Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Fuji Electric ZPAJ

- Page 1 Instruction Manual NDIR TYPE INFRARED GAS ANALYZAR TYPE: ZPAJ INZ-TN2ZPAJ-E...

- Page 2 PREFACE Thank you very much for purchasing Fuji’s Infrared Gas Analyzer (Type: ZPAJ). injury. Request INZ-TN2ZPAJ-E...

-

Page 3: Caution On Safety

CAUTION ON SAFETY To operate the analyzer properly, be sure to read “Caution on Safety” carefully. DANGER CAUTION damage. PROHIBITION CAUTION Caution on installation and transport of gas analyzer DANGER CAUTION INZ-TN2ZPAJ-E... -

Page 4: Caution On Use

Caution on piping Be sure to observe the following precautions while installing DANGER piping. Improper piping may result in gas leakage. If the leaking gas contains a toxic component, serious acci- dents may result. If it contains combustible gases, explosion Caution on wiring CAUTION Caution on use... - Page 5 Caution on use PROHIBITION Caution on maintenance and check DANGER Be sure to observe the following to perform work safely, CAUTION avoiding electric shock or injury. Others CAUTION INZ-TN2ZPAJ-E...

-

Page 6: Warranty And Maintenance

WARRANTY AND MAINTENANCE Scope of application Operating conditions and environment Precautions and prohibitions Warranty 4-1. Period of warranty of repair. 4-2. Scope of warranty from: INZ-TN2ZPAJ-E... -

Page 7: Failure Diagnosis

Failure diagnosis Service life Maintenance plan Maintenance Preventive Daily inspection maintenance Periodic inspection Corrective Troubleshooting maintenance Limited-life parts and consumable parts INZ-TN2ZPAJ-E... - Page 8 Spare parts and accessories and accessories. 10. Period for repair and provision of spare parts after product dis- continuation (maintenance period) INZ-TN2ZPAJ-E...

- Page 9 CONTENTS ........................i ....................ii ............... v ......................viii ................................................................................ 4 .................... 4 ......................5 ............... 5 ........................6 ................................................................................................................................................................................................................................................................................................................................................

- Page 10 ..............................................................................................................................................................................................................................................................................................................................45 ................... 45 ..................................................55 ......................................................................................................................................64 ..........64 ....................................................

- Page 11 ...................................................... INZ-TN2ZPAJ-E...

- Page 12 1. OVERVIEW INZ-TN2ZPAJ-E...

-

Page 13: Name Of Delivered Items And Each Parts

2. NAME OF DELIVERED ITEMS AND EACH PARTS Analyzer: 1 unit Standard: IEC127-2 Size: ø5 × 20mm Fuse: 2 pcs Rating: 250V/2A delay type Part No.: R75796N17 Instruction manual (this catalog): 1 copy (INZ-TN2ZPAJ-E) Power supply cord: 1 Part No.: R77419N14 Ferrite core: 3 For digital output signal Part No.: R79181N14... -

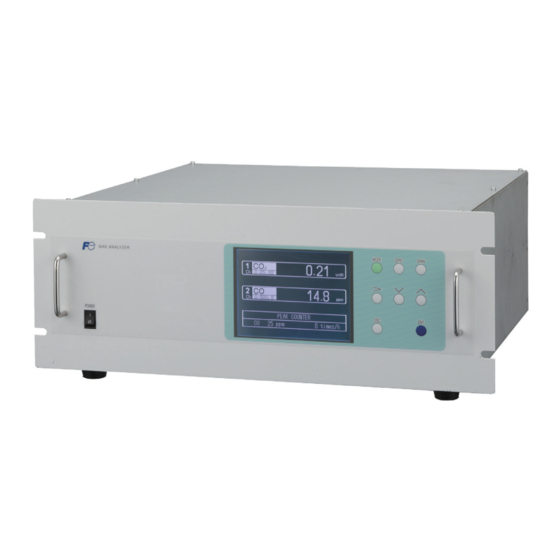

Page 14: Name And Description Of Analyzer

2.2 Name and description of analyzer (1) Power switch MODE ZERO SPAN < Front panel > POWER (2) Display/operation panel (9) Terminal Block 2 (5) Sampling gas outlet (11) Terminal Block 4 (4) Sampling gas inlet TN 1 TN 2 TN 3 TN 4 TN 5... -

