Summary of Contents for YASKAWA SLIO CP 042-1IO00

- Page 1 System SLIO CP | 042-1IO00 | Manual HB300 | CP | 042-1IO00 | en | 22-42 IO-Link Master - CP 042 IO-Link...

- Page 2 YASKAWA Europe GmbH Hauptstraße 185 65760 Eschborn Germany Tel.: +49 6196 569-300 Fax: +49 6196 569-398 Email: info@yaskawa.eu.com Internet: www.yaskawa.eu.com 042-1IO00_000_CP042 IO-Link,1,EN - © 2022...

-

Page 3: Table Of Contents

System SLIO Table of contents Table of contents General........................4 1.1 Copyright © YASKAWA Europe GmbH............4 1.2 About this manual..................... 5 1.3 Safety information..................... 6 Basics and mounting..................... 7 2.1 Safety notes for the user.................. 7 2.2 System conception................... 8 2.2.1 Overview...................... -

Page 4: General

This material is protected by copyright laws. It may not be reproduced, distributed, or altered in any fashion by any entity (either internal or external to Yaskawa) except in accordance with applicable agreements, contracts or licensing, without the express written consent of Yaskawa and the business management owner of the material. -

Page 5: About This Manual

About this manual Technical support Contact your local representative of YASKAWA Europe GmbH if you encounter problems or have questions regarding the product. If such a location is not available, you can reach the Yaskawa customer service via the following contact: YASKAWA Europe GmbH, European Headquarters, Hauptstraße 185, 65760 Eschborn, Germany... -

Page 6: Safety Information

System SLIO General Safety information 1.3 Safety information Applications conforming The system is constructed and produced for: with specifications communication and process control general control and automation tasks industrial applications operation within the environmental conditions specified in the technical data installation into a cubicle DANGER! This device is not certified for applications in... -

Page 7: Basics And Mounting

System SLIO Basics and mounting Safety notes for the user Basics and mounting 2.1 Safety notes for the user DANGER! Protection against dangerous voltages – When using System SLIO modules, the user must be protected from touching hazardous voltage. – You must therefore create an insulation concept for your system that includes safe separation of the potential areas of ELV and hazardous voltage. -

Page 8: System Conception

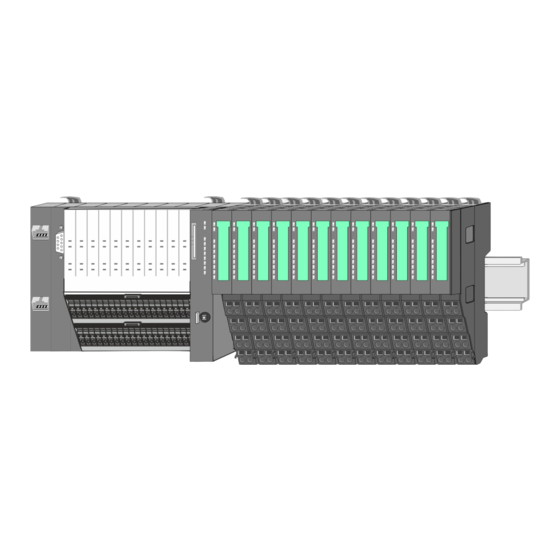

System SLIO Basics and mounting System conception > Overview 2.2 System conception 2.2.1 Overview The System SLIO is a modular automation system for assembly on a 35mm mounting rail. By means of the periphery modules with 2, 4, 8 and 16 channels this system may properly be adapted matching to your automation tasks. -

Page 9: Components

16x periphery modules Power modules Accessories CAUTION! Only Yaskawa modules may be combined. A mixed operation with third- party modules is not allowed! CPU 01xC With the CPU 01xC electronic, input/output components and power supply are integrated to one casing. In addition, up to 64 periphery modules of the System SLIO can be con- nected to the backplane bus. - Page 10 Please note that some modules do not support line extensions due to the system. For more information, see the ‘System SLIO - Compatibility List’ at www.yaskawa.eu.com Periphery modules The periphery modules are available in the following 2 versions, whereby of each the electronic part can be replaced with standing wiring: 8x periphery module for a maximum of 8 channels.

