Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Du Pont Cyrel FAST 2000TD

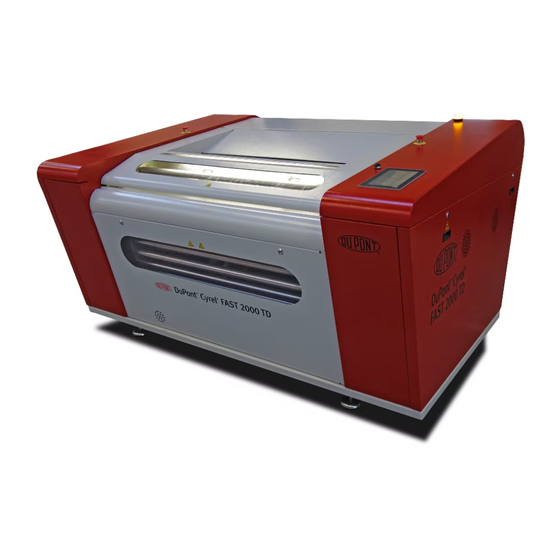

- Page 1 Operation Manual Cyrel FAST 2000TD IMPORTANT Please keep this manual with other equipment documentation for future reference. Please keep this manual with the 2000TD for future reference. January 8th, 2020 Edition BD10082030 English (en-us) Original version...

-

Page 2: General Information

General information About this manual This manual applies to the Flexo Processor Cyrel FAST 2000TD . Always read the separate Safety Instruction Manual part No 21741 before operating the equipment. This manual is valid for equipment with serial no(s) starting from:... -

Page 3: Reservations

User Manuals (Printed) Description Part No General Safety Instructions 10093396 CE Certification 10087683 SMC Chiller manual 10097986 User Manuals (Digital: USB stick) Description Part No General Safety Instructions 10093396 CE Certification 10087683 SMC Chiller manual 10097986 January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 4: The Equipment

For recycling purposes significant components are marked with material specification according to the ISO 11469 standard. • Plastic parts must be sent to a waste deposit with recycling. Alternatively the plastic parts can be incinerated at a suitable incinerating plant. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 5: Service Assistance

General information • PCBs and other electronics parts must be sent to a suitable waste deposit. Service assistance If help is needed to correct any problem with the equipment, please contact your local supplier. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 6: Table Of Contents

Catox exhaust system Control panel Operation procedures Starting up Shutting down Preparing the processor for plate load Loading a plate Selecting a job Stopping a processing job 2-10 Restarting a processing job 2-10 Ejecting plates 2-11 Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 7: Table Of Contents

Cleaning the lay-down and rubber roller Change of supply and waste rolls Changing nonwoven (NW) and PET rolls Changing the waste roll 4-15 Threading of nonwoven (NW), PET and waste 4-22 Appendix A Alarm list Appendix B January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 8 Table of Contents Replacing the slip fit adapter Air filter Operation and filling of the SMC chiller B-11 Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 9: Safety Precautions

Risk of injury from rotating parts Risk of burns from very hot surface Risk of crushing due to e.g. heavy equipment Maximum load (e.g. lift) Instruction labels (blue labels) Label Description Label Description Consult the manuals before further action January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 10: Emergency Stops

Pushing an emergency stop will instantly: • Make the processor stop. • Switch off the heating. • Stop the drum movement. • Pull back the heated roller. • Show an alarm on the control panel. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 11: Functional Description

Removes chemical fumes and hot air from the equipment and the working area. Correct temperatures are controlled by the built-in software. Plate exit Exit slot for unloading the plate. Control panel Operation and configuration January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 12: Processing Description

The stamper bar will lift away from the plate surface. The front clamp arm will rotate around the static drum pulling the plate into the processor. Operation Manual|Cyrel FAST 2000TD January, 2020... - Page 13 The stamper bar will press the rear edge of the plate into the rear clamp arm pin bar. The stamper bar will lift away from the plate surface. The lay-down roller lifts away from the plate surface. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 14 On each revolution the plate makes around the static drum, the heated roller will travel to the plate surface pushing the nonwoven and PET material onto the plate surface. The nonwoven material absorbs the unexposed photopolymer. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 15 The stripping finger bar will rise to its upper position as the plate is pushed out of the processor through the exit slot. January, 2020 Operation Manual|Cyrel FAST 2000TD...

