Summary of Contents for Microcom 334M

- Page 1 MODEL 334M DIRECT THERMAL PRINTER OPERATOR’S MANUAL PART NUMBER 880060-0110 Revised: January 22, 2019 CPC Copyright © 2019 by Microcom Corporation, Lewis Center, Ohio – All rights reserved.

- Page 3 For this reason, specifications are subject to change without notice. Liability Disclaimer Microcom Corporation makes every effort to assure that all information and specifications contained in this manual are accurate; however, mistakes are sometimes made. Microcom Corporation shall not be liable for any damages resulting in the use or misuse of this product.

- Page 5 3.4.11.2 Media tab - Feed Options ..............3-25 3.4.12 Printing Preferences - Presenter tab ............3-26 3.4.12.1 Presenter tab - Configuration ............... 3-27 3.4.12.2 Configuration - Modes ................. 3-27 3.4.12.3 Configuration - Advanced ..............3-28 334M Operator’s Manual - 880060-0110...

- Page 6 LDS Design Exercises ..................4-1 4.2.1 PC Connection (Serial) ................. 4-1 4.2.2 Format Creation .................... 4-2 Label Design: An Overview .................. 4-3 Label Header ......................4-4 4.4.1 HFM (Number of Fields in Layout) ..............4-6 334M Operator’s Manual – 880060-0110...

- Page 7 5.2.1.3 Software Switch #3 ..................5-7 5.2.1.4 Software Switch #4 ..................5-8 5.2.1.5 Software Switch #5 ..................5-9 5.2.1.6 Software Switch #6 .................. 5-10 5.2.1.7 Software Switch #7 .................. 5-14 5.2.1.8 Software Switch #8 .................. 5-15 334M Operator’s Manual – 880060-0110...

- Page 8 Compressed Binary GRAPHIC Downloads ........... 6-4 Advanced GRAPHIC Format Conversion for Programmers ......... 6-4 6.5.1 Save Compressed Graphics to RAM (D107) ..........6-4 6.5.2 Save Compressed Graphics to FLASH (D133) ..........6-5 Downloadable Graphics Commands ..............6-5 334M Operator’s Manual – 880060-0110...

- Page 9 UCC/EAN 128, TCI 50 ................8-19 8.1.23 UCC/EAN Text Information, TCI 51 ............8-23 8.1.24 Aztec, TCI 52 ....................8-23 8.1.25 QR Code, TCI 53 ..................8-25 Bar Code Rotation ..................... 8-28 Bar Code Human Readable Text ............... 8-29 334M Operator’s Manual – 880060-0110...

- Page 10 List of Tables ......................12-9 APPENDIX ....................13-1 Appendix A: Limited Warranty .................. 13-1 Appendix B: RMA Procedure ................... 13-3 Appendix C: ^D Command Summary ............... 13-5 Glossary ........................13-20 Appendix D: User Notes ..................13-24 334M Operator’s Manual – 880060-0110...

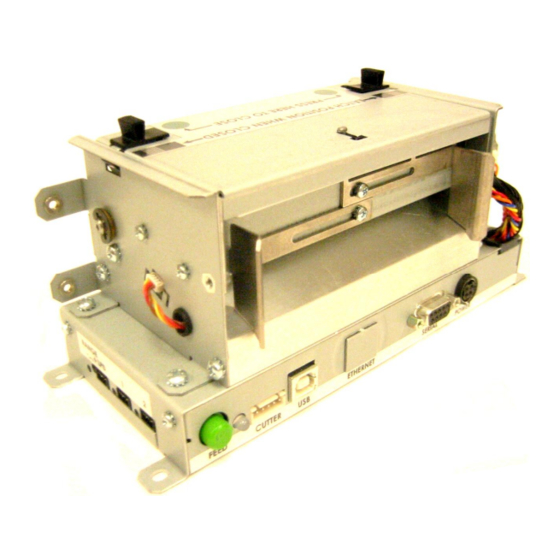

- Page 11 Introduction The Model 334M printer is a high performance Direct Thermal open frame printer specifically designed for kiosk, OEM, and specialty applications. The Model 334M is based on the X38 series engine and uses either LDS1 or a Windows Driver for operation.

- Page 12 334M Operator’s Manual – 880060-0110 viii...

- Page 13 324M 203DPI = 3.15” (80 mm); 640 dots Maximum Print Width 324M 300DPI = 3.200” (81.28 mm); 960 dots Maximum Print Length 26” (660.4 mm) Minimum Print Length 0.25” (6 mm) Table 1-2 Printing Specifications 334M Operator’s Manual - 880060-0110...

- Page 14 Corporation representative for additional information regarding testing and evaluation of thicker or rigid media types. **NOTE: The 334M printer’s media path has a maximum width of 3.5” while the actual printable width is 3.15” for the 203 DPI and 3.2” for the 300 DPI print head.

- Page 15 · Storage of fonts, label formats and graphics in both volatile RAM and non- volatile FLASH memory. · All BMP files may be converted using a Microcom utility program. · Rotated: 0 º, 90 º, 180 º, and 270 º.

- Page 16 · Internal statistical counters for inches and labels printed · Remote printer interrogation · On-site programmable flash memory updates · Supports 203 dpi and 300 dpi print heads · Four +24VDC control INPUTS · Four +24VDC control OUTPUTS · Automatic stock ejects on paper-out 334M Operator’s Manual- 880060-0110...

- Page 17 · Two reflective sensor inputs with indicator lights (Input 1 and Input 2) · Label Present Detector (LPD) reflective sensor with indicator light and adjustable range · 10/100BASE-T Ethernet communications port · Remote print button and unit indicator light · Cleaning kit 334M Operator’s Manual - 880060-0110...

- Page 18 Chapter 2 Features and Options 334M Operator’s Manual- 880060-0110...

-

Page 19: Typical Printer Accessories

Your shipment may contain different items. The foam and shipping container(s) should be kept and used if the printer is to be shipped at a later time. Additional shipping materials can be ordered by contacting the Microcom Corporation Service Department. - Page 20 100-240 VAC; 50-60 Hertz range; 4 Amps. The power supply should operate in an “output fold-back mode” during an overload situation rather than a shutdown and restart attempt; sometimes referred to as a “Hiccup” mode. Contact your Microcom Corporation representative for any questions regarding power adapter requirements and/or specifications.

-

Page 21: Optional Desktop Power Supply Output

The factory settings, unless otherwise requested, are set at 115200 baud, 8 data bits, 1 stop bit and no parity with both hardware and software handshaking enabled. The baud rate is user selectable from 110 to 115,200 and uses hardware CTS/RTS handshaking. 334M Operator’s Manual - 880060-0110... - Page 22 3.2.3 USB Communication Interface The 334M printer provides a single USB port for communication to a host device. In order to communicate with the printer, the FTDI based USB driver must be installed on the host computer. This may be downloaded at http://www.microcomcorp.com/drivers.htm. The combined driver model (CDM) may be installed on XP, VISTA, Windows 7, Windows 8, and Windows 10 allowing applications to access the FTDI devices as a virtual COM port.

- Page 23 Ethernet connection but on a serial channel inside the printer. This means that the speed is limited to 115200 baud rate. The second option is available on code version 1.11.32 and later is a Microcom developed solution that provide true Ethernet speeds that is not limited to the 115200 serial cap. The Microcom option board must be installed at the factory and is not intended for field installation.

- Page 24 192.168.200.3, a NET mask of 255.255.255.0, and a local port of 9100. After starting the Device Installer software, you will see a screen similar to the picture below. Select the Search button to search for the XPORT device. 334M Operator’s Manual - 880060-0110...

- Page 25 Select Assign a specific IP address and select Next. This screen allows you to assign the IP Address and the Subnet Mask. You will need to obtain these two items from your network administrator and select Next. 334M Operator’s Manual - 880060-0110...

- Page 26 Ethernet port selected as the active port. 3.3.2 Microcom Ethernet Option Board The Microcom Ethernet Option Board provides 4 methods of configuring the Ethernet port for usage. Please note that you will need to add the 192.168.200.3 address to your network in order to communicate to the printer via the Web Interface.

