Summary of Contents for Beckhoff EL28 Series

- Page 1 Documentation EL28xx-xxxx Digital HD Output Terminals Version: Date: 2019-01-03...

-

Page 3: Table Of Contents

Table of contents Table of contents 1 Foreword .............................. 5 Product overview: EtherCAT digital HD output terminals .............. 5 Notes on the documentation...................... 5 Safety instructions .......................... 7 Documentation issue status ...................... 8 Version identification of EtherCAT devices .................. 8 Non-reactive Bus Terminals ...................... 13 2 Product overview............................. 17 EL2808 ............................ 17 2.1.1 Introduction ........................ - Page 4 Table of contents 4.4.1 Connection system ...................... 67 4.4.2 Wiring.......................... 69 4.4.3 Shielding .......................... 70 Installation positions ........................ 70 Positioning of passive Terminals ..................... 73 UL notice ............................ 73 ATEX - Special conditions (standard temperature range) ............... 75 ATEX - Special conditions (extended temperature range) .............. 76 4.10 ATEX Documentation ........................ 77 5 Commissioning............................ 78 TwinCAT Quick Start ........................ 78...

-

Page 5: Foreword

The TwinCAT Technology is covered, including but not limited to the following patent applications and patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries. ® EtherCAT is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany. EL28xx-xxxx Version: 2.2... - Page 6 Foreword Copyright © Beckhoff Automation GmbH & Co. KG, Germany. The reproduction, distribution and utilization of this document as well as the communication of its contents to others without express authorization are prohibited. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or design.

-

Page 7: Safety Instructions

All the components are supplied in particular hardware and software configurations appropriate for the application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG. Personnel qualification This description is only intended for trained specialists in control, automation and drive engineering who are familiar with the applicable national standards. -

Page 8: Documentation Issue Status

• Additions to technical notes • First publication • Provisional documentation for EL28xx Version identification of EtherCAT devices Designation A Beckhoff EtherCAT device has a 14-digit designation, made up of • family key • type • version • revision Version: 2.2... - Page 9 Production lot/batch number/serial number/date code/D number The serial number for Beckhoff IO devices is usually the 8-digit number printed on the device or on a sticker. The serial number indicates the configuration in delivery state and therefore refers to a whole production batch, without distinguishing the individual modules of a batch.

-

Page 10: Fig. 1 El5021 El Terminal, Standard Ip20 Io Device With Serial/ Batch Number And Revision Id (Since 2014/01)

Foreword y - hardware version of the bus PCB z - firmware version of the I/O PCB u - hardware version of the I/O PCB Example: D.22081501 calendar week 22 of the year 2008 firmware version of bus PCB: 1 hardware version of bus PCB: 5 firmware version of I/O PCB: 0 (no firmware necessary for this PCB) hardware version of I/O PCB: 1 Unique serial number/ID, ID number... -

Page 11: Fig. 3 Cu2016 Switch With Serial/ Batch Number

Foreword Fig. 3: CU2016 switch with serial/ batch number Fig. 4: EL3202-0020 with serial/ batch number 26131006 and unique ID-number 204418 Fig. 5: EP1258-00001 IP67 EtherCAT Box with batch number/ date code 22090101 and unique serial number 158102 Fig. 6: EP1908-0002 IP67 EtherCAT Safety Box with batch number/ date code 071201FF and unique serial number 00346070 EL28xx-xxxx Version: 2.2... -

Page 12: Fig. 7 El2904 Ip20 Safety Terminal With Batch Number/ Date Code 50110302 And Unique Serial Num- Ber 00331701

Foreword Fig. 7: EL2904 IP20 safety terminal with batch number/ date code 50110302 and unique serial number 00331701 Fig. 8: ELM3604-0002 terminal with unique ID number (QR code) 100001051 and serial/ batch number 44160201 Version: 2.2 EL28xx-xxxx... -

Page 13: Non-Reactive Bus Terminals

Foreword Non-reactive Bus Terminals Use of non-reactive Bus or EtherCAT Terminals in safety applications If a Bus or EtherCAT Terminal is described as non-reactive, this means that the consecutive termi- nal behaves passively in a safety application (e.g. in the case of the all-pole switch-off of a potential group). -

Page 14: Fig. 9 Negative Example - Active Load

Foreword ◦ No switching of loads with a separate power supply Loads that have their own power supply must not be switched by standard terminals, since in this case feedback via the load cannot be ruled out. Fig. 9: Negative example – active load ◦... -

Page 15: Fig. 10 Ground Connection Of The Load: Correct (K1) And Incorrect (K2)

Foreword Fig. 10: Ground connection of the load: correct (K1) and incorrect (K2) ◦ If either a) the ground of the load is not fed back to the terminal or b) the ground is not safely switched but connected permanently then fault exclusions are necessary with regard to a short-circuit with external potential in order to be able to achieve Cat. -

Page 16: Fig. 11 Short Circuit Fault Exclusion Through Protected Cable Laying

Foreword Fig. 11: Short circuit fault exclusion through protected cable laying ◦ a) Possibility 1: Load connection via separate sheathed cables The non-safely switched potential of the standard terminal may not be conducted together with other potential-conducting cores inside the same sheathed cable. (Fault exclusion, see EN ISO 13849-2:2013, Table D.4) ◦... -

Page 17: Product Overview

Product overview Product overview EL2808 2.1.1 Introduction Fig. 12: EL2808 HD EtherCAT Terminals, 8 digital output channels, 24 V , 0.5 A The EL2808 digital output terminal connects the binary control signals from the automation device on to the actuators at the process level with electrical isolation. The EL2808 is protected against polarity reversal and processes load currents with outputs protected against overload and short-circuit. -

Page 18: Technical Data

Product overview 2.1.2 Technical data Technical data EL2808 digital outputs Rated load voltage 24 V (-15% / +20%) Load type ohmic, inductive, lamp load Max. output current 0.5 A (short-circuit-proof) per channel Short circuit current 0.6 ... 2.0 A Breaking energy < 150 mJ/channel Switching times : 60 µs typ., T : 300 µs typ. -

Page 19: Pin Assignment And Leds

Product overview 2.1.3 Pin assignment and LEDs Fig. 13: EL2808 EL2808 - LEDs Color Meaning OUTPUT 1- 8 green No output signal 24 V output signal at the respective output EL2808 - pin assignment Terminal point Description Name Output 1 Output 1 Output 2 Output 2 Output 3... -

Page 20: Introduction

Product overview EL2828 2.2.1 Introduction Fig. 14: EL2828 HD EtherCAT Terminals, 8 digital output channels, 24 V , 2 A The EL2828 digital output terminal connects the binary control signals from the automation device on to the actuators at the process level with electrical isolation. The EL2828 is protected against polarity reversal and processes load currents with outputs protected against overload and short-circuit. -