Page 15: Installation Conditions

3. INSTALLATION DANGER CAUTION injury. 3.1 Installation conditions unit : mm analyzer (installed) analyzer (Remove the cover) INZ-TN2ZPAJ-E... -

Page 16: Installation Of Analyzer Main Frame

3.2 Installation 3.2.1 Installation of analyzer main frame (Unit : mm) Type External dimensions Mounting dimensions Mounting method Guide rail MODE ZERO SPAN Guide rail POWER 450 or more Slide rail Slide rail Guide rail analyzer. INZ-TN2ZPAJ-E... - Page 17 3.3 Piping CAUTION analyzer. coupling. Sampling gas outlet 1 Sampling gas inlet 1 TN 1 TN 2 TN 3 TN 4 TN 5 Purge gas inlet FUSE 250V T 2A L POWER INLET 100-240V AC INZ-TN2ZPAJ-E...

- Page 18 Internal piping diagram Optical unit 2 (IR Unit 2) Optical unit 1 (IR Unit 1) Built-in sensor INLET1 OUTLET1 Sampling gas outlet Sampling cell Note) Sampling gas inlet 2 cells may be used by combination of range. Correspondence of measured components and optical units INZ-TN2ZPAJ-E...

-

Page 19: Conditions Of Sampling Gas

3.4 Sampling 3.4.1 Conditions of sampling gas consider- 3.4.3 Preparation of standard gas sensor sensor Zero gas Dry air measuring range. — 3.4.4 Purging of instrument inside INZ-TN2ZPAJ-E... -

Page 20: Pressure At Sampling Gas Outlet

3.4.5 Pressure at sampling gas outlet (1) Gas extractor ZPAJ unit (11) NO (7) Membrane ø10/ø8 converter filter Teflon tube (4) Gas aspirator 2-way (8) Flowmeter Infrared gas solenoid (2) Mist filter analyzer valve main frame (O Electronic gas cooler... -

Page 21: Power Supply

3.5 Wiring CAUTION CAUTION TN 1 TN 2 TN 3 TN 4 TN 5 FUSE 250V T 2A L POWER INLET 100-240V AC Communication Power inlet connector Terminal Terminal (100V to 240V AC, 50/60Hz) Terminal Block 5 Block 3 Block 1 Terminal Terminal Block 2... - Page 22 When noise source is in the vicinity Main unit power supply Varistor or spark quencher Install (connect) near the source. valves. Noise generating source (2) Analog output signal (A/O): terminal block 1 (1) to (10), (17) to (20) CAUTION (3) O sensor input: terminal block 2 (1) - (2) or more) analyzer prepared...

- Page 23 (4) Contact input (DI): terminal block 2 (13) to (20), terminal block 3 (7) to (10) or open (off). (5) Contact output (DO): terminal block 3 (11) to (20), terminal block 4 and terminal block 5 (on) or open (off). CAUTION (6) Communication interface: connector for communication (RS-232C interface) INZ-TN2ZPAJ-E...

- Page 24 (7) List of terminal blocks 1 to 5 Terminal block 1 Terminal block 2 <TN1> <TN2> CH5 output Unused sensor input Unused (AO) + CH4 remote range CH4 output Unused Unused changeover input (AO) (DI) CH3 remote range CH3 output Unused Unused changeover input...

-

Page 25: Terminal Block

(8) Description on terminal blocks 1 to 5 Terminal block 1 <TN1> Terminal block 1 <TN1> CH5 output Unused (AO) + CH4 output Unused (AO) CH3 output Unused (AO) CH2 output CH7 output (AO) CH1 output CH6 output (AO) (AO) (M3.5 screw) Terminal block 2 <TN2>... - Page 26 Terminal block 3 <TN3> Terminal block 3 <TN3> Instrument error Unused (DO) CH4 range identification Unused signal output (DO) CH3 range identification Unused signal output (DO) Remote hold input CH2 range identification (DI) signal output (DO) Auto calibration CH1 range identification remote start signal output (DO) input (DI)

- Page 27 Terminal block 4 <TN4> Terminal block 4 <TN4> Contact output for CH4 span calibration Unused (DO) Contact output for CH3 Auto calibration status contact output (DO) span calibration (DO) Contact output for CH2 Calibration error span calibration contact output (DO) (DO) Contact output for CH1 Pump ON/OFF contact...