- Page 11 System SLIO Basics and mounting System conception > Components 8x periphery modules Each 8x periphery module consists of a terminal and an electronic module. Terminal module Electronic module Terminal module The terminal module serves to carry the electronic module, contains the backplane bus with power supply for the electronic, the DC 24V power section supply and the staircase- shaped terminal for wiring.

-

Page 12: Accessories

System SLIO Basics and mounting System conception > Accessories Electronic unit The functionality of a 16x periphery module is defined via the terminal block, which is connected to the electronic unit via a secure flap mechanism. In the case of an error you can exchange the defective electronic unit for a functional unit with standing wiring. - Page 13 System SLIO Basics and mounting System conception > Accessories Bus cover With each head module, to protect the backplane bus connectors, there is a mounted bus cover in the scope of delivery. You have to remove the bus cover of the head module before mounting a System SLIO module.

-

Page 14: Hardware Revision

System SLIO Basics and mounting Dimensions 2.2.4 Hardware revision Hardware revision on the The hardware revision is printed on every System SLIO module. front Since a System SLIO 8x periphery module consists of a terminal and electronic module, you will find a hardware revision printed on each of them. Authoritative for the hardware revision of a System SLIO module is the hardware revi- sion of the electronic module. - Page 15 System SLIO Basics and mounting Dimensions CPU 01x Bus coupler and line extension slave Line extension master HB300 | CP | 042-1IO00 | en | 22-42...

- Page 16 System SLIO Basics and mounting Dimensions 8x periphery module Electronic module 16x periphery module 76.5 12.9 HB300 | CP | 042-1IO00 | en | 22-42...

-

Page 17: Mounting 8X Periphery Modules

System SLIO Basics and mounting Mounting 8x periphery modules 2.4 Mounting 8x periphery modules CAUTION! Requirements for UL compliance use – Use for power supply exclusively SELV/PELV power supplies. – The System SLIO must be installed and operated in a housing according to IEC 61010-1 9.3.2 c). - Page 18 Even with an existing coding on the terminal module, you can plug an electronic module without coding. The user is responsible for the correct usage of the coding pins. Yaskawa assumes no liability for incorrectly attached electronic modules or for damages which arise due to incorrect...

- Page 19 System SLIO Basics and mounting Mounting 8x periphery modules Mounting periphery modules Mount the mounting rail! Please consider that a clearance from the middle of the mounting rail of at least 80mm above and 60mm below, respectively 80mm by deployment of shield bus carriers, exist. Mount your head module such as CPU or field bus coupler.

-

Page 20: Mounting 16X Periphery Modules

System SLIO Basics and mounting Mounting 16x periphery modules After mounting the whole system, to protect the backplane bus connectors at the last module you have to mount the bus cover, now. If the last module is a clamp module, for adaptation the upper part of the bus cover is to be removed. 2.5 Mounting 16x periphery modules CAUTION! Requirements for UL compliance use... - Page 21 System SLIO Basics and mounting Mounting 16x periphery modules Electronic unit and ter- Each 16x periphery module consists of an electronic unit and a terminal block. minal block Electronic unit Terminal block To replace an electronic unit, you can push down and pull off the terminal block after releasing the lock.

-

Page 22: Wiring 8X Periphery Modules

System SLIO Basics and mounting Wiring 8x periphery modules Clack For mounting turn the locking lever of the module upwards until it engages. For mounting place the module to the module installed before and push the module to the mounting rail guided by the strips at the upper and lower side of the module. Turn the locking lever of the periphery module downward, again. - Page 23 System SLIO Basics and mounting Wiring 8x periphery modules Data 240V AC / 30V DC Cross section 0.08 ... 1.5mm (AWG 28 ... 16) Stripping length 10mm Wiring procedure Pin number at the connector Opening for screwdriver Connection hole for wire Insert a suited screwdriver at an angel into the square opening as shown.