Page 21: Technical Data

Product overview 2.2.2 Technical data Technical data EL2828 Connection technology 2 wire digital outputs Rated load voltage 24 V (-15% / +20%) Load type ohmic, inductive, lamp load Max. output current 2 A ( ∑ 10 A) Short circuit current < 40 A typ. Reverse voltage protection Breaking energy <... -

Page 22: Pin Assignment And Leds

Product overview 2.2.3 Pin assignment and LEDs Fig. 15: EL2828 EL2828 - LEDs Color Meaning OUTPUT 1- 8 green No output signal 24 V output signal at the respective output EL2828 - pin assignment Terminal point Description Name Output 1 Output 1 Output 2 Output 2 Output 3... -

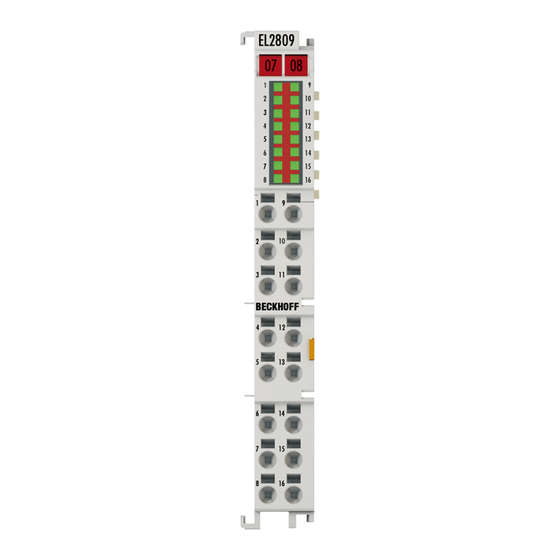

Page 23: El2809, El2889

Product overview EL2809, EL2889 2.3.1 Introduction Fig. 16: EL2809, EL2889 HD EtherCAT Terminals, 16 digital output channels, 24 V The EL2809 digital output terminal connects the binary control signals from the automation device on to the actuators at the process level with electrical isolation. The EL2809 is protected against polarity reversal and processes load currents with outputs protected against overload and short-circuit. -

Page 24: Technical Data

Product overview 2.3.2 Technical data Technical data EL2809 EL2889 digital outputs Rated load voltage 24 V (-15% / +20%) Non-reactive outputs yes (see notice [} 13]) Load type ohmic, inductive, lamp load Max. output current 0.5 A (short-circuit-proof) per channel Short circuit current 0.6 ... 2.0 A Breaking energy <... -

Page 25: Pin Assignment And Leds

Product overview 2.3.3 Pin assignment and LEDs Fig. 17: EL2809, EL2889 EL2809, EL2889 LEDs Color Meaning OUTPUT 1- 16 green No output signal • Output signal 24 V (EL2809) • Output signal 0 V (EL2889) EL2809, EL2889 pin assignment Terminal point Description Name Output 1... -

Page 26: El2872, El2872-0010

Product overview EL2872, EL2872-0010 2.4.1 Introduction Fig. 18: EL2872, EL2872-0010 HD EtherCAT Terminals, 16 digital output channels, 24 V , 0.5 A The EL2872-00x0 digital output terminal offers a very compact design with its 16 channels. A 20-pin connector enables the secure connection of plug connectors using insulation displacement contact, as is usual for ribbon cables and special round cables. -

Page 27: Technical Data

Product overview 2.4.2 Technical data Technical data EL2872 EL2872-0010 digital outputs Rated load voltage 24 V (-15% / +20%), max. 1 A per connection pin Load type ohmic, inductive, lamp load Non-reactive outputs yes (see notice [} 13]) Max. output current 0.5 A (short-circuit-proof) per channel Short circuit current 0.6 ... -

Page 28: Fig. 19 El2872, El2872-0010

Product overview 2.4.3 Pin assignment and LEDs Fig. 19: EL2872, EL2872-0010 EL2872, EL2872-0010 - LEDs Color Meaning OUTPUT 1- 16 green No output signal • 24 V output signal at the respective output (EL2872-0000) • 0 V output signal at the respective output (EL2872-0010) EL2872, EL2872-0010 - Pin assignment Terminal point Description... -

Page 29: Introduction

Product overview EL2819 2.5.1 Introduction Fig. 21: EL2819 HD EtherCAT terminals, 16 digital output channels, 24 V , 0.5 A, with diagnostics The EL2819 digital output terminal connects the binary control signals from the automation device on to the actuators at the process level with electrical isolation. The EL2819 is protected against polarity reversal and processes load currents with outputs protected against overload and short-circuit. - Page 30 Product overview 2.5.2 Technical data Technical data EL2819 digital outputs Rated load voltage 24 V (-15% / +20%) Load type ohmic, inductive, lamp load Distributed Clocks Max. output current 0.5 A (short-circuit-proof) per channel Short circuit current < 1 A typ. Breaking energy < 150 mJ/channel Output stage push (high-side switch) Reverse voltage protection...

-

Page 31: Fig. 21 El2819

Product overview 2.5.3 Pin assignment and LEDs Fig. 22: EL2819 EL2819 - LEDs Color Meaning OUTPUT 1- 16 green No output signal Output signal 24 V ERROR: Overcurrent / Overtemperature Flashing red ERROR: Short circuit to 24 V red / green alternating ERROR: Open Load EL2819 - Pin assignment Terminal point Description... -

Page 32: Technical Data

Product overview 2.5.4 Overload protection Technical data Please note the information in the technical data regarding load type, max. output current and short circuit current. When switching on lamp loads, high starting currents occur that are limited by the output circuit of the terminals (see fig. -

Page 33: Operating Modes And Settings

Product overview Short-circuit or prolonged overload on a channel leads to an increase in the device temperature. If several channels are overloaded, this leads to a rapid increase in the device temperature. The overloaded channels are switched off when the upper limit for the device temperature is exceeded. The channels are only switched on again if the temperature falls below the lower limit values for both the device and the channel. -

Page 34: Fig. 26 El2819 "Process Data" Tab

Product overview Fig. 26: EL2819 “Process Data” tab • Changes to the process data-specific settings are generally only effective after a restart of the EtherCAT master: Restart TwinCAT in RUN or CONFIG mode; RELOAD in CONFIG mode • Changes to the online CoE directory ◦... -

Page 35: Fig. 27 El2819 Online Illustration Of The Process Data And Structural Contents In The System Manager

Product overview Fig. 27: EL2819 Online illustration of the process data and structural contents in the System Manager The plain text display of the bit meanings is particularly helpful not only in commissioning but also for linking to the PLC program. By right-clicking on the Status variable in the configuration tree (A), the structure can be opened for linking (B). -

Page 36: Fig. 28 El2819 "Process Data" Tab

Product overview Fig. 28: EL2819 “Process Data” tab Selection of the diagnostic scope via the selection dialog “Predefined PDO Assignment” Display of (optional) PDOs (process data objects) Selection of the required Sync Manager Display of the PDOs available for selection Three pre-defined PDO assignments can be selected: •... - Page 37 Product overview 2.5.5.2 Diagnostics per channel Open Load (Index 0x60n1:02 [} 42]) The open load detection shows that no load is connected when the output is switched on. The “open load” bit (index 0x60n1:02) is set to TRUE if the output is TRUE and the output current is less than typ.