- Page 28 Terminal block 5 <TN5> Terminal block 5 <TN5> Unused Unused CH3 alarm output (DO) Peak count alarm CH2 alarm output output (DO) (DO) CH1 alarm output CH4 alarm output (DO) (DO) (M3.5 screw) INZ-TN2ZPAJ-E...

- Page 29 (9) Timing of contact output for calibration 1) Manual calibration (See Section 6.8 “Manual calibration procedure”.) 2) In case of automatic calibration (example shown in Section 6.4 “Setting of auto calibration”) (When the analyzer has auto calibration function.) Automatic calibration Ch1 span Ch3 span start...

-

Page 30: Preparation For Operation

4. OPERATION 4.1 Preparation for operation (1) Piping and wiring check 4.2 Warm-up operation and regular operation (1) Operation procedure Note) During warm-up, the display indicates midline horizontal bars. This is not an error. INZ-TN2ZPAJ-E... -

Page 31: Description Of Display And Operation Panels

5. DESCRIPTION OF DISPLAY AND OPERATION PANELS 5.1 Name and description of operation panel MODE ZERO SPAN POWER Power switch Operation panel Display unit (7) ZERO key (8) SPAN key MODE ZERO SPAN (1) MODE key (4) DOWN key (2) SIDE key (3) UP key (6) ENTER key (5) ESCAPE key... -

Page 32: Overview Of Display And Operation Panels

5.2 Overview of display and operation panels INZ-TN2ZPAJ-E... -

Page 33: Outline Of Display Screen

5.3 Outline of display screen (1) Measurement mode screen (appears when the power is turned ON) 0-500.0 0-200.0 0.00 vol% 0-500.0 0-25.00 CV. NOx Scroll 0-200.0 0-500.0 0.00 vol% 0-500.0 0-25.00 0.00 CV. NOx AV. O 0-500.0 vol% 0-25.00 vol% Instantaneous value and concentration value: corrected concentration values: INZ-TN2ZPAJ-E... - Page 34 corrected concentration average value: aver- (2) Setting/selection screen Message display area Status display area display area Cursor INZ-TN2ZPAJ-E...

- Page 35 (3) Contents of measured channel (Ch) Code symbol Display/output contents corresponding to each channel (CH) No. 6th digit 7th digit 21th digit 1, 2, 3, 4 1, 2, 3, 4 1, 2, 3, 4 1, 2, 3, 4 1, 2, 3, 4 Y, B 1, 2, 3, 4 1, 2, 3, 4...

-

Page 36: Basic Operation

5.4 Basic operation 0-500.0 0-500.0 0-200.0 ZERO 0.00 0-25.00 vol% CV. NOx 0-500.0 Manual zero calibration See 6.8.1. Manual span calibration 0-200.0 See 6.8.2. 0.00 vol% 0-25.00 SPAN CV. NOx 0-500.0 0-500.0 0.00 AV. O 0-25.00 vol% MODE User Mode Select an item with UP/DOWN and ENT Back with ESC... -

Page 37: Setting And Calibration

6. SETTING AND CALIBRATION 6.1 Switch of range Measurement Mode Screen 6.1.1 Setting of range switch mode MODE MODE User Mode Select an item with UP/DOWN and ENT Back with ESC Switch Ranges Calibration Parameters key. Alarm Setting Setting of Auto Calibration Setting of Auto Zero Calibration Setting of Peak Alarm Parameter Setting... -