-

Page 16: Feed And Exit

When the plate enters the processor, it is detected by feed sensors, and then automatic clamping and transport take over. When the processing is complete the plate automatically exits through the exit slot. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 17: Clamp Bars And Transport Arms

The static drum thus remains steady while the transport arms transport the plate around the drum. Cooling system To ensure the correct plate and internal temperature is controlled, a chiller unit supplies cooled water to the temperature control system inside the static drum. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 18: Catox Exhaust System

CAUTION: Use finger tips to avoid blocking editable area when operating the control panel. Do not place a palm on the touch panel, or use sharp objects. For detailed description of functions and behaviors please refer to chapter 3 "Control Panel". Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 19: Operation Procedures

"Ready to initialize" .. continue with step 3. Do not press the 'Initialize' button yet. NOTE: If by accident pressing the 'Initilize' button before turning the heat on, the following message will be displayed ... January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 20 Finish cycle - No" pop-up dialog will be displayed. The dialogue will close automatically after 10 sec. if nothing is chosen. • When the initialization process is complete the home view will display the 'Job selection' area. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 21 The heated roller and catox area will both be green. Start-up is then complete and the processor is ready for processing. Continue with description of "Preparing the processor for plate load" on page 2-5. January, 2020 Operation Manual|Cyrel FAST 2000TD...

-

Page 22: Shutting Down

When the message disappears it is safe to switch off .. . the chiller, the external exhaust system, the main power supply, the compressed air supply. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 23: Preparing The Processor For Plate Load

CAUTION: It is very important to make correct job selection for the plate type in use. If e.g. plate gauge does not apply to the actual plate, it could result in damage of the plate and potential damage to the processor. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 24: Loading A Plate

Gently reposition the plate if the blue light does not appear. When the stack light is blue, press the 'Start' button on the control panel. The processor will now automatically load the plate and start processing. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 25: Selecting A Job

'Start' button in order to complete processing of the plate. Allowed values: min. 1 - max. 18 (depending on program) When a processing job has been completed the 'First cycle' will automatically return to '1'. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 26 Either chose new plate gauge value or change the plate type. NW type (4): Enter the nonwoven material type used from the drop down list. There will be one or more options available. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 27 'Start' button is presented in the home view, both indicating that the processor is now set and ready to process the plate. January, 2020 Operation Manual|Cyrel FAST 2000TD...

-

Page 28: Stopping A Processing Job

Normally you should enter the cycle number that was about to start, when the plate was ejected. Then re- insert the plate and press the 'Start' button in order to complete processing of the plate. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 29: Ejecting Plates

Grab the plate when it exits the processor, to avoid it dropping on the floor. When the plate has been released, the stack light turns green, and the processor is ready for processing the next plate. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 30: Automatic Eject Function (After Completed Processing)

See also description of "Manual eject function (interrupting processing)" on the facing page. For more processing details see also description of "Processing description" on page 1-2. NOTE: It is recommended that once a plate has been ejected, it is immediately removed from the machine. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 31: Manual Eject Function (After Completed Processing)

Other reasons for need of manual ejection could be; emergency stop has been activated, top, front, or rear covers have been opened during processing, or an alarm which requires ejection/removal of the plate. Procedure (operator interrupted) Select the red 'Stop' button on the control panel. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 32 Only move the absolute minimum amount. Once the selection has been made, the 'Eject' button is displayed. Press the 'Eject' button to start unloading of the plate. See also description of "Automatic eject function (after completed processing)" on page 2-12. Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 33: Ejecting A Plate During Processor Start-Up

Press the 'Eject' button to eject the plate from the processor. The control panel will display the 'Ejecting plate' message. Remove the plate from the exit slot and await the 'Ready to initialize' message, and then press the 'Initialize' button. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 34: Opening Panels

This is to ensure that no plate is left inside the processor, and to re-establish safety circuits and correct processor conditions. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 35: Translyft Lift Table

Use a lift table for handling of the heavy nonwoven, PET and waste rolls. The Translyft lift table described below is offered as an accessory for the Cyrel FAST 2000TD. WARNING: Always read the safety instructions before handling a lift table. General safety instructions are described in the general Safety Instruction Manual part No 21741 whereas specific instructions for the Translyft lift table are described in this manual. - Page 36 Example showing a 44" roll at position (b). For detailed descriptions of unloading and loading rolls into the processor chuck bearings see descriptions in "Change of supply and waste rolls" on page 4-7 in this manual. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 37 Operation procedures 2-19 ( Blank ) January, 2020 Operation Manual|Cyrel FAST 2000TD...