-

Page 38: Fig. 29 El2819 Coe Directory

Product overview 2.5.5.4 Settings via the CoE directory CoE online directory Fig. 29: EL2819 CoE directory The online data are accessible (A) if the terminal is online, i.e. connected to the EtherCAT Master TwinCAT and in an error-free RUN state (WorkingCounter = 0). The entries “DIG Safe State Active Ch.n (index 0x80n0) (D) and “DIG Safe State Value Ch.n”... -

Page 39: Fig. 30 El2819 Change Of State Of The Outputs In The Case Of A Bus Error

Product overview DIG Safe State Active (index 0x80n0:01 [} 41]) / DIG Safe State Value (index 0x80n1:01 [} 41]) The setting in “DIG Safe State Active” (index 0x80n0:01) defines whether the outputs should assume a safe state in the case of a bus error. The safe state of the output in the case of a bus error is defined with “DIG Safe State Value”... -

Page 40: Object Description And Parameterization

EtherCAT XML Device Description The display matches that of the CoE objects from the EtherCAT XML Device Description. We rec- ommend downloading the latest XML file from the download area of the Beckhoff website and in- stalling it according to installation instructions. - Page 41 Product overview 2.5.6.1 Restore object Index 1011 Restore default parameters Index (hex) Name Meaning Data type Flags Default value 1011:0 Restore default parameters UINT8 0x01 (1 Restore default param- eters [} 155] 1011:01 SubIndex 001 If this object is set to "0x64616F6C" in the set value UINT32 0x00000000 dialog, all backup objects are reset to their delivery...

- Page 42 Product overview 2.5.6.4 Input data Index 60n1 DIG Diag Inputs (n=0 for Ch.1…n=9 for Ch.10; n=A for Ch.11…n=F for Ch.16) Index (hex) Name Meaning Data type Flags Default value 60n1:0 DIG Diag Inputs Ch.n Maximum subindex UINT8 0x04 (4 60n1:01 The overtemperature bit is set if the max.

- Page 43 Product overview Index 1008 Device name Index (hex) Name Meaning Data type Flags Default value 1008:0 Device name Device name of the EtherCAT slave STRING EL2819 Index 1009 Hardware version Index (hex) Name Meaning Data type Flags Default value 1009:0 Hardware version Hardware version of the EtherCAT slave STRING...

- Page 44 Product overview Index 1600 DIG RxPDO-Map Outputs Index (hex) Name Meaning Data type Flags Default value 1600:0 DIG RxPDO-Map Op- PDO Mapping RxPDO 1 UINT8 0x10 (16 utputs 1600:01 SubIndex 001 1. PDO Mapping entry (object 0x7000 (DIG Outputs UINT32 0x7000:01, 1 Ch.01), entry 0x01 (Output)) 1600:02...

- Page 45 Product overview Index (hex) Name Meaning Data type Flags Default 1A00:09 SubIndex 009 9. PDO Mapping entry (object 0x6021 (DIG Inputs UINT32 0x6021:01, 1 Ch.03), entry 0x01 (Overtemperature)) 1A00:0A SubIndex 010 10. PDO Mapping entry (object 0x6021 (DIG Inputs UINT32 0x6021:02, 1 Ch.03), entry 0x02 (Wire Break)) 1A00:0B...

- Page 46 Product overview Index (hex) Name Meaning Data type Flags Default 1A00:2A Subindex 042 42. PDO Mapping entry (object 0x60A1 (DIG Inputs UINT32 0x60A1:02, 1 Ch.11), entry 0x02 (Wire Break)) 1A00:2B Subindex 043 43. PDO Mapping entry (object 0x60A1 (DIG Inputs UINT32 0x60A1:03, 1 Ch.11), entry 0x03 (Overcurrent))

- Page 47 Product overview Index 1C00 Sync manager type Index (hex) Name Meaning Data type Flags Default 1C00:0 Sync manager type Using the sync managers UINT8 0x04 (4 1C00:01 SubIndex 001 Sync-Manager Type Channel 1: Mailbox Write UINT8 0x01 (1 1C00:02 SubIndex 002 Sync-Manager Type Channel 2: Mailbox Read UINT8 0x02 (2...

- Page 48 Product overview Index 1C13 TxPDO assign Index (hex) Name Meaning Data type Flags Default 1C13:0 TxPDO assign PDO Assign Inputs UINT8 0x02 (2 1C13:01 SubIndex 001 1. allocated TxPDO (contains the index of the associ- UINT16 0x1A00 ated TxPDO mapping object) (6656 1C13:02 Subindex 002...

- Page 49 Product overview Index 1C32 SM output parameter Index (hex) Name Meaning Data type Flags Default value 1C32:0 SM output parameter Synchronization parameters for the outputs UINT8 0x20 (32 1C32:01 Sync mode Current synchronization mode: UINT16 0x0001 (1 • 0: Free Run •...

- Page 50 Product overview Index 1C33 SM input parameter Index (hex) Name Meaning Data type Flags Default value 1C33:0 SM input parameter Synchronization parameters for the inputs UINT8 0x20 (32 1C33:01 Sync mode Current synchronization mode: UINT16 0x0022 (34 • 0: Free Run •...

- Page 51 Product overview Index F010 Module list Index (hex) Name Meaning Data type Flags Default value F010:0 Module list Maximum subindex UINT8 0x01 (1 F010:01 SubIndex 001 Profil 280 (Extended Digital Input and Output with Di- UINT32 0x00000118 agnostics) (280 F010:02 SubIndex 002 Profil 280 (Extended Digital Input and Output with Di- UINT32...