Page 38: Manual Range Switch

6.1.2 Manual range switch Switch Ranges Select method of switch ranges with UP/DOWN and ENT Back with ESC key. Range1 0–500.0 Range2 0–5000 Range1 0–500.0 Range2 0–2500 Range1 0–200.0 Range2 0–2000 Range1 0–10.00 vol% Range2 0–25.00 vol% Switch Ranges Select Ch No. with UP/DOWN and ENT key. -

Page 39: Setting Of Calibration Concentration

6.2 Calibration setting Cal. Parameters Select an item with UP/DOWN and ENT Back with ESC Calibration Value 6.2.1 Setting of calibration concentration About ZERO Calibration About Calibration Range Auto Calibration Components / Range Cal. Settings Select setting value Cal. Value RANGE ZERO SPAN... - Page 40 Cursor for setting value Cal. Settings Set calibration value Cal. Value RANGE ZERO SPAN 0–500.0 ppm +000.0 0500.0 0–5000 ppm +0000 05000 Note) Enter settings that correspond to each 0–500.0 ppm +000.0 0500.0 0–2500 ppm +0000 02500 range. If zirconia type is used as O 0–200.0 ppm +000.0 0200.0...

-

Page 41: Setting Of Manual Zero Calibration

6.2.2 Setting of manual zero calibration Cal. Settings Set each or at once Ch ZERO Cal. at ZERO Calibration Range1 0–500.0 at once Range2 0–5000 Range1 0–500.0 each Range2 0–2500 Range1 0–200.0 at once Range2 0–2000 Range1 0–10.00 vol% each Range2 0–25.00 vol%... - Page 42 Manual Calibration screen ZERO Cal. ENT : Go on calibration ZERO Cal. ENT : Go on calibration of selected Ch of selected Ch ESC : Not calibration ESC : Not calibration Range1 0–500.0 -2.1 Range1 0–500.0 Range2 0–5000 Range2 0–5000 -0.5 Range1 0–500.0...

-

Page 43: Setting Of Calibration Range

6.2.3 Setting of calibration range Cal. Settings Set calibration range Cal. Range current or both range Range1 0–500.0 both Range2 0–5000 Range1 0–500.0 current Range2 0–2500 Range1 0–200.0 current Range2 0–2000 Range1 0–10.00 vol% both key. Range2 0–25.00 vol% End of Calibration Range Setting To close “Setting of Calibration Range”... -

Page 44: Setting Of Auto Calibration Component/Range

6.2.4 Setting of auto calibration component/range Cal. Settings Select a range for Auto Cal. auto calibration Range1 0–500.0 enable Range2 0–5000 Range1 0–500.0 enable Range2 0–2500 Range1 0–200.0 enable Range2 0–2000 Range1 0–10.00 vol% disable Range2 0–25.00 vol% key. End of Auto Calibration performed. - Page 45 To close the setting Press the key to exit automatic calibration component/range setting, and the previous screen appears. Operation by setting Auto calibration is performed under the following rules. 1. Zero calibration is performed at the same time, for the Ch (component) in which “enable” is selected at the time of auto calibration and auto zero calibration.

-

Page 46: Setting Of Alarm Values

6.3 Alarm setting 6.3.1 Setting of alarm values key. Press key. key. Note 500.0 Set the values so that H-limit value > L-limit 5000 value and that (H-limit value - L-limit value) > hysteresis. For the case of reverse range O measurement: Set the values so that L-limit value >... - Page 47 Description of setting items The alarm contact assigned the same number as the alarm is operated accordingly. Channel: Channel setting targeted for issuance of alarm. One Ch No. can be selected for multiple alarms. H-Limit value: Sets the high limit value (concentration) of alarm. L-Limit value: Sets the low limit value (concentration) of alarm.

-

Page 48: Hysteresis Setting

6.3.2 Hysteresis setting esis. End of Hysteresis Setting To close "Hysteresis Setting" To close the “Hysteresis Setting” or cancel the mode midway, press the key. A previous screen will return. Note Setting range The hysteresis is common to all alarms (components). -

Page 49: Peak Alarm Setting

6.3.3 Peak alarm setting Measurement mode screen MODE MODE key. key. key. key. values are saved. Description of setting items End of Peak Alarm Setting INZ-TN2ZPAJ-E... - Page 50 Setting range Alarm value : 10 to 1000 ppm 5 ppm step (initial value: 500 ppm) Alarm count : 1 to 99 times (per hour) (initial value: 5 times) Hysteresis : 0 to 20 % of full scale (initial value: 0% of full scale) [% full scale] represents the percentage with the CO range regarded as 100%.