-

Page 38: Panel Overview

Panel overview Panel overview Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 39: Control Panel

Processing and • Graphical representation of the processor and All levels web status the processing cycles. • Web status. • Temperature 'On/Off' Navigation • Visible/accessible from home view and all sub All levels buttons views. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 40: Status Of Nonwoven (Nw), Pet And Waste

Press the 'Start' button to resume the process. For general information of alarms please refer to "Alarms" on page 3-7, and for a complete alarm list please refer to the "Alarm list" on page A-1. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 41: Buttons And Fields

"Starting up" on page 2-1. • The 'Heating - Power OFF' button deactivates heating of the heated roller and catox. Cooling down takes approx. 40 min. See also description of "Shutting down" on page 2-4. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 42 Opens the 'Setup' main menu. • Gives access to change of access level. • Gives access to users and service menus, dependent on access level. Read more about the 'Setup' button in "Tools menus" on page 3-12. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 43 'Stop' button. • Use the 'Eject' button to: complete an auto-eject process, or start a manual eject process. For detailed description of the 'Eject' plate functions please see "Ejecting plates" on page 2- January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 44 • Pressing 'Enter' will save the value entered into the value field and close the keypad. • Pressing x will cancel the input and close the keypad. Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 45: Alarms

NOTE: If a yellow and red alarm arise at the same time, the red alarm will always overrule the yellow = first priority. It is not possible to start a process when red alarms arise. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 46 All alarms has a numeric code. For more information of each alarm and relevant actions/remedies, look up the alarm code in the "Alarm list" on page A-1. The alarm codes may also be useful information to a service technician when service assistance is required. Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 47: Alarm History

Use the buttons in the right side of the display to navigate between the alarms: • Scroll up / down one line • Scroll up / down one page Colors codes White Message or alarm raised. Alarm has been confirmed. Green January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 48: Access Levels

Press the 'key' area to enter the access code. A numeric keypad will be displayed. Enter the 4 digit access code. NOTE: Entering an incorrect code with automatically reset access level to Operator level (= locked). Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 49: Menu Diagram

Control panel 3-11 Menu diagram January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 50: Tools Menus

User settings • Statistics • Maintenance • Diagnostics • Change of access level General settings General settings cover basic settings for screen text, parameter values, date and time, etc. • Press 'Setup -> General settings'. Operation Manual|Cyrel FAST 2000TD January, 2020... - Page 51 Selection will be effected immediately. No need for restart. Regional settings: • Select between metric/imperial and celsius/fahrenheit. See immediate effect in the test output fields. No need for restart. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 52 SW revision: • Displays the installed software version. NOTE: The software versions shown here is for illustrative purpose only. NOTE: When requesting for service, please inform the service technician of the installed software version. Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 53: User Settings

The minimum and maximum values that can be entered are: Minimum: 900mm (35.4”) Maximum: 1200mm (47.2”) Setting of the correct width of the nonwoven is VERY important because the setting determines the tension of the nonwoven, PET and waste rolls. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 54: Statistics

The same view is accessible through the 'General settings' button. CAUTION: Resetting of statistics is done by authorized personnel only. Press the 'Next page' button for display of statistics for the slip fit adapter. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 55: Maintenance

Push and hold the Neg. or Pos. direction button to move the arms. • Both arms will move together. • Releasing the Pos. or Neg. button will stop the movement. NOTE: The arms will not move if any cover is open. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 56: Diagnostics

Control panel 3-18 Diagnostics Diagnostics allows access to the Diagnostics Menu. The 'Diagnostics' menu gives access to • Manual functions for web feed and stack light test. • Operation check of sensors and guard switches. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 57: Main

(when standing at the rear side of the processor). Diagnostics shown are: • Emergency stops OK (LED is lit) • Air supply OK (LED is lit) • Exhaust and chiller flow volumes. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 58: Machine Diagnostics

Control panel 3-20 Machine diagnostics The machine diagnostics screen shows actual position and status of the sensors in a graphical presentation of the processor. NOTE: LEDs are green when sensors are active. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 59: Maintenance

Clean the lay- Clean with a moist cloth and a Daily See detailed description of down and rubber mild household cleaning solution. "Cleaning the lay-down and roller. rubber roller" on page 4-3. January, 2020 Operation Manual|Cyrel FAST 2000TD... -

Page 60: Service Reminders

WARNING: It is very important that a service visit is organised the first time any one of the reminders is displayed. Failure to do this immediately could seriously damage the machine and invalidate any warranty on the machine. Operation Manual|Cyrel FAST 2000TD January, 2020... -