-

Page 52: Basics Communication

EtherCAT devices from Beckhoff. Recommended cables Suitable cables for the connection of EtherCAT devices can be found on the Beckhoff website! E-Bus supply A bus coupler can supply the EL terminals added to it with the E-bus system voltage of 5 V; a coupler is thereby loadable up to 2 A as a rule (see details in respective device documentation). -

Page 53: General Notes For Setting The Watchdog

Basics communication Fig. 32: System manager current calculation NOTE Malfunction possible! The same ground potential must be used for the E-Bus supply of all EtherCAT terminals in a terminal block! General notes for setting the watchdog ELxxxx terminals are equipped with a safety feature (watchdog) that switches off the outputs after a specifiable time e.g. -

Page 54: Fig. 33 Ethercat Tab -> Advanced Settings -> Behavior -> Watchdog

Basics communication Fig. 33: EtherCAT tab -> Advanced Settings -> Behavior -> Watchdog Notes: • the multiplier is valid for both watchdogs. • each watchdog has its own timer setting, the outcome of this in summary with the multiplier is a resulting time. -

Page 55: Ethercat State Machine

Basics communication Example "Set SM watchdog" This checkbox enables manual setting of the watchdog times. If the outputs are set and the EtherCAT communication is interrupted, the SM watchdog is triggered after the set time and the outputs are erased. This setting can be used for adapting a terminal to a slower EtherCAT master or long cycle times. -

Page 56: Fig. 34 States Of The Ethercat State Machine

Basics communication Fig. 34: States of the EtherCAT State Machine Init After switch-on the EtherCAT slave in the Init state. No mailbox or process data communication is possible. The EtherCAT master initializes sync manager channels 0 and 1 for mailbox communication. Pre-Operational (Pre-Op) During the transition between Init and Pre-Op the EtherCAT slave checks whether the mailbox was initialized correctly. -

Page 57: Coe Interface

Basics communication Boot In the Boot state the slave firmware can be updated. The Boot state can only be reached via the Init state. In the Boot state mailbox communication via the file access over EtherCAT (FoE) protocol is possible, but no other mailbox communication and no process data communication. -

Page 58: Fig. 35 "Coe Online " Tab

Data management If slave CoE parameters are modified online, Beckhoff devices store any changes in a fail-safe manner in the EEPROM, i.e. the modified CoE parameters are still available after a restart. The situation may be different with other manufacturers. -

Page 59: Fig. 36 Startup List In The Twincat System Manager

Changes in the local CoE list of the terminal are lost if the terminal is replaced. If a terminal is re- placed with a new Beckhoff terminal, it will have the default settings. It is therefore advisable to link all changes in the CoE list of an EtherCAT slave with the Startup list of the slave, which is pro- cessed whenever the EtherCAT fieldbus is started. -

Page 60: Fig. 37 Offline List

Basics communication Fig. 37: Offline list • If the slave is online ◦ The actual current slave list is read. This may take several seconds, depending on the size and cycle time. ◦ The actual identity is displayed ◦ The firmware and hardware version of the equipment according to the electronic information is displayed ◦... - Page 61 • Channel 1: parameter range 0x8010:00 ... 0x801F:255 • Channel 2: parameter range 0x8020:00 ... 0x802F:255 • ... This is generally written as 0x80n0. Detailed information on the CoE interface can be found in the EtherCAT system documentation on the Beckhoff website. EL28xx-xxxx Version: 2.2...

-

Page 62: Distributed Clock

Basics communication Distributed Clock The distributed clock represents a local clock in the EtherCAT slave controller (ESC) with the following characteristics: • Unit 1 ns • Zero point 1.1.2000 00:00 • Size 64 bit (sufficient for the next 584 years; however, some EtherCAT slaves only offer 32-bit support, i.e. -

Page 63: Mounting And Wiring

• Each assembly must be terminated at the right hand end with an EL9011 or EL9012 bus end cap, to en- sure the protection class and ESD protection. Fig. 39: Spring contacts of the Beckhoff I/O components Installation on mounting rails... -

Page 64: Fig. 40 Attaching On Mounting Rail

Mounting and wiring Assembly Fig. 40: Attaching on mounting rail The bus coupler and bus terminals are attached to commercially available 35 mm mounting rails (DIN rails according to EN 60715) by applying slight pressure: 1. First attach the fieldbus coupler to the mounting rail. 2. - Page 65 Mounting and wiring Disassembly Fig. 41: Disassembling of terminal Each terminal is secured by a lock on the mounting rail, which must be released for disassembly: 1. Pull the terminal by its orange-colored lugs approximately 1 cm away from the mounting rail. In doing so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of the bus terminal block easily without excessive force.

- Page 66 Mounting and wiring Fig. 42: Power contact on left side NOTE Possible damage of the device Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively coupled to the mounting rail. This may lead to incorrect results during insulation testing or to damage on the terminal (e.g. disruptive discharge to the PE line during insulation testing of a consumer with a nominal voltage of 230 V).

-

Page 67: Installation Instructions For Enhanced Mechanical Load Capacity

Mounting and wiring Installation instructions for enhanced mechanical load capacity WARNING Risk of injury through electric shock and damage to the device! Bring the Bus Terminal system into a safe, de-energized state before starting mounting, disassembly or wiring of the Bus Terminals! Additional checks The terminals have undergone the following additional tests: Verification... - Page 68 Mounting and wiring • The terminals of ESxxxx and KSxxxx series feature a pluggable connection level and enable steady wiring while replacing. • The High Density Terminals (HD Terminals) include electronics and connection level in a single enclosure and have advanced packaging density. Standard wiring (ELxxxx / KLxxxx) Fig. 43: Standard wiring The terminals of ELxxxx and KLxxxx series have been tried and tested for years.

-

Page 69: Wiring

Mounting and wiring The Bus Terminals from these series with 16 terminal points are distinguished by a particularly compact design, as the packaging density is twice as large as that of the standard 12 mm Bus Terminals. Massive conductors and conductors with a wire end sleeve can be inserted directly into the spring loaded terminal point without tools. -

Page 70: Shielding

Mounting and wiring See the following table for the suitable wire size width. Terminal housing ELxxxx, KLxxxx ESxxxx, KSxxxx Wire size width (single core wires) 0.08 ... 2.5 mm 0.08 ... 2.5 mm Wire size width (fine-wire conductors) 0.08 ... 2.5 mm 0,08 ... 2.5 mm Wire size width (conductors with a wire end sleeve) 0.14 ... - Page 71 Mounting and wiring Fig. 47: Recommended distances for standard installation position Compliance with the distances shown in Fig. “Recommended distances for standard installation position” is recommended. Other installation positions All other installation positions are characterized by different spatial arrangement of the mounting rail - see Fig “Other installation positions”.

- Page 72 Mounting and wiring Fig. 48: Other installation positions Version: 2.2 EL28xx-xxxx...

-

Page 73: Positioning Of Passive Terminals

Beckhoff EtherCAT modules are intended for use with Beckhoff’s UL Listed EtherCAT Sys- tem only. Examination For cULus examination, the Beckhoff I/O System has only been investigated for risk of fire and electrical shock (in accordance with UL508 and CSA C22.2 No. 142). EL28xx-xxxx... - Page 74 Not for connection to telecommunication circuits. Basic principles Two UL certificates are met in the Beckhoff EtherCAT product range, depending upon the components: 1. UL certification according to UL508. Devices with this kind of certification are marked by this sign: 2.