- Page 27 Once signed in, you will be directed to the configuration page of the application: NOTE: If using the Host name (Microcom) to change the IP Address, you must close the browser and repair the network. To do this, go into Network Connections, click on the Local Test Network, click on the Support tab, and then click the Repair button.

- Page 28 The File Upload section of the configuration screen may be used to send commands or files directly to the connected printer. Any feedback sent from the printer will be displayed in the window. Notice the ^D29 command in the Send Command line and the response in the window. 334M Operator’s Manual - 880060-0110 3-10...

- Page 29 3.3.2.3 Telnet Using Command Prompt – Microcom Ethernet Option Open the Microsoft command line and enter “telnet microcom”. The user name and password by default are both “mic”. The “v” option must be used to save and reboot to save any changes.

- Page 30 3.3.2.4 LDS1 Commands – Microcom Ethernet Option The LDS1 commands may also be sent to the printer to configure the Microcom Ethernet Option. The ^D177 command is used to configure the Ethernet option. A basic summary is included below; for more detailed information, please refer to the ^D177 command in Chapter 5.

- Page 31 Sending a ^A1^D108 would set the printer to the 2 Port Autoselect between the USB or the XPORT Ethernet port. Sending a ^A5^D108 or ^A6^D108 command would set the printer to either use the Microcom Ethernet Option board or to the 3 Port Auto Select (Serial, USB, or Microcom Ethernet). Qualsoft Windows Driver 3.4.1...

- Page 32 Chapter 3 Getting Started 2. Click the “Next” to continue the installation. 3. Wait for the installer to finish setting up the driver files. 334M Operator’s Manual - 880060-0110 3-14...

- Page 33 4. Select the New install or Uninstall existing driver if already running a Qualsoft version or if installing more than one printer, select the Install another printer model (Copy n). 5. Select the Model number of the printer being installed. 3-15 334M Operator’s Manual - 880060-0110...

- Page 34 Chapter 3 Getting Started 6. Select the communication port that is going to be used with the printer. 7. Select next to start the installation. 334M Operator’s Manual - 880060-0110 3-16...

- Page 35 This section will explain how to configure the Windows Driver for proper operation. The example below also shows a Microcom Thermal Printer under Unspecified devices. This is the USB driver that is loaded when the printer is powered on and the printer USB port is connected to the printer.

- Page 36 This opens the printer properties page. From this screen, Print Test Page may be selected to generate a test page that is sent to the printer. The test page is printed on the media size and type that are specified in the driver preferences. 334M Operator’s Manual - 880060-0110 3-18...

- Page 37 Getting Started Chapter 3 3.4.4 Printer Properties Page - Ports tab Selecting the Ports tab at the top allows the printer port to be changed if connecting to a different printer communication port. 3-19 334M Operator’s Manual - 880060-0110...

- Page 38 “About” tab. This shows the driver version number and release date. 3.4.6 Printing Preferences - Print tab The Print tab shows the available options that may be set. Typically, these are already set for proper operation and do not need to be adjusted. 334M Operator’s Manual - 880060-0110 3-20...

- Page 39 3.4.7 Print tab - Halftone Adjustment The Halftone Adjustment icon opens the dialog windows below. This allows the user to manipulate the image settings that the driver uses to produce images. 3-21 334M Operator’s Manual - 880060-0110...

- Page 40 3.4.9 Print tab - User Commands The User commands tab allows for the user to pass printer commands directly into the data stream. This is typically used for either troubleshooting or custom override commands. 334M Operator’s Manual - 880060-0110 3-22...

- Page 41 New icon to create a form size that matches your media. 3.4.10.4 Paper tab - Mirror Selecting this option will cause the image to appear like it being observed in a mirror. 3-23 334M Operator’s Manual - 880060-0110...

- Page 42 Continuous setting instructs the printer to ignore registration marks and will move media based on the form size settings. The Blackline setting cause the printer’s reflective sensor to look for a blackline mark and register based on the other Feed options. The Diecut and 334M Operator’s Manual - 880060-0110 3-24...

- Page 43 The printer uses its reflective sensor to detect the blackline as the media is passed through the printer and would use its transmissive sensor to detect the blowhole. 3-25 334M Operator’s Manual - 880060-0110...

- Page 44 Check with your printer model operator’s manual to see if a presenter is supported. This tab is ignored on models that do not support the use of a presenter. 334M Operator’s Manual - 880060-0110 3-26...

- Page 45 This field controls the time that the presenter will present the paper before retracting into the waste bin. 3.4.12.2.2 Configuration - Maximum Present Distance (inch) This is the maximum size that the printer will present when using the enabled mode. This value is in inches. 3-27 334M Operator’s Manual - 880060-0110...

- Page 46 The Disable Status checkbox is used to control whether the Port Monitor Status popup window is displayed or not. This is used to get real time status from the printer while printing via the Windows driver. 334M Operator’s Manual - 880060-0110 3-28...

- Page 47 Getting Started Chapter 3 3-29 334M Operator’s Manual - 880060-0110...

- Page 48 This will force the driver defaults of the printer model installed. 3.4.15 Status Messages This section describes the Windows compatible Status messages that are displayed in spooler and the Status Monitor feature found on the Modification tab. These messages may 334M Operator’s Manual - 880060-0110 3-30...

- Page 49 >HEAD UP< message. 3.4.15.10 PRINTER_STATUS_IO_ACTIVE This message is used to indicate that the optional >INPUT 2< sensor is active. The >INPUT 2< message is the equivalent LDS1 control language printer message that is reported. 3-31 334M Operator’s Manual - 880060-0110...

- Page 50 Input 2 provides a visual reference (green LED) when the sensor is “tripped.” The printer issues an >INPUT 2< when an enquiry response (^E) is requested. The active state (normal or inverted) of the Input 2 is determined by the software switch bank 3, location 4 (^D23 Command). 334M Operator’s Manual - 880060-0110 3-32...

-

Page 51: Sensor Input Ports

Sensor Input Ports 3.5 Loading Media The easy- to-release print head makes loading media into the Model 334M printer an easy process. Follow the instructions below to properly load the media. 1. Feed the media into the paper path, located on the back of the printer, until you feel resistance. -

Page 52: Loading Media

This section provides a description to familiarize you with the basic function of the Print Button and the Status Indicator Light. Print Button Status Indicator Light Figure 3-6 Print Button and Status Indicator Light 334M Operator’s Manual - 880060-0110 3-34... - Page 53 The printer has four primary modes of operation. The different types of modes have an impact on how the Print Button and the Status Indicator Light operate. This section is intended to provide the user with an explanation of these different modes. 3-35 334M Operator’s Manual - 880060-0110...

- Page 54 These default settings will remain in effect until the printer power is cycled or a Soft RESET command is issued (^D32). These are the only 2 ways to get out of the DIAGNOSTICS mode. 334M Operator’s Manual - 880060-0110 3-36...

-

Page 55: Status Label (Examples)

The printer has some basic requirements in order to operate reliably for years. The printer has some basic requirements in order to operate properly for years. Microcom has a staff that is committed to helping integrate our products. We will do as much as needed to ensure that the process goes correctly and smoothly. -

Page 56: Printer Dimensions

· Ambient Lighting and external light sources which can affect printer’s behavior. · Keeping the printer cool and free from dust. 3.8.1 Environmental Considerations The operating environment for Microcom printers is listed below. - Relative humidity: 10-85% non-condensing - Operation Temperature: 40° to 104° F (5° to 40° C) 3.8.2... - Page 57 3.8.4 Designing a Roll Support Media roll supports may be purchased from Microcom. If you are designing a custom roll support, please be aware of the following design guidelines. • Implement a simple design which allows the media to be gently placed in the kiosk.

- Page 58 • Cables that are near the printer, media path, or media should be tied to the kiosk chassis or printer mounting hardware. The operator can accidentally disconnect the printer or other kiosk components when maintaining the kiosk. Cabling must not interfere with the proper 334M Operator’s Manual - 880060-0110 3-40...

- Page 59 Power supplies sold by Microcom Corporation have gone through rigorous testing to ensure the proper function of the printer. If a non-Microcom supplied power supply is used with the printer, it must comply with the requirements of that printer.

- Page 60 4. Go to the Power Management tab under the Properties. 5. Uncheck the “Allow the computer to turn off this device to save power”. 6. Select OK and repeat for the remaining USB hubs. 334M Operator’s Manual - 880060-0110 3-42...