-

Page 24: Wiring 16X Periphery Modules

System SLIO Basics and mounting Wiring 16x periphery modules Attach the cables with the accordingly stripped cable screen and fix it by the shield clamp with the shield bus. 2.7 Wiring 16x periphery modules Terminal block connectors CAUTION! Do not connect hazardous voltages! If this is not explicitly stated in the corresponding module description, hazardous voltages are not allowed to be connected to the corresponding terminal block! -

Page 25: Wiring Power Modules

System SLIO Basics and mounting Wiring power modules Insert wire The wiring happens without a tool. Determine according to the casing labelling the connection position. Insert through the round connection hole of the according contact your prepared wire until it stops, so that it is fixed. ð... - Page 26 System SLIO Basics and mounting Wiring power modules Wiring procedure Pin number at the connector Opening for screwdriver Connection hole for wire Insert a suited screwdriver at an angel into the square opening as shown. Press and hold the screwdriver in the opposite direction to open the contact spring. Insert the stripped end of wire into the round opening.

- Page 27 System SLIO Basics and mounting Wiring power modules PM - Power module For wires with a core cross-section of 0.08mm up to 1.5mm Pos. Function Type Description not connected DC 24V DC 24V for power section supply GND for power section supply Sys DC 24V DC 24V for electronic section supply not connected...

- Page 28 System SLIO Basics and mounting Wiring power modules Deployment of the power If the 10A for the power section supply is no longer sufficient, you may use the power modules module with the order number 007-1AB00. So you have also the possibility to define isolated groups.

- Page 29 System SLIO Basics and mounting Wiring power modules Shield attachment Shield bus carrier Shield bus (10mm x 3mm) Shield clamp Cable shield To attach the shield the mounting of shield bus carriers are necessary. The shield bus carrier (available as accessory) serves to carry the shield bus to connect cable shields. Each System SLIO 8x periphery module has a carrier hole for the shield bus carrier.

-

Page 30: Demounting 8X Periphery Modules

System SLIO Basics and mounting Demounting 8x periphery modules 2.9 Demounting 8x periphery modules Proceeding Exchange of an electronic Power-off your system. module For the exchange of a electronic module, the electronic module may be pulled for- ward after pressing the unlocking lever at the lower side of the module. For installation plug the new electronic module guided by the strips at the lower side until this engages to the terminal module. - Page 31 System SLIO Basics and mounting Demounting 8x periphery modules Exchange of a periphery Power-off your system. module Remove if exists the wiring of the module. For demounting and exchange of a (head) module or a group of modules, due to mounting reasons you always have to remove the electronic module right beside.

- Page 32 System SLIO Basics and mounting Demounting 8x periphery modules Exchange of a module Power-off your system. group Remove if exists the wiring of the module group. For demounting and exchange of a (head) module or a group of modules, due to mounting reasons you always have to remove the electronic module right beside.

-

Page 33: Demounting 16X Periphery Modules

System SLIO Basics and mounting Demounting 16x periphery modules 2.10 Demounting 16x periphery modules Proceeding Exchange of an electronic Power-off your system. unit To replace an electronic unit, you can push down and pull off the terminal block after releasing the lock. To mount the terminal block, place it horizontally on the lower side of the electronic unit and push it towards the electronic unit until it clicks into place. - Page 34 System SLIO Basics and mounting Demounting 16x periphery modules Pull the module. For mounting turn the locking lever of the module to be mounted upwards. To mount the module put it to the gap between the both modules and push it, guided by the stripes at both sides, to the mounting rail.

- Page 35 System SLIO Basics and mounting Demounting 16x periphery modules Pull the module group forward. For mounting turn all the locking lever of the module group to be mounted upwards. To mount the module group put it to the gap between the both modules and push it, guided by the stripes at both sides, to the mounting rail.

-

Page 36: Easy Maintenance

System SLIO Basics and mounting Easy Maintenance 2.11 Easy Maintenance Overview Easy Maintenance means the support for adding and removing an electronic module during operation without having to restart the system. Here the following behavior is shown by the example of a CPU: Electronic module is removed –... -

Page 37: Trouble Shooting - Leds

System SLIO Basics and mounting Trouble shooting - LEDs 2.12 Trouble shooting - LEDs General Each module has the LEDs RUN and MF on its front side. Errors or incorrect modules may be located by means of these LEDs. In the following illustrations flashing LEDs are marked by ☼. Sum current of the elec- tronic power supply exceeded... -

Page 38: Industrial Security And Installation Guidelines

Industrial security in information technology Latest version This chapter can also be found as a guide ‘IIndustrial IT Security’ at www.yaskawa.eu.com Hazards The topic of data security and access protection has become increasingly important in the industrial environment. The increased networking of entire industrial systems to the net- work levels within the company together with the functions of remote maintenance have all served to increase vulnerability. - Page 39 System SLIO Basics and mounting Industrial security and installation guidelines > Industrial security in information technology 2.13.1.1 Protection of hardware and applications Precautions Do not integrate any components or systems into public networks. – Use VPN "Virtual Private Networks" for use in public networks. This allows you to control and filter the data traffic accordingly.