-

Page 75: Atex - Special Conditions (Standard Temperature Range)

80°C at the wire branching points, then cables must be selected whose tempera- ture data correspond to the actual measured temperature values! • Observe the permissible ambient temperature range of 0 to 55°C for the use of Beckhoff fieldbus compo- nents standard temperature range in potentially explosive areas! •... -

Page 76: Atex - Special Conditions (Extended Temperature Range)

80°C at the wire branching points, then cables must be selected whose tempera- ture data correspond to the actual measured temperature values! • Observe the permissible ambient temperature range of -25 to 60°C for the use of Beckhoff fieldbus com- ponents with extended temperature range (ET) in potentially explosive areas! •... -

Page 77: Atex Documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive ar- eas (ATEX) Pay also attention to the continuative documentation Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX) that is available in the download area of the Beckhoff homepage http:\\www.beckhoff.com! EL28xx-xxxx... -

Page 78: Commissioning

• "offline": The configuration can be customized by adding and positioning individual components. These can be selected from a directory and configured. ◦ The procedure for offline mode can be found under http://infosys.beckhoff.com: TwinCAT 2 → TwinCAT System Manager → IO - Configuration → Adding an I/O Device •... - Page 79 Commissioning Fig. 51: Relationship between user side (commissioning) and installation The user inserting of certain components (I/O device, terminal, box...) is the same in TwinCAT 2 and TwinCAT 3. The descriptions below relate to the online procedure. Sample configuration (actual configuration) Based on the following sample configuration, the subsequent subsections describe the procedure for TwinCAT 2 and TwinCAT 3: •...

- Page 80 Commissioning Fig. 52: Control configuration with Embedded PC, input (EL1004) and output (EL2008) Note that all combinations of a configuration are possible; for example, the EL1004 terminal could also be connected after the coupler, or the EL2008 terminal could additionally be connected to the CX2040 on the right, in which case the EK1100 coupler wouldn’t be necessary.

- Page 81 Commissioning Generally, TwinCAT can be used in local or remote mode. Once the TwinCAT system including the user interface (standard) is installed on the respective PLC, TwinCAT can be used in local mode and thereby the next step is "Insert Device [} 82]". If the intention is to address the TwinCAT runtime environment installed on a PLC as development environment remotely from another system, the target system must be made known first.

- Page 82 Commissioning After confirmation with "OK" the target system can be accessed via the System Manager. Adding devices In the configuration tree of the TwinCAT 2 System Manager user interface on the left, select "I/O Devices” and then right-click to open a context menu and select "Scan Devices…", or start the action in the menu bar .

- Page 83 Commissioning Fig. 58: Mapping of the configuration in the TwinCAT 2 System Manager The whole process consists of two stages, which may be performed separately (first determine the devices, then determine the connected elements such as boxes, terminals, etc.). A scan can also be initiated by selecting "Device ..."...

- Page 84 Commissioning • Graphical languages ◦ Function Block Diagram (FBD) ◦ Ladder Diagram (LD) ◦ The Continuous Function Chart Editor (CFC) ◦ Sequential Function Chart (SFC) The following section refers to Structured Text (ST). After starting TwinCAT PLC Control, the following user interface is shown for an initial project: Fig. 60: TwinCAT PLC Control after startup Sample variables and a sample program have been created and stored under the name "PLC_example.pro": Version: 2.2...

- Page 85 Commissioning Fig. 61: Sample program with variables after a compile process (without variable integration) Warning 1990 (missing "VAR_CONFIG") after a compile process indicates that the variables defined as external (with the ID "AT%I*" or "AT%Q*") have not been assigned. After successful compilation, TwinCAT PLC Control creates a "*.tpy"...

- Page 86 Commissioning Select the PLC configuration "PLC_example.tpy" in the browser window that opens. The project including the two variables identified with "AT" are then integrated in the configuration tree of the System Manager: Fig. 63: PLC project integrated in the PLC configuration of the System Manager The two variables "bEL1004_Ch4"...

- Page 87 Commissioning Fig. 65: Selecting PDO of type BOOL According to the default setting, certain PDO objects are now available for selection. In this sample the input of channel 4 of the EL1004 terminal is selected for linking. In contrast, the checkbox "All types" must be ticked for creating the link for the output variables, in order to allocate a set of eight separate output bits to a byte variable.

- Page 88 Commissioning Fig. 67: Application of a "Goto Link" variable, using "MAIN.bEL1004_Ch4" as a sample The process of assigning variables to the PDO is completed via the menu selection "Actions" → "Generate Mappings”, key Ctrl+M or by clicking on the symbol in the menu. This can be visualized in the configuration: The process of creating links can also take place in the opposite direction, i.e.

- Page 89 Commissioning Fig. 68: Choose target system (remote) In this sample "Runtime system 1 (port 801)" is selected and confirmed. Link the PLC with the real-time system via menu option "Online" → "Login", the F11 key or by clicking on the symbol . The control program can then be loaded for execution.

- Page 90 Commissioning Fig. 69: PLC Control logged in, ready for program startup The PLC can now be started via "Online" → "Run", F5 key or 5.1.2 TwinCAT 3 Startup TwinCAT makes the development environment areas available together with Microsoft Visual Studio: after startup, the project folder explorer appears on the left in the general window area (cf.

- Page 91 Commissioning Fig. 70: Initial TwinCAT 3 user interface First create a new project via (or under "File"→“New"→ "Project…"). In the following dialog make the corresponding entries as required (as shown in the diagram): Fig. 71: Create new TwinCAT project The new project is then available in the project folder explorer: EL28xx-xxxx Version: 2.2...

- Page 92 Commissioning Fig. 72: New TwinCAT3 project in the project folder explorer Generally, TwinCAT can be used in local or remote mode. Once the TwinCAT system including the user interface (standard) is installed on the respective PLC, TwinCAT can be used in local mode and thereby the next step is "Insert Device [} 93]".

- Page 93 Commissioning Use "Search (Ethernet)..." to enter the target system. Thus a next dialog opens to either: • enter the known computer name after "Enter Host Name / IP:" (as shown in red) • perform a "Broadcast Search" (if the exact computer name is not known) •...

- Page 94 Commissioning Fig. 76: Automatic detection of I/O devices: selection the devices to be integrated Confirm the message "Find new boxes", in order to determine the terminals connected to the devices. "Free Run" enables manipulation of input and output values in "Config mode" and should also be acknowledged. Based on the sample configuration [} 79] described at the beginning of this section, the result is as follows: Fig. 77: Mapping of the configuration in VS shell of the TwinCAT3 environment The whole process consists of two stages, which may be performed separately (first determine the devices,...

- Page 95 Commissioning Fig. 78: Reading of individual terminals connected to a device This functionality is useful if the actual configuration is modified at short notice. Programming the PLC TwinCAT PLC Control is the development environment for the creation of the controller in different program environments: TwinCAT PLC Control supports all languages described in IEC 61131-3.

- Page 96 Commissioning Fig. 79: Adding the programming environment in "PLC" In the dialog that opens select "Standard PLC project" and enter "PLC_example" as project name, for example, and select a corresponding directory: Fig. 80: Specifying the name and directory for the PLC programming environment The "Main"...