- Page 61 DOS COPY (for example: C:\>COPY FILENAME COM1) command. When using DOS, set the communications port up using the DOS MODE (for example: C:\>MODE 334M Operator’s Manual - 880060-0110...

-

Page 62: Mct Window Example

Print head Dots/mm Dots/inch Inch/Dot 0.0049 0.0033 EXAMPLE: To enter the width of a label that is 2” wide when using a 203dpi head, the value entered would be 406 (2” x 203 dots/in. = 406). 334M Operator’s Manual - 880060-0110... - Page 63 ^D2 <CR> Text data is coming. Microcom <CR> Text data string #1. Corporation <CR> Text data string #2. Thermal Printing Solutions <CR> Text data string #3. 012345 <CR> Text data string #4. ^D3 <CR> Print label. 334M Operator’s Manual - 880060-0110...

-

Page 64: 3X3 Sample Label

The label header consists of eleven parameters that control the media layout as well as printer configuration. A comma (,) delimiter is used to separate the parameters and a carriage return is required to terminate the header. 334M Operator’s Manual - 880060-0110... -

Page 65: Header Elements

Dot or pixel size varies depending upon the print resolution of the print head. Two print resolutions are currently available for the 334M printer (203 DPI and 300 DPI). The dot size of a 203 dots per inch head (8 dots/mm) is 0.0049”. The dot size of a 300 dots per inch head (12 dots/mm) is 0.0032”. - Page 66 DPS value to a lower setting as shown on Table 4-2. Generally, better print quality is achieved by printing at lower speeds, however this is also dependent on the media and contrast settings as well. 334M Operator’s Manual - 880060-0110...

- Page 67 This is referred to as “transmissive” sensing. The label sample (Error! Reference source not found.) is die-cut, therefore, the LCB is set to “0”. 334M Operator’s Manual - 880060-0110...

- Page 68 This parameter is required to properly register print on each label. The table below lists proper SPG settings for particular printer configurations when the LSY is greater than the parameter value. Model/Print Head DPI D2G Value 334M – 203 DPI 334M Operator’s Manual - 880060-0110...

- Page 69 GAP header parameter. Calculation Examples: Die-cut Media: A 334M 203 DPI printer being used with 3" x 1" media containing a .125" die-cut gap. The SPG would be calculated as follows: SPG = (D2G + LSY - DRM) mod (LSY + SBL)

- Page 70 (“,”). A carriage return must follow each format field for proper operation to occur. The values entered must be positive integers for all of the parameters of the format field. 334M Operator’s Manual - 880060-0110 4-10...

-

Page 71: Label Format Field Elements

A TSN of “2” accesses the second line of data, and so forth. The text data is the text that follows the “^D2<CR>” command in the label’s layout. A graphic image field must point to a text string that contains at least one character. The maximum value for a TSN is 65536. 4-11 334M Operator’s Manual - 880060-0110... - Page 72 All of the TCI values used by the 334M printer are listed in Table 4-4 below. For example, a TCI of “1” for the text string data “012345” would print the text “012345” while a TCI of “15” would produce an “Interleaved 2 of 5 symbol”.

- Page 73 Code 93 Symbol PDF-417 Symbol Datamatrix Symbol Intelligent Mail Barcode Planetcode Symbol UCC/EAN 128 Symbol Text with EAN 128 Information Aztec Symbol QR Code * Human Readable - Refer to Chapter 8 Table 4-4 TCI Values 4-13 334M Operator’s Manual - 880060-0110...

- Page 74 6 and 7 for additional information regarding downloadable fonts and graphics. For example: If a graphic had been stored into RAM (volatile) memory slot 1 (see Chapter 5 for additional information), the proper TCI would be “8” and the CGN value would be “1”. 334M Operator’s Manual - 880060-0110 4-14...

- Page 75 Swiss™721 Bold 90 degree Swiss™721 Bold 0 degree Swiss™721 Bold 90 degree Swiss™721 Bold 0 degree Swiss™721 Bold 90 degree Swiss™721 Bold 0 degree Swiss™721 Bold 90 degree OCR-A Normal 0 degree OCR-A Normal 90 degree 4-15 334M Operator’s Manual - 880060-0110...

- Page 76 Table 4-7 CGN—Bar Code Symbologies * These Symbols must use the CMX or CMY multipliers by 2 to produce an 80% ratio. ** The “FO” field represents the available Field Orientation or print rotation. 334M Operator’s Manual - 880060-0110 4-16...

- Page 77 CMY would be the actual height in thermal dots. For bar codes with a FO of 90 & 270 degree rotation, the CMX would be the actual height in thermal dots while the CMY parameter would be the multiplier. 4-17 334M Operator’s Manual - 880060-0110...

- Page 78 An example of two lines drawn on a label is shown in Error! Reference source not found.. This 3 x 3” label was designed for a 424M printer with a 300 DPI print head. 334M Operator’s Manual - 880060-0110 4-18...

-

Page 79: Line Draw Sample

This is a list of the first label format field element mnemonics for the sample label in Error! Reference source not found.: TSN, XB, YB, CC, TCI, CGN, FO, FJ, CMX, CMY, CS, TSP, , , AN 1, 340, 750, 600, , , , 0 4-19 334M Operator’s Manual - 880060-0110... -

Page 80: Label Format Line Draw

CC (Character Count) This element is not used in line draw. No value is necessary, however, a comma needs to be entered to acknowledge the position. TCI (Text Conversion Identifier) The TCI is always set to a “6” for line draw. 334M Operator’s Manual - 880060-0110 4-20... - Page 81 Format Fields defining the line draw and the text fields. The size of the box is not defined by the text. Adjustment to the size of the box must be made by adjusting the line draw coordinates. 4-21 334M Operator’s Manual - 880060-0110...

-

Page 82: Reverse Video Sample

It is possible to create a reverse video effect with barcodes using this method. ^D57 5,960,900,20,40,7,0,1,420,0,0 1,640,700,8,1,5,0,4,2,2,,,,,8 2,640,591,11,1,5,0,4,2,2,,,,,8 3,640,465,26,1,3,0,4,2,2,,,,,8 4,640,350,6,1,3,0,4,2,2,,,,,8 4,640,50,6,16,3,,4,5,150,,,,,1 ^D56 Microcom Corporation Thermal Printing Solutions 012345 Figure 4-8 True Reverse Video Sample 334M Operator’s Manual - 880060-0110 4-22... - Page 83 “control B” is shorter, it is easier to use in direct terminal mode. In general it is better to use the ^D2 command sequence inside a file or program to assist in trouble-shooting the format. 334M Operator’s Manual - 880060-0110...

- Page 84 (D23 -SW3 bit 7), which is required if saving graphics, the ^E will not function. This means that if the printer is going to be using binary compression, the 5 NULL’s method should be used to request status instead of the ^E command. 334M Operator’s Manual - 880060-0110...

- Page 85 >INPUT 2< Input sensor #2 active >TRAY FULL< Printed label tray is full >PRINTER PAUSED< Printer is paused >TOF ERROR< Top of Form is not sensed properly >OVER VDD< VDD voltage is out of operational range 334M Operator’s Manual - 880060-0110...

- Page 86 The flash was unable to erase at the SECTOR n< memory sector noted by the “n” Table . Each string is represented by a single byte with nothing separating them. The end of the response is terminated with a 0xFF character. 334M Operator’s Manual - 880060-0110...

- Page 87 The printer failed to read and verify the FAILED< configuration parameters are present. >ERASE FAILED FOR The flash was unable to erase at the SECTOR n< memory sector noted by the “n” Table 5-1 Enquiry Responses 334M Operator’s Manual - 880060-0110...

- Page 88 Port #1 Parity Enable: Turns printer port #1 parity ON or OFF for serial communication. 1 = Disable Parity (NONE) 0 = Enable Parity Echo: If this feature is enabled, the printer will echo all received characters to the serial port. 1 = Enable 0 = Disable 334M Operator’s Manual - 880060-0110...

- Page 89 6,7,8 Power-up Format: These switches work in conjunction with switch location 5 above. They determine which stored format is loaded at power-up. The printer can be instructed not to load a format at power- up by setting all three switches to 0. 334M Operator’s Manual - 880060-0110...