Page 61: Cleaning The Lay-Down And Rubber Roller

Tools required • A mild cleaning agent (e.g. mild detergent) • Soft cloth. • Bucket with clean lukewarm water. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 62 Once the correct “Trained Operator” password has been entered, select the “Enter” button. If the correct password has been entered. The Padlock Icon will have changed from Locked to Unlocked. Press the 'Maintenance' button. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 63 WARNING: It is not possible to operate the machine in this condition. 14. Lift the top cover and start to clean both the hold down roller and rubber roller. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 64 21. Touch the password input area; a numeric keypad will be displayed. Input “0” (zero). Select the “Enter” button. This will exit the “Trained Operator” level. 22. Initialise the machine ready for production. Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 65: Change Of Supply And Waste Rolls

Release the lock ring, then lift the entire coupling upwards to remove. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 66 "12 o'clock" position. (The photo is for illustrative purpose only.) Unlock the chuck bearing in the left and right side of the roll by pressing the chuck bearing's top-edge outwards (away from the roll). Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 67 11. Pull back the lift table, and transport the roll away from the processor. 12. Pull out the air shaft. NOTE: Remove any remaining material from the empty roll and save it for later use as empty waste roll. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 68 17. Push the air shaft into the cylinder of the new roll. CAUTION: Make sure to insert the air shaft in the cylinder-end that will face the air-connection side of the processor when mounted! Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 69 21. Push the lift table into the processor and position the air shaft directly above the chuck bearing. Make sure that the air shaft is positioned correctly above the chuck bearings in both the left and right side of the processor. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 70 22. Ensure the air shaft's connection block is correctly positioned in the chuck bearing holder. 23. Slowly lower the lift table until the air shaft is resting in the chuck bearings. 24. Pull away the lift table. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 71 27. Remove the protection paper from the double-side tape. 28. Detach the end of the old material (attached to the roll above) and mount it on top of the double-sided tape (2). Make sure that the two layers of material are parallel. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 72 2 revolutions. 31. Close the rear cover. 32. Press the "Initialize" button to start the initialization process. Operation Manual|Cyrel FAST 2000TD January, 2020...

-

Page 73: Changing The Waste Roll

Release the lock ring, then lift the entire coupling upwards to remove. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 74 "12 o'clock" position. (The photo is for illustrative purpose only.) Unlock the chuck bearing in the left and right side of the roll by pressing the chuck bearing's top-edge outwards (away from the roll). Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 75 14. Transport the roll away from the processor. 15. Pull out the air shaft. 16. Remove the full waste roll from the lift table. 17. Insert the air shaft into an empty waste roll. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 76 19. Mount the air shaft with the empty roll in the chuck bearings. Make sure that the air shaft is positioned correctly in both chuck bearings. (The photo is for illustrative purpose only.) Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 77 20. Ensure the air shaft's connection block is correctly positioned in the chuck bearing holder. 21. Lock the chuck bearings in left and right side by pressing the chuck bearings inwards (towards the roll). (The photo is for illustrative purpose only.) January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 78 24. Mount another piece of double-side self- adhesive tape on top of the PET for mounting of the nonwoven. 25. Loosen the nonwoven from the top cover and mount it on top of the PET on the empty waste roll. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 79 5 revolutions and the NW and PET web is tight. 28. Close the rear cover. 29. Press the "Initialize" button to start the initialization process. January, 2020 Operation Manual|Cyrel FAST 2000TD...

-

Page 80: Threading Of Nonwoven (Nw), Pet And Waste

While waiting for the processor to cool down, prepare the tools needed, the rolls, the Translyft (or other lifting devicefor lifting of the heavy rolls). Open the rear cover. Remove the left side panel. Operation Manual|Cyrel FAST 2000TD January, 2020... - Page 81 Lead the PET foil below the roller (A) and back above the PET roll, and out of the processor as shown. Lead the nonwoven below the roller (A) and back above the PET roll, and out of the processor as shown. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 82 (D) and format cylinder (E) from underneath and follow the path around the heated roller. 14. Lead the tip of the nonwoven/PET above the roller (F) and out, above the waste roller. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 83 18. Loosen the PET from the top cover and mount it to the empty roll. 19. Mount another piece of double-side self- adhesive tape on top of the PET for mounting of the nonwoven. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 84 5 revolutions and the NW and PET web is tight. 23. Close the rear cover. 24. Install the left side panel. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 85 4-27 25. Press the ON/OFF button . 26. Then press the 'Heating - Power ON'button to switch the heating on. 27. Initialise the machine. When the processor is heated up, it's ready for processing. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 86 Operation Manual Cyrel FAST 2000TD January, 2020...