- Page 97 Commissioning Fig. 81: Initial "Main" program of the standard PLC project To continue, sample variables and a sample program have now been created: EL28xx-xxxx Version: 2.2...

- Page 98 Commissioning Fig. 82: Sample program with variables after a compile process (without variable integration) The control program is now created as a project folder, followed by the compile process: Fig. 83: Start program compilation The following variables, identified in the ST/ PLC program with "AT%", are then available in under "Assignments"...

- Page 99 Commissioning Fig. 84: Creating the links between PLC variables and process objects In the window that opens, the process object for the variable "bEL1004_Ch4" of type BOOL can be selected from the PLC configuration tree: Fig. 85: Selecting PDO of type BOOL According to the default setting, certain PDO objects are now available for selection.

- Page 100 Commissioning Fig. 86: Selecting several PDOs simultaneously: activate "Continuous" and "All types" Note that the "Continuous" checkbox was also activated. This is designed to allocate the bits contained in the byte of the variable "nEL2008_value" sequentially to all eight selected output bits of the EL2008 terminal. In this way it is possible to subsequently address all eight outputs of the terminal in the program with a byte corresponding to bit 0 for channel 1 to bit 7 for channel 8 of the PLC.

- Page 101 Commissioning Activation of the configuration The allocation of PDO to PLC variables has now established the connection from the controller to the inputs and outputs of the terminals. The configuration can now be activated with or via the menu under "TwinCAT"...

-

Page 102: Twincat 2

5.2.1 Installation of the TwinCAT real-time driver In order to assign real-time capability to a standard Ethernet port of an IPC controller, the Beckhoff real-time driver has to be installed on this port under Windows. This can be done in several ways. One option is described here. - Page 103 Commissioning Fig. 89: System Manager “Options” (TwinCAT 2) This have to be called up by the Menü “TwinCAT” within the TwinCAT 3 environment: Fig. 90: Call up under VS Shell (TwinCAT 3) The following dialog appears: Fig. 91: Overview of network interfaces Interfaces listed under “Compatible devices” can be assigned a driver via the “Install” button. A driver should only be installed on compatible devices.

- Page 104 Commissioning Fig. 92: EtherCAT device properties(TwinCAT 2): click on „Compatible Devices…“ of tab “Adapter” TwinCAT 3: the properties of the EtherCAT device can be opened by double click on “Device .. (EtherCAT)” within the Solution Explorer under “I/O”: After the installation the driver appears activated in the Windows overview for the network interface (Windows Start →...

- Page 105 Commissioning Fig. 94: Exemplary correct driver setting for the Ethernet port Other possible settings have to be avoided: EL28xx-xxxx Version: 2.2...

- Page 106 Commissioning Fig. 95: Incorrect driver settings for the Ethernet port Version: 2.2 EL28xx-xxxx...

- Page 107 Commissioning IP address of the port used IP address/DHCP In most cases an Ethernet port that is configured as an EtherCAT device will not transport general IP packets. For this reason and in cases where an EL6601 or similar devices are used it is useful to specify a fixed IP address for this port via the “Internet Protocol TCP/IP”...

-

Page 108: Notes Regarding Esi Device Description

The files are read (once) when a new System Manager window is opened, if they have changed since the last time the System Manager window was opened. A TwinCAT installation includes the set of Beckhoff ESI files that was current at the time when the TwinCAT build was created. - Page 109 1018 in the configuration. This is also stated by the Beckhoff compatibility rule. Refer in particular to the chapter ‘General notes on the use of Beckhoff EtherCAT IO components’ and for manual configuration to the chapter ‘Offline configuration creation’ [} 113].

- Page 110 Commissioning Fig. 100: File OnlineDescription.xml created by the System Manager Is a slave desired to be added manually to the configuration at a later stage, online created slaves are indicated by a prepended symbol “>” in the selection list (see Figure “Indication of an online recorded ESI of EL2521 as an example”).

- Page 111 Commissioning Reasons may include: • Structure of the *.xml does not correspond to the associated *.xsd file → check your schematics • Contents cannot be translated into a device description → contact the file manufacturer EL28xx-xxxx Version: 2.2...

-

Page 112: Twincat Esi Updater

Commissioning 5.2.3 TwinCAT ESI Updater For TwinCAT 2.11 and higher, the System Manager can search for current Beckhoff ESI files automatically, if an online connection is available: Fig. 103: Using the ESI Updater (>= TwinCAT 2.11) The call up takes place under: “Options” → "Update EtherCAT Device Descriptions"... -

Page 113: Offline Configuration Creation

Commissioning • the devices/modules be connected to the power supply and ready for communication • TwinCAT must be in CONFIG mode on the target system. The online scan process consists of: • detecting the EtherCAT device [} 118] (Ethernet port at the IPC) •... - Page 114 Commissioning This query may appear automatically when the EtherCAT device is created, or the assignment can be set/ modified later in the properties dialog; see Fig. “EtherCAT device properties (TwinCAT 2)”. Fig. 108: EtherCAT device properties (TwinCAT 2) TwinCAT 3: the properties of the EtherCAT device can be opened by double click on “Device .. (EtherCAT)” within the Solution Explorer under “I/O”: Selecting the Ethernet port Ethernet ports can only be selected for EtherCAT devices for which the TwinCAT real-time driver is...

- Page 115 (i.e. highest) revision and therefore the latest state of production is displayed in the selection dialog for Beckhoff devices. To show all device revisions available in the system as ESI descriptions tick the “Show Hidden Devices” check box, see Fig. “Display of previous revisions”.

- Page 116 If current ESI descriptions are available in the TwinCAT system, the last revision offered in the selection dialog matches the Beckhoff state of production. It is recommended to use the last device revision when creating a new configuration, if current Beckhoff devices are used in the real application. Older revisions should only be used if older devices from stock are to be used in the application.

- Page 117 Commissioning Fig. 114: EtherCAT terminal in the TwinCAT tree (left: TwinCAT 2; right: TwinCAT 3) EL28xx-xxxx Version: 2.2...

-

Page 118: Online Configuration Creation

Commissioning 5.2.6 ONLINE configuration creation Detecting/scanning of the EtherCAT device The online device search can be used if the TwinCAT system is in CONFIG mode. This can be indicated by a symbol right below in the information bar: • on TwinCAT 2 by a blue display “Config Mode” within the System Manager window: •... - Page 119 [} 123] with the defined initial configuration.Background: since Beckhoff occasionally increases the revision version of the delivered products for product maintenance reasons, a configuration can be created by such a scan which (with an identical machine construction) is identical according to the device list;...

- Page 120 Likewise, A might create spare parts stores worldwide for the coming series-produced machines with EL2521-0025-1018 terminals. After some time Beckhoff extends the EL2521-0025 by a new feature C. Therefore the FW is changed, outwardly recognizable by a higher FW version and a new revision -1019. Nevertheless the new device naturally supports functions and interfaces of the predecessor version(s);...