- Page 90 Accept “|” for Ctrl: Sets whether the “pipe” character will be interpreted the same as the “Ctrl” key. The “pipe” character is the <SHIFT> + \ key. 1 = Disable 0 = Enable (<|> key functions as <Ctrl> key) 334M Operator’s Manual - 880060-0110...

- Page 91 Slashed Zeros: If enabled, the printer will print a slash through the embedded zero (“0”) characters. 1 = Enable 0 = Disable External Print Request: (Call Microcom for more information.) 1 = Enable 0 = Disable Stock Out function: Enable this function to get a >LOW STOCK<...

- Page 92 3 Type of Top-Of-Form Sensor: The leading edge of the label stock can be sensed using either a reflective sensor or a transmissive sensor. The correct type of sensor is determined by the printer hardware configuration being used. 1 = TOF is TRANSMISSIVE 334M Operator’s Manual - 880060-0110 5-10...

- Page 93 >TRAY FULL< error condition when the printer is used with the optional catch tray on the Model 424 printer. This bit will also determine the printer’s response when pin 4 of P17 is active. Reserved 5-11 334M Operator’s Manual - 880060-0110...

- Page 94 “>IO 0nH< where “n” is a hex number from 0 to F. Example: A status of >IO 05H< would indicate that inputs 1 and 3 are active (24v) and that inputs 2 and 4 are inactive (0v); 05H = 0101(binary). 334M Operator’s Manual - 880060-0110 5-12...

- Page 95 ^D68<CR>05<CR> command (the <CR> indicates carriage return characters) would be issued. The printer ignores the LF characters, so a <CR+LF> is interpreted as a <CR> as well) would be sent to the printer. 5-13 334M Operator’s Manual - 880060-0110...

- Page 96 NOTE: Default power up will disable I/O mode. The P17 and P21 connectors are 8 pin Molex part number #51021- 0800 and Microcom Corporation part number 510129-0008. The pin out is as follows (the square pad denotes pin one on the PCB): Connector P17 is the input port.

- Page 97 Disable System Parameter Saving: When enabled, the printer will not save the non-volatile system parameters on power downs. The ^A1^D143 will continue to save system parameters. 1 = Disable system parameter saving 0 = Enable system parameter saving 5-15 334M Operator’s Manual - 880060-0110...

- Page 98 When enabled, the printer will report the >LPD STOCK JAM< message if the printer was sent a print job and the LTS did not detect the media exiting the printer. 1 = Enable LTS Jam Detection 0 = Disable LTS Jam Detection 334M Operator’s Manual - 880060-0110 5-16...

- Page 99 “Active” port. The USB port will be selected if the USB cable is connected between the printer and a PC that is powered “ON.” The RS-232 port will be selected if the USB cable is not plugged in and a character comes 5-17 334M Operator’s Manual - 880060-0110...

- Page 100 USB port. Microcom Ethernet option board: When the active port is set to a 5, the printer will ignore other ports being plugged into the machine and will only be active on the Microcom Ethernet option board.

- Page 101 Set the MAC Address: The MAC address is assigned at the Factory and should not be changed. If the CPU connected to the Ethernet Option Board is replaced, the MAC will need to be set. Contact Microcom Corporation for a valid MAC address if needed.

- Page 102 The printer’s Ethernet interface will send the printer status byte to the HOST every few milliseconds. This is the command byte configuration: 334M Operator’s Manual - 880060-0110 5-20...

- Page 103 General Purpose mode. The printer will NOT go into General Purpose Mode until a power cycle occurs to cause the data to be stored in FLASH memory. This command is nonvolatile, so once the General Purpose 5-21 334M Operator’s Manual - 880060-0110...

- Page 104 All outputs are active high. 24.0 VDC = high 0.0 VDC = low Signal logic levels: The signals are active high and must be between +15Vdc and +24Vdc to be “1”. The signals must drop below +10Vdc to be “0”. 334M Operator’s Manual - 880060-0110 5-22...

- Page 105 LDS command protocol. This mode also uses additional baud rates for higher speed image printing. Protocol: 1. The HOST sends a format to the printer that identifies the media being used: Example: ^D57[CR][LF] 1,1280,940,,,3,0,1[CR][LF] ^D56[CR][LF] 5-23 334M Operator’s Manual - 880060-0110...

- Page 106 Higher contrast settings will reduce the life of the print head. 5.4.2.1 Adjust Contrast Base (Non-volatile - ^D36) This command is used to adjust overall contrast on all formats. 334M Operator’s Manual - 880060-0110 5-24...

- Page 107 While the printer is designed to work with a wide variety of label media, it is sometimes necessary to adjust the printer’s thresholds in order to obtain proper registration and operation. The numerical value in which the printer senses a registration mark is referred as the threshold value. 5-25 334M Operator’s Manual - 880060-0110...

- Page 108 8 for more information. Printer Model Number Transmissive Dot2Gap 203dpi 438 300dpi 438 203dpi 438T Series 300dpi 438T Series 203dpi 238/338M Series 300dpi 238/338M Series 203dpi 334M 300dpi 334M Table 5-3 Transmissive Dot2Gap Values 334M Operator’s Manual - 880060-0110 5-26...

- Page 109 Uses the values obtained for header variables instead of what is specified in the format file’s header. Automatically sizes the label and displays to the terminal screen the values for the format header. Same as ^A2^D39<CR>, but the values will be printed on the media. 5-27 334M Operator’s Manual - 880060-0110...

- Page 110 The saved format or template is typically a format with the header configured for the media size/type being used and is configured to not print 334M Operator’s Manual - 880060-0110 5-28...

- Page 111 4. The feed forward stops and then the printer retracts the media a programmable distance as set by the ^D123 command and stops. Set ^D25, bits 6 and 7 to enable the AutoLoad+TOF feature. 5-29 334M Operator’s Manual - 880060-0110...

- Page 112 5.6.1 Basic Printing Commands COMMAND Print Command: (Equivalent ^C) Informs the printer to print a single label or start printing a batch of labels. Since commands are processed in the order 334M Operator’s Manual - 880060-0110 5-30...

- Page 113 Peel-n-Dispense mode and applicators. Label Header Parameter Override Commands It is possible to override label header parameters by adding one or more of the following commands after the ^D2 and before the print command. 5-31 334M Operator’s Manual - 880060-0110...

- Page 114 Disable Serial Number Function: This command disables both single and multiple serial number functions. The next three commands deal with the single serial number functions: Load Text String Number to Increment/Decrement: Instructs the printer 334M Operator’s Manual - 880060-0110 5-32...

- Page 115 ^A3^D75 <CR> ^D2 <CR> 20 <CR> ^D3 <CR> This format would enable the decrement function (^A2^D86). Select text string #1 to decrement (^A1^D84), load the step value of 5 (^A5^D85) and then print three serialized 5-33 334M Operator’s Manual - 880060-0110...

- Page 116 ^D62 command is sent. The following is an example of Pre=padded text: ^D57<CR> 3,1280,900,,38,7,0,1,385,0,0 <CR> 1,300,500,7,1,5<CR> 2,300,400,7,1,5<CR> 3,300,300,7,1,5<CR> ^D56 <CR> ^D2 <CR> A<CR> B<CR> 334M Operator’s Manual - 880060-0110 5-34...

- Page 117 ^D64 command. The following is an example of the ^D61, ^D63, and ^D64 commands: ^A0^D64<CR> (Clears any old settings) ^D57<CR> 6,1280,900,,38,7,0,1,385,0,0 <CR> 1,300,300,20,1,4<CR> 2,300,250,20,1,4<CR> 3,300,200,20,1,4<CR> 4,300,150,20,1,4<CR> 5,300,100,20,1,4<CR> 6,300,50,20,1,4<CR> 5-35 334M Operator’s Manual - 880060-0110...

- Page 118 The same distance will be used to retract the media to the print head for printing once the next job is sent. 334M Operator’s Manual - 880060-0110 5-36...

- Page 119 The valid arguments for the X value are the DPS speed values for the printer. Please refer to the DPS and ^D49 sections for valid speed values. 5-37 334M Operator’s Manual - 880060-0110...