-

Page 51: Setting Of Auto Calibration

6.4 Setting of auto calibration 6.4.1 Auto calibration key. Press the key, and date and time are Description of setting items displayed alternately. End of Auto Calibration Setting To close "Setting of Auto calibration" To close the "Setting of Auto calibration" or cancel this mode midway, press the key. - Page 52 key. key. key. Note) Only the Chs used are displayed on this screen. The Ex. time is the out- put signal hold extension time after the completion of calibration. It is valid only when the hold setting is set to “ON.” The Ex. time set here is also the hold extension time at the time of manual calibration.

-

Page 53: Remote Start

Example Start Time 12:00 Cycle Flow Time Zero 350 sec Ch1 Span 350 sec Ch2 Span 350 sec Ch3 Span 350 sec Ch4 Span 300 sec EX. time 300 sec ON/OFF In case where auto calibration is carried out at the above setting. Sunday Monday Tuesday... -

Page 54: Forced Run/Stop Of Auto Calibration

6.4.2 Forced run/stop of auto calibration 6.4.2.1 Execution of auto calibration (only once) key. 6.4.2.2 Forced stop of auto calibration key. INZ-TN2ZPAJ-E... -

Page 55: "Auto Calibration" Screen

“Auto Calibration” screen Example 0-500 0 3 . 0-500 0 6 . 2 1 0 2 0 4 . 0-500 4 8 3 2 0-500 0 0 . 0-500 0 0 . 0 0 0 2 4 4 9 0-500 0-500 4 9 1 3 . -

Page 56: Setting Of Auto Zero Calibration

6.5 Setting of auto zero calibration 6.5.1 Auto zero calibration key. Press the key, and date and time are Description of setting items displayed alternately. End of Auto Zero Calibration Setting To close "setting of Auto Zero Calibration" To close the “Setting of Auto Zero Calibration” or cancel this mode midway, press the key. - Page 57 Example Start time 12:00 Cycle hour Flow time ON/OFF In case where auto zero calibration is carried out at the above setting. Sunday Monday Monday 12:00 0:00 12:00 Cycle : Auto zero calibration Replace- Zero ment calibration time (Ch1 4) 300sec 300sec Gas replacement time after calibration is the same as...

-

Page 58: Forced Run/Stop Of Auto Zero Calibration

6.5.2 Forced run/stop of auto zero calibration 6.5.2.1 Execution of auto zero calibration (only once) key. key. cancel. 6.5.2.2 Forced stop of auto zero calibration key. key. INZ-TN2ZPAJ-E... - Page 59 “Auto Zero Calibration” screen Example 0-500 0 3 . 0-500 0 6 . 2 1 0 2 0 4 . 0-500 Caution During auto zero calibration, any key operation is not permitted other than operations such as key lock ON/OFF and “Forced stop of auto zero calibration”. When the key lock is set at ON, even the “Forced stop of auto zero calibration”...

-

Page 60: Parameter Setting

6.6 Parameter setting Description of setting items Parameter Select setting item Current Time 12/01/11 WED 13:50 key. Key Lock Output Hold Current Response Time Average Period Backlight Timer 05 min Contrast To Maintenance Mode 0000 Parameter Set day of week Current Time 12/01/11 13:50... -

Page 61: Setting Range

Setting Range Output Hold Manual calibration ZERO Press the key to flow gas. SPAN To execute calibration, press the key. Calibration Hold extending time Output hold Time set to gas flow time (See Section 6.4 Auto Calibration.) b. Auto calibration Auto calibration start Auto calibration end Calibration... - Page 62 Parameter Select Hold ON or OFF Current Time 12/01/11 WED 13:50 Key Lock Output Hold Current Response Time Average Period Backlight Timer 05 min Contrast To Maintenance Mode 0000 Parameter Select Hold setting key. Current Time 12/01/11 WED 13:50 Key Lock Output Hold Setting Response Time...