- Page 121 Commissioning Fig. 123: Manual triggering of a device scan on a specified EtherCAT device (left: TwinCAT 2; right: TwinCAT 3) In the System Manager (TwinCAT 2) or the User Interface (TwinCAT 3) the scan process can be monitored via the progress bar at the bottom in the status bar. Fig. 124: Scan progressexemplary by TwinCAT 2 The configuration is established and can then be switched to online state (OPERATIONAL).

- Page 122 Commissioning Fig. 128: Online display example Please note: • all slaves should be in OP state • the EtherCAT master should be in “Actual State” OP • “frames/sec” should match the cycle time taking into account the sent number of frames •...

- Page 123 A ‘ChangeTo’ or ‘Copy’ should only be carried out with care, taking into consideration the Beckhoff IO compatibility rule (see above). The device configuration is then replaced by the revision found; this can affect the supported process data and functions.

- Page 124 If current ESI descriptions are available in the TwinCAT system, the last revision offered in the selection dialog matches the Beckhoff state of production. It is recommended to use the last device revision when creating a new configuration, if current Beckhoff devices are used in the real application. Older revisions should only be used if older devices from stock are to be used in the application.

- Page 125 Commissioning Fig. 133: Correction dialog with modifications Once all modifications have been saved or accepted, click “OK” to transfer them to the real *.tsm configuration. Change to Compatible Type TwinCAT offers a function “Change to Compatible Type…” for the exchange of a device whilst retaining the links in the task.

-

Page 126: Ethercat Subscriber Configuration

Commissioning If called, the System Manager searches in the procured device ESI (in this example: EL1202-0000) for details of compatible devices contained there. The configuration is changed and the ESI-EEPROM is overwritten at the same time – therefore this process is possible only in the online state (ConfigMode). 5.2.7 EtherCAT subscriber configuration In the left-hand window of the TwinCAT 2 System Manager or the Solution Explorer of the TwinCAT 3... - Page 127 Commissioning „EtherCAT“ tab Fig. 138: „EtherCAT“ tab Type EtherCAT device type Product/Revision Product and revision number of the EtherCAT device Auto Inc Addr. Auto increment address of the EtherCAT device. The auto increment address can be used for addressing each EtherCAT device in the communication ring through its physical position.

- Page 128 For Beckhoff EtherCAT EL, ES, EM, EJ and EP slaves the following applies in general: • The input/output process data supported by the device are defined by the manufacturer in the ESI/XML description.

- Page 129 Commissioning Fig. 140: Configuring the process data Manual modification of the process data According to the ESI description, a PDO can be identified as “fixed” with the flag “F” in the PDO overview (Fig. “Configuring the process data”, J). The configuration of such PDOs cannot be changed, even if TwinCAT offers the associated dialog (“Edit”).

- Page 130 Commissioning Fig. 141: „Startup“ tab Column Description Transition Transition to which the request is sent. This can either be • the transition from pre-operational to safe-operational (PS), or • the transition from safe-operational to operational (SO). If the transition is enclosed in "<>" (e.g. <PS>), the mailbox request is fixed and cannot be modified or deleted by the user.

- Page 131 Commissioning Fig. 142: “CoE – Online” tab Object list display Column Description Index Index and sub-index of the object Name Name of the object Flags The object can be read, and data can be written to the object (read/write) The object can be read, but no data can be written to the object (read only) An additional P identifies the object as a process data object.

- Page 132 Commissioning Fig. 143: Dialog “Advanced settings” Online - via SDO Information If this option button is selected, the list of the objects included in the object list of the slave is uploaded from the slave via SDO information. The list below can be used to specify which object types are to be uploaded. Offline - via EDS File If this option button is selected, the list of the objects included in the object list is read from an EDS file provided by the user.

- Page 133 • DC-Synchron Advanced Settings… Advanced settings for readjustment of the real time determinant TwinCAT- clock Detailed information to Distributed Clocks are specified on http://infosys.beckhoff.com: Fieldbus Components → EtherCAT Terminals → EtherCAT System documentation → EtherCAT basics → Distributed Clocks EL28xx-xxxx...

- Page 134 Commissioning 5.2.7.1 Detailed description of Process Data tab Sync Manager Lists the configuration of the Sync Manager (SM). If the EtherCAT device has a mailbox, SM0 is used for the mailbox output (MbxOut) and SM1 for the mailbox input (MbxIn). SM2 is used for the output process data (outputs) and SM3 (inputs) for the input process data.

-

Page 135: General Notes - Ethercat Slave Application

Commissioning Download If the device is intelligent and has a mailbox, the configuration of the PDO and the PDO assignments can be downloaded to the device. This is an optional feature that is not supported by all EtherCAT slaves. PDO Assignment If this check box is selected, the PDO assignment that is configured in the PDO Assignment list is downloaded to the device on startup. - Page 136 Fig. “Basic EtherCAT Slave Diagnosis in the PLC” shows an example of an implementation of basic EtherCAT Slave Diagnosis. A Beckhoff EL3102 (2-channel analogue input terminal) is used here, as it offers both the communication diagnosis typical of a slave and the functional diagnosis that is specific to a channel.

- Page 137 Commissioning Code Function Implementation Application/evaluation The EtherCAT Master's diagnostic infor- At least the DevState is to be evaluated for mation the most recent cycle in the PLC. updated acyclically (yellow) or provided The EtherCAT Master's diagnostic informa- acyclically (green). tion offers many more possibilities than are treated in the EtherCAT System Documenta- tion.

- Page 138 Commissioning Fig. 148: EL3102, CoE directory EtherCAT System Documentation The comprehensive description in the EtherCAT System Documentation (EtherCAT Basics --> CoE Interface) must be observed! A few brief extracts: • Whether changes in the online directory are saved locally in the slave depends on the device. EL terminals (except the EL66xx) are able to save in this way.

- Page 139 Commissioning Fig. 149: Example of commissioning aid for a EL3204 This commissioning process simultaneously manages • CoE Parameter Directory • DC/FreeRun mode • the available process data records (PDO) Although the "Process Data", "DC", "Startup" and "CoE-Online" that used to be necessary for this are still displayed, it is recommended that, if the commissioning aid is used, the automatically generated settings are not changed by it.

- Page 140 Commissioning Standard setting The advanced settings of the EtherCAT Master are set as standard: • EtherCAT Master: OP • Slaves: OP This setting applies equally to all Slaves. Fig. 150: Default behaviour of the System Manager In addition, the target state of any particular Slave can be set in the "Advanced Settings" dialogue; the standard setting is again OP.