- Page 120 (^D97), peel-n-dispense (^D98), and cutter (^D99) commands. It is used to adjust the number of steps the printer will advance the media after printing has stopped and then retract the same distance so that media is not wasted. While the maximum value is 64,000 steps, it 334M Operator’s Manual - 880060-0110 5-38...

- Page 121 The ^Axx selects the memory slot (1- 128) into which the format is to be saved. A format file must be terminated by an ESC (HEX 1B) or “[“(left bracket) character to save the format. 5-39 334M Operator’s Manual - 880060-0110...

- Page 122 NOTES: RAM GRAPHICS can extend beyond the starting slot # into sequential ones. RAM formats are numbered #1 to #128 (RAM FONTS are limited to 64K in size.) xxyy 127 Save FONTS to RAM. (See Chapter 7, Downloadable Fonts) 334M Operator’s Manual - 880060-0110 5-40...

- Page 123 Valid values for Axx are 1 to 255. The user selects the CGN #xx that will be cleared. The ^D119 command may be used to verify what memory Slot #’s are available in FLASH for storage. 5-41 334M Operator’s Manual - 880060-0110...

- Page 124 The following 3 parameters are included in the FONT file when it is created: 1. Memory destination: RAM or FLASH 2. Memory File #: 1à255 (this is the CGN #) 3. Rotation: 0°, 90°, 180°, or 270° 334M Operator’s Manual - 880060-0110 5-42...

- Page 125 After this command is finished, the label may be printed by sending the ^C print command. NOTE: If the FORMAT file contains a print command, then the label will be printed at the end of this command. 5-43 334M Operator’s Manual - 880060-0110...

- Page 126 Hint: Use command ^D119 to confirm that FONTS and GRAPHICS were erased in user FLASH memory, and that all downloaded FORMATS, FONTS, and GRAPHICS were erased in RAM. 334M Operator’s Manual - 880060-0110 5-44...

- Page 127 ^A62519^D7 command will update the printer’s bootloader, application, and embedded font set. This process requires some interactivity with the printer and failure to follow the proper process will cause the printer to become inoperable. Please contact your Microcom Corporation Representative for more information. 5.14...

- Page 128 This command is a volatile command with a default of 0. The ^A1^D145 command lists the current setting under the Post Takeup Time. 25 msec 334M Operator’s Manual - 880060-0110 5-46...

- Page 129 Sensor Status Byte: This command is used to report the real time sensor status of all the printer sensors. When the ^D163 command is issued, the printer returns a byte status that is defined below. 5-47 334M Operator’s Manual - 880060-0110...

- Page 130 X value in steps after the main motor starts. The valid range is 0 to 65535 steps. Please note that if a value is selected that exceeds to format LSY, the takeup would not turn on. 334M Operator’s Manual - 880060-0110 5-48...

- Page 131 Chapter 6: Downloadable Graphics The 334M printer allows the user to download their own GRAPHICS and store the GRAPHICS in either non-volatile FLASH memory, or in volatile RAM memory. 6.1 FLASH Data Types The printer’s FLASH memory provides non-volatile storage for several types of data: 1.

- Page 132 Press [ENTER] C:\>BMP2MIC.exe 2. Type the conversion utility name and required information at the command prompt. Press [ENTER]. BMP2MIC - Convert BMP Graphic File to Microcom Printer Graphic Rev. 2.01 Copyright 1998-2005 Microcom Corp., Westerville, Ohio Use: BMP2MIC <infile> <outfile> <outtype> <slotnum> <limit> <destination>...

- Page 133 .<CR> <------------------------- “.” (Period) in the format to represent the graphic to be printed ^D3 <CR> 6.4 Graphic Download Methods The printer supports both compressed and uncompressed graphic downloads. The compressed format shortens the download time by reducing the number of bytes sent to the 334M Operator’s Manual - 880060-0110...

- Page 134 The following sections are provided to developers who wish to create usable GRAPHIC images within their own applications. Commands in the following section are not typically seen for users using Microcom GRAPHIC utilities. 6.5.1 Save Compressed Graphics to RAM (D107) The following is the format of the ^D107 command when used to store a compressed GRAPHIC image file into RAM.

- Page 135 “<” character. (i.e. >192690<) Save GRAPHICs or FONTs into RAM Memory without Compression: This command is intended for legacy support only and Microcom Corporation recommends either the ^D104 or ^D107 commands. Fonts must be less than 64KB for this command to function.

- Page 136 Chapter 6 Downloadable Graphics 334M Operator’s Manual - 880060-0110...

- Page 137 CGN refers to the memory slot location of the downloaded font. Nonvolatile fonts are accessed thru TCI “7”. The following section details the process required to convert and download fonts to the printer. The conversion utilities “Fontcv16.exe” may be downloaded at http://www.microcomcorp.com. 334M Operator’s Manual - 880060-0100...

- Page 138 7-bit data connections. The uncompressed (^D104) is usable on either 7 or 8-bit connections and is more flexible but encodes using ASCII-HEX. This results in a much larger file size. Microcom Corporation recommends the use of the compressed format when possible.

- Page 139 CGN #24 and TCI #7. The ^A0124^D135 command will be right at the beginning of the file. So the ^D135 command is never sent by itself, it’s always in a FONT download file, and the user never really sees it. 334M Operator’s Manual - 880060-0110...

- Page 140 This command clears all downloadable fonts, graphics, and stored label formats. List Memory Bytes Available: The printer will send the “>” character followed by the amount of available bytes and then finally a “<” character. (i.e. >192690<) 334M Operator’s Manual - 880060-0110...

- Page 141 Chapter 7 COMMAND Load GRAPHIC or FONT into RAM Memory without Compression: This command is intended for legacy support only and Microcom Corporation recommends either the ^D104 or ^D107 commands. Fonts must be less than 64KB for this command to function.

- Page 142 Chapter 7 Downloadable Fonts 334M Operator’s Manual - 880060-0110...

- Page 143 UPC-E bar codes do not use inter-character spacing, therefore the character spacing (CS) element must be defaulted. The chart listed in Table 14 illustrates how the 11 digits are reduced to only 6 using the “zero suppression” compression. 334M Operator’s Manual - 880060-0110...

- Page 144 (“*”) character, which is reserved for this purpose. This symbology uses 2:1, 3:1, 4:2, 5:2, and 8:3 ratios, which may be selected using the CGN parameter. Although most specifications require a specific inter-character 334M Operator’s Manual - 880060-0110...

- Page 145 Databar has been identified to solve problems in the grocery industry and in healthcare, where items are too small to allow for older barcode symbology. The printer should have binary compression disabled before using GS1 Databar. 334M Operator’s Manual - 880060-0110...

-

Page 146: Gs1 Databar Omni-Directional

The barcode contains a separator pattern, containing no data, which has a height equal to 3 times the X dimension. This symbology may be scanned omni-directionally. This symbology does not allow for human readable text with the barcode. 334M Operator’s Manual - 880060-0110... -

Page 147: Gs1 Databar Stacked Omni-Directional Sample

These are the 7 parameters that MUST follow the ^D114 command: 1) Type of GS1 Databar barcode 2) Multiplier 3) Segments per row 4) X undercut 5) Y undercut 6) Separator Height 7) Data to be encoded 334M Operator’s Manual - 880060-0110... -

Page 148: Gs1 Databar Sample Label Format

Postnet is a numeric-only symbology that is commonly used in postal application to sort mail. The five-digit zip or five-digit zip plus four-digit extension may be used to generate this Postnet (TCI 36) bar code. Example: 12345 or 12345-1234. 334M Operator’s Manual - 880060-0110... - Page 149 B if no start code is defined. The printer will also not attempt to compress the data unless subset C is used. Once in subset C the user must send the appropriate code (#n) to return to either subset A or B. 334M Operator’s Manual - 880060-0110...

-

Page 150: Code 128 Subset Switching

The Portable Data File 417 or PDF-417 is a two-dimensional stacked symbology that is capable of encoding the entire ASCII character set, 2710 digits, and up to 1108 bytes in a single bar code. The requirements for generating a PDF-417 symbology are the text data, 334M Operator’s Manual - 880060-0110... - Page 151 0. This parameter can only be used if the ECC% parameter is set to 0. Refer to Table 17 for the valid ECC_Level values and their equivalent correction code words. A carriage return character must be used to terminate this field. 334M Operator’s Manual - 880060-0110...

