектирование систем Кухонные вытяжных Воздуховоды вентиляции вытяжки вентиляторов Воздухораспределительные устройства...

Need help?

Do you have a question about the ER 60 E and is the answer not in the manual?

Questions and answers