-

Page 87: Alarm List

Remove plate from loading zone/feeding table while machine is not ready to load resetting machine. 002 003 Clamp arms, functional safety error Clamp arms too close to each other or another moving element during operation, please check before resetting machine. January, 2020 Operation Manual|Cyrel FAST 2000TD... - Page 88 If the problem persists, please call an authorized Service Technician. 003 025 Heated Roller, TCO Tripped Please call an authorized Service Technician. 003 026 IR, Thermal Cut Out (TCO) tripped Please call an authorized Service Technician. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 89 Web wrap detected, please check Please call an authorized Service Technician. heated roller for PET. 007 000 Web not at standstill, possibly web Web movement detected when not expected, rupture please check for broken web material. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 90 WEB PET, drive error Check for jammed plates and mechanical failures before initializing. 007 018 Motor could not move as expected. If the problem persists, please call an authorized 007 019 Service Technician. 007 020 007 021 Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 91 Catox. TCO on heater element tripped. If alarm can't be reset, please call an authorized Service Technician. 009 002 Catox. TCO on oxidizer tripped. If alarm can't be reset, please call an authorized Service Technician. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 92 009 021 Chiller. Flow too low. Cooling liquid flow not suficient. Please check that chiller is switched on. 000 007 Battery Discharged Don’t turn off machine before PLC battery is changed. Call authorised service. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 93 See description of "Change of access levels" on page 3-10. Select 'Tools - Maintenance'. Press the 'Enable maintenance mode' button. Press 'Arms to service position' button. Press the 'SFA change Move arms to safe pos.' button. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 94 Remove the set screw from the taper lock. 10. Mount the lift shaft delivered with the equipment and dismount the taper lock. 11. Dismount the format cylinders support bracket. Use the allen key No 5. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 95 NOTE: Before mounting the slip fit adapter notice the pin on the format cylinder. This pin fits into a slot in the slip fit adapter. 13. Mount the air hoses included with the tool kit in two fittings as shown. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 96 SFA along the Format Cylinder. 18. Keep pulling on the slip fit adapter along the format cylinder until is fully removed. 19. Turn the air pressure off and disconnect the air hose assembly. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 97 21. Mount the air hoses included with the tool kit in the two fittings in the end of the format cylinder. 22. Turn the pressure on. Adding pressure will ease the removal of the slip fit adapter. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 98 26. Dismount the air hose assembly from the format cylinder and the air switch. 27. Mount the 4 screws in the slip fit adapter's fixation ring. 28. Mount the format cylinders support bracket. Use the allen key No 5. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 99 36. In the 'Statics since Maintenance' area press the 'SFA change done/Reset' button. This will set a new date in 'Date of Slip Fit adapter change' and reset the 'Plates processed on current SFA'. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 100 WARNING: This operation has to be carried out with the supply for compressed air switched off. The moisture and dirt filter in the air filter should be checked and cleaned at least every 3 months. Follow the description below for disassembling and cleaning of the filter. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 101 Open the right side cover and locate the air filter unit (photo). Dismount the moisture trap housing by turning the housing to the left. Clean the inside of the moisture trap housing in water. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 102 Unscrew the bottom part of the filter (see photo) and clean in water. Re-assemble the filter. Mount the moisture trap housing by pushing upwards into the filter assembly and turn to the right to lock. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 103 To Start: Keep the [RUN/STOP] key pressed for approx. 2 seconds. The [RUN] lamp lights up (in green) and the chiller will start to run. To fill the chiller, remove the Tank Lid and carefully fill the tank until the level indicator is up to the “H” (high) mark. January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 104 If the coolant level was low during operation, the alarm “AL01; Low tank level", which stops the pump operation will have been activated. Reset the “AL01; Low tank level". Press the [RESET] key ([▼] and [▲] keys simultaneously) to stop the alarm buzzer. Operation Manual|Cyrel FAST 2000TD January, 2020...

- Page 105 To Stop: Keep the [RUN/STOP] key pressed for approx. 2 seconds. The [RUN] lamp flashes (green) and continues the operation until the chiller is ready to stop. After approx. 15 seconds, the [RUN] lamp goes off and the chiller stops January, 2020 Operation Manual|Cyrel FAST 2000TD...

- Page 106 Appendix B B-14 ( Blank ) Operation Manual|Cyrel FAST 2000TD January, 2020...

Need help?

Do you have a question about the Cyrel FAST 2000TD and is the answer not in the manual?

Questions and answers