-

Page 152: Sample Format #1

The following format samples show how to generate a PDF-417 bar code: Sample Format #1: ^D77<CR> :PDF-417 bar code data^\ 3<CR> 30<CR> 0<CR> 0<CR> 0<CR> 2:1<CR> ^D57<CR> 2,640,609,,25,35,0,1,284<CR> Text string 1,190,300,1,46<CR> 2,190,200,11,1,5<CR> ^D56<CR> ^D2<CR> P<CR> Text string<CR> ^D3<CR> Figure 8-9 PDF-417 Sample Format #1 334M Operator’s Manual - 880060-0110 8-10... -

Page 153: Sample Format #2

The D164 command is used to receive and process the Datamatrix barcode with the elements discussed below. Once the Datamatrix barcode data is entered and processed, the barcode image may be placed using the normal format field by using a TCI of 47. 8-11 334M Operator’s Manual - 880060-0110... - Page 154 This parameter is used to set the width or row size of the Data Matrix symbol. Zero entry will invoke auto sizing. Rotation - 1 0 = 0 degree rotation 1 = 180 degree counter clockwise rotation. 2 = 90 degree counter clockwise rotation. 3 = 270 degree counter clockwise rotation. 334M Operator’s Manual - 880060-0110 8-12...

- Page 155 The printer default is set to “Auto”, which will automatically switch to the most efficient encoding scheme for the data provided. Consult the Aim International Technical Specification for Data Matrix ECC 200 requirements for additional information. 8-13 334M Operator’s Manual - 880060-0110...

- Page 156 X12 encoding scheme is use to encode the standard ANSI X12 electronic data interchange characters, which are compacted three data characters to two codewords in a manner similar to C40 encoding. Edifact Encoding Scheme 334M Operator’s Manual - 880060-0110 8-14...

- Page 157 Barcode ID field. The CGN default is a 0 so if only one barcode is present and the Barcode ID is a 0, nothing has to be entered as the CGN. Data Data to be converted to 2D Data Matrix Barcode, maximum number of characters supported in the printer implementation is 1000. 8-15 334M Operator’s Manual - 880060-0110...

- Page 158 A maximum of 32 characters including the dash is allowed. Once the Intelligent Mail barcode data is entered and processed, the barcode image may be placed using the normal format field by using a TCI of 48. 334M Operator’s Manual - 880060-0110 8-16...

-

Page 159: Intelligent Mail Barcode Bars

Special Services Tracking Code Customer Identifier 567094 Sequence Number 987654321 Routing Code Delivery Point ZIP Code 0, 5, 9, or 11 01234567891 Table 8-7 Intelligent Mail Barcode Structure Complete data string from above: 0123456709498765432101234567891 01234567094987654321-01234567891 8-17 334M Operator’s Manual - 880060-0110... - Page 160 1 = 180 degree counter clockwise rotation. 2 = 90 degree counter clockwise rotation. 3 = 270 degree counter clockwise rotation. The second set of ASCII digits contains a valid planet code string with a <CR> as a 334M Operator’s Manual - 880060-0110 8-18...

- Page 161 3 alphabetic characters (fixed length) 3 numeric characters (fixed length) 3 alphanumeric characters (fixed length) a..3 3 alphabetic characters (variable length) n..3 3 numeric characters (variable length) 8-19 334M Operator’s Manual - 880060-0110...

- Page 162 325(***) Width, Diameter, or 2 Dimension, Feet n4+n6 326(***) Width, Diameter, or 2 Dimension, Yards n4+n6 327(***) Depth Thickness, Height or 3 Dimension, Inches n4+n6 328(***) Depth Thickness, Height or 3 Dimension, Feet n4+n6 334M Operator’s Manual - 880060-0110 8-20...

- Page 163 360(***) Volume, Quarts n4+n6 361(***) Volume, Gallons n4+n6 362(***) Gross Volume, Quarts n4+n6 363(***) Gross Volume, Gallons n4+n6 364(***) Volume, Cubic Inches n4+n6 365(***) Volume, Cubic Feet n4+n6 366(***) Volume, Cubic Yards n4+n6 8-21 334M Operator’s Manual - 880060-0110...

- Page 164 Mutually Agreed, Between Trading Partners or FACT n2+an..30 Intra-Company (Internal) n2+an..30 Intra-Company (Internal) n2+an..30 Intra-Company (Internal) n2+an..30 Intra-Company (Internal) n2+an..30 Internal-Carriers n2+an..30 Internal-Carriers n2+an..30 Intra-Company (Internal) n2+an..30 Intra-Company (Internal) n2+an..30 Internal n2+an..30 Table 8-8 UCC/EAN Application Identifiers 334M Operator’s Manual - 880060-0110 8-22...

- Page 165 The sample below shows how to generate a data matrix symbol: ^D193 <---------------------------------Start of Aztec Data 0 <----------------------------------------Size 0 <----------------------------------------Minimum error correction 0 <----------------------------------------Mode :0123456789^\<---------------------- Data to encode ^D57 2,1280,300,19,38,7,2,1,44,0,0 1,640,100,1,52,1,0,4,10,10 <---------- Multiplier (10, 10); TCI 52 1,640,25,11,7,10,0,4,2,2,,,,,0 ^D56 Aztec 8-23 334M Operator’s Manual - 880060-0110...

- Page 166 19x19 23x23 27x27 31x31 37x37 41x41 45x45 49x49 53x53 57x57 61x61 67x67 71x71 75x75 79x79 83x83 87x87 91x91 95x95 101x101 105x105 109x109 113x113 117x117 121x121 125x125 131x131 135x135 139x139 Table 8-9 Aztec Size Values 334M Operator’s Manual - 880060-0110 8-24...

- Page 167 The D194 command is used to receive and process the QR Code barcode with the elements discussed below. Once the QR Code barcode data is entered and processed, the barcode image may be placed using the normal format field by using a TCI of 53. 8-25 334M Operator’s Manual - 880060-0110...

- Page 168 This parameter is used to set the size the Aztec code to be generated. A value of “0” will generate an automatically scaled Aztec. The overall size of the barcode is controlled by the Size and by the formats X and Y multiplier values. 334M Operator’s Manual - 880060-0110 8-26...

- Page 169 Aztec Size Values Minimum Error Correction- 0 This parameter is used to set the Minimum Error Correction level. This parameter must be set to 0 for Auto if a non-Auto is selected for the size parameter. 8-27 334M Operator’s Manual - 880060-0110...

- Page 170 Y multiplied (CMY), the space between characters is also multiplied by the printer internally to maintain the correct ratio. When multiplying bar codes use the default value for the spacing element (SP) in the field format 334M Operator’s Manual - 880060-0110 8-28...

-

Page 171: Bar Code Rotations

For bar codes that do not require extended bars, simply access the data that the bar code is using with a second field that generates a text representation of the data and insert in the desired position. 8-29 334M Operator’s Manual - 880060-0110... -

Page 172: Upc-A Text/Extended Bars

The main purpose of these codes is to add the automatically calculated check digit character to the human readable code. The data used to generate the human readable code should be the same data used to generate the bar code. 334M Operator’s Manual - 880060-0110 8-30... - Page 173 Sample Format: ^D57<CR> 4,575,609,,25,35,0,1,285,0,0<CR> 1,200,418,11,12,,,,2,50<CR> 1,178,400,11,32,,,,2,2<CR> 1,200,150,11,12,,,,2,50<CR> 1,178,125,11,32,,,,2,2<CR> ^D56<CR> ^D2<CR> 01234567890<CR> ^D3<CR> 8-31 334M Operator’s Manual - 880060-0110...

- Page 174 Chapter 8 Bar Codes 334M Operator’s Manual - 880060-0110 8-32...