-

Page 40: Installation Guidelines

System SLIO Basics and mounting Industrial security and installation guidelines > Installation guidelines 2.13.1.2 Protection of PC-based software Precautions Since PC-based software is used for programming, configuration and monitoring, it can also be used to manipulate entire systems or individual components. Particular caution is required here! Use user accounts on your PC systems. - Page 41 System SLIO Basics and mounting Industrial security and installation guidelines > Installation guidelines Possible interference Electromagnetic interferences may interfere your control via different ways: causes Electromagnetic fields (RF coupling) Magnetic fields with power frequency Bus system Power supply Protected earth conductor Depending on the spreading medium (lead bound or lead free) and the distance to the interference cause, interferences to your control occur by means of different coupling mechanisms.

-

Page 42: General Data For The System Slio

System SLIO Basics and mounting General data for the System SLIO Isolation of conductors Electrical, magnetically and electromagnetic interference fields are weakened by means of an isolation, one talks of absorption. Via the isolation rail, that is connected conductive with the rack, interference currents are shunt via cable isolation to the ground. Here you have to make sure, that the connection to the protected earth conductor is impedance- low, because otherwise the interference currents may appear as interference cause. - Page 43 System SLIO Basics and mounting General data for the System SLIO Protection of persons and device protection Type of protection IP20 Electrical isolation to the field bus electrically isolated to the process level electrically isolated Insulation resistance Insulation voltage to reference earth Inputs / outputs AC / DC 50V, test voltage AC 500V Protective measures...

-

Page 44: Use In Difficult Operating Conditions

System SLIO Basics and mounting General data for the System SLIO > Use in difficult operating conditions Standard Comment Emitted interference EN 61000-6-4 Class A (Industrial area) Noise immunity EN 61000-6-2 Industrial area zone B EN 61000-4-2 8kV at air discharge (degree of severity 3), 4kV at contact discharge (degree of severity 2) EN 61000-4-3 HF field immunity (casing) -

Page 45: Hardware Description

System SLIO Hardware description Structure Hardware description 3.1 Properties Feature IO-Link master with 4 ports. The IO-Link ports are galvanically isolated from the backplane bus. Permanent memory for parameters. The ports can be used in the IO-Link mode or as standard I/O (SIO). Status LEDs for IO-Link, SIO mode and error indication. - Page 46 LEDs C1 and C2 are blinking alternately with 1 Hz. An error occurred during the firmware update. Check that the firmware file matches your IO-Link master and run the update again. If the error persists, please contact the Yaskawa hotline! An error occurred on port n.

- Page 47 System SLIO Hardware description Structure Pin assignment For wires with a core cross-section of 0.14mm up to 0.75mm . With a core Ä ‘Data’ page 24 cross-section < 0.25mm , ferrules must be used. L+ (24V) C/Q1 L+1 C/Q2 L+2 IO-Link C/Q3 L+3 L- (0V)

-

Page 48: Technical Data

System SLIO Hardware description Technical data 3.3 Technical data Order no. 042-1IO00 Type CP 042 - IO-Link Master Module ID 0A81BC80 Current consumption/power loss Current consumption from backplane bus 32 mA Current consumption from load voltage L+ (without load) 17.7 mA Power loss 1.2 W Status information, alarms, diagnostics... - Page 49 System SLIO Hardware description Technical data Order no. 042-1IO00 IO-Link mode Number of ports Specification IO-Link V1.1.3 Overload protection C/Q pins Reverse polarity protection C/Q pins Data transfer rates 4.8 kBaud (COM1) 38.4 kBaud (COM2) 230.4 kBaud (COM3) Connection 3-wire Cable length, unshielded max.

- Page 50 System SLIO Hardware description Technical data Order no. 042-1IO00 UL certification in preparation KC certification in preparation UKCA certification ChinaRoHS certification HB300 | CP | 042-1IO00 | en | 22-42...