-

Page 63: Response Time

Parameter Set Hold value 0 to 100%FS Hold key. key. Meaning of setting The setting is expressed as 1/1 full scale range for both respective ranges. When 0 to 1000 ppm is selected as the range, and 10% FS is selected as hold setting, the output equivalent to 100 ppm is held irrespective of the End of Hold Setting measurement value at that time. - Page 64 Average period Parameter Select Ch No. average. Average Period hour hour hour average value. (Press- Reset Reset Av. Output Average value reset Contact input flow With input (hold at least 1.5 sec.) Without input Reset input So long as with input, resetting lasts. At the edge of changing from “with input”...

-

Page 65: Backlight Timer

Backlight Timer Parameter Set Backlight Timer ON or OFF Current Time 12/01/11 WED 13:50 Key Lock Output Hold Setting off. Response Time Average Period Backlight Timer 05 min Contrast To Maintenance Mode 0000 Contrast Parameter key. key. Current Time 12/01/11 WED 13:50 Key Lock Output Hold Setting... -

Page 66: Maintenance Mode

6.7 Maintenance mode Maintenance Select operating item Mode 1. Sensor Input Value 2. Error Log 3. Cal. Log 4. Output Adj. key. 5. Other Parameter 6. To Factory Mode played. Note) “To Factory Mode” is used for our service engineers only. Each “Maintenance”... - Page 67 Description of Calibration Log screen Maintenance Select Ch No. Past calibration history is displayed. Cal. Log Sensor input value, concentration value, and the date when zero/span calibration is performed are logged. The 10 newest calibration data are logged by each component. Move the cursor to Clear Calibration Log and press the key, and the calibration log is...

- Page 68 Description of output adjustment screen Maintenance Adjust OUTPUT Analog output adjustment screen. ZERO and SPAN Mode Connect the digital multi meter to the output Output Adj. terminal corresponding to the number of OUT Zero Span Zero Span to be adjusted, and adjust the value so that 4mA or 0V is output at Zero and 20mA or 1V is 00600 03700 00600 03700...

- Page 69 Description of each setting screen Maintenance Set Password Mode Password Set : Set the password used to move Setting from the parameter setting screen to the maintenance mode. Password Set 2465 Arbitrary 4-digit number can be ref. Value 12% O limit 20% O selected.

- Page 70 Maintenance Select Ch No. Mode key. Range set Maintenance Select range or Mode range num. Range set key. Ch1 NOx Settable range MIN range 500.0 Range 1 500.0 The value for range 1 and range 2 must fall within Range 2 5000.

-

Page 71: Manual Calibration Procedure

6.8 Manual calibration procedure Measurement screen 6.8.1 Manual zero calibration ZERO ZERO Cal. Select Ch No. with UP / DOWN and ENT Back with ESC Range 1 0-500.0 ZERO Range 2 0-5000 Range 1 0-500.0 Range 2 0-2500 Range 1 0-200.0 Range 2 0-2000 Range 1 0-10.00 vol%... - Page 72 6.8.2 Manual span calibration sensor. SPAN SPAN SPAN Cal. Select Ch No. with UP / DOWN and ENT Back with ESC Range 1 0-500.0 Range 2 0-5000 Range 1 0-500.0 Range 2 0-2500 Range 1 0-200.0 Range 2 0-2000 Range 1 0-10.00 vol% 20.09 Range 2 0-25.00...