-

Page 175: Code Page - 865

The 334M printer provides 15 standard code pages. Please note that the printer implements the codes from 32 up. Code numbers below 32 are printed using the 334M’s standard letters. These are the Code Pages that are implemented in the printer: 1. -

Page 176: Code Page - Default

Code Pages The Default Code Page is selected when SW4:(5-8) = 0000. Figure 9-1 below is an actual printout from a 424M printer set to use the Default Code Page. Figure 9-1 Code Page - Default 334M Operator’s Manual - 880060-0110... -

Page 177: Code Page - Danish

Danish Code Page The Danish Code Page is selected when SW4:(5-8) = 0001. Figure 9-2 below is an actual printout from a 424M printer set to use the Danish Code Page. Figure 9-2 Code Page – Danish 334M Operator’s Manual - 880060-0110... - Page 178 The 860 Code Page is selected when SW4:(5-8) = 0010. Figure 9-3 below is an actual printout from a 424M printer set to use the 860 Code Page. This code page is also known as DOSPortuguese. Figure 9-3 Code Page - 860 334M Operator’s Manual - 880060-0110...

-

Page 179: Code Page - Spanish

Spanish Code Page The Spanish Code Page is selected when SW4:(5-8) = 0011. Figure 9-4 below is an actual printout from a 424M printer set to use the Spanish Code Page. Figure 9-4 Code Page - Spanish 334M Operator’s Manual - 880060-0110... - Page 180 European languages such as French, Spanish, Catalan, Basque, Portuguese, Italian, Albanian, Rhaeto-Romanic, Dutch, German, Danish, Swedish, Norwegian, Finnish, Faroese, Icelandic, Irish, Scottish, and English. It covers the entire North American continent, Australia, and much of Africa. 334M Operator’s Manual - 880060-0110...

- Page 181 Code Page Switching Chapter 9 Figure 9-5 Code Page - 850 334M Operator’s Manual - 880060-0110...

-

Page 182: Code Page - German

German Code Page The German Code Page is selected when SW4:(5-8) = 0101. Figure 9-6 below is an actual printout from a 424M printer set to use the German Code Page. Figure 9-6 Code Page - German 334M Operator’s Manual - 880060-0110... - Page 183 The 865 Code Page is selected when SW4:(5-8) = 0110. Figure 9-7 below is an actual printout from a 424M printer set to use the 865 Code Page. This code page is also known as DOSNordic. Figure 9-7 Code Page - 865 334M Operator’s Manual - 880060-0110...

-

Page 184: Code Page - Swiss

424M printer set to use the 852 Code Page. This code page is also known as DOSLatin2 (Eastern Europe). Latin2 covers the languages of Central and Eastern Europe: Czech, Hungarian, Polish, Romanian, Croatian, Slovak, Slovenian, and Serbian. 334M Operator’s Manual - 880060-0110 9-10... - Page 185 Code Page Switching Chapter 9 Figure 9-9 Code Page - 852 9-11 334M Operator’s Manual - 880060-0110...

-

Page 186: Code Page - French

The French Code Page is selected when SW4:(5-8) = 1001. Figure 9-10 below is an actual printout from a 424M printer set to use the French Code Page. Figure 9-10 Code Page - French 334M Operator’s Manual - 880060-0110 9-12... - Page 187 The 863 Code Page is selected when SW4:(5-8) = 1010. Figure 9-11 below is an actual printout from a 424M printer set to use the 863 Code Page. This code page is also known as DOSCanadaF. Figure 9-11 Code Page - 863 9-13 334M Operator’s Manual - 880060-0110...

-

Page 188: Code Page - Swedish

The 437 Code Page is selected when SW4:(5-8) = 1100. Figure 9-13 below is an actual printout from a 424M printer set to use the 437 Code Page. This code page is also known as DOSLatinUS. 334M Operator’s Manual - 880060-0110 9-14... - Page 189 Code Page Switching Chapter 9 Figure 9-13 Code Page - 437 9-15 334M Operator’s Manual - 880060-0110...

-

Page 190: Code Page - Italian

The Italian Code Page is selected when SW4:(5-8) = 1101. Figure 9-14 below is an actual printout from a 424M printer set to use the Italian Code Page. Figure 9-14 Code Page - Italian 334M Operator’s Manual - 880060-0110 9-16... -

Page 191: Code Page - British

The British Code Page is selected when SW4:(5-8) = 1110. Figure 9-15 below is an actual printout from a 424M printer set to use the British Code Page. Figure 9-15 Code Page - British 9-17 334M Operator’s Manual - 880060-0110... -

Page 192: Code Page - Usa

The USA Code Page is selected when SW4:(5-8) = 1111. Figure 9-16 below is an actual printout from a 424M printer set to use the USA Code Page. Figure 9-16 Code Page – USA 334M Operator’s Manual - 880060-0110 9-18... - Page 193 It is important to note that the optimum print quality and print head life is achieved by maintaining a clean printer and print head. A Microcom Corporation approved cleaning kit (part # 040005-0000) is available; contact your sales representative for purchasing information.

- Page 194 The necessary cleaning materials can be purchased through Microcom Corporation by contacting your sales representative and ordering the Cleaning Kit, part # 040005-0000. The print head should be cleaned after every roll of media or after every 512 feet of fanfold media (a typical stack of tag or fanfold media is approximately 3,200 tags).

-

Page 195: Inserting Cleaning Card

Place dampened cleaning card into printer as shown… … then close and latch print head assembly. Figure 10-1 Inserting Cleaning Card Firmly grasp printer… …and slowly pull cleaning card out of printer Figure 10-2 Removing Cleaning Card 10-3 334M Operator’s Manual - 880060-0110... -

Page 196: Internal Cleaning

(Drive Roller can be rotated by hand.) Clean Peel Edge with lint-free cloth or swabs dampened with isopropyl alcohol. Figure 10-3 Internal Cleaning 334M Operator’s Manual - 880060-0110 10-4... -

Page 197: Print Head Thermal Elements

Figure 10-4 Print head Thermal Elements CAUTION: Isopropyl Alcohol should be used to clean the drive roller. The use of other cleaning solvents or materials is not recommended and may degrade the performance of the drive roller. 10-5 334M Operator’s Manual - 880060-0110... - Page 198 Chapter 10 Printer Maintenance 334M Operator’s Manual - 880060-0110 10-6...

- Page 199 ü Verify that the printer is powered on with the USB connected before turning power ü Verify that the printer and the host port communication parameters are set exactly the same. ü Contact your Service Representative. 11-1 334M Operator’s Manual - 880060-0110...

- Page 200 ü Cycle power to reset the printer. The status indicator light is flashing red in color: ü Generally, due to a power fail error. ü Verify that the AC line-voltage is present at the AC outlet. ü Cycle power. 334M Operator’s Manual - 880060-0110 11-2...

- Page 201 ü The intended memory slot is already occupied. ü Verify that the printer is properly configured for the type of download being sent. ü Clear memory and attempt download again. ü Verify that the format has been created properly. 11-3 334M Operator’s Manual - 880060-0110...

- Page 202 Chapter 11 Troubleshooting 334M Operator’s Manual - 880060-0110 11-4...

- Page 203 ^D32 Reset Printer ..........................5-24, 13-9 ^D33 Display Model and Revision Number ..................5-38, 13-9 ^D36 Adjust Contrast Base ........................5-24, 13-9 ^D39 Auto-Size Label ........................... 5-26, 13-9 ^D40 Clear Commands 41 thru 51 ....................... 5-31, 13-9 12-1 334M Operator’s Manual - 880060-0110...

- Page 204 Agency Approvals .............................. 1-1 Alphanumeric ..............................13-20 Application Identifiers..........................8-19, 8-23 Bar Code Symbologies ............................ 4-16 Codabar ................................. 8-8 Code128 automatic compression ........................8-7 Code128 manual compression ........................8-7 Code93 ................................8-8 EAN-13 ................................8-3 334M Operator’s Manual - 880060-0110 12-2...

- Page 205 Data Matrix Symbol ........................8-12, 8-13, 8-14 DCD ................................13-20 DCE ................................13-20 Die-cut media ..............................13-20 Direct Thermal ............................... 13-20 DOSCanadaF ..............................9-13 DOSLatin1 (Western Europe) ........................... 9-6 DOSLatin2 (Eastern Europe) .......................... 9-10 DOSLatinUS ..............................9-14 12-3 334M Operator’s Manual - 880060-0110...

- Page 206 LCB ............................ 4-7, 4-8, 5-31, 13-10 LSX ................................4-6 LSY ............................4-6, 4-8, 5-31, 13-9 OFX ............................4-10, 5-31, 13-10 OFY ............................4-10, 5-31, 13-10 SPG ............................4-8, 5-31, 13-10 WEB ..............................5-31, 13-9 LDSII ................................13-21 Limited Warranty .............................. 13-1 334M Operator’s Manual - 880060-0110 12-4...