- Page 141 Commissioning Manual Control There are particular reasons why it may be appropriate to control the states from the application/task/PLC. For instance: • for diagnostic reasons • to induce a controlled restart of axes • because a change in the times involved in starting is desirable In that case it is appropriate in the PLC application to use the PLC function blocks from the TcEtherCAT.lib, which is available as standard, and to work through the states in a controlled manner using, for instance, FB_EcSetMasterState.

- Page 142 Commissioning Fig. 153: Illegally exceeding the E-Bus current From TwinCAT 2.11 and above, a warning message "E-Bus Power of Terminal..." is output in the logger window when such a configuration is activated: Fig. 154: Warning message for exceeding E-Bus current NOTE Caution! Malfunction possible! The same ground potential must be used for the E-Bus supply of all EtherCAT terminals in a terminal block! Version: 2.2 EL28xx-xxxx...

-

Page 143: Appendix

Check on the Beckhoff web page whether more up-to-date documentation is available. Firmware Update EL/ES/EM/EPxxxx This section describes the device update for Beckhoff EtherCAT slaves from the EL/ES, EM, EK and EP series. A firmware update should only be carried out after consultation with Beckhoff support. -

Page 144: Device Description Esi File/Xml

Appendix Customers can access the data via the EtherCAT fieldbus and its communication mechanisms. Acyclic mailbox communication or register access to the ESC is used for updating or reading of these data. The TwinCAT System Manager offers mechanisms for programming all 3 parts with new data, if the slave is set up for this purpose. - Page 145 The device revision is closely linked to the firmware and hardware used. Incompatible combinations lead to malfunctions or even final shutdown of the device. Corresponding updates should only be carried out in consultation with Beckhoff support. Display of ESI slave identifier...

- Page 146 Appendix Fig. 157: Configuration is identical otherwise a change dialog appears for entering the actual data in the configuration. Fig. 158: Change dialog In this example in Fig. Change dialog, an EL3201-0000-0017 was found, while an EL3201-0000-0016 was configured. In this case the configuration can be adapted with the Copy Before button. The Extended Information checkbox must be set in order to display the revision.

-

Page 147: Firmware Explanation

Firmware explanation Determining the firmware version Determining the version on laser inscription Beckhoff EtherCAT slaves feature serial numbers applied by laser. The serial number has the following structure: KK YY FF HH KK - week of production (CW, calendar week) -

Page 148: Updating Controller Firmware *.Efw

• offline: The EtherCAT Slave Information ESI/XML may contain the default content of the CoE. This CoE directory can only be displayed if it is included in the ESI (e.g. "Beckhoff EL5xxx.xml"). The Advanced button must be used for switching between the two views. - Page 149 Appendix Fig. 162: Firmware Update Proceed as follows, unless instructed otherwise by Beckhoff support. Valid for TwinCAT 2 and 3 as EtherCAT master. • Switch TwinCAT system to ConfigMode/FreeRun with cycle time >= 1 ms (default in ConfigMode is 4 ms). A FW-Update during real time operation is not recommended.

-

Page 150: Fpga Firmware *.Rbf

Appendix • Check the current status (B, C) • Download the new *efw file (wait until it ends). A pass word will not be neccessary usually. • After the download switch to INIT, then PreOP • Switch off the slave briefly (don't pull under voltage!) •... - Page 151 Appendix Fig. 163: FPGA firmware version definition If the column Reg:0002 is not displayed, right-click the table header and select Properties in the context menu. Fig. 164: Context menu Properties The Advanced Settings dialog appears where the columns to be displayed can be selected. Under Diagnosis/Online View select the '0002 ETxxxx Build' check box in order to activate the FPGA firmware version display.

- Page 152 Older firmware versions can only be updated by the manufacturer! Updating an EtherCAT device The following sequence order have to be met if no other specifications are given (e.g. by the Beckhoff support): • Switch TwinCAT system to ConfigMode/FreeRun with cycle time >= 1 ms (default in ConfigMode is 4 ms).

- Page 153 Appendix • In the TwinCAT System Manager select the terminal for which the FPGA firmware is to be updated (in the example: Terminal 5: EL5001) and click the Advanced Settings button in the EtherCAT tab: • The Advanced Settings dialog appears. Under ESC Access/E²PROM/FPGA click on Write FPGA button: EL28xx-xxxx Version: 2.2...

-

Page 154: Simultaneous Updating Of Several Ethercat Devices

Appendix • Select the file (*.rbf) with the new FPGA firmware, and transfer it to the EtherCAT device: • Wait until download ends • Switch slave current less for a short time (don't pull under voltage!). In order to activate the new FPGA firmware a restart (switching the power supply off and on again) of the EtherCAT device is required. -

Page 155: Firmware Compatibility - Passive Terminals

Appendix Firmware compatibility - passive terminals The passive terminals [} 73] ELxxxx terminal series have no firmware to update. Restoring the delivery state To restore the delivery state for backup objects in ELxxxx terminals, the CoE object Restore default parameters, SubIndex 001 can be selected in the TwinCAT System Manager (Config mode) (see Fig. Selecting the Restore default parameters PDO) Fig. 167: Selecting the "Restore default parameters"... -

Page 156: Support And Service

Beckhoff's branch offices and representatives Please contact your Beckhoff branch office or representative for local support and service on Beckhoff products! The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet pages: http://www.beckhoff.com You will also find further documentation for Beckhoff components there. - Page 157 "CoE Online " tab ........................Fig. 36 Startup list in the TwinCAT System Manager ................Fig. 37 Offline list ............................. Fig. 38 Online list ............................ Fig. 39 Spring contacts of the Beckhoff I/O components................. Fig. 40 Attaching on mounting rail ......................EL28xx-xxxx Version: 2.2...

- Page 158 List of Illustrations Fig. 41 Disassembling of terminal......................Fig. 42 Power contact on left side......................Fig. 43 Standard wiring..........................Fig. 44 Pluggable wiring .......................... Fig. 45 High Density Terminals........................ Fig. 46 Connecting a cable on a terminal point ..................Fig. 47 Recommended distances for standard installation position ............

- Page 159 List of Illustrations Fig. 87 Application of a "Goto Link" variable, using "MAIN.bEL1004_Ch4" as a sample ......100 Fig. 88 TwinCAT development environment (VS shell): logged-in, after program startup....... 101 Fig. 89 System Manager “Options” (TwinCAT 2)..................103 Fig. 90 Call up under VS Shell (TwinCAT 3) ................... 103 Fig.

- Page 160 List of Illustrations Fig. 131 Correction dialog ......................... 123 Fig. 132 Name/revision of the terminal ...................... 124 Fig. 133 Correction dialog with modifications ................... 125 Fig. 134 Dialog “Change to Compatible Type…” (left: TwinCAT 2; right: TwinCAT 3) ......125 Fig. 135 TwinCAT 2 Dialog Change to Alternative Type ................125 Fig.

Need help?

Do you have a question about the EL28 Series and is the answer not in the manual?

Questions and answers