-

Page 73: Daily Check And Maintenance Procedures

7. MAINTENANCE 7.1 Daily check (1) Zero calibration and span calibration (2) Flow rate check 7.2 Daily check and maintenance procedures Table 7.1 Maintenance and check table Phenomena sampling cell. repair. gas and purge gas analyzer analyzer Gas analyzer INZ-TN2ZPAJ-E... -

Page 74: Long Term Maintenance

7.3 Long term maintenance Gas analyzer annual inspection plan Infrared gas analyzer annual inspection plan sheet Delivered period (year) year year year year year year year year year year year analyzer − − INZ-TN2ZPAJ-E... -

Page 75: Cleaning Of Sampling Cell

7.4 Cleaning of sampling cell Caution Maintenance actions should only be accomplished by properly trained and qualified personel. Not withstanding these maintenance steps, local facility and organizational safety program requrirements must be followed. 7.4.1 Disassembly and assembly of sampling cell a. - Page 76 Name Screw (for fixing the light source unit) Screw (for fixing the detector) Screw (for fixing the gas filter) Base plate Light source unit Screw (for fixing the support) Screw (for fixing the cell retainer) Gas filter Filter Support Cell retainer Pipe cell O-ring Infrared transmission window...

- Page 77 b. How to remove block cell (See Fig. 7-2) Note) The O-ring (No. 9) is placed between the window holder and block cell. Take care about the O-ring position. With 2-component analyzer, install 2-component detector last. Take care so that no space is left between the 1-component and 2-component detectors.

- Page 78 Name Screw (for fixing the light source unit) Filter Screw (for fixing the detector) Base plate Light source unit Screw (for fixing the block cell) Block cell Infrared transmission window (window holder) O-ring Screw (for fixing the measuring unit) Gas filter Detector Light source power PCB INZ-TN2ZPAJ-E...

- Page 79 How to remove measuring unit (See Fig. 7-3) Note) Special care should be taken when assembling or disassembling the measuring cell to avoid the application of force to the detector pipe or light source unit pipe. If the pipe is deformed or damaged by excessive force, there is a danger of gas leak, thus resulting in misoperation.

-

Page 80: Replacement Of Fuse

7.4.2 How to clean sampling cell dow roughly. 7.5 Replacement of fuse TN 1 TN 2 TN 3 TN 4 TN 5 FUSE 250V T 2A L POWER INLET 100-240V AC Fuse holder Rear view Note) Prior to the following work, be sure to repair blown down fuse (short, etc), if any. INZ-TN2ZPAJ-E... -

Page 81: Error Message

8. ERROR MESSAGE Error contents Error No.1 Light source/motor rotation is faulty. Error No.2 Error No.3 Error No.5 of full scale. Error No.6 Error No.7 50% of full scale. Error No.8 Error No.9 Error No.10 source. INZ-TN2ZPAJ-E... - Page 82 Screen display and operation at the occurrence of error Auto Cal. error Error No. 9 Error No.9 0-500.0 0-500.0 SPAN NOx Calibration error 0-200.0 Cause 0 0 0 0-25.00 vol% 0 0 . CV NOx 0-500.0 ZERO Cal. ENT : Go on calibration ZERO cal.

-

Page 83: Error Log Screen

nance mode. Error log screen Date and time when an error occurred. Maintenance ENT : Clear Error Log ESC : Back Error Log Component for which the error occurred. error No. No. 10 No. 9 Errors that occurred No. 5 No. -

Page 84: Specifications

9. SPECIFICATIONS Digital output: 1 form A contact (250 V AC / 2A, resistive load) Principle of measurement: NO, SO , CO , CO, CH auto calibration status, solenoid valve drive for auto Non-dispersion infrared (NDIR) absorption method calibration, pump ON/OFF Single light source and single beam (single beam 1 form C contact (250 V AC / 2A, resistive load) Galvanic fuel cell (built-in) or... -

Page 85: Standard Functions

Upper/lower limit alarm: Standard Functions Output signal holding: to the value right before the calibration is started or the are available. Instrument error contact output: be held. The contact is closed if a device error occurs. Range changeover: Calibration error contact output: The contact is closed if a calibration error occurs. -

Page 86: Installation Requirements

Standard gas for calibration: Performance Repeatability: ±0.5% of full scale Linearity: 90–100% of its measuring range (recom- ±1% of full scale mended). Zero drift: sensor and Span drift: Response time (for 90% FS response): measurement) gas having concentration of 90–100% of its measuring range , balance N NO/SO... - Page 87 9.2 Table 1 Measurable component and range - availability check table - Procedure of range selection First determine 1st range, then select 2nd range from the corresponding column. 1. Check the available options referring to Table 1 to Table 12, and determine the 1st range. Select the corresponding range code from“NDIR range codes”...