- Page 207 Printer Weight ..............................1-1 Printer Width ..............................1-1 Printhead ............................13-20, 13-22 Return Material Authorization .......................... 13-3 Reverse Video ..............................4-21 RI .................................. 13-21 Rolled media ..............................13-21 Rotary Cutter ..............................13-21 RS-232 ................................13-21 12-5 334M Operator’s Manual - 880060-0110...

- Page 208 Tag stock ............................... 13-22 Temperature ..............................1-1 Thermal Printer Card ............................10-2 Troubleshooting ............................... 11-1 TXD ................................13-22 Unpacking ................................3-1 UPC-A Symbol ..............................8-1 UPC-E Symbol ............................. 8-1, 8-2, 8-3 USB................................13-22 Warranty ................................13-1 334M Operator’s Manual - 880060-0110 12-6...

-

Page 209: Table Of Contents

PDF-417 Sample Format #2 .................. 8-11 Intelligent Mail Barcode bars .................. 8-17 Bar Code Rotations ....................8-29 UPC-A Text/Extended Bars ..................8-30 Code Page - Default ....................9-2 Code Page – Danish ....................9-3 12-7 334M Operator’s Manual - 880060-0110... - Page 210 Code Page - Italian ....................9-16 Code Page - British ....................9-17 Code Page – USA ....................9-18 Inserting Cleaning Card ..................10-3 Removing Cleaning Card..................10-3 Internal Cleaning ....................10-4 Print head Thermal Elements ................10-5 334M Operator’s Manual - 880060-0110 12-8...

- Page 211 PDF-417 Sample Format #2 .................. 8-11 Intelligent Mail Barcode bars .................. 8-17 Bar Code Rotations ....................8-29 UPC-A Text/Extended Bars ..................8-30 Code Page - Default ....................9-2 Code Page – Danish ....................9-3 12-9 334M Operator’s Manual - 880060-0110...

- Page 212 Code Page - Italian ....................9-16 Code Page - British ....................9-17 Code Page – USA ....................9-18 Inserting Cleaning Card ..................10-3 Removing Cleaning Card..................10-3 Internal Cleaning ....................10-4 Print head Thermal Elements ................10-5 334M Operator’s Manual - 880060-0110 12-10...

- Page 213 Although the user is not required to purchase Microcom Corporation brand supplies, to the extent it is determined that the use of other supplies (such as non-approved label stock, ribbons, and cleaning solutions) shall have caused any defects in the thermal print head for which the warranty claim has been made, the user shall be responsible for Microcom Corporation’s...

- Page 214 13-2 334M Operator’s Manual - 880060-0110...

- Page 215 Return the defective item(s) for repair to the address listed above, freight and insurance prepaid. Upon receipt of an RMA number, the customer contact will be notified by a Microcom Corporation representative regarding repair charges, at which time the ship method will be determined.

- Page 216 13-4 334M Operator’s Manual - 880060-0110...

- Page 217 Print Command: Prints a single label or starts the printing of a batch of labels (Equivalent to ^C). Send Printer Status: (Equivalent to ^E). Update printer flash: This command is used to update the printer’s software which includes the application, the bootloader, and the embedded fonts. 334M Operator’s Manual - 880060-0110 13-5...

- Page 218 1 = Enable >RESTARTED< Response; 0 = Disable 1 = Disable Button; 0 = Enable 1 = Enable Print Repetition; 0 = Enable Form Feed 1 = Use Saved Format File; 0 = ROM Format 13-6 334M Operator’s Manual - 880060-0110...

- Page 219 1000 = 852 (8 bit) 1001 = French (7 bit ) 1010 = 863 (8 bit) 1011 = Swedish (7 bit) 1100 = 437 (8 bit) 1101 = Italian (7 bit) 1110 = British (7 bit) 334M Operator’s Manual - 880060-0110 13-7...

- Page 220 Software Bank Switch #7: A non-volatile command used to set the various functions identified below. ^AB12345678 Position: Reserved Reserved 1 = Disable System Parameter Saving; 0 = Enable 1 = Enable Finish Mode; 0 = Disable 13-8 334M Operator’s Manual - 880060-0110...

- Page 221 Load Label Height in dots (LSY): The ^Axx specifies the value. Load the Web Size in dots (WEB): The ^Axx specifies the value. Load the Gap Size in dots (GAP): The ^Axx specifies the value. 334M Operator’s Manual - 880060-0110 13-9...

- Page 222 Disable 1 and 2 Enable Auto-Print Mode Clear all previous text upon receiving new data. Enable 1 and 2 Auto-Print String Count: The ^Axx instructs the printer how many text strings to accept before printing. 13-10 334M Operator’s Manual - 880060-0110...

- Page 223 Load Text String Number to Increment/Decrement: Instructs the printer which text string to increment/decrement. Only used in conjunction with single serial numbers. Load Increment/Decrement Step Value: The ^Axx specifies the value that the serial number will be incremented or decremented. 334M Operator’s Manual - 880060-0110 13-11...

- Page 224 Milliseconds, the printer waits before retracting to dot row in cutter and dispense modes. Tag/Tear Dispense Mode: Disables Tag/Tear Mode Advance after every label. Advance after copies count. Advance when idle. Peel-n-Dispense Mode: Disable Peel-n-Dispense Enable Peel-n-Dispense 13-12 334M Operator’s Manual - 880060-0110...

- Page 225 (i.e. >192480<). Use the D119 command for additional reporting. Save ASCII Graphics to RAM: This command is intended for legacy support only. Microcom Corporation recommends using the ^D107 command instead of the ^D106. xxyy 107...

- Page 226 Milliseconds, that the printer waits after detecting that media has been put into the printer before it starts feeding it in. Top of Form Command: This command causes the printer to perform a Top-of-Form. This command requires a LPD sensor to be installed on the printer. 13-14 334M Operator’s Manual - 880060-0110...

- Page 227 The number of additional 64KB sectors needed to save the graphic file. The memory slot location of the graphic being saved; CGN # (1-255) 334M Operator’s Manual - 880060-0110 13-15...

- Page 228 LDSI code base that the printer uses. Issuing a ^D145 or ^A0^D145 causes the printer to generate a list of commands supported by the LDSI code base to communications port. 13-16 334M Operator’s Manual - 880060-0110...

- Page 229 8.0 ips (inches per second) 7.5 ips 7.0 ips 6.5 ips 6.0 ips 5.5 ips 5.0 ips 4.5 ips 4.0 ips 3.5 ips 3.0 ips 2.5 ips 2.0 ips 1.5 ips 1.0 ips 334M Operator’s Manual - 880060-0110 13-17...

- Page 230 After a power up, reports the “running” total of detected Brownouts. Clears the “running” total or volatile brownout count Reports the non-volatile brownout count stored in memory Clears the non-volatile brownout count stored in memory 13-18 334M Operator’s Manual - 880060-0110...

- Page 231 The range is 0 to 65535. If the delay distance is set to a value greater than the label height, the takeup will not turn on. Generate Aztec Barcode Generate QR Code Barcode 334M Operator’s Manual - 880060-0110 13-19...

- Page 232 DSR (Data Set Ready) - A status signal from the printer (DCE) to the host PC (DTE) telling the PC that the printer is powered up. Used in conjunction with DTR. Microcom Corporation does not use this signal.

- Page 233 DCE end of an RS-232 link. Used in conjunction with DSR. Microcom Corporation does not use this signal. Ethernet - A fast and capable serial interface used by many networks for connecting host computers to various peripherals.

- Page 234 1M bits/second. (Hardly used at all anymore). 2) USB 1.1 transfers at 12M bits/second. (The 324 & 424 printers use this). 3) USB 2.0 transfers at 480M bits/second. (All newer PC’s use this). 13-22 334M Operator’s Manual - 880060-0110...

- Page 235 _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ _________________________________________________________________________ 334M Operator’s Manual - 880060-0110 13-23...

- Page 236 13-24 334M Operator’s Manual - 880060-0110...

Need help?

Do you have a question about the 334M and is the answer not in the manual?

Questions and answers