-

Page 51: Deployment

Link device takes place as point-to-point communication. IO-Link Manager IO-Link Manager is software from Yaskawa for configuring your IO-Link master and the connected IO-Link devices. You can find the software IO-Link Manager in the ‘Download Center’ of www.yaskawa.eu.com at SW300I0EA. -

Page 52: Commissioning

System SLIO Deployment Commissioning Signal transmission IO-Link uses 24V levels for signal transmission. In the event of an error, a telegram is repeated 2 times. The IO-Link master then reports a communication abort. Transfer rate An IO-Link master supports the following transfer rates defined according to IO-Link specification V1.1: COM 1 = 4.8 kbaud COM 2 = 38.4 kbaud... - Page 53 System SLIO Deployment Commissioning Power supply The module is to be power supplied with the both DC 24V voltages power section supply I/O area and electronic power supply. When commissioning these may simultaneously or electronic power supply must be switched on first. When commissioning these may simultaneously or power section supply I/O area must be switched on first.

-

Page 54: In-/Output Area

System SLIO Deployment In-/Output area > Input area 64byte In the PREOPERATE state, the IO-Link device is supplied with the corresponding parameter data and changes to the OPERATE state . In the OPERATE state, the IO-Link device is in cyclic data exchange with the IO-Link master. If no connection could be established or if the basic parameters for device identifica- tion deviate from the configured basic parameters, you will receive an error message and the IO-Link device remains in the STARTUP state... -

Page 55: Output Area 64Byte

Bootloader Mode after the firmware update, an error has occurred. Check that the firmware file matches your IO-Link master and run the update again. Ä Chap. 4.6 ‘Firmware update’ page 61 If the error persists, please contact the Yaskawa hot- line! STS_TOGGLE Toggle bit The toggle bit changes state every 100ms (default). -

Page 56: Product Specific Parameters

System SLIO Deployment Product specific parameters 4.4 Product specific parameters The product-specific parameters for the IO-Link master can only be set or retrieved via the IO-Link Manager configuration tool. For access, the IO-Link Manager uses product- specific SMI services for reading and writing the parameters. The IO-Link master has the following product-specific parameters: Product specific parameters Name... - Page 57 System SLIO Deployment Product specific parameters Mapping of the I/O data Here you can adapt the mapping of the process data accordingly. Whenever the configu- ration is changed, consistency checks are done according to the following rules: The process data of each port must be within the input respectively output process image of the IO-Link master.

-

Page 58: Diagnostics

System SLIO Deployment Diagnostics Example of incorrect port mapping Output process image Input process image Port Offset Length Port Offset Length Port 1 0x00 0x04 Port 1 0x01 0x02 Port 2 0x3D 0x04 Port 2 Port 3 Port 3 0x3C 0x02 Port 4 0x02... - Page 59 System SLIO Deployment Diagnostics Diagnostic data Name Bytes Function Default ERR_A Diagnostic MODTYP Module information ERR_C reserved ERR_D Diagnostic CHTYP Channel type NUMBIT Number diagnostics bits per channel NUMCH Number channels of the module CHERR Channel error CH0ERR Channel error port 1 CH1ERR Channel error port 2 CH2ERR...

- Page 60 System SLIO Deployment Diagnostics NUMBIT Diagnostic bits Byte Bit 7 ... 0 Number of diagnostic bits of the module per channel (here 08h) NUMCH Channels Byte Bit 7 ... 0 Number of channels of a module (here 04h) CHERR Channel error Byte Bit 7 ...

-

Page 61: Firmware Update

When installing a new firmware you have to be extremely careful. In certain circumstances, your CP 042 IO-Link may become unusable if, for example, the power supply is interrupted during transmission or the firmware file is faulty. In this case, please call the Yaskawa hot- line! –... -

Page 62: Reset To Factory Settings

System SLIO Deployment Reset to factory settings 4.7 Reset to factory settings Proceeding Switch on the power supply for your system. Open the IO-Link Manager and establish an online connection to your IO-Link master via the head module.. Select the corresponding IO-Link master in ‘Topology’ . Navigate to the reset dialog via ‘Master Control è...

Need help?

Do you have a question about the SLIO CP 042-1IO00 and is the answer not in the manual?

Questions and answers