- Page 88 Table 8 2-component analyzer: CO 1st component: CO 2nd component: CO 1st range 2nd range (max.) 1st range/2nd range (max.) 0-500ppm 0-2000ppm 0-200/2000ppm, 0-250/2500ppm, 0-300/2500ppm, 0-500/5000ppm, 0-1000/5000ppm, 0-2000/5000ppm 0-2500/5000ppm, 0-3000ppm/2%, 0-5000ppm/3%, 0-1/3%, 0-2/3%, 0-2500ppm 0-3% 0-500ppm 0-5000ppm 0-500/5000ppm, 0-1000/5000ppm, 0-2000/5000ppm, 0-2500/5000ppm, 0-3000ppm/2%, 0-5000ppm/3%, 0-1/3%, 0-2/3%, 0-3% 0-1000ppm 0-5000ppm 0-200/2000ppm, 0-250/2500ppm, 0-300/2500ppm, 0-500/5000ppm, 0-1000ppm/1%, 0-2000ppm/2%, 0-2500ppm/2%, 0-3000ppm/2%, 0-5000ppm/5%, 0-1/10%, 0-2/10%,...

- Page 89 Table 10 2-component analyzer: CO 1st component: CO 2nd component: CH 1st range 2nd range (max.) 1st range/2nd range (max.) 0-500ppm 0-2500ppm 0-1000ppm/1%, 0-2000ppm/2%, 0-2500ppm/2%, 0-3000ppm/2%, 0-5000ppm/2%, 0-1/2%, 0-2/10%, 0-3/10%, 0-5/10%, 0-10% 0-500ppm 0-5000ppm 0-1000ppm/1%, 0-2000ppm/2%, 0-2500ppm/2%, 0-3000ppm/2%, 0-5000ppm/2%, 0-1/2%, 0-2/10%, 0-3/10%, 0-5/10%, 0-10% 0-1000ppm 0-2500ppm 0-500/5000ppm, 0-1000ppm/1%, 0-2000ppm/2%, 0-2500ppm/2%, 0-3000ppm/2%, 0-5000ppm/3%, 0-1/3%, 0-2/20%, 0-3/20%, 0-5/20%, 0-10/20%, 0-20%...

-

Page 90: Code Symbols

9.3 Code symbols Digit 1 2 3 4 5 6 7 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Z P A J Description note Digit <Specification/Structure> Replacement for ZRJ (with power inlet and power cable) note1 <Mounting>... - Page 91 NDIR range codes range codes Range Code Range Code Range range code None note10 note10 note10 Others sensor (7th code “1”), set 0–1 V DC linear signals from the external O Note that the external O 6. O , and CO measurement. ranges.

-

Page 92: Outline Diagram

9.4 Outline diagram (1) Analyzer main unit (Unit : mm) <TOP VIEW> <SIDE VIEW> 88.5 <FRONT VIEW> Power Switch <Rack mount hold pitch> MODE ZERO SPAN Applicable both for JIS 100mm and EIA 101.6mm POWER <REAR VIEW> Sample Gas Outlet Rc1/4 or NPT1/4 Sample Gas Inlet Rc1/4 or NPT1/4 TN 1 TN 2... - Page 93 (2) Accessory slide rail (unit: mm) Slide rail *Slide rail is provided when the 5th code is “S”. Slide in 530±3 Cabinet member Slide out 1.52t (22.7) (9.5) Intermediate member 508.0±0.8 Drawer member 476.2±0.3 15.9±0.5 1.27t 463.5±0.3 352.4±0.3 111.1±0.3 25.4±0.3 12.7±0.3 12.7±0.3 4.5×5.3...

- Page 94 Instrumentation & Sensors Planning Dept. 1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan http://www.fujielectric.com Phone: +81-42-514-8930 Fax: +81-42-583-8275 http://www.fujielectric.com/products/instruments/...

Need help?

Do you have a question about the ZPAJ and is the answer not in the manual?

Questions and answers